How the mechanism works

Almost all tools, both foreign (Husqvarna, Makita, Shtil, Partner 350), and Chinese chainsaws, and domestic (Druzhba, Ural), are designed the same. Therefore, finding the reason why the device does not start and stalls will not be difficult.

There are four elements where problems may arise:

- The fuel for which the carburetor is responsible;

- Lubrication;

- The air that enters through the air filter;

- A spark, the quality of which depends on the ignition unit.

They all depend on each other and interact with each other. If any element does not work correctly, the saw stops working.

Let's start with the fact that all tools start up differently - hot and cold. Two commonly used mechanisms are responsible for this process.

Be sure to look at what is written in the user manual. It states that when turning it on, you need to make sure that the emergency stop brake is engaged. But starting a saw with a brake is much more difficult, so sometimes it’s better not to turn on the brake.

As you can find out from the instructions, inside the body there is a fuel tank and an engine, and outside there is a saw part (bar with chain), a handle and a starter.

First you need to figure out exactly how the tool won’t start. For example, the saw starts up, but immediately stalls, or loses power and cutting quality.

Perhaps interruptions in operation occur due to problems in the engine. But I would not recommend disassembling it right away. It is better to look for the problem from the simplest option.

It is very important to consider the quality of the fuel. If the mixture is prepared incorrectly or has deteriorated over time, then even such reliable tools as the Ural or Husqvarna 145 will not work. The instructions must indicate the proportions and special oil specifically for your chainsaw.

Another common problem is that the user fills the candle during startup. It needs to be inspected; if it is completely dry, then fuel is not passing into the cylinder.

If you see black carbon deposits or a lot of fuel, then the carburetor may not be properly regulating the fuel supply.

If your saw tool starts, but immediately stalls, then the problem needs to be looked for in the carburetor jet or fuel filter. Perhaps they are clogged.

To check if the breather is damaged, you need to disconnect the fuel hose from the carburetor and see if the fuel mixture leaks out of it.

If the saw does not start when hot, then the problem may be in the muffler. Sometimes it gets clogged from the exhaust itself.

Quite often, saw breakdowns occur due to a small amount of chain lubricant. This happens when the channels are clogged or the oil line is leaking.

Also inspect the connections of the pipes with the oil pump fittings to see if they are leaking.

It is very bad when a breakdown occurs in the cylinder. When examining it, you may find unevenness or chips, and this may be the cause of the problem.

Video on the topic

Share articles on social networks and comment. And I say goodbye to you, good luck and see you again!

Question: A standard problem occurred with the Husqvarna 137 chainsaw (impulse channel seal). After replacement, the saw developed an unknown malfunction.

It starts up well, idles stable, but after 5 minutes of operation the power drops, the saw begins to operate at high speeds and choke. I assume that the problem is in the carburetor settings, but I don’t know what exactly to adjust.

Answer: it is possible that air is leaking through the same pulse generator. In principle, after replacing it is recommended to adjust the carburetor.

You shouldn’t adjust it yourself; for this you need a pressure gauge; if the mixture becomes lean, you’ll throw out the piston. Look at the carburetor mount; when the saw heats up, it starts to suck in air somewhere.

Question: I have a question about the Husqvarna 137 chainsaw. At first (when the problems started), the saw worked at idle normally, but at high speeds it worked for several seconds and the speed dropped until the engine stopped, then at medium speeds it began to stop abruptly and it was impossible to start until did not unscrew the spark plug and did not screw it back in.

I removed the carburetor, disassembled it, washed it and blew it out - 0 results.

I completely disassembled the saw and discovered that the rubber tube that connects the carburetor and the sleeve (small) had worn out, the group is normal, there is also a gap in the ring, there is play in the bearings (more noticeable on the ignition side since 1 petal on the flywheel is broken off, I think that’s where the play comes from) assembled, starts only on choke, runs for 3-5 seconds and stalls.

When you open the valve, it melts immediately; after several attempts, the spark plug and piston become wet. What could be the reason? Could there be an air leak from under the seals? Is the carburetor overfilling?

Answer: You need to disassemble the chainsaw. A rubber tube connects the cavity under the piston to the fuel pump diaphragm in the carburetor. If the tube is torn, then dirt will be sucked under the piston, and the pump in the carburetor will not work.

