Many motorists, when operating their car, think about when it is time to change their tires. To do this, you need to be able to determine the level of their wear. However, not everyone knows how to do this, which is why sometimes tires become unusable right on the road, which is very dangerous.

This indicator is also important when buying used tires. Of course, new ones will be ideal, but some people buy used tires, and the percentage of wear can be significant.

But how to determine tire wear? There are several options for this. Let's look at each of them.

By appearance

This method is the easiest, but it will not provide one hundred percent results. Its essence is a visual inspection of tires. There are a number of factors that unmistakably indicate that they can no longer be used:

- If the rubber shows cuts, cracks and other defects.

- The tread shows uneven wear, when one area is in normal condition, and the other is completely worn down to the cord layer.

- Worn inner part of tires - sometimes it can touch some element of the car and wear off.

- The presence of lumps also indicates that the degree of wear is higher than acceptable.

Workers at service stations and tire shops, and even some motorists, are able to detect the level of tread wear by eye, determining its approximate height.

Methods for determining wear

Next, you need to find out how you can determine tire wear yourself. There's really nothing complicated here. Even for a motorist who has recently tried on such a role.

Using existing wear identification marks provided by the manufacturer on its tires, or using a simple tool, you can quickly solve the problem. If the mark has not reached its maximum value, feel free to continue operating the car on the current set of tires.

You can get an answer about wear using:

- indicator;

- digital index;

- colors;

- depth measurements;

- improvised tools.

Now each of the presented options should be considered separately.

Bus indicator

Using a tire wear indicator is the easiest way to complete the task assigned to the motorist. In fact, it is a small rubber column of a fixed height. Most often it is 1.6 millimeters, but there are others, depending on the tire itself and its purpose.

There is no need to calculate a percentage or follow a specific algorithm before determining the current degree of wear of car tires. Just check periodically.

When the tread level is in line or at the same height with this indicator block, the tire has reached the end of its life. It needs to be changed soon.

Finding the indicator itself is also easy. Look for the corresponding mark on the side. Usually this:

- triangle;

- manufacturer's logo;

- TWI icon.

There are tire manufacturers that use intermediate wear indicator elements in their design. Once they are achieved under dry asphalt and pavement conditions, operation can continue. But grip on wet roads will deteriorate significantly.

Digital types of indexes

You can also figure out tire tread wear using digital indices.

There is also nothing complicated about how to independently find out the current wear of your tires. The protectors and sipes come from the factory with digital indicators that differ in different depths.

The greatest value is often squeezed out at a shallow depth. And the smallest (4 or 2) is at the maximum. As the tires wear out, the numbers gradually wear off. The degree of wear is determined by which largest number remains legible. When the last indicator is erased, this tells us that the tire is experiencing a critical loss of service life.

Moreover, the indicators themselves come in 3 types:

- A series of numbers with values from 2 to 4. Marking is carried out in millimeters.

- A series of numbers, but in percentage terms depending on the height of the remaining tread on the tire.

- Display element in the form of one segment with a number. Moreover, it is performed in such a way that each subsequent segment is located at a certain depth. When the tire wears off, the following numbers appear. Millimeters are also used here.

The definition scheme is quite convenient and universal. Allows you to quickly understand how much longer the tire’s life will last.

Color

An interesting and not entirely usual option for how to check the degree of tire wear. This is done using variable color.

This is a fairly new method, so there are not many sets of rubber on sale with a similar determination method.

At the same time, in practice it is extremely simple to figure out how to determine the current wear of your tires on a car. When abrasion reaches critical levels, the tire acquires a bright color. This allows you to understand, even without a detailed examination, that the resource is coming to an end.

Depth measurement

All the indicators presented above are convenient to use, but in fact they only provide conditional values. They are not able to fully and accurately show wear.

If you need accurate values, you should use a special meter. This device was created specifically for those for whom it is important to know how to determine the degree of tire wear themselves.

The device is inserted into the protector at several points. There are markings on the device. If the level is higher than existing standards, then operation can continue. But if the readings at the measurement points are low, the kit should be changed.

Available means

Not everyone wants to spend money on purchasing a special measuring device. There is no urgent need for this when you have a regular ruler or caliper at hand. With the help of such simple tools, you can quickly get an answer to a motorist’s question.

