Hello dear readers of the blog RtiIvaz.ru. Today's article will be devoted to replacing the front, side and gearbox engine mounts of a VAZ 2109 car. Factory engine mounts for the VAZ 2109 are quite reliable and last for quite a long time. This is due to the fact that high-quality materials were used in their production, and the technology of the production structure of rubber technical rubber products was also followed.

However, everything has its own lifespan during the operation of the car; the material of the rubber supports ages due to natural wear and tear and then the car requires maintenance, for example, replacing the engine mounts of a VAZ 2109. In addition to the natural “age-related” wear of the part, there is also an emergency failure of the rubber engine mounts. This may be a consequence of an accident, hitting an obstacle, falling into an open sewer manhole, etc.

Replacing rubber cushions is necessary in cases of: vibration, knocking when starting the car and braking, as well as sudden acceleration, poor gear shifting. In addition, when the engine mounts sag, the operation of replacing the timing belt becomes difficult, since the sagging engine “fits” almost closely to the right mudguard, which makes it difficult to remove the timing belt cover and service the car engine.

When the engine sag significantly, the CV joints, the so-called axle shaft grenades, are loaded, as the geometry of their operation changes, which leads to a noticeable reduction in their service life. On many cars, a barely perceptible knock appears in the area of the rocker, which is associated with sagging of the engine and the gearbox slide hitting the body of the anti-roll bar.

As you can see, worn-out rubber mounts can bring a lot of trouble to car owners, and therefore replacing the VAZ 2109 engine mounts should be done as soon as possible. If faulty engine mounts are not replaced in time, parts of much greater value may fail.

To complete the work you will need an inspection hole or overpass. As a matter of principle, we do not consider a lift, since, as a rule, it is not available in the garages of our car enthusiasts. To complete the work you will also need: a new support/cushions, a hoist or jack, a set of socket heads and wrenches, spanners, a ratchet, and rust preventative (if necessary).

It’s worth mentioning right away that if only the front engine mount (boom) needs to be replaced, then this work can be done without a hole on any flat area.

Work diagram for replacing engine mounts of a VAZ 2109 car:

- The car is “driven” into the pit and secured with reliable stops.

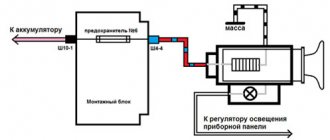

- The terminal is removed from the battery for safe operation.

- A hoist cable is placed on the engine or a jack is placed under the pallet through a wooden support. If the cable starts, the hood is torn off to the maximum possible height and a homemade stop is placed using any available means.

- The engine protection is removed.

VAZ 2109 front engine mount

Before starting work, you need to treat all support fasteners with an anti-rust solution, which will facilitate the replacement process itself. When lifting the engine, you must be careful not to damage wiring or piping elements, and do this work slowly. The socket head “undermines” all the mounting bolts of the cushion and the engine is raised, then it is most convenient to carry out the work with a ratchet wrench.

It is best to start replacing with a long bolt connecting the bracket on the body cross member to the support. Having given away the nut, you need to try to pull out the bolt, “playing” back and forth to do this with a hoist or a jack. As soon as the common center is “caught”, the bolt will come out with a light hand force. Having found this position, leave the bolt in the connection and remove the bolts securing the pillow to the engine block, after which, having removed all the bolts, remove the old support.

Don’t forget to mark the old cushion (its top) with any mark so that when installing a new rubber support you don’t have to “guess” how to install it correctly.

Then install a new rubber support, first just tightening the bolts so that everything matches everywhere, and then tighten them, but not completely. After preliminary tightening, release the hoist cable tension or lower the jack and perform final tightening of the bolts. Before assembly, clean the bolts (if there are traces of rust, then with a metal brush) and lightly lubricate the threads with any grease, for example Litol-24 or graphite lubricant.

Side engine support for VAZ 2109

At the beginning of the checkpoint, the box is hooked with a hoist cable or jacked up for insurance.

Features of engine mounts for a VAZ 2109 car

When developing cushion designs to reduce vibrations of the power unit, manufacturers are guided by the magnitude of the loads that the supports perceive. These devices constantly perceive loads that change periodically. One operates when the car is stationary - the weight of the unit; at start - the other. When the car moves backwards, the airbags absorb negative forces.

Sudden acceleration, unexpected braking, encountering an obstacle or hitting a pothole cause negative forces to occur. They must be extinguished by the installed rear, front and side supports. To manufacture the elements, natural rubber, high-grade rubber of the SKI-3 brand, high-quality steel and special glue are used. Engine mounts can withstand from (-45) to (+70) degrees Celsius.

