Why is the suspension called dependent?

The definition of the term contains the main feature of the mechanism - a rigid connection between the wheels of the same axle. Any change in the spatial position of one of them will necessarily affect the second. That is, the wheels are dependent, which somewhat simplifies the design, but does not always have a beneficial effect on the characteristics of the suspension.

Principle of operation

Like any other type of suspension, dependent includes:

- elastic elements in the form of coil springs, leaf springs, or more exotic devices that are quite rare on passenger cars;

- vibration dampers, usually hydraulic shock absorbers of the telescopic type;

- a guide device that maintains the wheel alignment angles more or less unchanged during the suspension's compression and rebound strokes.

When one of the wheels hits an obstacle, the second, located on the same axis, due to its connection with the first through a rigid beam, begins to change its camber angle, maintaining toe.

In this case, the contact patch shifts, its shape and area changes, which is very undesirable from the point of view of controllability at high speed. To weaken this effect, various technical tricks are used, but it is impossible to completely avoid it.

Design and diagram of dependent suspension

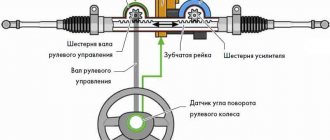

There are different dependent suspension schemes for driving and free axles of a car. In this case, any axle can be steered, but the steering drive does not affect the operation of the suspension and does not belong to its components.

The dependent suspension of a non-driving axle looks the simplest. Most often, this occurs on trucks, since similar designs on cars are a thing of the past, and on off-road vehicles, to which the folklore name of jeeps has been assigned, all axles are drive axles.

The free bridge is a fairly powerful forged profiled beam, at the ends of which wheel hub units with bearings and brake mechanisms are mounted.

Springs or springs can be used as an elastic element. In the first case, the sufficient strength and rigidity of the leaf spring packages in the longitudinal and transverse directions makes it possible to do without other parts of the guide vane, since the vertical spring has the necessary elasticity.

The drive axle with dependent suspension is designed in approximately the same way. Sometimes it is also called continuous. It is no longer a channel, but a hollow pipe with a housing (often called the “apple”) of the gearbox.

Rigid axle shafts go from the gearbox through the beam pipes (stockings) to the wheel hubs. If the axle is simultaneously steerable, then the axle shafts are connected to the hubs through CV joints - constant velocity joints, which allows the wheels to change the position of their plane of rotation during a turn.

A driveshaft fits to the axle hub. The suspension of the entire beam with gearbox and wheel units is similar to the non-driving axle. The same springs, springs and shock absorbers.

Types of independent suspensions

McPherson

- the most common front axle suspension of modern cars. The lower arm is connected to the hub via a ball joint. Depending on its configuration, longitudinal jet thrust can be used. A shock absorber strut with a spring is attached to the hub assembly, its upper support is fixed to the body.

The transverse rod, attached to the body and connecting both levers, is a stabilizer that counteracts the roll of the car. The lower ball joint and shock absorber cup bearing allow the wheel to turn.

The rear suspension parts are made according to the same principle, the only difference is that the wheels cannot be turned. The lower arm has been replaced with longitudinal and transverse rods that secure the hub.

- simplicity of design;

- compactness;

- reliability;

- inexpensive to manufacture and repair.

- average handling.

Double wishbone front suspension

More efficient and complex design. The upper mounting point of the hub is the second wishbone. A spring or can be used as an elastic element. The rear suspension has a similar structure. This type of suspension design ensures better vehicle handling.

Air suspension

Air suspension

The role of springs in this suspension is performed by air cylinders with compressed air. It is possible to adjust the height of the body. It also improves ride quality. Used on luxury cars.

Hydraulic suspension

Adjusting the height and stiffness of the Lexus hydraulic suspension

Shock absorbers are connected to a single closed circuit with hydraulic fluid. makes it possible to adjust the rigidity and ride height. If the car has control electronics, as well as functions, it independently adapts to road and driving conditions.

Types of dependent suspensions

Depending on the elastic elements used, the entire suspension scheme changes. Additional complication begins when designers strive to minimize the impact of the inherent shortcomings of a dependent suspension or increase its strength and load-carrying capacity.

On longitudinal springs

The most common design for trucks and other vehicles of the mid-20th century. Typically, semi-elliptical type springs are used, replacing the previously used full spring ellipses on carriages and early automobiles.