Using a caliper, its probe is lowered to the bottom of the groove and the value is recorded. In the same way, the operation is carried out using a ruler.

Also, a very ordinary coin will be a good tool for express analysis. If you take a coin with a denomination of 2 rubles, you can quite accurately understand whether the tire is badly worn or not. To do this, place a coin in the groove so that the eagle's head is pointing down. If you cannot see the bird's head when diving, the wear is normal and you can continue using it.

A 1 euro coin is also great. For passenger cars, the coin is dropped into a groove. If the gold band has disappeared, there is no need to rush to replace it.

You can independently deal with the current wear of car tires even using improvised means. The main thing here is to periodically conduct an audit and identify problems in a timely manner.

Tread height

The best way to determine tire wear is to use a caliper. It will allow you to know exactly how high the tread is. A ruler with a depth gauge or other tool is also suitable for these purposes.

To accurately understand how many millimeters are left and determine tire tread wear, it is recommended to measure the thickness in different areas, since the percentage of wear may be uneven. If all measured values are greater than the minimum acceptable values, then the tires are still suitable for use.

If the value is less, then it is not recommended to continue operating the car with these tires, since they will not ensure safe driving, especially in emergency situations.

If you don’t have a caliper at hand, you can measure the tread height using a coin. It will allow you to understand how much height is left, but it does not guarantee the accuracy of measurements, but only allows you to roughly compare the indicators of uniformity/unevenness of rubber abrasion.

Why is it important to know your tire wear?

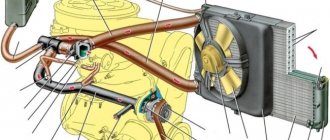

The main characteristics of car tires are provided by a convex pattern applied to their surface - the tread. Thanks to the tread, a contact patch between the tire and the road tread is formed, the wheel’s engagement with the road is ensured, and most importantly, the tread removes water, dirt and slush from under the wheel, ensuring better contact with the road surface.

However, rubber is constantly subject to wear, so over time the tread wears out and its height decreases. This entails a number of negative consequences, including a decrease in the speed at which “aquaplaning” begins, deterioration in controllability, an increase in the likelihood of skidding, etc., and wear on the tread of trucks and tractors also reduces the cross-country ability of these vehicles. Ultimately, excessive tire wear reduces vehicle safety and can cause an accident.

Therefore, tread height is strictly regulated by law, and every driver must comply with the established tire wear requirements. The remaining tread height, upon reaching which the tires can no longer be used, is established by paragraph 5 of the “List of faults and conditions under which the operation of vehicles is prohibited,” which is an appendix to the traffic regulations.

Tire KAMA NR-202 drive axle

Tire CORDIANT Business CW-2 stud.

Tire ID-304 Nizhnekamsk 18-layer with NK camera

NOKIAN Nordman 5 stud tire.

Tire Forward Professional 156 AShK tubeless

NOKIAN Nordman 5 stud tire.

Tire KAMA NR-201 drive axle

Ya-166 tire with T-40 tube

Tire TIGAR Cargo Speed Winter stud.

Tire KUMHO Wi-31 stud.

To date, the following values for the remaining tread height have been established:

- For motorcycles - 0.8 mm;

- For trucks - 1 mm;

- For passenger cars - 1.6 mm;

- For buses - 2 mm.

When the specified values are reached, the tire must be replaced, otherwise it will be a traffic violation with the imposition of appropriate sanctions on the driver. There are various ways to determine the remaining tread height, but today the most common and simplest is a wear indicator built into the tires.

By indicator

Some tires have a wear indicator. If it is level with the tread, the tires are completely worn out. Typically the indicator consists of numbers. The wear of summer tires should not be more than 2-3 mm, and for winter tires - no more than 4-6 mm.

At the same time, winter tires must also have studs; if they are less than 40%, then the tires are not suitable for further use, since they will not provide safe driving in winter.

In urban conditions, you can still drive without spikes in emergency situations, but be extremely careful, but on the highway you definitely can’t do this under any circumstances.

