We fix error P0171 ourselves

Sometimes a car owner encounters problems, the cause of which is very difficult to determine. Error P0171 is one of these problems. There are many versions as to why this error is displayed on the car panel. In this article we will look at the most well-known causes of error P0171 and tell the reader about ways to eliminate it.

What does error P0171 (“fuel supply system too lean”) look like?

At some point, a car owner may discover that a message with code P0171 appears on the dashboard of his car. This message can appear on any car if the engine management system in it is made according to the Euro-2 standard. In such systems, so-called lambda probes are installed, whose task is to monitor the chemical composition of the fuel mixture. The probe monitors that there are 14 parts of air to 1 part gasoline. The amount of air can deviate from this number in any direction, but no more than 30%. As soon as this threshold is exceeded, the driver sees error P0171 on the dashboard.

Reasons for appearance

As stated above, error P0171 occurs due to a lean mixture. This is the root cause. The problem is that the fuel mixture in a modern Euro-2 car can become lean due to a variety of different problems. It is not possible to list them all, so we will limit ourselves to the most famous:

- Dirt has entered the sensor that takes into account air flow, causing the measurement to be incorrect.

- There has been a leak in the EGR valve, which is responsible for recycling exhaust gases in the engine. The valve began to close poorly, as a result, excess air began to flow into the intake manifold.

- The EGR differential pressure sensor is faulty, resulting in more air flowing through the EGR valve than required.

- One or more vacuum leaks have occurred.

- There were problems with the fuel pump, due to which its power decreased significantly.

- The fuel injectors are clogged.

- The fuel pressure regulator has lost its seal.

- The air flow sensor is faulty.

- The oxygen metering sensor is faulty.

All these problems lead to the fact that the mixture becomes lean and the engine cannot operate stably even at idle. And since a lean mixture burns more slowly, the engine quickly overheats, and the car does not pick up speed well.

Elimination method

It usually consists of three large stages:

- Checking fuel sensors.

- Checking the fuel system and injectors.

- Check the tightness of all hoses and manifolds.

Sensors

A clogged MAF (mass air flow sensor, mass air flow sensor) is the most common cause of error P0171. Dust and dirt accumulate on its wires over time. As a result, it does not immediately respond to changed air flow. It's not just dirt that can get into this sensor. Combustion products may be deposited on it, which come out of the throttle valve and from the intake manifold with vapors after the engine stops. Because of these vapors, a thin layer of paraffin appears on the wires, after which the sensor begins to send a signal to the system that there is little air in the fuel mixture. Something similar can happen with other sensors. All of them are thoroughly cleaned using a special spray for cleaning electrical appliances. The second solution to the problem is to completely replace all “suspicious” sensors with new ones. We should not forget about the service life of the sensors. They can simply serve their purpose. Example: it is recommended to change the differential pressure sensor every 80,000 km.

Tightness

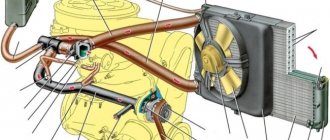

If the previous point did not help in solving the problem, you need to check the fuel system for leaks. First of all, the throttle valve is checked for depressurization. Next, all places where the vacuum hoses connect to the exhaust manifold are checked. The hoses are also inspected for mechanical damage, and this applies not only to the intake manifold. It is necessary to inspect the hoses of the fuel vapor trap and crankcase ventilation. The rule is simple: at least within a radius of half a meter from the oxygen sensor, the system must be absolutely sealed. If this condition is not met, the sensor is guaranteed to produce incorrect readings, leading to an error.

Fuel system

If it has reached this stage, the first thing to check is the injectors. They are removed and installed on a special stand, which will give you an idea of their performance. Then the fuel pressure level in the system is measured. If it is too low, the fuel pump is removed and disassembled. It is inspected for contamination, leaking gaskets and mechanical damage. The voltage supplied to this pump is also measured. If none of this helps, check the fuel pressure regulator. If it is ok, you should check to see if the fuel filter is clogged. Many of the above problems can be solved with the help of a high-quality car scanner, the purchase of which should be taken care of.

Reasons for error P0171

In reality, this will lead to flooding of candles. If the engine openly overuses fuel, misfires, shoots into the exhaust, but the ECU “complains” about the lean mixture, the death of the oxygen sensor is inevitable. The simplest tester connected to the signal terminal of the oxygen sensor will show a voltage within 0.25V.

