Oil pressure sensor VAZ 2106

The operating principle of the oil pressure sensor is based on the property of deformation of an elastic membrane under the influence of liquid (oil) or gas pressure. Almost all pressure sensors are based on this property of materials. The amount of membrane shift is mechanically transmitted to a variable resistor (rheostat), the change in its resistance is recorded by the vehicle’s equipment and displayed on the pressure gauge.

Connection

1. Connect the “orange wire” to the positive of the ignition switch.

2. “White wire”, to the dimensions wire,

3. We throw the “white and black” wire to ground.

4. Gray wire to the emergency oil pressure sensor (which we had, standard)

5. We connect the “dark gray and black” wire to the oil pressure sensor (indicator) we installed.

Replacement

To replace the oil sensor, no special knowledge of plumbing is required, and this work is a simple technological process. We stock up on a standard set of plumbing tools and begin repair work. The sequence of technological operations is as follows:

Disconnect the oil pressure sensor and the wiring that goes with it.

Using a wrench, unscrew the device.

We dismantle the product and install the updated device.

How to check

As a rule, anything related to pressure is usually checked using a pressure gauge. Screw in the pressure gauge instead of the sensor and start the engine. At idle speed, the pressure gauge should show a pressure of 0.65 kgf/cm2 or more, we can conclude that the pressure is OK, but the pressure sensor is not, so an immediate replacement of the oil pressure sensor is necessary.

If you don’t have a pressure gauge on hand and somewhere in the middle of the highway your oil pressure light comes on, you can check the pressure sensor in another way. To do this, you need to unscrew the sensor and turn the starter without starting the engine. If, during rotation by the starter, oil splashes or pours from the socket where the sensor was installed, we also conclude that the sensor is faulty and requires replacement.

Does not work

If the emergency oil pressure sensor works (the light on the panel goes out after the engine starts), measure the voltage on the device. Its absence will indicate a malfunction of the oil pressure sensor; its presence will indicate a malfunction of the device. First, look at the contact on the sensor.

When the oil pressure suddenly drops to zero and the light comes on, you should not panic. It’s possible that the engine is running normally, but there are some problems with the oil sensor. In any case, it is best to stop the car and turn off the engine.

First of all, after a forced stop, you need to open the hood and inspect the engine compartment. If oil leaks are not visible, you should check the level of lubricating fluid in the engine. A lack of engine oil can cause low pressure. If the garage or service station is close, you can slowly get there at your own pace.

When the inspection did not answer the question of why the light came on, it is better to get home by tugboat.

In a quiet environment at home or in the garage, it is necessary to diagnose the oil pressure sensor. To do this, you will have to find a pressure gauge with a suitable measurement range. Please note that the connecting thread of the BAZ-2106 sensor is designated M14x1.5. Accordingly, the testing device must have the same parameters or it will require an additional adapter.

To remove the oil sensor you will need an open-end wrench. The work is performed with the engine not running. Now a pressure gauge is mounted in its place. All that remains is to start the engine and see the real pressure parameters in the oil line. To increase engine speed and look at the upper pressure limits, you will have to ask for help from neighbors or relatives. If all measurements are normal, it is necessary to replace the oil sensor.

Oil pressure indicator VAZ 2103-2106, VAZ 2121 UK194

Dear customers, in order to avoid errors when sending the UK194-3810010M oil level indicator to the instrument cluster of VAZ 2101-03, VAZ 2106, VAZ 2121, indicate your car model and year of manufacture in the “Comment” line.

Before shipping, we check all electromechanical devices for functionality, eliminating the possibility of defects.

All control devices of VAZ 2101-03, VAZ 2106, VAZ 2121 cars are combined into an instrument cluster.

The electro-mechanical instrument cluster of VAZ 2101-03, VAZ 2106, VAZ 2121 performs the function of displaying all the vehicle parameters necessary for the driver.

