What to do if there is no spark at the injector? Possible problems

One of the most common reasons causing the inability to start a gasoline engine is the banal lack of spark at the spark plugs. Under such circumstances, there is nothing to ignite the combustible mixture on the compression stroke, and as a result, the engine refuses to work. Depending on what kind of power system the car is equipped with, it is determined exactly how to proceed to determine the exact cause of the lack of a spark and measures to return it. We’ll talk in more detail about this problem on injection engines today. Interesting? Then be sure to read the material below to the end.

If there is no spark on the VAZ 2107 carburetor

One of the most common problems encountered on cars is the lack of spark on the fuel spark plugs. If there is no spark from the ignition coil of a VAZ 2107 carburetor, then this indicates problems with ignition. With such a malfunction, the car engine may not start at all or its operation will be unstable when starting. Such a breakdown must be repaired immediately, otherwise it will lead to accelerated wear of engine parts, overheating, increased fuel consumption and other breakdowns. Why the spark disappears on the VAZ 2107, we will consider in detail in the material.

Lost spark in carburetor seven

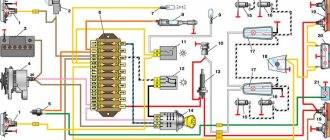

The search for a breakdown in the form of a lack of spark should begin directly with an inspection of the high-voltage cables, coil and distributor. The cause of the malfunction may be an armored wire whose contact has moved away from the distributor or spark plug. If the high-voltage wire is working properly, then you need to resort to checking for the presence of a spark in the spark plug.

To check the presence of a spark in the spark plug, you need to unscrew it from the cylinder and place it on the engine, connecting it to the armor wire. After this, one person should try to start the engine by turning the starter, and the second should observe the presence or absence of sparking. The presence or absence of a spark can indicate malfunctions:

- If a spark is present, this indicates a malfunction in the spark plugs, high-voltage wires or distributor distributor.

- The absence of a spark means that the breakdown has occurred in the switch, ignition coil or Hall sensor.

After such an easy test, you can understand in which direction to look for a breakdown. To identify a breakdown, you should check each part listed above.

We identify the reasons for the disappearance of the spark

If there is no spark on a carburetor VAZ 2107 with contactless ignition, then the cause of the breakdown can be identified independently by checking every part of the car’s ignition system. How to check each element of the ignition system, we will consider further:

- If the coil fails, to check it, you need to measure the resistance of the windings and insulation. To do this, you will need to use a multimeter, setting it to resistance measurement mode. Depending on what type of coils is used, the resistance value will differ. Initially, you need to set the multimeter to the 200 Ohm measurement mode, and touch the “+” and “K” contacts with the probes. The device should show a value ranging from 0.2 to 3 ohms. At the next stage, you need to turn the multimeter into the 20 kOhm resistance measurement mode. One probe touches the “K” contact, and the second one needs to touch the central terminal to which the high-voltage wire is connected. The resistance value that the device should show is 2-4 kOhm. If it is not possible to check the coil with a device, then you must use a known good one.

- If the switch is faulty, you will need an oscilloscope to check it. However, not everyone has such devices, so the easiest way to check is to install a known-good device. There is a simple test method by which you can determine whether this device is working properly. To check, the following manipulations are performed: disconnect the wire from the ignition coil that is from the switch, and then connect it to a 12V lamp. The second end from the lamp should be connected to the ignition coil terminal. After this, you need to try to start the engine. The lamp should blink. If it does not blink, the device is faulty.

- Hall sensor malfunction. Using a voltmeter, you need to check the serviceability of the sensor. To avoid removing the sensor, we check it in the following way - using pins, we pierce the insulation of the green and white-black wires with them. After this, touch the pins with the probes of the multimeter, setting the voltage measurement mode. The crankshaft rotates, and at the same time we monitor the readings of the device. The readings should drop to 0.4V and rise to 9-12V. Such readings mean that the sensor is working.

- If the low voltage circuit is broken, it is necessary to check the integrity of the supply wires for insulation damage. To determine the presence of a break in the supply wires, you need to use a multimeter in continuity mode.

If the VAZ 2107 uses a contact-type ignition system, then troubleshooting should begin directly with the serviceability of the mechanical breaker on the distributor. If the distributor contacts show signs of oxidation and carbon deposits, and there is no gap between them, then the part must be replaced. In the contact ignition system, the serviceability of the coil is also checked, and the low voltage circuit is called.

