Fuel rail for Lada VAZ 2114 2001-2013, 1.5L, 8V with injectors

Fuel rail for Lada VAZ 2114 2001-2013, 1.5L

Fuel rail for Lada VAZ 2114 2001-2013, 1.6L

It is most difficult for novice motorists to monitor the condition of their car. They do not yet know the main signs of failure of its parts and often miss the first manifestations of malfunctions. The manufacturer installed a weak fuel pressure regulator on the VAZ-2115. Therefore, it is important to learn how to check it and replace it.

Why is this device needed?

The regulator, responsible for maintaining normal fuel pressure in the system, is in direct interaction with the power unit. According to its location, it can be located in the fuel tank or in the rail (this is where you will be able to find the regulator if you have an injection VAZ-2115). The reason for the failure of this element is often the low quality of gasoline. If you fill up at gas stations with greatly reduced prices, then it is not surprising that very soon the regulator will fail.

The fuel flows through the injectors to the intake manifold, and it is important that its pressure does not change at this moment. The regulator measures the volume of fuel required for engine operation, and also monitors the pressure in the fuel rail and intake manifold.

The main task of the RTD is to maintain the pressure difference at the same level, as well as monitor the indicators.

Fuel rail VAZ 2114

The fuel rail is used to install injectors on it. It is a tube or a hollow bar, the ends of which are welded on both sides. It is attached to the intake pipe on the manifold using two bolts.

Fuel rail VAZ 2114

The pressure in the fuel rail of the VAZ 2114 in front of the injectors is maintained by a fuel pressure regulator. In this case, the fuel pressure must be higher than the pressure in the intake manifold, otherwise fuel will not be injected from the injectors and create a mixture. At the fuel rail, the pressure must be maintained within strictly limited limits - from 2.9 to 3.3 kg/cm2.

It is necessary to measure the pressure in the fuel rail if problems arise with the fuel system. Before work, make sure that the vehicle is sealed, there are no microcracks or leaks, otherwise the pressure gauge readings will be unreliable.

- Insert a pressure gauge into the end of the prepared hose and secure it tightly using a clamp.

- On the fuel pressure fitting, which is located at the free end of the ramp, unscrew the plastic cap. He closes the nipple.

- Place an empty bucket to collect gasoline, press the nipple and release any remaining pressure in the rail.

- Do not remove the bucket, unscrew the nipple.

- Place the free end of the hose onto the fitting and tighten the clamp onto the free one.

- Tighten the clamp on the fitting to avoid leakage.

- Pump fuel into the ramp using a fuel pump.

- Start the ignition, check the pressure gauge readings. As a rule, it is 2.9-3.1 kg/cm2, but not less . If the reading drops to zero, then the pressure regulator or pump check valve has failed.

- Now check at idle speed. Start the engine, look at the pressure gauge readings. The norm is an indicator of at least 2.5 . If pulsation occurs and the sensor rises and falls by 0.2, then the coarse filter should be cleaned.

- Before checking the rail pressure to inspect the RTD, remove the vacuum hose that comes from the exhaust manifold. In this case, the pressure should become 3.0-3.3. If no changes occur or they are minimal, then most likely the fuel pump has failed.

- Turn off the return line and check the pressure under such conditions. Pinch the return hose from the RTD to the tank with pliers. Then the pressure increases to 6-7. If the readings are lower, then the pump is worn out. An indicator of 4.0 indicates the need to clean the pipeline and fine filter.

Main symptoms of a malfunction

Problems with the regulator can manifest themselves in various ways:

- reduction in engine power (you can notice this when driving downhill or during acceleration);

- problems with starting the power plant (the starter rotates, but the engine does not start);

- Unstable engine operation at idle (you may often stall at intersections).

Even an inexperienced car user can notice these failures. It is important to diagnose your car in a timely manner so as not to spend money on fixing more serious breakdowns later. If you detect these signs in time, you will be able to carry out the repair yourself. Otherwise, you will have to evacuate the car to a service station.

When can fuel consumption increase?

It is worth paying special attention to such a sign of a regulator malfunction as increased fuel consumption. The car will require more gasoline to operate if the valve in the regulator is faulty or, conversely, it does not hold fuel. In the first case, excess fuel is not returned to the tank; the car owner may notice a pressure above 2.5 kg/cm2. As a result, more gasoline enters the combustion chamber of the engine, which is not completely consumed.