One of the important parameters that must be monitored during engine operation is oil pressure. Excessive reduction or excess of this indicator can lead to expensive damage to the power unit. The oil pressure indicator UK194-3810010M (VAZ 2101-03, VAZ 2106, VAZ 2121) was made quite successfully. It is equipped with a dial indicator, as well as a signal lamp.

The oil level indicator (type UK194) shows the driver the oil level in the engine of VAZ 2101-03, VAZ 2106, VAZ 2121 cars, located on the dashboard. Works in conjunction with the MM393A-3829010 M oil pressure sensor installed on the engine.

The oil pressure sensor in a VAZ 2101-03, VAZ 2106, VAZ 2121 car is simple and reliable. The operation of this device is based on reading the deformation from the elasticity of the membrane, which, under the influence of oil, deviates from its original position. The magnitude of the shift is fixed by a variable oscillator (resistor). Any change in resistance is transmitted to the dial pressure gauge.

To transmit a signal from the engine to the instrument panel, several main parts and assemblies are used:

— resistors (variable and thermal compensation);

— a magnet that sets the pointer to the zero mark;

The entire chain is powered by the rechargeable battery after turning the key in the ignition switch.

If the oil pressure sensor MM393A-3829010 fails, the easiest way is to replace it with a new device. Experts do not recommend disassembling this inexpensive device, because after assembly it may not work correctly.

Pressure sensor 2103-3810010 is configured to operate the oil system in the range of 0.2 kgf/sq. cm. up to 0.6 kgf/sq. cm. In MPa this interval looks like this: 0.02-0.06. If pressure is created in the engine oil line in a given range, then the contacts at the sensor are in an open state. As soon as the allotted limits are exceeded, the contacts will close and the signal light will light up.

When the oil pressure suddenly drops to zero and the light comes on, you should not panic. It’s possible that the engine is running normally, but there are some problems with the oil sensor. In any case, it is best to stop the car and turn off the engine.

First of all, after a forced stop, you need to open the hood and inspect the engine compartment. If oil leaks are not visible, you should check the level of lubricating fluid in the engine. A lack of engine oil can cause low pressure. If the garage or service station is close, you can slowly get there at your own pace.

When the inspection did not answer the question of why the light came on, it is better to get home by tugboat.

It is necessary to diagnose the oil pressure sensor. To do this, you will have to find a pressure gauge with a suitable measurement range. Please note that the connecting thread of the MM393A sensor is designated M14x1.5. Accordingly, the testing device must have the same parameters or it will require an additional adapter.

Technical characteristics of oil level indicator UK194-3810:

— measurement limit – (0. kgf/cm2;

kgf/cm2;

— body, landing diameter of the casing – 52 mm;

- voltage - 12 V.

Installation of the oil pressure indicator 2103-3810010 can be done independently, without contacting specialized maintenance services.

Other article numbers of the product and its analogues in the catalogues: 21030381001000, UK194-3810010M.

VAZ 2101, VAZ 2102, VAZ 2103, VAZ 2106, VAZ 2121.

Any breakdown is not the end of the world, but a completely solvable problem!

How to independently replace the oil pressure gauge in the instrument cluster of VAZ 2101, VAZ 2102, VAZ 2103, VAZ 2106, VAZ 2121.

AvtoAzbuka online store, repair costs will be minimal.

Just COMPARE and BE SURE.

Don't forget to share the information you find with your friends and acquaintances, because they may also need it - just click one of the social networking buttons located above.

Purpose of the oil pressure control sensor

All moving and rubbing parts of the power unit are constantly washed with liquid lubricant supplied by a gear pump from the engine sump. If, for various reasons, the supply of lubricant stops or its level drops to critical, the motor will face a serious breakdown, or even more than one. The result is a major overhaul with replacement of the crankshaft bearings, cylinder-piston group, and so on.

To protect the car owner from these consequences, classic Zhiguli models provide two-level control over the engine lubrication system, operating according to the following algorithm:

- After turning the key in the lock and turning on the ignition, the red warning lamp lights up, indicating a lack of oil pressure. The pointer needle is at zero.