I hope the tube has been replaced. Was the carburetor disassembled, were the idle speed and mixture quality screws turned out? If the seals are sucked, the mixture will become leaner, and in theory the spark plug should not be filled. The fact that the blade on the impeller is broken is extremely bad. The imbalance at 11,000 rpm will be terrible, the bearing will wear out quite a bit.

Question: I have a Husqvarna 137 petrol saw. I don’t remember how old the saw is. I sawed a lot. Recently it began to lose power, and a few days ago it stalled and stopped starting.

What was done: Replaced the spark plug with a new Bosch one. The result is zero. Removed the fuel filter - zero. They put it back. We disassembled and reassembled the carburetor. (The screws were never touched). The membranes are intact. A set of membranes will arrive soon, we want to replace them just in case. They changed the fuel.

We replaced the ignition coil from the 142nd saw. The result is that it starts, but before starting you need to pump the trigger many times. And if it starts, the engine only works if you pull the trigger. That is, intermittently. It doesn't work at full throttle, nor does it work at idle. What else should I check?

Restoring the operation of the tool

To restore the operation of the saw, no matter the Ural or Shtil brand, you need to know the location of the breakdown.

First, we check and change the unsuitable fuel mixture. If the saw still does not start, then we check further point by point.

The problem is in the candle - we pull it out and dry it. Under no circumstances should you pierce it, as this will lead to a malfunction of the part. 30 minutes after drying, you can insert the spark plug back, first checking to see if there is any fuel left in its place.

In addition, the spark plug may simply break, so it is better to have a spare one to rule out the cause.

Another reason that the tool does not start well and stalls is poor contact between the spark plug and the high-voltage wire. If everything is in order here, but there is still no spark, the ignition unit itself may be broken. Such a breakdown can only be corrected by replacing it.

Air filters should be checked and cleaned from time to time. If you have not checked it since purchase, it could become clogged with dust and cause a malfunction.

In models such as Shtil 180, Ural or Partner 350, the breather becomes clogged, which often leads to breakdown. To clean it, you can use a sewing needle.

For models Shtil 180, Druzhba, Ural and Husqvarna 142, the muffler sometimes gets clogged, it also needs to be checked and cleaned.

If the problem is in the carburetor, then without appropriate experience you should not try to fix it. It is best to turn to specialists.

If, after checking and eliminating the above problems, your saw still does not start, then most likely the breakdown is hidden in the cylinder group.

When, during inspection, you see damage and chips on the piston or cylinder assemblies, these elements will have to be replaced.

If the cause of a chainsaw malfunction is pipes that are leaking, then most likely there is not enough lubricant supplied to the chain. To fix the problem, just replace the tubes and seal the joints with sealant.

Mechanism parts cannot last forever, so they will have to be changed periodically. To find out how long each part lasts, you need to look at the instructions.

Why won't my petrol trimmer start? Causes and their elimination

In the near future, the gasoline trimmer acquired the status of one of the main tools in the arsenal of summer residents. And this is logical, because a motorized scythe allows you to quickly get your garden plot in order. But from time to time it happens that the trimmer does not start when hot.

and even when cold.

In such situations, you have to independently determine the cause of the malfunction. Let's find out what to do if the trimmer won't start

. The reasons that most often lead to such troubles will be discussed below.

Separately about the breakdown of the most common model

Let's look at the problems of Shtil 180 in more detail:

- Clogged carburetor or fuel filter. These are the most common problems that can be easily resolved after cleaning. Sometimes the filter has to be changed;

- Replacing the spark plug;

- Sometimes the cylinder or seals need to be replaced.

The Shtil saw is quite strong and durable, so you can often fix a breakdown yourself. In fact, the same applies to the Partner, Ural, Makita and Husqvarna models.

When we discover a malfunction in our chainsaw, we look for the cause in small ways, gradually checking and eliminating the problems. Such problems are easy to fix yourself. But if the breakdown is serious, and you do not have enough experience, then this should be done by a specialist.

Husqvarna Chainsaw 137 Doesn't Start Reason

What to do if your chain saw won't start

Good afternoon, dear readers and subscribers of my blog! At some inopportune moment, you may find that your chainsaw will not start. But don’t rush to immediately take a repair tool; perhaps you can fix this breakdown yourself. I will tell you what to do in cases where the chainsaw does not start, and how to find the right solution to this problem.