Video: P0171 - lean mixture. One possible reason.

1. DMRV malfunctions

Failures of the mass flow sensor rarely lead to this error. The operating principle of the mass air flow sensor gives an overestimation of readings (contaminants on the sensitive element act as a heat insulator, which is interpreted by the injection system as an increase in air flow speed - that is, an increase in its quantity). More likely, it is not an “imaginary”, but a very real source of excess air at the intake.

2. Intake manifold leaking

Air leaks through cracks, which is not uncommon in plastic manifolds (in Renault Duster 2.0, for example, in 2013-2014 they were massively replaced under warranty). Through seals (if we remember Renault again, this is an eternal disease on a 1.6-liter engine K4M), through the vacuum booster pipe, and so on. In this case, the suction is maximum at idle and at low loads, when the vacuum in the manifold is greater. With significant suction, which can cause error P0171 to appear, it can even be heard by a characteristic hissing sound. Spraying a suspicious area with carburetor cleaner will immediately indicate a leak and change engine performance.

3. Cracks in the crankcase ventilation pipes, vacuum booster and others communicating with the throttle space.

4. Problems with the air temperature sensor

Cars that use an absolute pressure sensor (MAP or MAP sensor) to calculate cylinder filling may have problems with the air temperature sensor. Since calculating the theoretical filling requires a temperature correction, since air density strongly depends on its temperature, incorrect data on it also causes errors in calculating the injection time - accordingly, the injection time correction may go beyond the limits. To be precise, there is also a temperature sensor on cars with a mass flow sensor, but there it is interlocked with the mass air flow sensor, so we did not dwell on it separately. The sensor assembly will have to be replaced in any case, regardless of what exactly it “counted” incorrectly - the speed of the air flow or its temperature.

In addition to the traditional “knee-jerk” method of diagnosing a temperature sensor (that is, turning it off to switch the injection ECU to a bypass algorithm), you can also use a tester. All you need to do is find calibration data for your sensor on the Internet and measure its actual resistance.

Causes of a lean mixture

The error shows that the mixture is lean

How to determine the problem of the occurrence of a lean mixture effect in the engine cylinders? There are several reasons why this process may occur. So, let's look at all the possible options:

- The reason lies in the electronic control unit.

- Sensors and electrical equipment.

- Fuel system.

- Throttle valve and air filter.

- Ignition system.

Now that all the reasons have been considered, you can move directly to elimination methods.

Making a poor mixture into a good one!

To eliminate the causes of a lean mixture, you will have to work hard, since there are quite a lot of components in which a malfunction could occur. It is worth considering the sequence of actions to find the problem area and eliminate the cause.

Problems in the ECU

The first place you need to look is the electronic control unit of the engine and its systems. Thus, the accumulation of errors in the ECU can lead not only to changes in the mixture, but also to other malfunctions. In order to eliminate the cause, you need to connect to the unit using a USB-Auto cable and look for any faults. Often, this is where the initial answer to the question lies. This or that error will show which node caused the malfunction. As practice shows, this may be one of the sensors.

Diagnostics of the ECU for errors

If, however, a large number of errors are detected during connection, then a reset is necessary. If it does not help, and the sensors are all working, then motorists recommend reinstalling the car software. It depends on the type of control unit that is installed on the vehicle.

Self-diagnosis and reset of ECU errors on the instrument panel

Sensors and electronics

Failure of one of the sensors can result in a lean mixture. So, exactly what indicators need to be checked for performance in engines:

Mass air flow sensor

The IAC sensor is located on the throttle valve

Throttle position sensor

After checking all these products, you need to connect to the computer and reset the errors.

It is also recommended to check the wires that go to the sensors for breakdowns. If necessary, damaged elements must be replaced and the error reset procedure repeated.

Fuel system

One of the main systems that leads to a lean mixture is the fuel system. The main reason is insufficient pressure in the fuel rail. This may be due to several reasons:

- The filter mesh in the module is clogged . To eliminate the problem, you need to replace the element with a new one.

Mesh filter installed in the fuel module

Checking the fuel pump by immersion in water

Sectional view of the fuel filter after removal from the vehicle

Cleaning injectors without removing them from the car

Throttle

If the problem does not go away when repairing the fuel system, then you need to pay attention to the air supply system to the engine. So, the cause of a lean mixture may be a clogged throttle valve or air filter.