This indicates that for the VAZ 2109, the side left and right, front and rear engine mounts should be used only those manufactured by the manufacturer. In this case, they will meet all the requirements of manufacturing technology and are supplied to specialized stores. Car owners must purchase products from reliable suppliers who have proven themselves and have good reviews from customers.

Factors influencing the replacement of pillows for a VAZ 2109 engine

All manufactured products have a warranty period, after which they may fail. This also applies to the supports for the power unit of the VAZ 2109 car. Natural aging of rubber occurs, it can crack from long-term use. In addition, there are also mechanical breakdowns associated with the consequences of an accident, an unexpected collision with an obstacle, an encounter with a sewer hatch along the way, and many other reasons.

Replacing engine and gearbox mounts

There are three supports in total:

- Lateral.

- Rear.

- Front.

In fact, only the front one is the engine support. The other two are attached to the box. The replacement procedure is slightly different. Rear replacement process:

- Place the car on a pit, overpass, or lift. Depends on what “amenities” you have. If you are of a thin build, you can mount the car on a jack and stands. It is advisable to place a support under the engine so that it does not fall when removing the cushion.

- Disconnect the negative power cable.

- Using a key set to “17”, unscrew the nuts securing the airbag to the body.

- Using the same wrench, unscrew the nuts from the bolts that secure the cushion to the gearbox housing.

- Install the new VAZ 2109 cushion in the reverse order.

On a VAZ 2109 car, the engine mount (side) can be easily removed. The execution process is as follows:

- Disconnect the battery, secure the car and, if necessary, remove the mudguard.

- Using a key set to “17”, unscrew the nut securing it to the body.

- Unscrew the three nuts from the bracket. Remove the support from the box body.

- Reinstall the element in reverse order.

When installing and removing, you can rock the box from side to side so that the centers of the holes coincide. The front one is replaced according to the same principle:

- Place a jack under the engine. Place a wooden block between it and the pallet.

- Unscrew the nut from the bolt securing it to the body using a “17” wrench.

- Using the same wrench, unscrew the four bolts from the engine block. Don't lose the engraving washers.

- Install a new element and perform assembly. This completes the replacement of the VAZ 2109 engine mount.

The procedure is simple and does not require special skills. But when carrying out repairs, be sure to treat the threads with a lubricant like WD-40. Thoroughly clean all seats before installing a new support. To completely replace all three elements it will take no more than 1-1.5 hours. Repairs are carried out similarly on Samara and Samara-2 cars. The price of the complete set will be 1,400 rubles (front 600 rubles, rear 350 rubles, side 450 rubles). Prices are current as of April 2020.

Video about replacing pillows using the example of Samara-2 VAZ 2114:

Before replacing the engine mount, which is also the front engine mount on a VAZ 2109, I recommend reading about what engine mounts are, what they are needed for, and also about the signs of mount malfunction.

To replace the front engine mount of a VAZ 2109 you need to have:

- Remove the engine protection, if you have one, as well as the left edge of the additional plastic protection.

- We put a jack on and jack up the engine a little.

- Next, we treat the bolts with WD-40 penetrating liquid, then unscrew them one by one.

- We remove the old engine mount, and in its place we install a new one and fasten it in the same way. Before tightening the bolts, I recommend treating them with graphite lubricant, this will make unscrewing it easier in the future.

- Tighten the bolts, after which you can remove the jack.

Photo sources: 1, 2.

Sources

- https://vazpro.ru/zamena-podushek-dvigatelya-vaz-2109.html

- https://vaz-remont.ru/zamena-perednej-opory-dvigatelya-vaz-2109-v-domashnix-usloviyax-poshagovaya-instrukciya/

When do you need to change engine mounts on a VAZ 2109?

— Body vibrations. — Knocking that occurs when the car starts or brakes, difficult gear shifting or unexpected acceleration. — Replacing the timing belt is accompanied by great difficulties. This is due to the fact that a sagging engine “approaches” the right mudguard almost closely, and it may interfere with removing the timing belt cover, and servicing the engine will be difficult. - Strong sagging of the unit increases the load on the CV joints. The geometry of the work may change on them, which will reduce the service life of the structures. - The appearance of a barely perceptible knock in the backstage area. This occurs due to engine sagging. - In this case, the gearbox slider may begin to touch the outer surface of the anti-roll bar. - In the case when the replacement of the engine mount on a VAZ 2109 is not carried out in a timely manner, the cost of further repairs will increase significantly.

Replacing engine mounts

- The engine is hung using a special bracket. It is installed at the bolted joints of the front fenders.

