Post by Green » Sat Jun 15, 2013 21:54 pm

Today, out of the blue, the traction suddenly disappeared and the Volga stopped. Once diagnosis No. 402 started up, rattled for about three seconds, then damn it, they arrived. Having opened the hood, it was discovered that the fuel filter was empty, the Pekar fuel pump did not respond to pumping (usually 3-4 pumps - the filter is full, but here you even bother pumping - there's no point). While being dragged home by a tie, attempts to launch from the pusher were unsuccessful.

Having removed the fuel pump, nothing criminal was seen (it grunts as it should), put it back - zero emotions, gutted it, nothing criminal either, but just in case the fireman inserted new guts from the purchased repair kit - zero emotions, there was a Shaaz fuel pump in stock, installed it - zero emotions, no gasoline is supplied. I poured gasoline into the carb - the diagnosis rattled. I removed the fuel hose from the tank, inserted it into a bottle of gasoline - the shaaz does not pump, reinstalled the Pekar, and it also does not pump from the bottle.

Question: “What the hell?” "

Zavolzhsky Motor Plant (ZMZ) is one of the first domestic manufacturers of automobile engines to begin producing engines with an injection power system. One such high-quality engine can be called the ZMZ 405 - an engine from a family of four-cylinder engines that have been produced for almost 15 years. For the first time, this particular engine hit the market back in 2000, installed on the GAZ-3111 car. The plant itself positions the engine as an engine for small trucks and minibuses. It is installed on them - various cars of the GAZelle and Sobol injector line have this engine.

Over the past time, the ZMZ 405 has established itself as an excellent, unpretentious engine, ready for even the greatest difficulties on the road. The 405 motor is capable of withstanding heavy loads and this will not affect its service life. Also, the design of the motor is based on the unprecedented simplicity of the device - this engine, installed on any car, can be repaired and maintained by anyone in an ordinary garage with minimal knowledge, everything is done according to the included book and does not raise any questions. The same applies to fuel system repairs. In particular, the engine fuel pump injector is very easy to repair yourself.

Fuel pump location

The gas pump of a GAZelle car with a 405 injector engine, as in most injection cars, is not made independently, but as a unit that is located in the gas tank. It includes:

- fuel pump;

- fuel primary filter;

- fuel level sensor.

This arrangement made it possible to save space under the hood of the GAZelle 405 injector and increase the efficiency of each element of the block. So, for example, the filter cleans the fuel much better, since the gas pump is located immediately behind the filter and draws gasoline under pressure through the filter. The advantages for the fuel level sensor are that the electrical wires that go to the gas tank go together with the wires for the pump, thereby making its connection easier. By the way, the fuel level sensor is just a float on an iron stick. A high-quality fuel pump is the key to good operation of the fuel supply system of the GAZelle 405 injector: gasoline must be pumped in the required volume and at the right time.

Other causes of fuel pump malfunctions

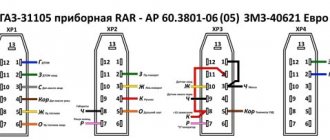

Quite often, unprofessional installation of additional electrical equipment or security anti-theft systems leads to the fact that the power to the fuel pump is lost due to mixed up contacts or other connection errors.

Finally, let’s add that the gas pump in the gas tank is immersed in gasoline, in which it is actively cooled. The habit of driving with an empty tank can quickly damage the electric motor of the fuel pump, as it burns out.

What functions does the fuel pump relay perform, signs of breakdown. Where is the fuel pump relay installed, how to properly check the fuel pump relay.

Why does the starter turn normally, but the engine does not catch and does not start? Main causes of malfunction, checking fuel supply and ignition systems. Adviсe.

Diagnose faults that may indicate problems with the fuel pump. Self-check of the device, measuring the pressure in the fuel rail.

The causes of whistling and increased noise during operation of the fuel pump are overheating of the pump. How to diagnose and fix the problem yourself. Tips and tricks.

How to change a fuel pump. Location of the fuel pump, releasing pressure in the system, unscrewing the fuel lines, removing the pump, reassembling.

What to do if the car accelerates worse, does not pick up speed, or has failures during acceleration. Why the engine does not pull, how to find the reason for the decrease in power.

One of the most important elements of the fuel injection system of a gasoline engine is the electric fuel pump, which is located in the fuel tank of the car. The fuel pump pumps fuel into the system from the gas tank, creating a certain pressure.

Auto repair experts identify the following common fuel system problems that are related to the fuel pump:

- The fuel pump pumps poorly and does not create the required pressure;

- the fuel pump does not pump when the ignition is turned on;

Considering that the fuel pump is an electromechanical device, the most common fuel pump malfunctions are related to both the mechanical and electrical parts. Next, we will look at what signs indicate a breakdown of the fuel pump and why the fuel pump stops pumping partially or completely.