- In the first 1-2 seconds after starting the engine, the indicator continues to light. If the oil supply is normal, the lamp goes out. The real pressure created by the pump is immediately shown by the arrow.

- When the engine turns off, a large amount of lubricant is lost, or a problem occurs, the red indicator lights up immediately.

- If the lubricant pressure in the motor channels decreases to a critical level, the light begins to flash periodically.

Malfunctions leading to a drop in pressure - breakdown or wear of the oil pump, complete wear of the crankshaft liners or breakdown of the crankcase.

The main role in the operation of the system is played by the sensor - an element that records the oil pressure in one of the main channels of the engine. The indicator and pointer are just a means of displaying the information transmitted by the pressure meter.

Where is it located, checking, replacing pressure sensors

The location of pressure sensors on the engine can be very different, but it crashes into the oil passages of the lubrication system. Some manufacturers install them on the cylinder head, others at the installation location on the cylinder block, near the oil filter. The first option is used for emergency elements, the second - for measuring ones.

It is not difficult to detect the sensors, since they are screwed into the body of the cylinder head or block and one wire goes to it.

Despite the simplicity of the design, the sensors fail. By the way, when problems are detected in the operation of the lubrication system using a warning light, the malfunction is often associated with the sensor, and not with parts of the system itself.

Location and appearance of the device

The sensor installed on classic VAZ 2106 models consists of the following parts:

- an element in the form of a round metal barrel with one terminal for connecting a wire (factory name - MM393A);

- the second part is a membrane switch in the form of a nut with a contact at the end (designation MM120);

- a steel tee into which the above parts are screwed;

- sealing bronze washers.

The large “barrel” MM393A is designed to measure pressure, the “nut” with the MM120 terminal fixes its absence, and the tee is a connecting element that is screwed into the engine. The location of the sensor is on the left wall of the cylinder block (if you look in the direction of movement of the car) under spark plug No. 4. Do not confuse the device with the temperature sensor installed higher in the cylinder head. Wires leading inside the cabin, to the dashboard, are connected to both contacts.

In later models of the “classic” VAZ 2107, the indicator arrow on the dashboard is missing, only a warning lamp is left. Therefore, a stripped-down version of the sensor is used without a tee and a large barrel.

Device and connection diagram

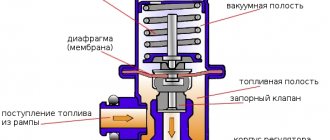

The task of the membrane switch, made in the form of a nut with a terminal, is to promptly close the electrical circuit with the warning lamp when the lubricant pressure drops. The device consists of the following parts:

- metal body in the form of a hexagon;

- contact Group;

- pusher;

- measuring membrane.

The element is connected to the circuit according to the simplest circuit - in series with the indicator. The normal position of the contacts is “closed”, so after turning on the ignition the light comes on. When the engine is running, there is a pressure of oil flowing to the membrane through the tee. Under the pressure of the lubricant, the latter presses the pusher, which opens the contact group, as a result the indicator goes out.

When one of the malfunctions occurs in the engine, causing a decrease in the pressure of the liquid lubricant, the elastic membrane returns to its original position and the electrical circuit is closed. The driver immediately sees the problem by the flashing “control”.

The design of the second element, the “barrel” called MM393A, is somewhat more complicated. The main role here is also played by an elastic membrane connected to an actuator - a rheostat and a slider. The rheostat is a coil of high-resistance chromium-nickel wire, and the slider is a movable contact that moves along the turns.

The electrical circuit for connecting the sensor and pointer is similar to the first one - the rheostat and the device are in series in the circuit. The operating algorithm is as follows:

- When the driver turns on the ignition, on-board voltage is supplied to the circuit. The slider is in its extreme position, and the winding resistance is maximum. The instrument needle remains at zero.

- After starting the engine, oil appears in the channel, flowing through the tee into the “barrel” and pressing on the membrane. It stretches and uses a pusher to move the slider along the winding.

