Design and operation of RTD

The RTD is a valve with a diaphragm that is installed in the fuel line. When the engine is running, a certain pressure is formed in the system, which must be maintained in the required range, but since the gas pump pumps fuel continuously, the pressure increases. When the pressure increases, the RTD opens the check valve and releases excess pressure into the return system, which communicates with the fuel tank.

Fuel pressure sensor VAZ 2114: main functions

Like most pressure sensors, this one is also a membrane type. Installed in the fuel rail, next to the injectors. Its function is to maintain pressure in the rail in a certain operating range. This is especially true not for a steady state, but for a changing operating mode. Using the regulator, the load on the engine is adjusted. Let’s say that when the pressure in the intake tract decreases, the pressure of the air-fuel mixture increases. And vice versa - when it increases, it decreases. Three important points can be highlighted:

- It changes the pressure when it also changes up or down in the intake tract.

- Allows you to maintain the pressure in the VAZ 2114 ramp in a certain range.

- Under various operating modes, the internal combustion engine helps compensate for loads.

Where is it installed?

There are two options for installing an RTD: on the fuel rail and in the fuel tank.

The regulator was installed on the fuel rail on cars with a 1.5 liter injection engine. On such engines, two fuel lines come from the fuel tank: direct and return.

The regulator was installed in the fuel tank on cars with a 1.6 liter engine. In such engines, the return line was abandoned. Now the regulator directly relieves pressure in the car tank.

Symptoms of a problem

There are quite a lot of signs of RTD malfunctions and it is quite easy to confuse them with other problems, so before you start replacing, you need to check it, but this is discussed below.

One of the main and most obvious signs of a regulator malfunction is its jamming in the open position. For this reason, engine power drops noticeably. The engine may idle well, but the engine will not be able to develop high speeds due to lack of fuel pressure.

When starting the engine, whether cold or hot, you have to rotate the starter for a long time.

When the RTD is jammed in the closed position, excess pressure occurs, which can cause the fuel pump to fail. Excess pressure in the system leads to increased fuel consumption and incomplete combustion in the combustion chamber. The exhaust gases will have a distinct smell of gasoline with characteristic black smoke.

There are also other less noticeable signs of its malfunction:

- The internal combustion engine operates unevenly at idle and stalls;

- The required internal combustion engine power does not develop;

- The car jerks when driving;

You can learn more about the fuel system in our article.

Operating principle and typical failures

A fuel pump is a kind of small electric motor that pumps fuel and creates pressure in the fuel rail of a VAZ 2114 car. The pump is a component of the fuel module.

Structurally, the pump and electric motor are a single unit. Its electrical part is washed with fuel, which provides cooling, plus lubricates the surfaces that come into contact with each other.

Fuel pump VAZ 2114

There are many signs of breakdowns, which indicate a failure or malfunction in the fuel system, or more precisely the fuel pump. Almost every person is able to detect some of them:

- The engine does not start;

- When you try to start the engine, you cannot hear the electric motor;

- The engine runs intermittently;

- Jerking occurs when moving at low speed.

Causes

As for the reasons why the fuel pump fails, they may be:

- Fuse on the pump is broken;

- Failed relay;

- Failure of the pump electric drive;

- Poorly secured block masses;

- Damage to the pump itself;

- Missing or poor contacts at the motor terminals.

In fact, it is extremely rare for an electric motor to break down. This is due to the active cooling of the element by fuel, which not only cools, but also flushes all its components.

Shidron blower and mesh

But the centrifugal gate hydraulic supercharger suffers more often than others. The reason is small contaminants in the fuel, which end up inside the mechanism, rub against the structure and wear them out. The performance of the unit drops, the pressure decreases. This leads to the formation of the first signs of pump wear, operation noise increases, and the engine refuses to start. It is impractical to repair a broken pump; it must be completely replaced.

Examination

The check must be carried out using a special device for checking fuel pressure (pressure gauge).

This device is connected to the fuel rail fitting and the engine starts. With a working RTD on 1.5 liter engines, the fuel pressure should be from 2.9 to 3.3 kgf/cm²

Then the vacuum tube is removed from the RTD and measurements are taken again. The fuel pressure should increase by 0.2-0.7 kgf/cm².