If the valve does not perform its functions, fuel “staggers” through the system. The pressure in the fuel system decreases, and as the speed increases, the engine feels a clear shortage of gasoline. The power unit becomes less responsive and powerful. A valve malfunction can be noticed when starting the car for a long time - during the process, the starter has to be turned for a long time until it creates the necessary pressure.

How much does a ramp cost for a VAZ 2110?

This product was chosen by 3 customers

Fuel rail is a part of the intake manifold in which gasoline and gas are mixed in a ratio of 1 to 15 (an increase or decrease in the amount of gas can be adjusted manually, but the optimal gasoline consumption is observed precisely at the above ratio). Next, the mixture is supplied to the injectors, after which it enters the combustion chambers.

Attention! When ordering, in the “Order Comments” line, indicate the model and year of manufacture of your car.

Weight, kg: 0.65 Dimensions, cm: 41 x 5 x 4 Volume, m3: 0.00082

How to properly check RTD

In order to independently check the pressure in the system, and therefore the correct operation of the regulator, you need to take a pressure gauge, the maximum pressure in which is up to 10 atmospheres. You should not use a device with a larger scale, as its readings will have a serious error. It connects between the fitting and the fuel pipe:

- first turn off and cool the engine;

- locate the fuel rail under the hood;

- remove the plug from the fuel pressure fitting;

- unscrew the fitting nipple using a spool valve;

- wipe the surfaces if fuel splashes appear under the influence of residual pressure;

- pull a hose with a diameter of up to 9 millimeters onto the fitting and secure it with a clamp;

- Connect the second hole of the hose to the pressure gauge.

Next, you will need an assistant, because the readings from the pressure gauge need to be read at one of four moments:

- when the ignition is turned on, the pressure should be 3 atmospheres;

- at idle speed - 2.5;

- when squeezing the fuel outflow hose - 7;

- with the hose removed on the RTD – 3.3.

If on your VAZ-2115 the measurements show different indicators, then you need to replace the regulator with a new one. To do this, it is enough to detect it in the system, dismantle it, and then return the fuel line to its original state. In the VAZ-2115, the engine of which has 8 valves or another system, the RTD is mounted at the very end of the fuel rail.

It is important to check the integrity of the fuel system. If leaks are detected in it, then the pressure gauge readings should not be trusted. After checking under different conditions, it is worth turning off the engine and looking at the pressure gauge again; the pressure should be within 0.7 atmospheres. If the pressure drops completely, then the problem is definitely in the regulator.

Remember that a regulator will cost you much less than a large-scale repair of the fuel system or engine. It is precisely such global breakdowns that a failed RTD can lead to. The cost of this spare part is from 500 rubles. The final price of the repair depends on which manufacturer’s spare part you purchase. The cheapest parts are stock parts produced in Togliatti, and the most expensive are BOSCH components.

If you look at the fuel system of a modern car, you can state the fact that it is a complex mechanism that requires qualified care and maintenance. This system includes:

- Fuel reserve tank;

- Fuel sensor VAZ 2114;

- Fuel pump;

- Gasoline fine filter;

- Pipeline system for gasoline supply;

- Ramp with nozzles;

- Fuel pressure control.

In case of violations or failures of one of the elements of the fuel system, interruptions in the operation of the engine begin, or even its complete stop. To guide you on what to do in such cases, in particular, let’s consider the operation of the fuel pressure regulator on the VAZ 2114.

The principle of operation of the main elements of the fuel unit

Video Replacing the cabin air filter on a VAZ 2114 VAZ 2115 VAZ 2113 Lada Samara 2

Fuel system VAZ 2114

Container for storing flammable materials

It is made of steel, consists of two firmly welded parts, the neck through which the fuel enters is connected to the tank with a rubber pipe and secured with clamps.

Gasoline pump

This tool with an electric mechanism is located in a tank with a fuel mixture level indicator. Its actions are coordinated by the engine control box, through a special pump relay, which supplies fuel through the line to the injectors. At idle or when the engine is completely turned off, the pressure is maintained due to the action of a one-way lock, which is located near the unit itself.

The VAZ 2114 power system has a fuel pressure regulator and injectors. The voltage is supplied to them from the battery through the main relay. Thus, the amount of driving fluid is indicated by the duration of the pulses, which are generated by the engine control unit and transmitted to the injectors.

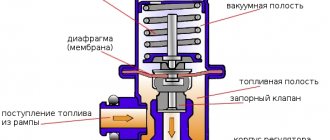

Ramp

Located on the intake manifold, it includes a fuel control element and a pressure valve with a spring-loaded diaphragm. It, in turn, divides the regulator body into 2 parts: the fuel part regulates the pressure of the combustible mixture, the air part, due to the rarefaction of the air, raises the membrane and produces constant fuel pressure readings in the rail.