The tire wear indicator is located on the tread itself, but it is not so easy to find. To do this, on the side you should find a mark in the form of a brand logo, a triangle, or a special TWI sign.

On Michelin tires, the indicator is located in the central groove and is indicated by a special symbol.

The Continental company uses an intermediate indicator on its models, the erasure of which signals a loss of resistance to the effect of aquaplaning.

Nokian and Matador tires usually use a digital indicator. It is the most convenient of all, since the numbers on it correspond to the tread height in millimeters.

How to use the wear indicator and when to replace a tire

Assessing tread wear using an indicator is quite simple and does not require any special skills. First of all, you need to find the position of the indicators using the icons on the side of the tire, and then use the indicator to assess the degree of tread wear.

In the case of a volumetric indicator, it is necessary to focus on the difference in the height of the tread and the indicator, and if they are equal, the tire should be replaced. Aligning the tread height with the intermediate indicator is not a signal that the tire needs to be replaced, but it does let the driver know that they should be careful and prepare for a tire change soon.

In the case of a digital indicator, you need to focus on the largest number embossed in the tread. So, if all the numbers on summer tires have been erased, except for “4” and “2”, then the tire can still be used, but you should prepare to replace it soon. The need to install new tires is indicated by the disappearance of the number “2” on summer tires and the number “4” on winter tires.

You cannot delay changing tires when they are worn out, as this is dangerous and, moreover, illegal. Therefore, it is recommended to periodically inspect tire wear indicators and replace them when critical wear occurs. This is the only way to avoid many of the dangers posed by “bald” tires and sanctions from traffic police officers.

Replacement timing

If you do not want to constantly measure the tread height and determine tire wear, then you can simply change them every 6 years, then they will not let you down on the road. However, this period is only relevant for a calm driving style.

Those who like to “drive” will have to change tires more often, and it is better to check the tread, since tires wear out much faster and more severely.

It is always necessary to monitor the degree of wear of tires, regardless of which road the car is most often driven on and what driving style the car owner has. On expensive models this is easy to do; an indicator is provided for this.

Budget cars don’t have it, but you can also understand that the tires are worn out. As it turns out, there are several ways to do this. If the tires were originally purchased used or budget ones, then their condition must be monitored more carefully, as they quickly become unusable.

Source kolesadom.ru

How to assess tire tread wear?

As a rule, when selling used tires, sellers lure the buyer with a low wear value, calling virtual percentages - 10, 20 or 30. In fact, the actual wear in the vast majority of cases turns out to be more than stated. Often this is not even due to the desire to deceive the buyer, but rather to an incorrect approach to assessing tire tread wear. But the main problem is not even the absolute wear of the tread, but its uniformity - it is the nature of wear that can say a lot about the past of the tire and whether it is suitable for further use. A correct assessment of tire wear is useful not only when buying used tires, but also when deciding whether it is time to replace the tires with new ones.

How worn is the tire?

What does the tire tread height indicate? The most common criterion by which the price is usually set and the consumer attractiveness of used tires is determined is the tread height. Height is certainly important, but you also need to understand that different tires have different tread heights initially (when they are new), and most importantly, different tires have different maximum wear heights (tread height at which the tire loses almost all important characteristics). These differences are most noticeable between winter and summer tires. Let's take two tires as an example, one is a summer high-speed rain tire, the other is a winter tire with a Scandinavian type of tread. The material from which summer tires are made is much harder than the rubber for winter tires; in addition (if we are not talking about summer off-road tires), for winter tires the tread height is much more important in terms of the ability to “catch” onto the ground covered with a layer of snow. In addition, for driving at high speeds on asphalt, the high tread is more of a hindrance than a help.