- Each of the pillows is changed one by one. It is advisable to first replace the rear airbag and only then the front airbag. If it is not possible to use a bracket, then you can resort to using a conventional jack. It is installed under the engine sump.

- Unscrew the engine mount fasteners. And we replace the worn part with a new one.

If the new part is not installed properly, then when the engine starts there will be noise associated with increased engine vibration. Therefore, it will be necessary to adjust the supplied cushions in height and, if necessary, longitudinally. This adjustment is necessary to ensure that engine parts do not touch body elements.

Thus, replacing engine mounts is not difficult. It is worth noting that replacement must be made immediately as soon as a characteristic hum and noise appears in the vehicle. The cost of these parts has a wide price range, since the price depends, first of all, on the country of origin. For obvious reasons, Russian-made parts are much cheaper than their foreign prototypes. This does not mean that domestic manufacturers produce low-quality parts, not at all. Do not forget that the price of the same German or Japanese spare part is often higher only because of expensive transportation. Russian engine mounts can be called quite wear-resistant, because they are made with some consideration for local roads, which means they are more durable.

Rules for replacing VAZ 2109 engine mounts

In a VAZ 2109 car, the engine is mounted on three supports: the right one, which is mounted on the engine bracket, the left and rear ones, which are fixed on the gearbox housing brackets. The instructions call for replacing the side airbag with the mudguard removed.

To work you will need:

- New side cushion. - Set of socket heads. - Hoist or jack. - Spanners. - Wrench. - Ratchet. - Rust remover, if necessary.

Work order:

Tip: Disassembling the unit should begin by removing rust from all fastening units, which will help disassemble these units. You need to remove the mudguard. Use a 17 mm spanner to unscrew the nut that secures the support to the body. Tip: When unscrewing the bolt, it must be kept from turning in the same way with a wrench. The bolt is pulled out. The three nuts securing the support bracket on the gearbox are unscrewed with a “17” head, as shown in the photo. The support is removed. After replacing the cushion on a VAZ 2109, the assembly must be performed in the reverse order. How to correctly replace the engine mounting VAZ 2109 can be seen on video.

Description of engine mounts

In the VAZ 2109, in fact, like in others, there are two engine mounts. They are two rubber salen blocks. These elements reduce vibration and engine noise on the vehicle body. In addition, with their help, the engine is held in the engine compartment. As for the cost of these parts, there is a wide price range on this issue. For domestically produced cars, you can purchase these parts from 300 to 1500 rubles per piece

The manufacturer is of no small importance. It is best to purchase products that are produced by the manufacturer of a particular car.

It is generally accepted that they are a guarantor of excellent quality and enormous wear resistance of parts for their line of engines. Of course, the cost of original spare parts is much higher. Let's take a closer look at the malfunctions in engine mounts that every car enthusiast can encounter.

Ways to increase the rigidity of engine fixation on the body of a VAZ 2109

To prevent the VAZ 2109 cushion from being replaced frequently, and to increase the rigidity of the power unit, instead of the standard support, a more advanced part is installed, which has a rigid body and a rubber part inside.

Minimize the movement of the motor when braking, hitting bumps on the roads, or abruptly starting the car. With its help, you can avoid self-switching off the transmission. Increase the resource in the exhaust system and drive the drive wheels. Improve the design of the engine compartment. You can increase the rigidity of the motor by installing an additional fourth support . Its purpose is to connect the clutch housing to the cross member of the front suspension of the VAZ 2109. When installing the device, it is necessary to install a new bracket and find a place for the ignition module. The work procedure includes: Dismantling the VP for spark plugs. Disconnecting the wire connectors from the ignition module of the car. Disconnecting the clutch housing of this module from the cylinder block. The remaining three nuts securing the module are unscrewed, which is then removed. The ignition module takes a different place and new fasteners are installed. A bracket for mounting the fourth support is attached to the cross member of the front suspension. A bolt is installed in the hole on the terminal clamp, the nut is placed and screwed initially by two turns. The lower head of the rod is inserted into the support fixing eye. The bolt is installed in the eye and support, the nut is tightened. The size of the rod is adjusted until the holes in the clutch housing and on the upper head coincide. Another bolt is installed.

For a car to move, it needs an engine. This unit is installed in the front part of the body (in most cases). It is mounted on a subframe or on side members. However, the vibrations that the engine gives off during operation are strongly reflected on the body. To smooth them out, it is installed using rubber pads. They are a kind of buffer. Over time, all rubber products become unusable. Engine supports are no exception. What are engine mounts, signs of malfunction and methods of elimination are further in our article.