We analyze the possible causes of the breakdown

Find why the tool cannot be run in the instruction itself. But instructions don't always come.

Why does a chainsaw have trouble starting?

- fuel and air filters;

- reduced compression;

- carburetor adjustment;

- spark plug;

- ignition coil;

- gap between the ignition coil and the flywheel;

Let's look at each reason in more detail.

Fuel and air filter

Contamination of the main filter elements of a chainsaw negatively affects its operation.

For example, a dirty air filter will not provide enough air to the carburetor, which will affect the quality of the air-fuel mixture and normal engine starting. A dirty fuel filter will make it difficult or even cut off the flow of gasoline to the carburetor and make it impossible for the engine to operate.

Chainsaw won't start when hot

In cases where the chainsaw does not start when hot, you need to conduct a visual inspection of all the main components of the chainsaw. The inspection should start with the spark plug. Check the spark, inspect the surface of the spark plug electrode, these actions will help determine the direction in which to look for the problem.

Malfunctions in the ignition system

If, upon inspection of the spark plug, it is found that it is wet and sparking does not occur at the contacts, this means that the problem should be looked for in the ignition system, inspect the coil, and check the gap between the flywheel and the coil contacts. You can also check how tightly the cap of the high-voltage wire sits on the spark plug, and the spark plug itself. Try replacing it with a new one.

Problems in the fuel system

If upon inspection it is discovered that there is a spark, but the spark plug is dry, then there is a problem in the fuel system. Checking it should start with the fuel filter. Next, you need to inspect the fuel hose and its attachment to the carburetor, pay attention to fuel leaks from the carburetor and the presence of gasoline in the air filter housing. It is advisable to start removing the carburetor only if a visual inspection does not allow you to determine the cause of the breakdown.

A characteristic sign of a problem in the fuel system is an excessive amount of fuel in the engine cylinder. Typically, signs of this include an excessively wet spark plug and the presence of a spark at the plug contacts. In this situation, it is necessary to turn the chainsaw over so that the spark plug hole is directed towards the bottom. If gasoline flows from the cylinder, then the reason that the chainsaw does not start is fuel overflow into the engine.

It “fills” with fuel, sometimes due to incorrect carburetor adjustment or malfunction.

You can familiarize yourself with the process of adjusting the carburetor using the example of the Champion 254 saw by watching the video instructions.

Identifying and eliminating obvious chainsaw faults.

To determine the reason why the chainsaw does not start or stalls when starting, it is necessary to troubleshoot the tool. The essence of the procedure is a sequential inspection of the condition and operation of the main working elements of the saw engine. At this stage we check:

- Presence of a spark on the spark plug;

- Fuel supply;

- Filter status;

- Operation of the breather built into the fuel cap of the stalling unit;

- Functioning of the exhaust channel.

Checking the spark on the spark plug and eliminating the causes.

The first step in finding the reasons why a gasoline saw does not start is to check the spark on the spark plug. There are many factors that influence the operation of this element. However, the main ones at the initial stage of tool troubleshooting are:

- Incorrect carburetor adjustment;

- The presence of more than the required amount of oil in gasoline;

- Air filter clogged.

All of them contribute to the formation of carbon deposits on the spark plug electrodes. In 50 cases out of 100, saws do not start when cold due to the lack of a spark due to carbon deposits on the electrodes and their corrosion. The result is either a decrease in the gap or an increase in it.

Checking the spark plug of a non-working chainsaw

Checking for spark is quite simple. To do this you will need:

- Remove the tip of the high-voltage wire;

- Unscrew the spark plug;

- Put the tip back on;

- Place the candle skirt against the cylinder;

- Start with the starter.

If at the moment the chainsaw engine starts, a good spark is observed between the electrodes, then everything is in order with the ignition unit. If it is not there, then it is worth cleaning the element itself and checking the electrode gap. If necessary, use a special probe to adjust the distance between the contacts.

For spark plugs from different manufacturers, the distance between the electrodes may vary. For some it may be equal to 0.5 mm. Others have 0.2 mm. Therefore, carefully study the manufacturer's recommendations.