The spring is an arc-shaped set of sheets of spring steel, assembled into a package using clamps. Sometimes there are plastic anti-squeak washers between the sheets. They also reduce unwanted friction between the sheets, which reduces comfort on small uneven surfaces. The spring is attached to the bridge beam using U-shaped stepladders secured with nuts.

On off-road vehicles, in order to maximally raise the body above the road, springs can be located on top of the beam, but the design where they are located under it has become typical. This makes the car more stable due to a lower center of gravity.

Differences between dependent and independent suspension

In an independent suspension there are no connections between the wheels; each can move only within the limits set by its guide vane.

At the same time, its structure is much more complicated, since this device does not have common parts for the left and right sides, which means a lot has to be duplicated. But for passenger cars this is not so significant; they do not require a large margin of safety, which means the parts can be small in size and weight.

As for jeeps, there are constant debates about the desirability of one scheme or another. And this mainly concerns issues of ensuring clearance. With a dependent suspension, it is always constant under the beam and does not depend on the wheel travel. Only the clearance under the bottom or frame changes.

Independent allows you to provide no less than its value, but the clearance will change when the springs are compressed or unloaded. Which is better is a moot point. In addition, it is believed that continuous bridges are stronger and more durable, especially with inevitable contacts with the surface in deep ruts.

Dependent or independent suspension - what to choose?

Manufacturers install two types of suspensions on modern cars - dependent and independent. Many car enthusiasts do not think about the difference between these types of structures. At the same time, very important characteristics directly depend on the characteristics of the suspension: handling, smoothness, comfort, etc.

What is the difference between dependent and independent suspensions and what advantages do they have over each other?

Advantages of dependent suspension. Budget crossovers are mainly equipped with dependent suspensions; one of the most striking examples is the UAZ model, which will be updated in the near future. The drive can be rear or front, since the suspension is now attached to the rear wheels.

Among the advantages of dependent suspension are:

- Strength,

- Protection of the components that drive the wheels

- tightness,

- Moisture protection

- CV joint boots do not break often.

Among the disadvantages of such equipment, we can only note the rolliness, since the tires of such cars do not operate at optimal angles when driving off-road and in potholes, of which there are a lot in Russia.

Advantages of independent suspension. As a rule, independent suspension is installed on premium cars, which immediately suggests reliability. It is worth noting that cars with independent suspension are sold with both front and rear wheel drive, and the variations allow you to choose a car with good performance.

As an advantage, independent suspension gives the car greater controllability and the ride becomes smoother. The contact area between rubber and asphalt remains optimal, and passengers and driver can enjoy a higher level of comfort.

This configuration option is ideal for driving on city streets; off-road it will not be so advantageous. Therefore, before choosing a car, it is worth considering exactly where the owner plans to drive: in the city or off-road.

Bottom line. Most modern drivers prefer to overpay, but get a car with independent suspension, because it provides a high level of comfort for passengers and the car owner, controllability and a smooth ride.

However, such characteristics will be more suitable in urban conditions, but off-road it is better to drive with a dependent one. It is well protected from moisture and is not afraid of dirt. It is not surprising that the UAZ, equipped with a dependent suspension, occupies a leading place in popularity among motorists who are interested in fishing and hunting.

- Experts explained why renting a car has become more profitable than buying

See all photo news >>

Advantages and disadvantages

The advantages of dependent suspension include:

- simplicity and low cost in production, maintenance and repair;

- high strength, especially in the version with springs; a good spring is difficult to break precisely because it is flexible;

- off-road endurance, first of all, the steel beams of the bridges will come into contact with the road, and not the body, frame and other units;

- stability of ground clearance, since it is determined by unsprung beams.

There are also plenty of negative sides:

- significant unsprung masses, which makes it impossible to ensure a smooth ride with a small body weight;

- inability to obtain acceptable stability and controllability at high speeds;

- blurred reactions to the driver’s actions, which greatly removes his sensations from the actual behavior of the wheels on the road;

- the impossibility of obtaining the effects of useful steering and programmable changes in other wheel alignment angles during suspension travel.

All this imposes restrictions on the use of these types of suspensions.

Concept of suspension

Before talking about the pros and cons, as well as the superiority of one suspension over another, if possible, I propose to understand the essence of the concept of suspension.