- The total resistance of the rheostat begins to decrease, the current in the circuit increases and causes the indicator arrow to deviate. The higher the lubricant pressure, the more the membrane stretches and the less resistance of the coil, and the device notes the increase in pressure.

The sensor reacts in the reverse order to a decrease in oil pressure. The force on the membrane decreases, it is thrown back and pulls the slider with it. He turns on new turns of the rheostat winding in the circuit, the resistance increases, and the instrument needle drops to zero.

Video: what pressure should a working device show?

How to check and replace an element

During long-term operation, the internal parts of the sensor wear out and periodically fail. The malfunction manifests itself in the form of false readings on the indicator scale or a constantly burning emergency lamp. Before drawing conclusions about power unit failures, it is highly advisable to check the functionality of the sensor.

If the control light comes on while the engine is running and the indicator drops to zero, your first action is to immediately turn off the engine and do not start it until the problem is discovered.

When the light comes on and goes out in a timely manner, and the needle does not deviate, you should check the serviceability of the oil sensor - the MM393A pressure meter. You will need a 19 mm open-end wrench and a pressure gauge with a scale of up to 10 Bar (1 MPa). A flexible pipe with a threaded tip M14 x 1.5 must be screwed to the pressure gauge.

The verification procedure is as follows:

- Turn off the engine and let it cool to 50-60 °C so you don’t have to burn your hands while working.

- Disconnect the wires from the sensors and unscrew them with a 19 mm wrench along with the tee. Please note that during disassembly a small amount of oil may leak out of the unit.

On the road, it is more difficult to check the VAZ 2106 oil sensor, since there is no pressure gauge at hand. To make sure there is lubricant in the engine channels, unscrew the element, disconnect the main ignition wire and rotate the crankshaft with the starter. If the pump is working properly, oil will splash out of the hole.

If the arrow on the instrument scale shows normal pressure (in the range of 1-6 Bar), but the red lamp is on, the small MM120 membrane sensor has clearly failed.

When the light signal does not light up at all, consider 3 options:

- the light bulb burned out;

- broken wiring;

- The small sensor in the form of a hexagon has become unusable.

The first 2 versions can be easily checked by testing them with a tester or multimeter. The serviceability of the membrane element is tested as follows: turn on the ignition, remove the wire from the terminal and short it to vehicle ground. If the lamp lights up, feel free to change the sensor.

Replacement is done by unscrewing the large or small sensor with a wrench. It is important not to lose the bronze sealing washers, since they may not be included with the new part. Remove any leaks of engine lubricant from the hole with a rag.

Both meters cannot be repaired, only replaced. Their metal cases, capable of withstanding the oil pressure of a running engine, are hermetically sealed and cannot be disassembled. The second reason is the low price of VAZ 2106 spare parts, which makes such repairs pointless.

Video: how to check lubricant pressure with a pressure gauge

Video: replacing the VAZ 2106 sensor

Pointer functions and operation

The purpose of the device, built into the dashboard to the left of the tachometer, is to display the engine oil pressure level, guided by the sensor. The principle of operation of the pointer resembles the operation of a conventional ammeter, which responds to changes in current strength in the circuit. When the mechanical rheostat inside the measuring element changes resistance, the current increases or decreases, deflecting the needle. The scale is graduated in pressure units corresponding to 1 Bar (1 kgf/cm2).

The device consists of the following main elements:

- round body;

- pointer mechanism with permanent magnet and windings;

- a control light connected to the corresponding sensor by a separate line;

- scale with backlight;

- compensation resistor;

- connecting wires with connector.

Zero readings of the device correspond to a circuit resistance of 320 Ohms. When it drops to 100-130 Ohms, the needle stays at 4 Bar, 60-80 Ohms - 6 Bar.