There may be no spark at the spark plug for other reasons. The main malfunctions that affect poor starting of the chainsaw and unstable operation of the internal combustion engine at idle, which can cause the tool to stall, include the following:

- Overfilling of the spark plug channel with fuel;

- Lack of contact between the high-voltage cradle and the tip of the spark plug;

- Failure of the ignition unit.

How to start a cold chainsaw if the spark plug channel is constantly flooded with gasoline? You can fix the problem while starting the tool using the following algorithm:

- Unscrew the spark plug with a special wrench;

- Wipe it with a clean and dry cloth;

- Dry for 20...30 minutes;

- Remove carbon deposits with a file and adjust the gap between the electrodes;

- Drain the remaining fuel from the spark plug channel and dry it;

- Collect everything and try to start the mechanism.

As a rule, these measures are quite enough to start the chainsaw and get the job done. However, this extreme measure does not eliminate the main reason why the engine does not start or stalls - improper operation of the carburetor, which needs fine adjustment.

If there is no spark due to poor contact of the high-voltage cradle with the tip of the spark plug, it is necessary to check the connection. The test can be carried out using a regular tester. If a defect is detected and corrected, the chainsaw should start without any problems.

If the check shows that the contact is reliable, but the saw still does not start, look for the reason in the ignition unit. As a rule, a faulty unit cannot be repaired or restored. This will require a complete replacement.

We determine the availability of fuel and its supply.

First, you need to make sure that there is a fuel mixture in the tank of the chainsaw that does not want to start, and that it is properly supplied to the carburetor. With a full tank, check how the mixture is supplied through the gas line. We disconnect the fuel system pipe from the carburetor and try to pump it up. In case of complete order, when pumping, gasoline will be supplied jerkily in accordance with the standards set by the manufacturer. Weak fuel supply or its absence can result from:

- The fuel supply channel is clogged;

- Fuel filter clogged with debris.

Often the cause of poor starting of a chainsaw can be a too full tank. In this case, you should pay attention to the presence of smudges under the saw housing cover. If they are present, then look at the connection of the gasoline supply pipe to the carburetor. Most often, it is squeezed out by pressure when screwing on the tank cap, which is tucked right under the neck, which prevents the engine from starting.

The quality of the fuel mixture can also be one of the reasons why the chainsaw does not start. If, after completing the work, you do not drain the remaining gasoline and leave the tool for long-term storage (more than 2 weeks), then the processes of resin formation and polymerization of the components will begin to occur inside the tank. What can cause carbon deposits to appear on the piston, rings and cylinder liner. Therefore, always prepare the mixture in only the required quantity before work.

Checking the condition of the fuel and air filters.

If the fuel quality is fine, the chainsaw engine may not start due to clogged fuel and air filters. To diagnose these elements, you will need to perform a number of manipulations associated with their dismantling.

Chainsaw doesn't start well when cold

Violation of the sequence of actions when starting on a cold

If a new chainsaw does not start when cold, the reason may be the incorrect engine starting sequence. As a rule, each manufacturer, in the instructions for the chainsaw, indicates the procedure for starting the chainsaw when cold. Basically, it is similar for all two-stroke internal combustion engines that are installed on chainsaws, and represents the following procedure.

- Closing the air damper (necessary to enrich the fuel during startup).

- Fuel suction using a special primer for this (on some models of chainsaws, the primer is not provided by the design, and therefore this item is not available for them).

- Turning on the ignition (if you forget about this, you may mistakenly consider the tool to be faulty).

- Carry out several movements of the starter until the first “flash” of the engine (it is important not to miss this moment, otherwise it is possible to “flood” the engine).

- Set the air damper to the open position.

- Start the chainsaw engine.

Fuel problems

As in the case of difficult starting when hot, problems in the fuel system can also affect starting or the inability to start even when cold. Carburetor adjustment, contamination of the fuel filter and line are all reasons that cause starting difficulties.

Carry out diagnostics of the fuel system, this is the first thing you need when it is difficult to start when cold.

It is worth paying attention to the quality of the fuel, because... When using a mixture of gasoline and oil that contains a small amount of water, starting may be significantly difficult or impossible.

The mixture must be used fairly fresh, because... When gasoline diluted with oil is stored for more than a month, its properties are lost and it becomes difficult to start, both on a cold and hot engine. For this reason, gasoline may burn poorly.