In conclusion, it should be noted that finding the reason for the lack of a spark on the spark plugs is not at all difficult if you know the principle of operation of the system. The operating principle of this system is that at a certain point in time, a high current appears, which flows through armored wires to the spark plugs. A large current is created by the ignition coil, the primary winding of which is supplied with a low voltage. For a non-contact system, the current is interrupted by signals coming from the Hall sensor, while in a contact system a mechanical breaker with contacts is used.

provaz07.ru

Checking for spark

Let's say your fuel-injected car has stopped responding to the ignition key and refuses to start. It is quite irrational to immediately complain about a malfunction in the ignition system. First of all, you need to make sure that it is the spark that has disappeared and not something else that has broken. To check spark plugs for the presence of the coveted “light”, you can resort to several procedures at once. Perhaps the most effective and simple ones are the following:

- The first method is a mass test. To implement it, you need to turn off the ignition, unscrew each spark plug in turn and, placing its body against ground (the metal body of the engine), try to start the engine;

- The second method is checking with a multimeter or a tester based on a piezoelectric element. This diagnostic option is quite similar to the method described above, except that the spark plug is applied not to ground, but to the contacts of the tester or multimeter. However, in this case there is no need to “turn” the starter; the spark must come from the devices themselves.

If, as a result of the above-mentioned testing methods, sparking on the spark plug is not detected, or there is a spark, but weak (dimmed, dim, dull), it is necessary to identify the cause of the malfunction. Do not forget that operating a car with a poorly functioning ignition negatively affects engine performance and significantly reduces its service life.

Note! Checking the spark on the injector is an extremely important undertaking, since such cars have very sensitive electronics. Considering this particular feature, it is important to carry out diagnostics carefully and as quickly as possible, that is, without numerous repetitions of the test and using only high-quality testers.

There is no spark on the VAZ 2107 injector - the main reasons, check and repair

The main reasons that there is no ignition spark can be divided into the following groups:

- general violation of engine synchronization: malfunction of electrical equipment, blown fuses, main relay, malfunction of crankshaft and camshaft sensors, broken timing belt (or chain);

- failure of the spark distribution mechanism (distributor), slider, burnout of the limiting resistor in the slider, failure of high-voltage wires;

- spark plug wear;

- malfunction of the ignition coil(s);

- failure of the engine control unit.

If the spark is lost, when analyzing a complex malfunction, it is necessary to consistently monitor all possible causes in order to accurately determine the main source.

Monitoring the presence of a spark on a spark plug can be done using several methods:

- Visual, using a control candle.

With this method, the spark is checked by removing the high-voltage wire from the spark plug and installing a known-good test spark plug on the wire cap, the metal base of which is connected to engine ground. After this, an attempt is made to start the power unit. Visually check the presence of a spark on the control spark plug.

Attention! During this operation, precautions should be taken not to touch the metal body of the spark plug. The voltage of the high-voltage spark pulse is more than 10 kilovolts. This may result in electric shock. High-voltage damage is especially dangerous for people with problems of the cardiovascular system.

- Visual inspection is best done in a slightly darkened room; an assistant is required for this.

- Video - why there is no spark on injection VAZ cars (Kalina, 2109, 2110, 2114, 2115):

- Visual without using a control candle.

The method is similar to the previous one. In this case, a candle is not used. The exposed end of the high-voltage wire is placed 2-3 millimeters from the metal part of the body or body part.

An attempt is made to start the engine. By the maximum distance through which the spark strikes, one can estimate the magnitude of the impulse.

It is believed that 1 mm of air breakdown corresponds to about 6 kilovolts of pulse voltage.

Thus, if a spark strikes at a distance of 4 mm from the end of the wire to a metal part of the engine, then the pulse voltage is more than 20 kilovolts.

You can purchase a special spark indicator.

Warning! With this control method, you need to be even more careful, since electric current can flow through the assistant who is holding the high-voltage wire.

In this case, special rubber gloves may not prevent damage: their standard breakdown value is only 6.3 kilovolts.

It is better to use bulky dry rags as an additional insulator.

In this case, the state of the working area of the dismantled spark plug is monitored. If it is damp after removing the spark plug, it is highly likely that there is no spark. This method is safe. The condition of the spark plug can indicate problems with the ignition system.

Using a gas discharge test lamp. You can make such a probe yourself using a gas-discharge light bulb and a high-resistance resistor (on the order of several megaohms). Various sample options can be found on Aliexpress - VIEW OPTIONS.

Most modern injection engines are equipped with individual or combined ignition coils (several combined ignition coils in one housing). This design simplifies the process of assembly, repair and maintenance.

Along with this, it (the design) complicates the process of monitoring the presence of a spark.

To carry out this operation, it is necessary to dismantle the individual (combined) ignition coil, reconnect it to the power connector, place the spark plug on the high-voltage output, connect it to the engine body, and attempt to start. In some models of motors and coils, this operation is structurally difficult.

A selection of various inexpensive automotive ignition testers can be viewed HERE.