When the engine is stopped, the pressure should drop slightly and remain in the system for about 2 hours.

Checking the head pressure

The quality and efficiency of the regulator can be determined independently using a pressure gauge. You will use it to measure the pressure in the system.

Diagnostics is performed in three modes. Before starting the inspection, be sure to make sure that there is no damage in the fuel line and that fuel is not leaking anywhere. If there is damage to the line, checking the pressure pressure will not give an objective result.

After checking the line and making sure that it is solid and has no defects, proceed to measurements in four modes.

| Diagnostic mode | Standard pressure indicator |

| Check when ignition is turned on | 2.5 Atm |

| Idle check | 3 atm |

| Checking with the tube removed from the regulator | 3.3 Atm |

| Checking if the return flow tube is pinched | 7 atm |

You will need to connect a pressure gauge to the gap between the fitting and the fuel hose, disconnecting the vacuum hose.

By pressing the gas pedal, the parameter will first rise to 3 Atm, but then drop to the normal 2.5 Atm. But this is only provided that the device that regulates the fuel pressure in the system works well and has no malfunctions.

If the pressure does not begin to increase during the check, replace the vacuum hose and take repeated measurements with it. If there are no changes in measurements, this indicates a malfunction of the regulator. There is no point in repairing it. It’s easier to immediately replace the device with a new one, and one of the highest quality and reliability.

Replacement

Replacing the RTD on a VAZ 2110 is not a complicated process when using our instructions. Even an amateur can cope with this task. Before starting work, you need to prepare the tool and vehicle.

Necessary tool

- Open-end wrench 24 mm;

- 6mm hexagon;

- Rags;

Preparing the car

Before starting work, it is necessary to relieve the fuel pressure in the system. To do this, remove the fuel pump fuse (F15), it is located under the panel on the passenger side. We start the engine and let it run until it stalls.

Next, we remove the negative mark from the battery to avoid fire, since we will be working with flammable substances, such as gasoline.

Step-by-step instruction

- Using a 24mm wrench, unscrew the nut securing the return tube to the RTD and remove it.

- Remove the vacuum tube from the RTD

- Using a 6 mm hexagon, unscrew the two bolts securing the RTD

- Carefully remove the RTD from the fuel rail.

- Installation of a new RTD is carried out in the reverse order. Before installing a new regulator, it is recommended to replace the sealing collar and lubricate it with gasoline before installation, so as not to damage it during the process of connecting the RTD to the ramp.

The structure of the Lada Granta fuel system and its features

The Lada Granta fuel supply system is designed to transport fuel to the car engine in the form of a working mixture consisting of gasoline and air. Each section of the system performs certain functions:

- 1. The tank is used to store fuel reserves;

- 2. The air filter cleans the air, which, mixed with fuel, enters the combustion chamber through the air duct;

- 3. The throttle valve controls the air pressure;

- 4. The submersible fuel pump supplies fuel from the tank, cleaning it through a mesh filter;

- 5. The fuel module, consisting of a fuel level sensor and a pressure regulator, is combined with a submersible electric pump to control fuel consumption.

- 6. The intake pipe and receiver serve to pump air to the intake valves.

- 7. The pressure regulator ensures uninterrupted fuel pressure in the system.

- 8. The adsorber, consisting of a container with activated carbon, absorbs gasoline vapors and, if necessary, supplies them to the intake manifold by blowing.

Power supply system LADA GRANTA

The 50-liter gasoline tank is made of special plastic and attached to the bottom of the car using steel clamps. Gasoline is supplied thanks to the fuel pump, which, under the influence of a signal from the ECU, starts working when the car’s ignition is turned on. Passing through the module into the coarse filter, the fuel flows through the tee to the fuel rail, where the excess passes through the regulator and goes back into the tank.

A special bypass valve (pressure regulator) creates constant pressure in the fuel line, due to which the fuel passes through a fuel filter made of special paper and enters the ramp, and then to the injectors and into the engine.