When the engine starts, the vacuum behind the damper decreases, the diaphragm closes the power system valve, so the pressure increases. When the vacuum is maximum, then the fuel pressure decreases. The regulator is not dismountable, so if it fails, it is replaced with another one.

Fuel mixture control sensor

The pump module has a float, which is located in the tank cavity. When the position of the float changes, the resistance of the unit changes proportionally. According to a certain signal, the fuel quantity indicator on the dashboard displays the presence of fuel in the system.

Why does the sensor often fail?

- fragility of the case;

- frequent temperature changes;

- condensation formation in the tank;

- when using a low-quality combustible mixture;

- oxidation of contacts when sealing is broken.

That is why it is so important to carry out preventive maintenance on time, clean the unit, change contacts in order to prevent its destruction. Changing a device is not so easy

Many markings are original and unique, which means that the services of professionals will be required, which are also not cheap.

Hoses and pipelines

Such irreplaceable products guarantee uninterrupted circulation of flammable liquid from the container to the main line and nozzles, and if there is excess, they transfer the residual liquid back to the tank. The pipelines are located on the bottom of the vehicle, they need to be carefully checked, cleaned, inspected for integrity, various deformations identified and promptly eliminated in order to avoid fuel leakage, as well as poor transmission to the injectors.

Another function of the pipelines is the transfer of fuel vapor from the tank to the activated carbon section, where waste is collected when the engine is turned off. After it is started, the electromagnetic device is triggered and the vapors escape into the engine, where they are destroyed.

Highway

The design of the VAZ 2114 fuel system includes a main line that guarantees the supply of fuel to all injectors. Today, the fuel pressure regulator is placed in the tank and is not located on the line; there is also a service valve, which performs the function of eliminating air after a technical inspection of the vehicle.

The fuel injection system of the VAZ 2114 includes an uninterrupted mode for collecting fuel vapors, and the gravitational unit located in the device helps prevent fuel from leaking when the vehicle is in an emergency position.

When the engine's air consumption is high, the system is purged more intensively. The filter element is made of durable paper material, after which the air moves through the mass air flow sensor and moves into the intake hose, which leads to the throttle assembly.

Thus, the operation of the fuel fluid supply mode of an engine with a fuel injection system on a VAZ 2114 car occurs.

A LITTLE ABOUT THE OPERATION OF THE FUEL SENSOR

The latest developments by the designers of the automobile plant in Togliatti have brought the produced models closer to the best European models, but annoying, minor breakdowns can add “a fly in the ointment.” These fully include problems with the gasoline level sensor in the car tank.

It is located in the same block as the fuel pump. It includes a movable lever with a float, a resistor and a contact group, which turns on the signal lamp for the gasoline reserve in the tank. Among the most common malfunctions of this unit, the most common are problems such as resistor breakage, oxidation of the moving contact or output terminals. It is very rare that the float in the fuel level indicator loses its seal.

In any case, to repair or service this unit, it must be removed from the fuel tank. To perform this work, remove the rear seat cushion and upholstery that blocks access to the gas tank cap. When performing this operation, do not forget that you are working with a flammable substance. Fire safety rules must be strictly followed.

Unscrew all the screws securing the cover, move it slightly forward and remove it from the fuel tank. Before removing the fuel block, it is necessary to relieve the pressure in the fuel line. There are several ways to do this, and the simplest of them is to leave the car idle for about 4 hours.

Disconnect the wires and fuel line from the module, being careful not to spill any remaining gasoline in the hoses. You need to pull out the fuel pump carefully so as not to damage the float. Replacement of the fuel sensor is carried out using a screwdriver with a thin blade.

How does this happen:

- Use a screwdriver to move the locking ring and make it possible to remove the cover from the fuel module;

- Remove all the wires, release the latches on the cover and remove the sensor itself along the grooves;

- The next step is to remove the meter from the block.

To install a new fuel sensor, everything must be done in reverse order.

OPERATIONAL CHECK

Let's briefly look at the question of how to check the fuel pressure regulator of a VAZ 2114. This fully applies to the VAZ 2113 and VAZ 2115 models. On carburetor engines, the gasoline supply could be checked by disconnecting the fuel hose from the carburetor to see the stream of gasoline supplied. On injection engines this technique is no longer acceptable. The VAZ 2114 fuel pressure regulator is checked by measuring the pressure of the supplied gasoline with a pressure gauge.

