How to check engine compression?

Measuring tools

In order to measure engine compression you will need tools such as:

- compression gauge

- wrench for unscrewing spark plugs or injectors

- syringe

- machine oil (30-20 ml)

Before measuring engine compression in the cylinders, it is necessary to correctly set the clearances in the cylinders; the measurement results depend on this.

How do you know if the engine is decompressed?

Factors that indicate that the motor is decompressed:

- Gray smoke pours out of the muffler.

- the car mercilessly “eats” engine oil;

- fuel consumption increased;

- the engine does not pull;

All of the above factors indicate that the piston rings are badly worn. The cause of piston ring wear was loss of elasticity and burning in the piston grooves. Piston rings are responsible for ensuring tightness between the cylinder and pistons, preventing oil from entering the combustion chamber, and gases from entering the crankcase.

Methods for checking engine compression

There are two methods for checking engine compression:

- manually (the result will be approximate)

- precise measurement (using a compression gauge)

Of course, measuring engine compression using an accurate method requires some skill, but there is essentially nothing difficult about this process.

How to measure engine compression with your own hands?

So how do you measure engine compression manually?

- To do this, first of all you need to unscrew the spark plugs (we do not unscrew the spark plug of the first cylinder).

- Next, we turn the engine crankshaft until the compression stroke ends in the first cylinder (look at the coincidence of the marks).

- Now we screw the spark plugs into the other cylinders and turn the crankshaft.

- By comparing the forces applied to crank the crankshaft, you can understand which cylinder has low compression.

How to measure compression using an accurate method?

So how can you measure engine compression using an accurate method?

- Checking engine compression using a precise method is carried out on a hot engine.

- First you need to start the car and warm it up to the desired temperature.

- Next, remove the spark plugs.

- For the next step, you will need an assistant, since the main measurement condition is the fully open throttle.

- Then you need to tightly insert the tip of the compression gauge into the spark plug hole (the connection must be reliable).

- Now you need to turn the crankshaft, turning on the starter, until the pressure gauge needle stops (2-3 seconds in time).

- Important condition: the crankshaft rotation speed must be 100 rpm (this can only be achieved with a working battery).

- Next, turn off the starter and decipher the compression gauge readings. These procedures are carried out for each cylinder. It should be remembered that after each measurement it is necessary to remove air from the compression meter or move the chart cassette to its original position.

How is normal engine compression calculated?

If you do not know the standard data, normal engine compression is calculated using the formula:

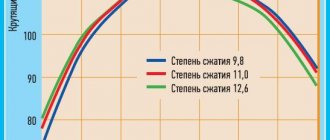

Engine compression (kgf/cm2) = coefficient X* compression ratio

In order to find out the compression ratio, you need to look at the technical characteristics of the engine. The next indicator, coefficient X, depends on the type of engine.

How to calculate the compression of a diesel engine?

The compression of a diesel engine will be calculated with a different coefficient (X = 1.7-2). For a four-stroke spark-ignition engine X = 1.2-1.3.

The compression of a gasoline engine between the cylinders should not exceed ten percent of the maximum value (1 kgf/cm2). A drop in compression of fifteen percent indicates wear on the valves, piston rings, cylinder or piston.

Measuring compression in the cylinders of a carburetor car engine: 8 comments

Compressions need to be changed by removing the spark plugs one at a time. Because by unscrewing all the spark plugs, the crankshaft rotation speed increases and the compression gauge readings will be incorrect.

I have similar pressure, I think the reason for the high readings is the valve seals (small portion of oil + readings increase), they practically do not last long.

Thanks, I forgot about this little detail. The statistics of the last three measurements are as follows: decoking1 12.3 12.3 13.4 12.7 after decoking 2 12.3 12.1 13 12.5 measurement after changing the oil this year 12.3 12.3 14 13 the compression meter is the same.

The high compression in the third cylinder is really confusing. Perhaps with increasing mileage of the car, for example, at the next oil change, it will level out. Additionally, check the small branch of the boat's ventilation (the fitting on the valve cover, the tube from it, the fitting and the channel into the throttle space on the carburetor).

The car was driven by an elderly person, he was driving very slowly, I had to change the oil, having previously unbraced it, drive it at high speeds - the result was that the compression leveled out, but the third cylinder was completely stuck and did not want to change the value. Thanks in advance for your opinion. An excellent site, taught a lot and made CO CH students independent from grief.

clutch? well, it was turned on for all 4 measurements (i.e. the pedal was not pressed) I’m ready to drive quietly and not pay attention to it, but the presence of a stable couple of drops of oil on the cover of the air filter housing every 1,000 km does not seem like much, but and it shouldn’t be (I cleaned the mesh, the pipes are still like new)

Try again to measure the compression, with the clutch pedal pressed and with it not pressed. Perhaps the numbers will level out. And so, you described an almost serviceable engine with excellent compression, I would drive it like that and not change anything. For prevention, I would change the engine oil.

I measured the compression according to the methodology - 12.3 12.5 14 13, the compression is 14, the engine 2108 has less than 50,000 km mileage! a couple of points from observations, on the cover of the air filter housing after a couple of thousand mileage - a couple of drops of oil from the crankcase ventilation. A couple of times I observed light smoke from the exhaust during intense acceleration, but it does not smoke at all, there is no oil consumption, the spark plug in the 3rd cylinder was a little darker before decarbonization, but now it is the same. What to do ? After all, the spread is more than 1.5. Thank you

Checking compression in engine cylinders. | Topic author: Wlodzimiera

Compression is the maximum pressure in the cylinder created when the engine is idling with the starter.