Based on these differences, a summer speed tire initially has a tread height of 6-8mm, while a winter tire with a Scandinavian tread pattern typically has a tread height of 9-11mm. It is clear that, other things being equal, a winter tire will wear out faster than a summer tire due to softer rubber and a smaller outer surface area of the tread blocks (which increases the load per unit of this area in the context of wear). From a safety point of view in the most typical seasonal conditions (dry hard surface), the most critical for winter tires is the presence and quality of transverse lamellas in the tread blocks (the so-called “Velcro”, which provide a reduction in braking distance and directional stability). In a summer tire, the main thing is simply the presence of tread, since reducing it to a certain level will simply reduce the tire’s ability to counteract hydroplaning. If we exclude extreme driving from the possible operating conditions of the car (and it will have to be excluded in any case when thinking about buying used tires), and also take into account the fact that the transverse sipes on winter tires cannot be technologically cut to the base of the tread and usually have depth of 4-5 mm, then the bottom line is the following: if a summer tire with 50% wear can still be considered suitable for use for some time, then a winter tire with 50% wear and a tread height of 5-6 mm, but with worn out lamellas, is actually no longer suitable for safe use in winter conditions, despite the higher tread height compared to summer ones.

How to calculate actual tire tread wear?

How to calculate the actual wear of a tire tread? What could be simpler, you ask? We divide the actual remainder of the tread height by its original height, and we get... But we won’t get anything like that, in fact, although sellers of used tires (at best) consider wear that way. But we won’t get it, first of all, because this formula would make sense only if you could “roll” the tire to “zero”, but this is impossible.

Tire manufacturers, as a rule, put signal marks in the tread 1.6 mm high, the achievement of which officially means that the tire is completely unsuitable for further use. Traffic regulations (TRAF) prohibit the use of tires with a remaining tread height of less than 2 mm. Driving on tires with less tread is not only illegal, but also extremely unsafe. And if we are talking about winter tires, then the real “zero” is even greater - 3-4 mm, depending on the type of tread and operating conditions.

Therefore, to determine the actual wear of a tire, you should use the formula:

Z is the actual tire wear percentage (note wear, not remainder!). The remainder as a percentage is 100-Z

Hn is the tread height of a new tire of a given model and size.

Hf – actual tread height (minimum based on the results of all measurements on both tires that are planned to be installed on one axle)

Hmin is the minimum permissible tread height for a given tire.

You will not always be able to find out what tread height was on the new tire of the desired model (Hn), therefore, based on the differences between different types of tires in the height of the new tread, to determine wear, you need to focus on the following average indicators:

1. For winter tires with a Scandinavian pattern (all-terrain tires, including studded ones) Hn = 10 mm. 2. For winter tires with classic and asymmetric tread, Hn = 9 mm. 3. For high-speed winter tires (tread pattern resembles summer tires) Hn = 7 mm. 4. For summer tires with a classic tread and increased resistance to aquaplaning (rain tires) - Hn = 8 mm 5. For high-speed summer tires Hn = 7 mm

To determine the actual tread height (Hf), you need to carefully measure both tires on the same axle and select the minimum tread height value from all those obtained. (read more about uneven tread wear).

Things are a little more complicated with the minimum permissible tread height (Hmin). The critical mark (absolute zero) is 2 mm from the traffic regulations, but this indicator is applicable only to summer tires, and even then not to all. A winter tire loses the absolute majority of its characteristics by 4 mm (on average). Therefore, your real minimum will be somewhere in this range - from 2 to 4 mm, depending on the type of tire, seasonality and your individual operating conditions. It is important to remember that you are buying tires for yourself, and therefore you will have to calculate wear and tear with some degree of subjectivity.

It is also important to understand that the method for determining the actual wear of a tire, given above, is intended solely for determining your individual advisability in purchasing a particular used tire, but not for making any claims to the seller - you will most likely never be able to convince him of that wear is considered as written here.

What does uneven tire tread wear indicate?

How to correctly measure tire tread height?