A suspension is a component of a car that is part of the chassis. This is an intermediate link located between the road surface and the body part of the vehicle chassis. The work of the suspension is to convert into elastic movement all the impacts that the wheels of the car have to face while driving. And these are all kinds of bumps, holes, unevenness, etc. That is, the suspension absorbs energy from impacts and increases the smoothness of the ride.

In this case, a distinction is made between the design of the front and rear suspension. They can be divided into several categories. At the same time, all structures are subject to the same requirements.

The car suspension must keep the car in a horizontal position, regardless of the acting forces, and dampen vibrations. Plus, the structures must be elastic, strong and as durable as possible. Otherwise, expensive repairs will be required.

The current classification provides for the division of pendants into 3 categories.

- Dependent. It comes with longitudinal and transverse springs, it can use guide arms or a thrust pipe. Also distinguished are the torsion-lever design and the De Dion type system;

- Independent. Such systems differ from each other in the use of oblique and double wishbones located transversely, and may have swinging axle shafts. There are options with double and single trailing arms and transverse ones. But still the most popular option is the MacPherson type suspension;

- Active or semi-dependent. Here the rigidity and position change depending on the command given through the control device. Active systems are divided into pneumohydraulic, hydraulic and pneumatic.

But this is objectively not enough to understand what the difference is between them, what differences exist and which type of suspension travel is preferable in terms of comfort. You can also read useful material about checking shock absorbers for performance.

Dependent constructs

First, let's define what it is and what the concept of car suspension dependence means. In simple terms, this is a pair of opposite wheels (left and right), which are rigidly connected to each other using a single beam. This is one of the key ways to distinguish designs from each other. Just take a look at how the left and right wheels connect to each other.

We recommend: How to determine the polarity of a battery: forward or reverse?

When the impact on one wheel begins, the position of the second changes. The dependence of one wheel on the other explains the name of the design. Such units are more focused on vehicles that are operated in rather difficult operating conditions. Dependent suspension is extremely rare on ordinary passenger cars designed for city driving. Therefore, finding a car is not so easy if you just need a passenger car. But the system is still in demand and is finding its place in the auto market.

Dependent auto suspension components have strengths and weaknesses.

Let's start with the shortcomings. There are several main points worth highlighting here:

- worse sustainability indicators;

- insufficiently clear controllability;

- reduced level of comfort;

- high requirements for road surfaces when driving at high speeds;

- low information content of management.

All this when compared with cars equipped with an independent type of suspension.

The weaknesses are quite significant, and are more pronounced on ordinary roads. But if you drive into ideal conditions for such a suspension, the car will show its maximum.

It is in the element of the dependent structure that its true advantages are revealed. Namely:

- Low cost of maintenance. Maintenance and repair (maintenance and technical work) are quite cheap, which allows you to significantly save on repairs;

- Resistant to damage. This suspension is not afraid of impacts, active driving on bad roads, etc. The design behaves well under heavy loads;

- High strength. Independent suspension is not a competitor in this regard;

- Constant ground clearance. The clearance does not change, which provides a number of advantages;

- Excellent adaptation to off-road and bad roads;

- A small number of design components, which simplifies maintenance and makes repairs more affordable. This also directly affects reliability.

As you can see, in its element, the dependent system allows you to count on a solid list of advantages. But on regular roads everything is not so perfect.

Independent suspension

Unlike the previous design, here the opposite wheels do not have a direct structural connection with each other. Each of the wheels acts and works independently relative to each other.

Such units perform well when driving on highways, in the city, and behave excellently at high speed. Therefore, independent designs are found mainly on passenger cars, crossovers and SUVs.

We recommend: Coolant temperature sensor (TES): characteristics, principle of operation, symptoms of malfunction, replacement

This also has its strengths and weaknesses. Benefits include:

- excellent grip on the road surface;

- excellent level of comfort;

- excellent handling;

- minor deviations along the longitudinal axis.

All this affects comfort, agility and handling. Dependent suspensions are not capable of this.

But don't jump to conclusions about the superiority of the independent system. It also has disadvantages:

- repairs are much more expensive, as is maintenance;

- the lever stroke is short, which may reduce ground clearance;

- the design consists of many components;

- due to the complexity of the layout, the likelihood of breakdowns increases;

- It is almost impossible to carry out repairs in the field.

If we take an initially high-quality independent suspension as a basis, and operate the car in the conditions for which it is intended, all these shortcomings will not be so obvious.