The Zhiguli engine lubrication pressure indicator is a fairly reliable element that breaks very rarely. If the arrow does not want to leave the zero mark, then the culprit is usually the sensor. When you doubt the functionality of the indicating device, check it using a simple method: measure the voltage at the connection contacts of the MM393A oil sensor with the engine running. If voltage is present and the needle is at zero, the device should be changed.

The VAZ 2106 oil pressure monitoring system with two sensors and a mechanical indicator is simple and reliable in operation. Despite the outdated design, car enthusiasts often buy and install these meters on other, more modern cars, equipped from the factory with only a control indicator. Examples are the updated VAZ Seven, Chevrolet Aveo and Niva.

Main aspects of the operation of sensors on the domestic “Six”

Any modern car is equipped with various regulators and controllers designed to monitor the condition of the components and assemblies of the car. Even the old domestic “sixes” in this case are no exception. You can learn more about what the oil pressure, fuel level, antifreeze temperature sensor is on the VAZ 2106 from this article.

Lamp switch sensor

Take a look at the instrument panel of the VAZ-2106, you will see an indicator with an arrow and a warning lamp. It signals that the pressure in the lubrication system has dropped to a critical value. And this lamp operates from a separate reading device, which is located in close proximity to the pressure sensor. If this lamp does not light, the reader must be replaced.

To do this, you need two tools - a 21 socket and an open-end wrench of the same size. The first step, of course, is to disconnect all wires that may interfere with removal. Why do you need two keys? You hold the metal adapter with one so that it does not turn. And with the second you unscrew the body of the device. Install the new one in reverse order. This completes the work, replacing the oil pressure sensor was successful.

Oil pressure

On “sixes” and other classic models, a VAZ 2106 oil pressure sensor of type Mm393A is installed. The pressure indicator works on the principle of converting this parameter, which is created in the lubrication system, into resistance. The oil pressure sensor is installed in the engine cylinder block. A regulator is also installed here, which turns on the oil pressure light.

This element is triggered as a result of the closing and opening of contacts at a particular level of pressure in the system. The corresponding indicator on the control panel may light up if the characteristics are violated, namely, if there is little liquid in the system.

Designation of part elements

How to check the controller? You can check the engine fluid pressure sensor by removing the regulator from its installation location. After removal, you should turn the starter; you do not need to start the power unit. If everything is fine with the supply of consumables, then you need to change the regulator. You can tell about the oil supply by the splashing of liquid from the controller seat.

Sensor device

Today you can encounter two types of oil pressure sensors:

- Emergency . It is he who is responsible for lighting the light bulb with the pictogram. The critical level here is the complete absence of pressure. There is a membrane inside the sensor that responds to oil pressure. As soon as pressure appears in the system, the membrane is pulled out, acts on the pusher and breaks the contacts. The light goes out;

- Control . The sensor readings are displayed on a dial indicator, which, however, is not available on all cars. Inside the sensor there is a slider that moves along a plate on which nichrome wire is wound. There is also a membrane inside, which, due to increased pressure, stretches and moves the pusher. The latter acts on the slider, which, moving along the plate, changes the resistance. Accordingly, the resistance of the sensor changes depending on the pressure. The instrument needle shows the driver only pressure.

In this case, regardless of the type, the sensor must be sealed. This is easy to check: a soap solution is applied to the joints, which should not foam during operation of the device as the oil pressure in the system increases.

Fuel level

On the “sixes” a fuel level indicator of the BM-150 type is installed, the controller itself is mounted in the gas tank according to the scheme, and it is fixed with bolts. The FLS includes a resistor device and a float. In order for the controller to indicate the correct level of gasoline in the system, a resistor device is controlled by the movement of the float.

The fuel level indicator float itself is directly connected to the resistor using a lever, at the end of which there is a sliding element. Thanks to the latter, the gasoline reserve lamp on the dashboard can light up. If the controller adjustment is correct, then this light comes on when there are 5-6 liters of gasoline in the tank.