This is not difficult and any suitable device will do: for example, a caliper or a ruler with a depth gauge. You can, of course, use an ordinary coin, but in this case the accuracy of the measurements will suffer significantly, and you will not be able to get a reliable picture of the uniformity of wear, which is quite important. First of all, the tire tread height must be measured at at least 6 different points (preferably 9 or even 12), in the center and on both edges of the tread, at different points around the tire circumference. The measurement results at all specified points must match! Uneven wear indicates the following: 1. The tread is higher at the edges of the tire than in the center. This indicates that the previous owner was too frugal - the tire was overinflated for a long time. Accordingly, the load on the tire frame was increased, which obviously could not affect the overall service life of the tire. It is not recommended to buy such a tire. 2. The tread is higher in the center than at the edges. The tire was systematically underinflated. If there are no obvious signs of driving on a completely flat tire (the pattern has been erased from the top of the sidewalls), most likely, this tire can still be driven, but wear should be calculated according to the minimum tread height value, since at normal pressure the center of the tire will wear down to the edges very quickly . 3. The tread is worn unevenly across its width (one of the edges of the tire is worn out). Such wear indicates a faulty vehicle suspension (wheel camber adjustment). When you install such a tire on a working car, at first the tire will have very little grip on the road surface until the wear “evens out” across the entire width of the tire. This should happen quite quickly, but during this period you will have to exercise extreme caution - both directional stability and braking distance will be greatly affected. In any case, the wear of such a tire is calculated based on the minimum tread height. 4. The tread is worn unevenly around the wheel circumference (at different points on the circle, the central or side blocks have different heights). Such wear indicates the “extreme” preferences of the previous owner. The tire has most likely seen extreme braking and/or acceleration. Accordingly, such operation significantly changed the temperature conditions, which could affect the structure and condition of the rubber and tire carcass (the total service life of the tire). In addition, a tire with an uneven tread height around the circumference will necessarily have a static imbalance (which cannot be determined and eliminated on a tire balancing machine), which will negatively affect the safety and condition of the vehicle's suspension. This tire can be safely scrapped. 5. An erased pattern (pattern) in the upper part of the tire sidewall (the junction with the tread area - the rubber is “chewed”). Such a defect is the result of prolonged driving on a heavily deflated tire. In this case, as a rule, the power part of the tire frame is damaged and the tire acquires a strong static imbalance, which cannot be eliminated using balancing weights at a tire shop. In most cases, such a tire will make a lot of noise and create a significantly increased load on the wheel bearing. Of course, you can’t buy such tires, no matter what the seller says. 6. Different tread wear on two tires of a pair (from the same axle). First of all, in this case, you need to look at the production date of the tires, as well as the batch number (if indicated). If the dates are different, most likely this pair of tires was assembled from “spare tires”. Whether it is worth buying them is up to you to decide. If the dates coincide, there was probably a faulty suspension (wheel toe adjustment). In any case, a difference in tread height of more than 1 mm is already a serious threat of uncontrolled skidding if such a pair of wheels is installed on the front axle of the car.

Source www.drive2.ru

Many car parts have their own specific service life. These include tires. Manufacturers of automobile tires have provided the possibility of constant monitoring of their condition. For example, there is a special tire wear indicator for Nokian, Continental, Michelin and others. You need to constantly monitor them, otherwise you can end up in a very unpleasant situation.

How to use the wear indicator and when to replace a tire

Assessing tread wear using an indicator is quite simple and does not require any special skills. First of all, you need to find the position of the indicators using the icons on the side of the tire, and then use the indicator to assess the degree of tread wear.

In the case of a volumetric indicator, it is necessary to focus on the difference in the height of the tread and the indicator, and if they are equal, the tire should be replaced. Aligning the tread height with the intermediate indicator is not a signal that the tire needs to be replaced, but it does let the driver know that they should be careful and prepare for a tire change soon.

In the case of a digital indicator, you need to focus on the largest number embossed in the tread. So, if all the numbers on summer tires have been erased, except for “4” and “2”, then the tire can still be used, but you should prepare to replace it soon. The need to install new tires is indicated by the disappearance of the number “2” on summer tires and the number “4” on winter tires.

You cannot delay changing tires when they are worn out, as this is dangerous and, moreover, illegal. Therefore, it is recommended to periodically inspect tire wear indicators and replace them when critical wear occurs. This is the only way to avoid many of the dangers posed by “bald” tires and sanctions from traffic police officers.

Operation and resource

The durability and optimal performance of automobile tires largely depends on proper operation. Maintaining normal pressure in them is only a small part of the activities that need to be carried out with them. It should be noted right away that different tires have different service life.