Replacing the fuel pressure regulator on a VAZ-2112: signs of malfunction and diagnostic video

The fuel pressure regulator, or simply abbreviated as (FLS - approx.) on the VAZ-2112, is designed to ensure that operating pressure is constantly maintained in the vehicle’s fuel system. And if this element malfunctions, it may require replacement. We described in detail how to do this correctly below in our article.

The video describes in detail the process of replacing the fuel pressure regulator on the VAZ-2112 (and other cars of the LADA family):

Replacement process for a 16-valve VAZ-2112

If the regulator is still faulty, we replace it in the following order:

- We disconnect the negative terminal from the battery for fire safety.

- Next, we reduce the pressure in the fuel system by unscrewing the nut that secures the fuel line and the RTD to each other.

To avoid fuel spillage, use a rag.

You will have to remove the bolts using hexagons.

Be careful when dismantling.

When connecting, pay due attention to the condition of the O-rings.

Attention! Before installing a new regulator, lubricate the O-rings with gasoline, so they will retain their elasticity longer and will be less susceptible to cracking.

Signs of a faulty RTD?

You can understand that the regulator is not performing its functions by the behavior of the car, and they are expressed as follows:

- When all systems are working properly, there may be interruptions in the engine idling . You will see unstable idle speed. And in some cases, the engine may stall completely when idling and also begin to stall.

- The crankshaft rotates either with increased or decreased frequency .

- The throttle response and dynamics of the engine have decreased significantly , and in order to gain the required speed, you need to apply more pressure to the gas pedal.

- Dips appear and jerk during acceleration, which greatly increases fuel consumption.

- It doesn’t happen often, but sometimes it happens that the engine does not start the first time .

All these reasons have one thing in common: during operation, the fuel pump releases much more gasoline into the system than required, as a result of which it does not burn out completely, which causes gasoline consumption to increase.

Fuel system diagnostics

We first learn about increased fuel consumption from the arrow on the instrument panel. However, on the VAZ-2112 it happens that it fails, or the fuel pressure sensor is lying. We advise you to read this article to be sure that this device is in good working order on your car, and to begin diagnosing the RTD itself as quickly as possible.

Checking the fuel pressure regulator

If you have checked and are already sure that your FLS (fuel level sensor - approx.) is working, but you simply have fuel consumption and other problems indicating it, then you must first check the regulator as follows:

- We unscrew the fitting plug, which is designed to control the fuel pressure. Please note that if it has lost its elasticity, has cracks or other damage, it needs to be replaced.

The location of the fitting plug on the editorial machine (although ours is 8-valve). Pay attention to the condition of the O-ring inside.

This element is also worth checking for serviceability.

When connecting the pressure gauge, make sure that all connections are tight.

In stores, the price of a new RTD is in the range of 300-600 rubles , such a range in price results from the presence of a large number of analogues from different manufacturers.

Fuel pressure sensor VAZ 2114: diagnostics and replacement

The VAZ 2114 fuel pressure sensor is today’s topic of conversation. I accidentally came across a question from a person who is having difficulty starting the engine. And I changed several fuel pumps, but it didn’t do much good.

The electric pump works, but it feels like it’s not pumping at all. Let's try to figure out what could be the reason? And is it worth blaming the pump right away? Yes, if the “diaper” is clogged and has never been changed, then it’s worth taking it off and seeing what’s going on there?

But if everything is fine here, you should pay attention to a small element that has a huge impact on the fuel supply - the check valve, also known as a pressure sensor. Let's talk about it now.

Signs of a malfunctioning fuel pressure regulator

Every engine fuel system contains a fuel pump. Electric fuel pumps have recently been installed in gasoline engines; mechanical models are already outdated and are no longer used on modern vehicles. Mechanical fuel pumps live out their days on cars produced in the last century.

The performance of the electric fuel pump must be such as to ensure uninterrupted fuel supply at any engine speed and under any load. But what to do when the engine is running at idle or low speed, and a small portion of fuel is required? After all, the pressure that is created in the engine power system for heavy loads will be excessive at idle speed. And excess pressure can lead to disastrous results - breakage of fuel hoses or other damage. For normal operation of the fuel system, there is a fuel pressure regulator.