Let's look at how to check the fuel pressure regulator yourself in some detail:

- The plug on the fitting is unscrewed, and at the same time the ring that serves as a seal is checked for elasticity;

- The spool valve is unscrewed from the fitting in much the same way as from a tire;

- The pressure gauge is secured to the fitting with a clamp and the generated gasoline pressure is checked in different modes.

Gasoline pressure indicators are marked on the RTD body for comparison with the results obtained during testing. If the readings differ from the recommended ones, the VAZ fuel pressure regulator must be replaced.

How to clean injectors on a VAZ 2114 - instructions

Method for testing and adjusting injectors and a stand for testing and adjusting injectors

Hello dear readers! In today’s article I want to talk about how to clean the injectors on a VAZ 2114 yourself. First, a little theory.

VAZ 2114 engine power supply system.

In the photo pos. Figure 2 shows a VAZ 2114 fuel rail on which four injectors are installed, position 1, which actually need to be cleaned.

Here is a photo of the dismantled fuel rail and injectors:

When should injectors be cleaned?

It is recommended to clean the injectors if:

- the engine is unstable,

- fuel consumption has increased,

- there are misfires at idle,

- The car's dynamics have deteriorated.

How to remove injectors on a VAZ 2114?

On different cars, injectors are removed in different ways, however, as a rule, the principle is the same.

- First of all, disconnect the battery.

- Next, unscrew the two 5mm hex screws.

- Using the fitting plug (located on the left of the ramp, pos. 3), release the pressure.

- Each injector is secured to the fuel rail with a latch. Remove all injectors.

This process is described in more detail in the video.

https://youtube.com/watch?v=H55y5s0mBEw

And so the injectors are dismantled, now you need to check them.

Injector diagnostics.

To diagnose the performance of the injectors, you will need a multimeter, which must be turned on in resistance measurement mode up to 200 Ohms. Insert probes between the contacts and take readings.

The resistance of a working injector should be somewhere from 11 to 15 ohms. If your injector is broken, or the resistance is much higher, then I advise you to replace it.

Do-it-yourself cleaning of VAZ 2114 injectors: instructions.

After checking the injectors, start cleaning. To do this, you need to assemble the following circuit. Two contacts are output from the battery in series through the lamp, then through a switch (microphone or non-latching button). These two contacts connect directly to the injector.

Here's the diagram:

The question arises of how to connect to the nozzle; you need to know the polarity of the nozzle itself. On some injectors, the polarity is indicated on the body with a plus sign, on some, the polarity is not indicated. In such cases, it is necessary to install the fuel rail as shown in the photo.

Then the left terminal from you will be a plus, and the right one will be a minus.

How to clean injectors?

For cleaning, use ABRO CARB & CHOKE CLEANER cleaning solution (carburetor cleaner).

Many sites describe cleaning methods using all kinds of adapters, hoses, etc., everything is much simpler.

- Remove the top of the carburetor cleaner can.

- Insert the valve-spray system of the can into the nozzle.

- Connect the two contacts of our circuit to the injector contacts. Press down on the nozzle installed on the can. For one or two seconds, use the switch to activate the circuit so that the nozzle starts working (it is not recommended to hold it for more than two seconds at a time).

Important: Be sure to follow safety precautions. Spray strictly away from yourself, take care of your eyes, use protection! For more information on cleaning injectors, watch the video.

For more information on cleaning injectors, watch the video.

ABOUT REPLACING RTD

Replacing the VAZ 2114 fuel pressure regulator is carried out with the engine cooled down and the pressure in the fuel system removed. Let's look at how to remove the fuel pressure regulator. To do this you need:

- Disconnect the battery terminals;

- Remove the brake booster hose;

- Unscrew the nuts on the gasoline drain pipe. In this case, you must carefully unscrew the nut and hold the hose. There may be gasoline left in the system ;

- It is necessary to securely fasten the washer and tube;

- After unscrewing the bolt installed on the clamping bar, remove it;

- You should slightly loosen the nut holding the regulator and drain tube;

- Remove the screws that connect the RTD and the ramp;

- Remove the nut with care and you can remove the RTD with the ramp.

The new regulator is installed on the fuel rail in the reverse order.

The operation of replacing the regulator will not pose any particular problems for experienced car enthusiasts, but if there is even the slightest doubt about your competence, it is better to turn to specialists.

Pressure regulators today do not belong to the category of particularly scarce spare parts. You can purchase them in retail chains, car markets, and service centers. The cost of the regulator can range from 500 to 700 rubles.