Engine faults

CPG scuffing, ring sticking, CPG wear, air leaks through seals and gaskets, decreased compression, all these problems can make starting a chainsaw impossible or significantly complicate it. For example, if the CPG wear is not significant, the compression in the engine decreases. In this case, starting “cold” will be significantly difficult, or the saw may stop, the tool will start well.

It is quite difficult to accurately diagnose problems in the engine associated with problems in starting it, and it is better to contact a specialist in this field.

Video

The main reasons why the chainsaw does not start in the video. The video will be useful for those who quickly want to start a saw; the author gives practical advice.

If a situation arises when the chainsaw does not start, it is important to correctly diagnose it and determine the direction in which to look for the fault. You should not use a tool that does not idle, as this indicates that there is air leaking into the engine and can lead to serious problems. If you don’t have enough experience in repairing chainsaws, it’s better to contact a specialist who will save your time and nerves.

Other Possible Causes

Other problems that many chainsaw owners experience is when the chainsaw starts but something goes wrong. It may stall, the chain begins to work poorly or not work at all. Here are some additional things to check if these problems occur.

- Inside the chainsaw there is a small screen necessary to control the sparks emitted by the engine. This is a spark arrestor and is usually made of fiberglass. It can become clogged with soot over long periods of tool use, leading to starting problems. The issue is easily resolved by removing the spark arrester and cleaning it with a wire brush. If problems arise with the spark arrester after cleaning, you should replace it with a new one. It is recommended to change the spark arrester after 25 hours of using the chainsaw.

- If the engine starts, but the circuit does not respond to starting. This may be the result of worn clutch mounts. When they become worn from use, they do not interact with the clutch drum to allow the chain to rotate. If the pads are worn, the clutch assembly must be replaced.

Chainsaw maintenance

Like any other power tool, a chainsaw has many moving parts in the motor. Most people tend to ignore maintenance and care, believing that good quality tools can work effectively without additional care. Over time, using a chainsaw will cause wear on parts that need to be checked regularly.

Cleaning and properly maintaining important parts of your chainsaw can be an effective preventative measure. It is important to take into account tips that can keep your chainsaw in good condition.

- Make the necessary adjustments to tighten the nuts and tension the chain.

- Clean all necessary parts from debris, sawdust, etc.

- Periodically inspect the chain blades.

- Make sure that all moving parts such as gears and chain are lubricated as needed.

Chainsaws "Husqvarna" - main malfunctions

A tool from a Swedish manufacturer can turn hard work into a simple task. The Husqvarna 137, Husqvarna 240 and Husqvarna 365 chainsaw models are distinguished by three features:

- high engine power;

- improved engine filtration system;

- the ability to absorb excess vibrations.

If you operate the tool strictly according to the instructions and correct its problems in a timely manner, then it will delight you with reliable and stable operation. Correctly carried out repairs with original spare parts will allow you to use the saw for a long time.

The main cause of chainsaw failure is most often engine failure, which can manifest itself as follows:

- won't start;

- Unstable operation at idle speed;

- starts and stalls immediately;

- do not have enough power.

In this case, the fault should be looked for in the ignition system, piston group or fuel system. Often the reason for poor tool performance may be related to the clutch, brake system, lubrication mechanisms, or tire.

Ignition system

Do-it-yourself repair of the Husqvarna 240 chainsaw, or any other model, should begin with troubleshooting in the ignition system.

First of all, experts recommend removing and inspecting the candle . The condition of this element will indicate shortcomings in the operation of the fuel system.

A malfunction in the ignition system may be due to the use of bad oil or an incorrect ratio of gasoline to oil.

Fuel supply system

If fuel does not enter the chainsaw tank, there may be two reasons for this:

- The filter is clogged.

- The lid is clogged.

In this case, the fuel is not supplied in full, and the tool does not start or starts and immediately stalls. The repair consists of cleaning the air filter and cover.

The filter must be removed very carefully so that the dirt that clogs it does not get into the carburetor. It can be cleaned and washed with ordinary detergents.

Carburetor repair

Do-it-yourself repair of this unit involves disassembling and cleaning. If the breakdown is serious, then you should contact a service center for help.