The controller diagnostic procedure is carried out by measuring the resistance level of the resistor device. If the gas tank is empty, this parameter should be about 315-345 Ohms, if it is half full - 108-128 Ohms, if full - about 70 Ohms. Diagnostics is carried out using a combined tester (the author of the video is VAZ 2101-2107 REPAIR AND MAINTENANCE).

As for the temperature indicator, the VAZ 2106 uses a TM-106 type device; this regulator is also often called a fan switch sensor. The controller itself is made in the form of a screw, which is connected to the cylinder block. As for the operating principle of the temperature sensor or fan sensor, it is similar to that described above. But only in this case is a thermistor element installed, which changes the resistance parameter depending on the temperature of the consumable material.

The correct operation of the engine depends on the fan switch on sensor, because if the temperature is too high and the fan does not start working, this will lead to overheating of the motor. There is an engine temperature indicator on the car dashboard, allowing the car owner to always know about its condition.

JOT and the fan switch on sensor on a carburetor machine are two different sensors, and on an injection machine there is one sensor.

Six DTOZH

How to check the oil pressure sensor on a VAZ 2106, connection diagram and replacement, instructions with photos and videos

In front-wheel drive VAZs, unlike the “classics”, there is no oil pressure indicator, but only an emergency low oil pressure lamp. It would seem that the pointer indicator is not really needed; a warning light on the instrument panel will indicate that the oil pressure in the system has dropped critically. But for those who once drove a classic, the pointer indicator may not be enough. And it’s just nice for some to realize that he controls the operation of all car systems to the fullest extent.

Therefore, in this article we will look at how to display engine oil pressure readings on the instrument panel of a VAZ 2109.

For this we need:

The oil pressure sensor on a 1.5 liter 8-valve Nine engine is located on the cylinder block on the side facing the passenger compartment in the area of the timing case.

We unscrew the standard sensor, screw in an adapter (with a tee) in its place, and screw back into the tee the standard emergency oil pressure sensor and the “six” sensor onto the pointer indicator. Don’t forget to install copper washers, having previously calcined them over a fire to give them softness and ductility. Tighten all connections tightly.

Now our device needs to be connected. To do this, you need to run a wire from the sensor on the engine into the cabin, to the place where the indicator is installed. There are 5 contacts on the sensor from the VAZ 2106; they must be connected as in the figure:

You can install the pressure indicator itself instead of the headlight hydraulic corrector - few people use it, and few places it works. You can choose another place as you prefer.

Here are installation examples:

That's it, now our car is equipped with an oil pressure indicator, you can use it.

Problems with the level indicator

If the oil in the engine of a VAZ 2106 car is lost, you may encounter a number of unpleasant breakdowns that will lead to the waste of additional funds. Due to these circumstances, it is more profitable to take care in advance to prevent this error and regularly visit service centers. When observing a drop in oil below a critical level, it is advisable to identify the cause. To do this, follow the following instructions:

- First of all, if there is no pressure, you need to open the hood of your VAZ 2106 vehicle and check for fresh oil leaks on the power plant.

- After completing the task, you should look under the car and check the condition of the crankcase. If a leak is detected, you should fix the problem at least temporarily before arriving at the service center. To do this, try using a cloth or a special rubber band.

- Quite often, troubles are concentrated in the oil filter. If the whole point is that it is not tightened well, you can simply tighten the product clockwise, avoiding contacting specialists. However, if the breakdown is serious, you must urgently go to professionals to receive qualified assistance.

- After stopping the car for 10 minutes, you can start checking the oil, remember this. If a VAZ 2106 has traveled 100,000 kilometers, it is necessary to take into account that more oil will be consumed. This, in turn, will lead to high oil consumption and a drop in pressure. Therefore, there is no need to be surprised and look for a breakdown, unless, of course, the pressure has dropped significantly.

- Finally, I would like to add that one of the reasons is the pressure sensor. To normalize the readings in this case, it is enough to simply replace the specified part.

#1 Quattro

#2 Gmek

#3 Alexey

#4 Muchachos

#5 2-eschnik

Quattro, the car as I understand it is 2101?