Characteristic

What is this item? An engine mount is a gasket between body elements and the power unit. This is installed on all cars without exception. On Soviet Zhiguli cars, the cushion was a durable piece of rubber with fasteners on both sides. On more modern “nines” and “eights” (and subsequently all VAZs with a front-wheel drive layout) full-fledged rubber-metal supports were installed.

So, the power unit was mounted on four pillows. Two of them are on the gearbox, and the rest are on the engine. To avoid unnecessary loads, the box and motor are rigidly fixed. Any distortion leads to a change in the geometry of the input shaft. As a result, all the vibration is strongly transmitted to the gearbox lever and the transmission itself.

Where are the pillows? This element is installed on the engine from several sides:

- Front cushion. Attached to the front beam of the power unit.

- Back cushion. Installed to the front subframe. Located in the bottom area.

- Right support. It is located on top, near the front side member of the body.

What is this?

If we talk about the VAZ 2114 model, then there are three supports, two of which are intended directly for the gearbox, and another one for the engine itself.

The main purpose of pillows is to reduce vibrations.

When the car drives, serious vibrations occur, which are transmitted to the body from the power unit. To ensure the necessary level of comfort while driving and not to be distracted by extraneous noise or shaking, special supports are mounted on the car. If you remove them, driving a VAZ 2114 can be compared to riding an old wooden cart.

Causes of malfunctions

The most important problem that pillows face is the loss of elasticity of the material. This is due to the fact that the supports are made of rubber. Over time and with use, these elements lose their original characteristics. Various factors accelerate the wear process of bearings:

- Regular exercise;

- Long service life;

- Cold;

- Heat;

- Temperature changes, etc.

If elasticity decreases, this entails the formation of cracks and delamination of the material.

Replacement is purely a matter of time. But the procedure for changing the front and all other pillows should be carried out on time. If you drive for a long time with worn out bearings, this will result in a negative impact on engine performance. Then the repair will cost much more than the cost of new supports.

The main advice is to periodically check the condition of the supports for wear. If you detect a fault in a timely manner, you can replace it yourself and significantly save on car repairs.

Price issue

If you do everything correctly and in a timely manner, then your costs will be insignificant. You will have to purchase new supports and contact a car service. Of course, it is quite possible to do it on your own. This is a matter of desire and availability of appropriate skills.

Article on the topic: Self-repair of struts on a VAZ 2109 (Video)

How much will it cost to replace engine mounts? We suggest that you familiarize yourself with the current prices for the VAZ 2114.

| Detail | Minimum cost | average price |

| Front airbag | 600 rubles | 1200 rubles |

| Rear cushion | 500 rubles | 900 rubles |

| Left pillow | 500 rubles | 900 rubles |

| Set of three supports | 3500 rubles | 5000 rubles |

| Car service | 1500 rubles | 2500-3000 rubles |

There is no need to pay someone, since the replacement can be done by yourself.

Why does it wear out?

Many motorists ask this question. Signs of faulty engine mounts can vary. This is primarily due to natural wear and tear that occurs due to vibrations. The resource of these elements is about 150 thousand kilometers. The stronger the vibration, the greater the load on the support (especially if one of the engine cylinders is not working).

If you think that the resource directly depends on the mileage, you are mistaken. The cushion wears out even when the car is parked in the garage. Over time, the rubber dries out. Microcracks appear. Another negative factor is oil. It is necessary to change the seals in time to prevent leaks.

Oil negatively affects the life of the engine mount. Signs of a VAZ 2110 malfunction may also be in the driving style. So, with a sharp start with slipping, a colossal load is placed on the support.

How to quickly determine whether an engine mount is faulty?

You can determine the serviceability of the element without opening the hood.

While driving, you will notice characteristic signs of faulty engine mounts:

- Characteristic knocks and clicks appear when starting and braking the car (in the front part).

- When driving on uneven roads, strong impacts are transmitted to the body.

- Excessive vibration appears at idle speed.

- Shocks are given to the gearbox when driving (especially when the car drives through potholes).

- Strong vibration of the steering wheel in all engine operating modes.

We determine the condition of the supports visually

The above signs will not always indicate a malfunction of the engine mounts. So, if impacts are observed in the front part of the body, you need to visually inspect the element. We already know where he is. So, open the hood and look at the condition of the rubber buffer.

There should be no breaks or cracks on it. For better convenience, it is recommended to use an inspection hole (especially if it is a front and rear support). Move it from side to side. There should be no play between the cylinder and the silent block. If so, signs of engine mount failure have been confirmed. The part must be replaced.

How to change it yourself?