Compression in the engine cylinders is a fairly important factor in the proper operation of the engine. If your car doesn’t start well, the previous power has disappeared somewhere, then in this case it would be a good idea to measure the compression.

To check compression you will need a compression gauge. This is an inexpensive device, which is a pressure gauge with a check valve, thanks to which it records the highest compression in the cylinder.

For diesel engines, compression meters are designed for higher pressure and always have a threaded tip.

FOR VAZ 2103, the compression value must be at least 1 MPa (10 bar). The compression difference between the engine cylinders should not exceed 0.1 MPa (1 bar)

When purchasing, preference remains with the first type, as this allows you to make more accurate measurements, where you do not need an assistant, and there is not much difference in price. In the second case, you simply cannot do without help.

If you purchased a compression meter or have had one for a long time, then you can go directly to the measurement. But before measuring compression in the engine cylinders, two conditions must be met:

The battery must be well charged, the starter must turn the engine at a frequency of at least 200 rpm, otherwise we will not get real results. Immediately before starting compression measurements, it is necessary to warm up the engine to an operating temperature of 80 - 90 degrees. After the preliminary procedures, we move on to the main part: Remove all the spark plug wires. We turn out all the spark plugs, remembering which one is from which cylinder, it is advisable to then twist them all into place. Some people unscrew only one spark plug, only in the cylinder where the compression is being measured at the moment. In fact, this is a misconception about the measurement, and as a result we will get incorrect, underestimated compression readings. Since the speed will be lower due to the compression created in those cylinders where the spark plugs are not unscrewed. We disconnect the low-voltage wires from the coils so that they do not break through. We prevent the supply of fuel to the cylinders. By disconnecting the fuel hose if you have a mechanical fuel pump, if the pump is electric, you can pull out the pump relay, fuse, or remove the power wires from all injectors. Having completed all the preparatory work, we proceed to the measurement itself. Let's consider the case if we have a compression gauge with a rubber tip. Insert the compression gauge into the spark plug hole, pressing it tightly. The partner gets behind the wheel, depresses the gas pedal (thus opening the throttle) and turns the engine with the starter until the readings on the device stop increasing. Record the pressure in this cylinder. We reset the reading on the device. And we carry out this procedure in all other cylinders. By measuring the compression in the engine. We put everything back together in reverse order. After assembling the engine, we go to analyze our results. Analysis of the obtained data.

If the compression in all cylinders is in the range of 11 - 15 and the pressure difference between the cylinders is not more than 1, then your engine has excellent compression (to more accurately determine the limits of the compression rate, specifically for your engine, consult the technical documentation of your car, since These indicators may differ for different engines).

How is the compression ratio determined?

The engine compression ratio (CR - compression ratio) is defined as the ratio of the internal volume of the cylinder above the piston at bottom dead center to the internal volume of the cylinder above the piston at top dead center. When repairing an engine using standard reassembly technology, the following machining operations are performed:

- The cylinders are bored to a larger diameter and oversized repair pistons are installed in the engine. Boring of cylinders leads to an increase in the working volume and compression ratio, since the volume of the cylinder increases while the volume of the combustion chamber remains unchanged, resulting in an increase in the amount of compressed fuel-air mixture.

- The bearing surfaces of the cylinder block are re-ground. This machining operation is called cylinder block plate grinding and leads to an increase in the compression ratio, since it lowers the cylinder head lower to the piston heads.

- The bottom plane of the cylinder head(s) is ground again, which also leads to an increase in the compression ratio. With these seemingly simple, useful tips, you can measure the compression ratio.

To keep the engine compression ratio at the production engine's nameplate, most repair shops use rebuild pistons that are shorter than stock by anywhere from 0.015 inch to 0.020 inch. This is how the engine compression ratio in a car is measured.

To calculate the exact compression ratio, it is necessary to accurately measure the cylinder diameter, piston stroke and combustion chamber volume.

What compression ratio does, for example, the eight-cylinder V-twin engine of a 350 cc Chevrolet car have? inches, after the only change was made to its design - instead of cylinder heads with a combustion chamber volume of 74 cm3, new ones with a combustion chamber volume of 62 cm3 were installed?

- cylinder bore is 4.000 inches, stroke is 3.480 inches, number of cylinders is 8,

- volume of the combustion chamber before replacing the heads CV = = 74 cm3 = 4.52 cubic meters. inches,

- volume of the combustion chamber after replacing the heads CV = = 62 cm3 = 3.78 cubic meters. inches.

- GV = Bore x Bore x 0.7854 x x Compressed Gasket Thickness = 4.000" x x 4.000" x 0.7854 x 0.020" = 0.87 cu.m. inches.

In order not to complicate the calculation, but simply to show what effect a change in the volume of its combustion chamber has, we assume that the pistons have flat bottoms and the gap from the piston bottom, located at TDC, to the cylinder block plate is zero.

It was enough just to change the volume of the combustion chamber - from 74 cm3 to 62 cm3, and the compression ratio increased from 9.1:1 to 10.4:1. Since a compression ratio of 10.4:1 is generally not recommended for modern gasoline, such an upgrade is only permissible for racing engines that will run on expensive fuel or fuel using special additives. We hope we helped you figure it out and you now know how the compression ratio of the engine in your car is determined.