Dirty air filter removed from the car

To diagnose, you need to remove the filter element from its seat and inspect it. The presence of oil stains may indicate poor performance of the valve stem seals. A large accumulation of dust causes it to not allow air to pass through in the required amount. To fix the problem, you need to replace the element. The throttle also needs to be dismantled and inspected. If there is too much blockage, clean it with WD-40.

Cleaning the throttle valve

Ignition system

The last system where a lean mixture could be caused is the ignition system. So, it is necessary to diagnose the following elements:

- Spark plug . This part requires a comprehensive check, namely: checking the gap between the electrodes, resistance diagnostics, visual inspection for damage, clogging and cracks. If damaged, replace.

Characteristics of different spark plugs

Error "Lean mixture"

Error on the on-board computer screen

This is a lean mixture error.

Video on lean mixture and fuel economy from “ICE Theory”

In this case, the amount of fuel in the working mixture is too low, while too much air is supplied there.

A similar problem appears in a situation where the engine takes in a significant portion of air from the atmosphere for one of many reasons. Also, the problem may lie in insufficient fuel injection due to clogging or other problems.

Symptoms and behavior of the car with such an error

This phenomenon can lead to misfires, as well as delays that occur in the car’s response to pressing the gas pedal. The car may start to stall or stall at stops (idling).

In addition, when accelerating, a noticeable twitching is felt, and dips are observed during idle.

Well, the engine itself changes its sound, starting to work extremely unstable. In those engine monitoring and control systems that support Euro 2 and higher standards, there is a lambda probe. It is he who is responsible for controlling the quality of the mixture. It is optimal if there are about 14.7 parts of ordinary atmospheric air per part of fuel.

If there is a shift from this value by more than a quarter, the system will generate error message P0171.

How does a car behave with a similar problem?

If the engine receives too lean a mixture, this can cause the car to begin to “chop” at idle, and also overheat, since the rate of combustion of the mixture becomes much lower. If you listen closely, you may hear popping noises in the intake manifold. The revs pick up extremely slowly under load.

A lean mixture can be recognized by deposits on the spark plugs.

Burnout of valves and piston system

In the most difficult situations, if the engine overheats very much, this can lead to burnout of the valves and piston system , which entails serious costs for further maintenance and repairs.

A burnt valve will require serious financial investment in car repairs.

High fuel consumption

If a car is used for a long time with such a problem, this can lead to very high fuel consumption, which occurs due to a slow increase in speed. So, drivers have to operate their car in lower gears more often. A lean mixture can occur when the supply balance of its components is upset.

Reasons for the error

The reasons for the appearance of error P0171 can be divided into two main types:

- too little gasoline enters the combustion chambers of the engine cylinders;

- Too much air enters the combustion chambers.

In both cases, the required ratio in the fuel-air mixture is violated, as a result of which the engine begins to operate unstably, which manifests itself in the appearance of an error.

Specific reasons for the imbalance of air and fuel in the engine cylinders can be associated with various components of the car. Too much air coming in can be caused by the following problems.

- The mass air flow sensor is malfunctioning. Observed when the sensor is contaminated with oxidation products.

- There is a vacuum leak in the intake system.

- Excess air enters the intake manifold through the exhaust gas recirculation (EGR) valve. Associated with poor valve closure, resulting in exhaust gases entering the intake manifold.

- The EGR valve is bleeding excessively due to a faulty EGR speed difference sensor.

An insufficient amount of fuel entering the engine combustion chambers may be caused by incorrect operation of the following vehicle components.

- Malfunction of the fuel pump.

- Contaminated or damaged fuel injectors, resulting in insufficient fuel entering the combustion chambers.

- Dirty or worn fuel filter.

- A malfunction of the pressure regulator, as a result of which fuel does not enter the combustion chambers in full.

Causes of a lean mixture

There are several main reasons why the mixture is supplied to the car lean. But, they are all divided into two main groups: a large amount of air and a small amount of fuel.

A lean mixture error may occur in the case of excessive air supply, then the problem lies in the incorrect operation of the fuel flow sensor. This can happen when the channels become dirty. The second reason can be called the problem of vacuum leakage. And reason number three talks about the problem of air intake through the EGR valve when it is broken or does not close tightly enough.

Carrying out an inspection

Speaking about the lack of fuel, there are also three main reasons.

- The first includes problematic operation of the fuel pump, when it does not have enough power or it does not work as it should.

- Next comes the non-optimal resistance of the fuel filter.