The most durable tires are for winter use, while the flight or asphalt tire wears out the fastest. Over the course of its service life, the latter simply wears off on the road surface, like the heel of a shoe. Winter tires have a different purpose - to keep the car on ice and snow, and they become unusable due to the aging of the rubber, the appearance of cracks and the loss of studs (this is why studding of winter tires is recommended). In addition, the reasons for tire wear may be the following:

- Increased loads on the vehicle (exceeding the maximum weight)

- Low or high tire pressure

- Chassis and steering malfunctions

- Incorrect tire fitting

- Wheel imbalance

- Natural aging of rubber.

All these reasons, together or separately, can contribute to accelerated wear, which normally can range from 30 to 60 thousand kilometers. Of course, you can resort to new tread cutting, but such rubber will not last more than one season. In addition, regardless of mileage, the tire can be stored or used for no more than 10 years.

Tire wear indicator: its location and explanation

Hello everyone, dear motorists! Any normal driver strives to drive a car not only with the maximum level of comfort, but also safety. This criterion is directly influenced by the steering and braking system, as well as the quality of car tires. And we have already discussed which tires are better to buy, friction or studded, for the winter, and we talked about the advisability of buying all-season tires. The degree of wear plays an important role; in determining it, a tire wear indicator can be a good assistant - what it is and where it can be found, we’ll talk in today’s publication.

Traffic regulations

One of the key characteristics that is responsible for vehicle controllability and stability on the road is the tire tread height. Sometimes it is not possible to objectively assess this indicator by eye. In this case, a special indicator that is integrated into the rubber by the manufacturer will not help. It is the tread that provides high-quality traction between the wheel and the road surface, and it is especially important to monitor its degree of wear in bad weather. During and after rain, snow, and ice, the vehicle's contact with the road deteriorates significantly.

The traffic rules, for their part, regulate what the degree of wear should be, and clear quantitative indicators are provided for this:

- passenger cars - 1.6 mm;

- motorcycles - 0.8 mm;

- buses - 2 mm;

- trucks – 1 mm.

And in order to assess the tread height, we just need an indicator indicating tire wear. It is a part of the tread that differs in position, shape and size from the rest of the tire pattern. Most often, such an indicator is volumetric and placed in a groove. Another option is a digital beacon in the form of digital markings at different depths.

Main types of indicators

The simplest is a volumetric type determinant, which functions simply and clearly. As the tread wears off, it begins to compare with the height at which the beacon is located. This means that the tire must be replaced. Today, manufacturers equip tires with not only the main indicators, but also intermediate ones, so that the driver can monitor the wear of the pattern in advance and prepare for replacement.

The digital indicator on the tires looks somewhat different. Represents numbers extruded into the tire at a certain depth. The smallest number (usually 2) is at the greatest depth and vice versa. During operation, the tread will wear out, and the numbers themselves, accordingly, will disappear. As soon as the last one disappears, it means that the rubber has reached a critical level of wear. It is digital beacons that have become most widespread for the reason that they do not need to be deciphered, and even a child can understand their meaning.

Offers from well-known manufacturers

The Nokian wear indicator has its own distinctive feature: these are several numbers located in the center of the car tread. It is with their help that it is possible to determine the change in the height of the pattern on the rubber, which is measured in millimeters. This manufacturer can additionally place a snowflake icon, which allows you to determine the nature of wear in the winter season. As soon as the designation disappears, that is, “is eaten up,” the car tires must be immediately replaced with new ones, since they will no longer provide the same contact on a snowy road surface.

The bridgestone indicator is somewhat different from it. There are arrows in several places on the outside of the rim. When they disappear, it means that the tread has reached its critical point, that is, its height does not exceed 1.6 mm. Winter tires have an additional indicator in the form of a ribbed protrusion. It is applied in 4 places on the tires, which are equally spaced from each other.

Let's consider what the Michelin manufacturer offers its customers. To do this, you need to find any of the marks on the side of the tire. This can be a brand logo, a TWI icon, or a triangle image. The TWI icon tells us where to look for the indicator itself, which characterizes the degree of tire wear.

As soon as the wheel tread height begins to approach a dangerous value, the driver needs to take action. If you neglect this rule, the length of the braking distance of the car increases. And this threatens with increased accident rates. Experienced drivers always pay attention to the wear indicator values.