- orange - power supply is +. You can take it from the power supply that goes to the tidy - there is also orange (or red) in the block

- gray to the pressure lamp sensor - this wire is already there (gray)

- gray-black needs to be laid on the pointer sensor

- white - backlight. It's best to take it from the instrument lighting - the white wire is in the block

- black and white - the ground (body) is also in the tidy block

10th grade or college test

Message modified: 2-eshnik, December 11, 2010 - 17:44.

If you want to tell me something, try using your mouth. type(c)BG

#6 Quattro

#7 Quattro

Somehow it always shows a maximum of 8 atmospheres. I connected it incorrectly.

Added after 10 minutes Connecting like this:

#8 RIDIK

#9 Alexey

#10 RIDIK

#11 Quattro

#12 slavik2101

The ignition is on - the light is on, the arrow points to 8. I turn it on - the light goes out, the arrow points to 8

#14 RIDIK

#15 TheForester

The ignition is on - the light is on, the arrow points to 8. I turn it on - the light goes out, the arrow points to 8

#16 Quattro

Disconnect the terminal from the sensor and see what the device readings are.

#17 slavik2101

#18 TheForester

try swapping the orange and gray-black ones, or the wires on the engine may be mixed up, swap them.

#19 Quattro

#20 2-eschnik

according to the diagram everything is correct. I already thought that my memory had failed me in my old age, but no! the diagram is 100% correct. I checked. Most likely the sensor is buggy.

Remove the wire from the sensor (pressure indicator sensor). Turn on the ignition. If the arrow returns to the beginning of the scale, then the sensor is faulty (or return it to the seller).

The front axle howls on a Chevrolet Niva

If you have a multimeter, you can check the sensor immediately in the store. The resistance of a working sensor is 290-320 Ohm

how to connect a gear temperature sensor, tidy 011

the connection is not much different from the oil gauge

- orange - power supply is +. You can take it from the power supply that goes to the tidy - it’s also orange in the block

- green - to the coolant temperature sensor. We connect to the green wire from the sensor in the tidy block.

- white - backlight. It's best to take it from the instrument lighting - the white wire is in the block

- black and white - the ground (body) is also in the tidy block.

If you want to tell me something, try using your mouth. type(c)BG

The performance of any engine in a car directly depends on the quality and quantity of oil, as well as its pressure, which is created using an oil pump. The oil pressure sensor controls the transmission of the status indicators of these parameters.

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Not every VAZ 2106 owner knows where this or that element is located. The oil pressure sensor in this vehicle is located on the left side of the cylinder block, under the fourth spark plug. This element should not be confused with the temperature sensor, which can also be found in the cylinder block, but a little higher.

The sensor design includes the following elements:

- A round metal barrel on which there is one terminal for connecting a wire.

- Membrane switch with contact on the end surface.

- Steel tee.

- Bronze washers acting as seals.

The principle of operation of the barrel is based on determining the amount of pressure, the nut, if necessary, manages to fix its absence, and the tee plays the role of a connecting element screwed into the engine.

Price and article

At the moment, there are several oil pressure sensors for the VAZ-2106 from different manufacturers. Below is a table of the most common of them, which shows the name of the sensor, the article number and its price.

Check and replacement

During operation of a VAZ 2106 car, the oil pressure sensor may fail, and the main reason for this will be its wear. Basically, a breakdown is detected by viewing the sensor indicators on the dashboard, and an emergency light can also indicate possible malfunctions.

In any case, before making hasty conclusions, you should check its performance.

Rear cushion of the VAZ 2110 gearbox

So, for example, if the emergency light suddenly lights up while the car is running, and the arrow does not deviate, then it is recommended to check the serviceability of the pressure meter in the sensor. In order to carry out the check, you will need to use an open-end wrench and a pressure gauge.

- A flexible pipe with a threaded tip is additionally screwed to the pressure gauge.