Read in this article

Pump diagnostics and repair

The importance of maintaining the fuel pump in a constant working condition is that if it does not work correctly, constant breakdowns of other components of the GAZelle 405 car will begin, and the injector may not work correctly or even fail.

You need to start repairing the fuel pump by determining what exactly the problem is, that is, diagnosing it. The first alarm bell that the fuel pump is not working properly is that the GAZelle 405 injector moves unevenly, as if in jerks. If this particular symptom appears, then do not be discouraged - repairs are possible on your own. Also, if the GAZelle 405 engine takes a long time to start, and the injector usually always starts with half a turn, this is another bad sign that the fuel pump is starting to fail, although it is still far from complete failure.

Although, if you do not repair the fuel pump for a long time and do not pay attention to such a breakdown, then at one point the car may simply not start. The cause of this problem is a drop in pressure in the fuel system, which is caused by a faulty fuel pump.

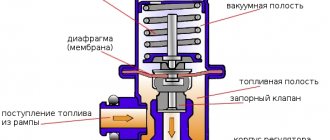

You can check the fuel pump using a special indicator, which can be bought at any spare parts store for the GAZelle 405 injector. This device is installed on the gas pump and you can do it yourself, the main thing is to strictly follow the instructions and not make mistakes. The check takes place with the engine turned off; the device itself will do everything. If a significant decrease in pressure in the fuel network was noticed in less than 10 minutes, this means that the fuel pump is working properly, and either the pressure regulator or the injectors of the GAZelle 405 injector are to blame.

What should the pump power be?

Of course this is not true. Let's say there are two different cars. One has a 3.5 liter engine, the other has a 1.6 liter engine. In addition to the difference in volume, the engines also differ in the number of cylinders. One installation has six cylinders, the other has four. Question: Do the pumps require the same performance to supply both units with fuel fluid?

It is clear that the pressure and performance of the superchargers installed on these machines will be different. Even if the pumps are similar in appearance, their power will not be the same. That’s what it says on them: on one device – 3.8 bar at 90 liters per hour, on the other – 2.8 bar at 60 liters per hour.

There are known types of fuel pumps with even greater performance. For example, in the Bosch catalog there are devices capable of pumping 160 liters per hour or even more.

In general, it is generally accepted as follows:

- on pumping devices in which the pressure is not standardized (used for single injection) - about 1 bar;

- on pumps for electronic injection - 3-4 bar;

- on mechanical injectors - 6 bar.

Where is the Fuel Pump Relay Gazelle Business

If the starter of your car turns normally, but the car does not start, the first thing you need to do is check that the fuel pump is turned on. On domestic cars, its operation can be heard from the passenger compartment; when the ignition is turned on, a characteristic buzzing sound comes from under the rear seat or trunk. If the fuel pump does not work, you need to check the integrity of the fuses and the activation of the main relay of the engine management system and the fuel pump relay. On the VAZ-2107, VAZ-2108, VAZ-2109 and their modifications, relays and fuses are located on the shelf under the glove compartment or under it. On VAZ-2110 and similar ones, you should look in the heater console on the passenger side by unscrewing the fastening screws and removing the side cover. On GAZ cars they are located under the hood on the front wall of the cabin, closer to the passenger side.

Fuel pump does not work on Gazelle

Zavolsky Motor Plant (ZMZ). one of the first Russian automobile engine manufacturers to begin producing engines with an injection system. One such high-quality engine is the ZMZ 405, a four-cylinder engine that has been running for almost 15 years. This type of engine first appeared on the market back in 2000, installed on the GAZ-3111. The plant itself positions the engine as an engine for trucks and minibuses. It is adapted for them. The different engines of the GAZelle and Sable injectors have this common auditory engine.

In the past, the ZMZ 405 has proven itself to be a good, demanding engine, ready for even the most difficult road conditions. The 405 engine is capable of withstanding enormous loads, and all this will not affect its service life. In addition, the extraordinary simplicity of the design of the device lies in the design of the engine. Each of us in an ordinary garage with the least knowledge can establish and maintain the myth installed by the engine on any car, our client remains to do in accordance with the attached book without any questions. This also applies to the repair of the fuel metering software. Namely, the engine injector fuel pump is not difficult to repair without outside help.

GAZelle with a gas pump 405 with an engine injector, as well as in the main injection, the machines are made not without outside help, since the unit is located in the gas tank. This includes:

- Fuel pump;

- primary fuel filter;

- fuel level sensor.