How to reduce fuel consumption on a Lada Granta

To reduce fuel consumption on the Lada Granta, it is recommended to adhere to the following rules:

- 1. Drive the car in normal mode without speeding or sudden maneuvers;

- 2. The driving speed should always correspond to the engine speed, which will protect the engine from overload as much as possible. There is a rule of intelligent driving - the less you use the brakes, the more fuel you save. This means don't rush to the changing traffic light to brake hard before the stop line. The driver must learn to calculate the speed of the car in certain driving situations;

- Use high-quality lubricants and fuel for the engine;

- Regularly and promptly carry out maintenance and repair of the engine and fuel system in a timely manner.

What is a fuel pressure regulator?

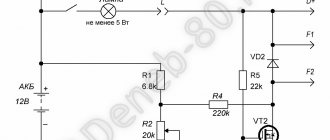

The fuel pressure regulator (FPR) is a vacuum valve that transfers excess fuel through a return hose into the fuel tank. The RTD is a housing that contains a valve, a membrane and a spring. There are also three terminals in the housing: two terminals for the passage of fuel through the regulator, the third is connected to the intake manifold. As engine speed increases, the vacuum created in the manifold (at the third terminal) overcomes the force of the spring and moves the membrane, thereby opening the valve slightly. Excess fuel gets access to the second outlet and goes back to the gas tank. An RTD is often also called a check valve.

As a rule, the check valve is located on the fuel rail; it can also be embedded in the fuel return hose of the power supply system.

Causes of fuel pressure regulator malfunctions

RDT may fail for several reasons. For example, defective parts are found on Russian-made cars. There are significantly fewer defects on foreign models, but you can purchase a defective RTD by purchasing a non-original spare part.

Mostly the check valve breaks down due to natural aging. Let's say this can happen after a hundred thousand mileage or more. It should be noted that check valve failures are not common. Most often, in an RTD, the membrane dries out over time, less often the valve jams, and even less often the spring breaks or weakens.

Sensor failure may occur due to low-quality gasoline. For example, in winter, fuel was filled with water, and water got into the regulator. If the fuel filter is not replaced on time, dirt gets into the parts of the power system, including the regulator. In this case, the RTD valve most often jams. It’s hard to imagine what could happen to the spring, but apparently, it still breaks sometimes.

Characteristic symptoms of fuel pressure regulator malfunctions

By what signs can you determine that an RDT is not working:

- the engine is very difficult to start, you need to turn the starter for a long time and at the same time keep the gas pedal pressed in order for the engine to start;

- The engine idles unsteadily or the speed is very low, the engine often stalls. At the same time, it does not gain power at all; when trying to accelerate, it results in a deep failure;

- The spam engine changes speed sharply, this is especially noticeable at idle:

- Fuel is leaking from the fuel hoses. Attempts to tighten and replace clamps and replace hoses do not help.

How to check the fuel pressure regulator for serviceability

The fuel pressure regulator is not an electrical sensor and cannot be checked using instruments. It should also be taken into account that the RDT cannot be disassembled or repaired. Someone writes that the fuel check valve can be repaired. I would like to see what it looks like and where you can buy a repair kit. Typically, RTDs are inexpensive, and even for that reason they would not be worth repairing if they were repairable.

You can verify that the regulator is working properly by checking the pressure in the fuel system. This is usually done with a mechanical pressure gauge, which is connected to the engine power system.

Measurement is carried out as follows:

- connect the pressure gauge to the fuel system;

- start the engine and look at the pressure gauge readings.

The standard system pressure for a passenger car is usually within 3 kg/cm2. When stopping the engine, the pressure should not drop immediately - the regulator closes the return flow. If the pressure gauge needle quickly goes to zero, the RTD is most likely faulty.

Another way to check: if you manage to pinch the fuel return hose while the engine is running, then if the regulator is working properly, the pressure in the fuel system should increase. The indication of the arrow of the device depends on the degree of compression. But there are foreign cars where it is impossible to clamp the return line - instead of rubber hoses there are metal tubes, or the hoses are very short.

In some cases, by squeezing the return hose, you can verify that the RTD is faulty without a pressure gauge. But this is only due to one sign - when the engine idles and does not develop speed at all. If, when the return line is pinched, all cylinders begin to fire and the engine acquires the required power, then the RTD is definitely faulty and needs to be replaced.