So we tried, friends, to determine where exactly the indicator is located, which monitors the degree of tread wear on car tires. Do not forget to also maintain the required pressure in the wheels of your car. Now you have all the necessary knowledge to independently determine the moment when you need to go to the auto shop for new wheels. Well, we’ll say goodbye for today, read the blog in the next issues and bye!

Sincerely, blog author Andrey Kulpanov

Place for contest advertising

Author:Andrey

avto-kul.ru

Types of wear

When a car moves, a whole complex of multidirectional forces acts on its wheels, and they differ depending on which wheels they are - steered or driven. In the first case, the edges of the tire wear out, in the second - in the middle of the tread. That is why, in order to wear tires more evenly, it is recommended to change them at least once a season.

Uneven one-sided wear is most often due to incorrect wheel alignment angles or defects in the steering, due to which the contact patch is shifted to the side.

Bilateral and central abrasion occurs from incorrect pressure - in the first case it is low (the tire is flattened), in the second it is high (the tire is overinflated).

Local defects and spots on the tires can be caused by improper wheel balancing, as well as from harsh driving with frequent acceleration with slipping and braking with wheel locking.

What affects tire wear?

No matter how high-quality a tire is, it will wear out over time and will need to be replaced. But it’s one thing when it lasts for a completely normal period, approximately coinciding with , and the wear is uniform (along the entire circumference of the working surface), and it’s quite another thing when the tire doesn’t last even half of its declared life, and its wear is uneven. And here it’s more about the financial part, since changing tires every season is quite an expensive pleasure.

The service life of a set of tires depends on a number of factors:

- quality of manufacturing materials;

- technical serviceability of the car;

- operating features;

As for the material of manufacture, everything is clear here. Tires made of low-grade rubber with a high soot content will wear out the tread very quickly, and cord breaks are possible, since the material itself is simply not able to withstand the loads that fall on the wheels.

The technical serviceability of some components seriously affects the service life of the tires. Such components include the suspension, brake system, and steering mechanism. Malfunction and violation of adjustments of each specified component will certainly lead to uneven wear. This also includes the technical condition of the wheels themselves - mismatch, imbalance, long-term parking of a car without moving - some of the main reasons for uneven and rapid wear of the tread.

Video: Uneven tire wear.

As for the characteristics of operation, the condition of the tires can be affected by an aggressive driving style with frequent slipping, inconsistency in the type of tires for the season (especially if winter tires are used in the summer), frequent or constant trips on roads covered with gravel and crushed stone.

It is worth noting that tire wear also depends on the axle on which they are used. If this is the case, then the side zones of the working surface are more erased. All this is due to the fact that when the trajectory of movement changes (when turning), all the forces acting on the wheel lead to deformation of the tire, as a result of which it comes into more contact with the side surfaces of the tread rather than the central one. As for the drive axle, it has nothing like that; on the contrary, its main contact patch is in the middle of the tread.

In front-wheel drive cars, all this is combined, so the wear of the front tires is more even, but their tread wears off faster than that of wheels mounted on the rear axle.

Since traffic safety, vehicle handling, and braking distance depend on the condition of the tires, they should be periodically inspected for defects, and also the depth of the remaining tread should be checked.

It is noteworthy that uneven tire wear has its own specific reasons, so it is not difficult to determine what caused this. But the wheels themselves cannot be restored, so all the measures taken will help preserve the tires that will replace the damaged ones.

How to determine tire wear

Let us assume that the tire tread surface does not have the above defects. How to determine the degree of wear? The easiest way is to measure the remaining tread height. Approximate values are given in the table (depending on the manufacturer).

Tread height is measured with a ruler or caliper. Measurements are taken at several locations around the circumference and the average value is calculated. All wheels are measured.

But there is an even simpler and more visual way - using a tire wear indicator.

What level of tire wear is considered acceptable?

The maximum permissible level of tire wear is determined by the legislation in force in Russia. The permissible remaining tread depth of a summer tire is 1.6 millimeters, and that of a winter tire is 4 millimeters. However, experts strongly recommend changing tires before reaching the minimum value. Otherwise, the wheels cannot provide the required level of safety. After all, worn tires are at greater risk of puncture and aquaplaning; in addition, they increase braking distance and reduce vehicle stability on the road, especially in winter weather conditions.