To do this, you will need a set of tools (sockets and open-end wrenches), a jack and repair stands (since the engine will be suspended). So, jack up the car on the right side. We hang the motor on a chain. We unscrew the bolts (there are 3 in total) that secure the support to the engine and body. Next, remove the brackets and take the element out. We install the new part in place.

To replace the rear support, jack up the body on the left side. However, unlike the previous case, we will also have to suspend the gearbox. We use a wooden backing to avoid damaging the pallet. We unscrew the bolts securing the pillow and take it out. We install a new one in place of the old one and perform the assembly in the reverse order.

What influences the replacement

There are two main factors that force motorists to replace airbags.

- Natural wear and tear. Each pillow has its own service life, exceeding which is very rare. Often they don’t work it out for the second reason.

- Mechanical impacts leading to breakdowns. These are our roads, potholes, accidents, collisions with manholes, etc.

When replacement is required

There are several factors you should know about replacing engine components.

Situation

Peculiarities

If you feel vibration in the body, you should definitely check the condition of the supports. This effect can be caused by various reasons, but pillows are one of the main

Replacing the timing belt

When replacing a belt, removing its cover can be very difficult, since the engine is almost tightly pressed to the right mudguard of the front wheel. You have to remove the pillow in order to fully carry out repairs.

The engine sags, loads the CV joints

Due to the impact of the engine weight on CV joints, their geometry changes, which leads to a significant reduction in the service life of the elements. The resource is reduced, it is necessary to carry out replacements ahead of schedule

There is a knocking noise in the backstage area

It may be barely noticeable. But its presence indicates that the engine has sagged. Consequently, the supports do not work properly and need to be replaced

If you do not replace the supports in a timely manner, this will lead to more serious consequences and expensive repair of the breakdown. Therefore, it is better to replace the pillows when primary signs of wear are detected. To do this, we additionally recommend periodic inspection of the unit.

Now we move on to replacing elements. Doing it yourself or contacting a car service is purely your personal decision.

For the VAZ 2109, the use of three supports is provided:

- Front;

- Rear;

- Left side.

The replacement of each of them should be discussed separately, since the processes differ from each other.

Replacing the rear cushion

- Find a suitable place to carry out repairs. You will need a pit or overpass.

- Place the car there, secure it with stops, and put the car on the handbrake.

- Disconnect the negative terminal from the car battery.

- Using a 17mm spanner, unscrew the nut that holds the cushion to the body.

- Using a 17 socket, remove the mounting nuts of the support bracket to the gearbox. There are 3 of them in total.

- Remove all the bolts and remove the old engine mount.

- Install a new motor element and reassemble the unit.

Dismantling works

Side left pillow

Left element

- Provide yourself with free access to the bottom of your VAZ 2109.

- Secure the vehicle with jack stands and the handbrake.

- Disconnect the minus from the battery.

- Remove the left engine splash guard.

- Using a 17mm spanner, remove the nut that holds the cushion to the body.

- Using a 17 socket, unscrew the 3 mounting nuts of the support bracket, removing them from the gearbox.

- After removing the mounting bolts, replace the worn engine mount with a new one.

- Carry out the reassembly procedure. Stick to strict consistency.

Replacing the front airbag

Here, follow all the same conditions that were relevant for previous works. That is, drive the car into a pit, place supports and turn off the power to the car by removing the negative terminal from the battery.

- Using a 17mm spanner, remove the nut holding the cushion to the body.

- Using a 17mm wrench, remove the 4 fastening nuts securing the airbag to the engine.

- Remove the rubber element from the eyelet.

- Place a new support in place of the old unit.

- Reassemble the unit.

When replacing engine mounts, be sure to make sure that the new mounts meet the quality and size requirements. It is also recommended to thoroughly clean the seats before installing a new element, which will extend the service life of the new motor mounts.

Replacement does not require special skills, special tools or special conditions. Therefore, VAZ 2109 owners often change the pillows with their own hands. But if you are not confident in your abilities, contact a trusted car service center.

Useful tips

Motorists recommend replacing the support in warm weather. In winter, the pillow becomes very dull, and can only be removed after preheating (using a hairdryer or blowtorch). If the support does not come out, it is recommended to use VD-40 type lubricant or its equivalent from. Regular lubricant will not work for this.

Often dust and moisture enter the cavity of the old cushion, resulting in corrosion processes occurring on the cylinder. It is not possible to remove the pillow. If you are replacing the rear support, pay attention to the direction indicated by the arrow on the part. It must be installed in the direction of travel of the vehicle. Otherwise, there is a risk that the element will not withstand the load and will break.