Troubleshooting

To find problems, we suggest you use the appropriate methods.

- Pump fuel into the system, turn off the ignition and monitor the behavior of the pressure gauge. In a normal situation, the pressure drops to 0.7 Bar and stops at this level. If the regulator fails, the pressure gauge will tend to zero. The problem may lie in the device itself, or in the fuel pump motor valve.

- Increase the engine speed to 3 thousand and again look at the pressure gauge readings. If the arrow points down, the fuel pump is broken. It needs to be replaced.

- If the pump takes a long time to build up pressure, the problem lies in the filter or mesh of the tank, which is clogged with debris.

Article on the topic: Repair of the exhaust manifold on a VAZ 2109 (carburetor)

Fuel pressure regulator VAZ 2112 16 valves

The fuel pressure regulator (FPR) serves to maintain constant pressure in the engine fuel system, ensuring uninterrupted operation of the internal combustion engine and its maximum performance in all modes. Most often, the fuel pressure regulator is located on the fuel rail, or on the fuel pump itself in the tank.

We are repairing a VAZ-2112 car produced in 2003, with a 1.5 liter engine with a power of 94 hp. The owner complained about difficult starting after long periods of parking and roughness at idle.

Fault diagnosis

First you should measure the pressure in the fuel system. The regulator on this engine is located on the fuel rail. On the left as the car moves. On the right side of the ramp there is a fitting for connecting a pressure gauge.

To connect the pressure gauge, unscrew the plastic cap and nipple.

The nipple can be unscrewed with a metal cap from a regular camera. The external thread size for connecting a pressure gauge is 10 mm. You can contrive to put a VAZ fuel hose on it. You must first make an internal chamfer in it, otherwise it will be difficult to put it on the fitting.

To relieve pressure in the system, remove the fuel pump fuse and start the car. When the engine starts to shake, turn off the ignition.

Fuel pressure gauge

Now connect the pressure gauge and tighten it with clamps. Turn on the ignition and start the car. Normal pressure in the fuel system is 2.8-3 atm. The fuel pressure regulator is configured to dump excess fuel back into the tank when the pressure reaches above 0.3 MPa (3 atmospheres). The data is indicated on the pressure regulator itself.

My pressure gauge has a knocked-off reference point by 3 divisions (0.03 MPa), so taking this correction into account, the following figures were obtained.

0.23 MPa at idle (0.26 MPa on the pressure gauge). This is not enough for normal fuel atomization and the creation of an air-fuel mixture, so the engine was a little “wobbly”.

Checking the fuel pressure regulator

To further check the regulator, remove the vacuum hose from the RTD. It is connected to the intake manifold and controls the operation of the valve. If the pressure returns to normal (as in my case). It became 0.3 MPa. This means that the fuel pump is working and the reason for the low fuel pressure in the rail is in the regulator (also known as a check valve).

Removing the fuel pressure regulator

The fuel pressure regulator is attached to the rail with two Allen-head bolts. They are not visible from above, but the key can be found by touch. It is better to use a torx wrench, as the heads are often clogged with dirt. In this case, the torx bit is easier to insert.

The return pipe is screwed to the RDT using a fitting with a 24 mm edge. If you can’t unscrew it in place, you can remove the regulator along with the fuel pipe, and then unscrew it in a vice.

The photo shows a new fuel pressure regulator code 2112-1160010-01 and a removed tube.

Now we put the new fuel pressure regulator in place and screw the fuel pipe.

Before the first start, you need to pump up the pressure in the fuel rail and fill it with gasoline, otherwise the engine may not start for a long time.

To do this, turn on the ignition three times, and each time wait until the pump stops humming. Of course, don’t forget to replace the fuel pump fuse before doing this. Then we start the engine.

Conclusion

I was too lazy to reconnect the pressure gauge, so there are no pressure measurements after replacing the regulator. But the engine began to run much smoother and calmer. It’s also easier to start and more fun to gain momentum. At the same time, removing the vacuum hose no longer affected its operation. Therefore, the fault was correctly identified. The renovation paid off.