This assembly saves space under the hood of the GAZelle 405 injector and increases the efficiency of each element of the block. For example, a filter cleans fuel even better because the gasoline pump is located immediately after the filter and supplies gasoline under pressure through the filter. The advantage of a fuel gauge is that the electronic wires going to the gas tank come with the wires for the pump, making it easier to connect. By the way, the fuel level indicator. it's just a float on a steel rod. High quality gas pump. this is the key to a good set of fuel delivery accounting programs. GAZelle 405 Injector: Gas must be pumped out in the right volume and at the right time.

fuel pump is not working

The importance of maintaining the fuel pump at all times is that if it is not working properly, there will be permanent breakdown of other GAZelle 405 components and the injector will not work properly or not work properly.

Repairing a gas pump must begin with removing all additional parts, what needs to be found, what directly, in other words, to diagnose the problem. The first clue that the fuel pump is not working properly is that the GAZelle 405 injector is moving unevenly, seemingly unreasonably. If such a sign appeared on purpose, then there is no need to drive it away. repair, most likely, without outside help. In addition, if the GAZelle 405 engine has been running for a long time, and the injector usually always starts at half speed, this is another bad sign that the gas pump is starting to fail, although it is far from working. breakdown version.

Although, if you do not repair the fuel pump for a long time and do not even pay attention to such a breakdown, one day the car may not start. A prerequisite for this problem is a drop in pressure in the fuel system, which makes the gas pump especially faulty.

It is also possible to check the operation of the pressure gauge. This method is also quite accurate as long as you test the fuel pump correctly. We need a special pressure gauge to measure the pressure in the fuel line of the GAZelle 405 injector. The instructions for such a pressure gauge say that it must be connected to the injector rail and secured so that the pressure gauge is visible from the passenger compartment. When the driver turns on the ignition, the pressure gauge should start and take the pressure reading produced by the fuel pump. The norm for pressure fluctuations in the GAZelle 405 fuel system is the injector from 300 to 380 kPa (kilogram Pascal). You then need to drive a section of road to get into at least 3rd gear and then measure again. If the pressure gauge hasn't changed, you don't need to worry about it at this point and you need to fix something other than the fuel pump.

The fuel pump does not bleed! Or there is a problem in stock!!!

On the contrary, the readings have undergone significant changes; you need to consult a specialist in repairing the GAZelle 405 injector.

On the contrary, the car starts to move while driving, then the fault is hidden in an electronic component. Make sure that the fuel pump is not working, it is working, of course, by organizing a test of the fuel pump relay. For this we use a regular test indicator and the check is issued as follows: when the light bulb is connected to the beam and the ignition is turned on, the light bulb should burn very little. If the leak was found at low pressure and was found to be the culprit, then it would need to be repaired. To do this, you need to indicate exactly where to go, and only then, depending on the situation, choose what will help. change some gaskets, valves, diaphragms and much more. To quickly understand what is breaking and how best to fix the breakdown, you need to correctly understand the diagram of the fuel equipment of the machine itself, and what place the fuel pump occupies there.

Source

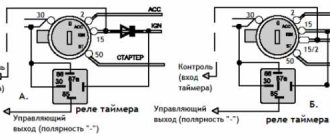

The fuel pump does not work, the relay turns on.

Checking relay power.

In the case when the fuel pump relay turns on when the ignition is turned on, but the pump itself does not work, you need to check the power at terminal 87 of the fuel pump relay. To do this, touch terminal 87 of the relay socket with the output of the control lamp connected to the vehicle ground, and the lamp should light up. If the lamp does not light, it means the fuse has blown or there is a break in the wire.

If there is power at terminal 87, you should remove the relay from the socket, and instead place a jumper between pins 87 and 30. In this case, if the pump and connecting wires are working properly, the pump should start working and if this happens, the relay should be changed. If the pump does not start working, then, without removing the jumper, you need to touch the power wire on the fuel pump with a test lamp connected to the vehicle ground.

Checking the fuel pump power circuit.

If a submersible pump is installed on the car as part of the fuel module, you need to remove the connecting connector and touch one of the thick wires. When you touch one of them, the indicator lamp should light up. If the lamp does not light up on any of the wires, then it is necessary to eliminate the break in the wire from the fuel pump relay to the module connector or the pump itself, if the pump is of a remote type. One of the reasons for the break may be the anti-theft blocking of an installed non-standard alarm system.

In the case when the test lamp lights up on one of the thick wires of the connector or one of the terminals of the remote pump, you need to connect these terminals with a test lamp to each other. In this case, the control lamp should light up. If the lamp does not light, it is necessary to eliminate a break or poor contact in the wire connecting the pump to the vehicle ground.