- Well, the third reason will be a leak that may occur in the pressure regulator . Also, the breakdown may consist of simple contamination of the fuel injectors.

Sometimes we may need to check almost all possible causes in order to find exactly the one that is typical for our case.

Checking the MAF sensor using a multimeter (video)

Therefore, the first thing you need to do is check the sensors. As you may know, one of the most common problems is a clogged sensor, which is responsible for controlling air flow . If too much dirt has accumulated on its wire, this may cause the response to changes in air flow to become too slow.

It can also be contaminated by fuel vapors that pass through the intake manifold and through the throttle body when the engine is not running. These pairs can deposit a special layer of paraffin on the sensor wire, which will send data to the system about the incorrect proportion of the mixture.

What happens next is that the engine control unit cannot add fuel when the amount of air is too high. And after that, an error code will appear on the sensor screen indicating a lean mixture.

False errors P0100 and P0102

It also happens that along with the indicated error, other codes appear, like p0100 or p0102, by which you should definitely know that the problem lies in the sensor. To solve this problem, you need to clean the sensor. To do this, use specialized means for cleaning electrical appliances or the so-called carb cleaner, which is evenly sprayed onto the element that needs to be cleaned. But, still, the best option would be to install a new sensor.

“Vacuum” leak (video about checking for air leaks)

In the video, craftsmen made a simple smoke generator from a bottle and a cigarette.

Also, be sure to check the system for vacuum leaks. Depressurization can occur in any part of the inlet pipeline. But this can also happen at the outlet of the throttle body, namely at the place where the vacuum-type hoses and the intake manifold are connected. In addition, depressurization can even appear in places such as the throttle body gasket and the intake manifold.

Checking the fuel system (video)

And, of course, it wouldn’t hurt to check the fuel system. First of all, it is necessary to monitor the performance of the injectors, which is carried out exclusively on a special stand. Most problems with injectors occur due to low-quality fuel; in this case, flushing the injectors will help.

Next, you need to check the fuel pressure, as well as the performance of the gasoline pump, if present. You also need to check the voltage on it. Among other things, pay attention to the fuel pressure regulator and the fuel filter, as they must be in good working order so as not to cause a lean mixture.

How is the check carried out?

Check sensors . One of the most common causes of the P0171 code is a clogged air flow sensor (MAF). The sensor's response to changes in air flow may be slow due to dirt accumulated on its wire. It can also be contaminated by fuel vapors that escape through the intake manifold and throttle body when the engine is not running. These vapors deposit a waxy layer on the sensor wire, which causes a signal to be sent indicating that there is not enough air in the mixture. And the engine control unit, in turn, does not add fuel when the amount of air increases and the overall balance of the mixture is disrupted. All this leads to a lean fuel mixture and the appearance of error P0171. Often, along with this error, errors p0100 or p0102 may appear, which clearly mean a malfunction of the mass air flow sensor. To solve the problem, the sensor itself must either be cleaned using a special cleaner for electrical appliances or carb cleaner (spraying onto the sensitive element), or a new one must be installed.

Check for vacuum leaks . If the cause is not the mass air flow sensor, then you should check for a vacuum leak. Depressurization can occur at any point in the inlet pipe, as well as at the outlet of the throttle body - at the connection point between the vacuum hoses and the intake manifold, in the throttle body gasket, in the inlet manifold gaskets. It is also worth inspecting the hoses of the crankcase ventilation system, fuel vapor recovery system and plugs on the intake manifold for physical damage. The entire exhaust system near the oxygen sensor, half a meter before and after it, must be sealed. In another case, the sensor readings may be incorrect (for example, an error may occur when a corrugation burns out). The easiest way to check for leaks is using an auto scanner (by checking the fuel balancing value).

Lean mixture codes

But you should not think that for all reasons there is only one code, as for all cars. For example, the P0171 code in question is standard. But, in Ford cars, this code will indicate problems in the first cylinder block, while the P0174 code will indicate shortcomings in the second cylinder block. But on some Honda car models, code P0172 (45) may appear, which also indicates a lean mixture error, which turns out to be incorrectly prepared.

On the popular Chevrolet Captiva car in our country, a similar problem will be indicated within its own diagnostic system with code (DTC) P2177. But, the methods for eliminating this code are exactly the same as for other cars. In the Mazda 6, code 2178 may appear, which is exactly the same as what the previously mentioned codes indicate.