- The check sequence is as follows:

- The car engine turns off and cools down to a temperature not exceeding 60 0 C. This is necessary in order to avoid getting burned during work.

- The next step is to disconnect the wires attached to the sensor. They can be unscrewed with a key together with the tee. It should be taken into account that during disassembly of the sensor, oil may spill out of the unit.

- After this, the threaded part of the pipe is screwed into the vacated hole and tightened. Then the engine is started and the pressure gauge readings are monitored. The connection diagram is shown in the figure.

- If, as a result of measuring pressure, the sensor produces results that differ from the standard ones - “7 Bar”, then we can conclude that there is a malfunction in the sensor and the need to replace it.

- If the light signal on the dashboard lights up and immediately goes off completely, then the cause of the breakdown may be:

- failure of light bulbs;

- broken wires;

- wear of the small hexagon-shaped sensor.

The first two options can be checked using a multimeter or a special tester, which will demonstrate the difference between the required indicators and the standard characteristics. In order to check the performance of the small sensor, you will need to see how the light bulb reacts to changes. This is done by turning on the ignition and removing the terminal from the wires.

The element is replaced by unscrewing any of the sensors - large or small with a wrench. In this case, it is important to pay attention to the number of sealing washers, since the new part may not contain such components. It is worth noting that both parts cannot be repaired, they can only be replaced.

What to do if the sensor lights up

If the oil pressure sensor warning light comes on, you must first check the oil level. The fact is that its deficiency can reduce the pressure in the oil system, which will negatively affect the performance of the engine. This is what the oil pressure sensor records.

- At the same time, you should not delay adding oil, since any further breakdown of the system can lead to serious repair costs.

- As a result, it must be said that the operation of the VAZ-2106 requires a responsible attitude, regular inspection of the performance of all systems and elements, among which the oil pressure sensor plays an important role.

Oil pressure sensor VAZ 2106

The performance of any engine in a car directly depends on the quality and quantity of oil, as well as its pressure, which is created using an oil pump. The oil pressure sensor controls the transmission of the status indicators of these parameters.

Not every VAZ 2106 owner knows where this or that element is located. The oil pressure sensor in this vehicle is located on the left side of the cylinder block, under the fourth spark plug. This element should not be confused with the temperature sensor, which can also be found in the cylinder block, but a little higher.

The sensor design includes the following elements:

- A round metal barrel on which there is one terminal for connecting a wire.

- Membrane switch with contact on the end surface.

- Steel tee.

- Bronze washers acting as seals.

The principle of operation of the barrel is based on determining the amount of pressure, the nut, if necessary, manages to fix its absence, and the tee plays the role of a connecting element screwed into the engine.

How to install a new oil pressure sensor on a BAZ-2106 or other cars

There are drivers who do not like the sensors that are installed on later VAZ models. For example, on 8s and 9s it makes sense to install an oil pressure sensor from a VAZ 2106. The procedure for replacing the sensor is quite simple, and anyone can handle it.

- First you need to buy a new sensor with an indicator and wires. An adapter is also needed that will connect the new system to the cylinder block.

- The 9 or 8 does not have room for a pressure indicator, unlike the 6. Some owners replace the headlight range control knob, which does not work, with a sensor indicator. And for those whose headlight range control knob works, it makes sense to cut a special socket in the instrument panel to accommodate the oil pressure sensor indicator. Such a nest can be made with an electric drill with a thin drill. The holes must be drilled in a pre-marked circle, then using a round file, adjust the location for the VAZ 2106 oil pressure sensor. An adapter with a copper O-ring must be placed in the place where the standard sensor was located. Then you need to attach the sensor from the VAZ 2106 through this copper ring.

- Next, you need to connect the dial indicator to the sensor using wires.

But this is for those who really liked the oil pressure sensor from the 6. Of course, a simple system, clear instruments that show exactly what pressure is in the oil line, and if the sensor breaks down, you can simply throw it away and install a new VAZ 2106 oil pressure sensor yourself; it is not at all expensive - about 300 rubles.