Most often, tool malfunctions are associated with the use of low quality gasoline or oil . To protect the carburetor from damage, you must follow some preventive measures:

- The chainsaw should be started strictly according to the instructions.

- It is not recommended to store gasoline in a plastic container. This will help avoid severe soot.

- The fuel mixture cannot be stored for a long time, as over time it loses its quality.

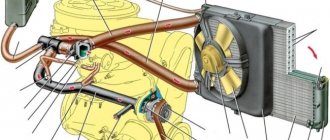

Switching system design

A key role in any chainsaw is played by a two-stroke carburetor power unit. Its power directly depends on the chosen model and purpose. The second important mechanical unit in the device is the saw part, which consists of a bar, cutting chain and sprocket. The parameters of these components may vary.

Treatment with lubricating mixtures is carried out using special oil, which is poured into a specialized reservoir, which is located on the hand block. Separately, it should be noted that the volumes of the oil tank and fuel are calculated in such a way that their contents, as a rule, end at the same time.

Troubleshooting options and methods

Regardless of the brand of chainsaw - Champion, Husqvarna 236 or Patriot, the reasons for poor performance are identical. There are a lot of options why the Shtil chainsaw won’t start, but the most common are the following.

Chainsaw doesn't start well when cold

If the saw does not start well when cold, it means there is no compression. This occurs due to abrasion of the rings due to prolonged use. It turns out that when the user tries to start the Champion 137 in a cold state, the compression will not be enough to carry out this manipulation.

In this case, it is not recommended to systematically pull the handle. In the end, the unit will still start, but other mechanical components may break down. In this situation, you need to replace the worn rings with new ones.

Chainsaw won't start when hot

Here the reasons lie in engine flooding and wet spark plugs. Here's what to do in this situation:

- move the air damper to the middle position;

- Blow the component parts well;

- start the device for 10 seconds;

- switch to idle mode;

- on a caliber chainsaw or another model, fully open the damper.

Next, simply start the engine at idle speed by pulling the handle. If the engine does not overheat, it will start easily.

If this troubleshooting option did not help, it means that the motor has already cooled down significantly. Fix the half-gas according to the recommendations from the instructions and repeat the operation.

You should also try turning the cold speed screw in a clockwise direction. The higher the rotation speed in the equipment, the easier it is to start it. You should know that the chain must remain stationary at idle.

VIDEO: Why the saw does not start or stalls and how to fix it

The chainsaw has difficulty starting and immediately stalls

In this situation, the cause is the filling of the spark plugs with gasoline at the moment when the user tried to turn on the unit. A small amount of fuel accumulates under the spark plug electrodes, which is why there is no spark in the equipment.

Removing the candle and drying it thoroughly will help solve the problem. In addition to these actions, you can additionally carry out heating. But this manipulation should be carried out exclusively using a gas burner. Otherwise, a small deposit may form in the area of the electrodes. After the spark plugs have completely dried, you need to drain off the excess fuel and leave the equipment itself to dry.

Chinese saw won't start

It should be noted right away that Chinese devices do not have any distinctive features from other analogues. They are just as reliable and productive, and also cost less. The only thing that is necessary individually for this device is to use only branded oil and fuel.

Most units do not work well with fuel from domestic manufacturers; gasoline clogs the channels and, as a result, fuel does not flow to the engine. Use fuel either of high quality or from the manufacturer of the saw itself.

VIDEO: How to properly adjust the carburetor so it doesn’t stall

Why doesn't the new saw work?

New equipment should not have problems with wear and tear on functioning mechanical parts, since the model has just left the assembly line. Such untidiness may arise if you purchase demonstration equipment that has been used more than once to advertise the company. The reason may also be improper operation of the unit, which does not comply with the recommendations from the instructions.

Husqvarna chainsaw repair diagram

First of all, you should check whether all the parts and components are installed in their places. Also, for example, Husqvarna will not start if it has been filled with a fuel mixture prepared without taking into account the required proportions.

But if all the recommendations are followed, every detail is carefully fixed in its place and the equipment was not purchased from a stand, the buyer probably received a defective device.

There is not enough fuel in the tank or it is of poor quality

This is one of the most common reasons. Users of gasoline vehicles, in order to save money, often use budget fuel. At first, the unit will perform its job properly, but the problem will certainly arise after a few months of operation.