In most cases, to check for the presence of a spark, it is necessary to connect the high-voltage output of the test spark plug coil and apply an ignition pulse to the low-voltage input. In some older version coils, you can check the coil autonomously (without a car). For this:

- contact “ ” is connected to the positive terminal of the battery;

- using a free high-voltage wire, connect the high-voltage output of the ignition coil to the high-voltage spark plug cap;

- the metal base of the spark plug is connected to the negative terminal of the battery;

- a short-term ignition pulse is carried out by instantaneously connecting the positive terminal of the battery with the control contact “K” of the ignition coil using a conductor.

This circuit is similar to simulating a contact ignition system.

With this method, the spark may be slightly noticeable, especially with electronic ignition coils.

A weak spark on the spark plugs is possible for the following reasons:

- replacing the electronic ignition contact coil (and vice versa), outwardly they may not differ in any way;

- high-voltage breakdown in the coil body;

- interturn short circuit in the coil;

- poor “ground” in the engine or on the car body;

- breakdown of additional resistance in the slider, individual coil;

- breakdown of high-voltage wires, the presence of cracks in them as a result of high temperatures.

The presence of a breakdown in high-voltage wires can be checked by ground by starting the engine in a completely dark garage. In this case, the “extraneous breakdown” will reveal itself visually.

Most car enthusiasts believe that the main reason for the loss of spark is a malfunction of the ignition coil. Experience shows that this is far from the case. There is a well-known driver’s saying about this: “It wasn’t about the reel, ..... I was sitting in the cab.” In order not to find yourself in the role of a careless driver, you should investigate all possible reasons for the lack of spark.

What does the P0420 error code mean and how can it be resolved.

When do you need to change spark plugs and what does it depend on?

One of the most common reasons causing the inability to start a gasoline engine is the banal lack of spark at the spark plugs. Under such circumstances, there is nothing to ignite the combustible mixture on the compression stroke, and as a result, the engine refuses to work.

Depending on what kind of power system the car is equipped with, it is determined exactly how to proceed to determine the exact cause of the lack of a spark and measures to return it. We’ll talk in more detail about this problem on injection engines today.

Interesting? Then be sure to read the material below to the end.

Let's say your fuel-injected car has stopped responding to the ignition key and refuses to start. It is quite irrational to immediately complain about a malfunction in the ignition system.

First of all, you need to make sure that it is the spark that has disappeared and not something else that has broken. To check spark plugs for the presence of the coveted “light”, you can resort to several procedures at once.

Perhaps the most effective and simple ones are the following:

- The first method is a mass test. To implement it, you need to turn off the ignition, unscrew each spark plug in turn and, placing its body against ground (the metal body of the engine), try to start the engine;

- The second method is checking with a multimeter or a tester based on a piezoelectric element. This diagnostic option is quite similar to the method described above, except that the spark plug is applied not to ground, but to the contacts of the tester or multimeter. However, in this case there is no need to “turn” the starter; the spark must come from the devices themselves.

If, as a result of the above-mentioned testing methods, sparking on the spark plug is not detected, or there is a spark, but weak (dimmed, dim, dull), it is necessary to identify the cause of the malfunction. Do not forget that operating a car with a poorly functioning ignition negatively affects engine performance and significantly reduces its service life.

Read more: Knock sensor VAZ 2114: where is it located, replacement

Note! Checking the spark on the injector is an extremely important undertaking, since such cars have very sensitive electronics. Considering this particular feature, it is important to carry out diagnostics carefully and as quickly as possible, that is, without numerous repetitions of the test and using only high-quality testers.

If there is no spark on the injector, and not, for example, on a carburetor or gear motor, you will have to try to identify the reasons for its loss. This is due to the fact that there are slightly more factors influencing spark formation in injection systems and they look more multifaceted. If we summarize the general list of possible causes of the problem, then it is worth highlighting the following most common ones:

- The spark plug or spark plugs are flooded with fuel - there is either no spark or very weak, the spark plugs themselves are wet;

- The spark plug or spark plugs are faulty - there is no spark at all, deposits on the contacts are usually black or white;

- The crankshaft sensor, ignition module, ignition coil, switch or distributor is faulty - there is no spark at all, the engine shows no signs of “life”, the injector does not work correctly;

- High-voltage wires have broken through or there has been a loss of contacts - one or two spark plugs do not work, the rest are fully operational;

- The injector electronics (ECU or wires) are faulty - the unit does not work correctly, there is no spark at all spark plugs;

- The injector nozzles are clogged - there is no spark at the spark plugs of specific cylinders, the injector is not working correctly.

Please note that for a complete and most accurate diagnosis, it is necessary to carry out several procedures at once:

- Naturally, check for a spark;

- Assess for the presence of the symptoms described above;

- Check for relevant errors on the dashboard or on-board computer screen;

- Check the potentially faulty unit (disassembly, cleaning, diagnostics with a multimeter, etc.).

Causes of sparking problems

If there is no spark on the injector, and not, for example, on a carburetor or gear motor, you will have to try to identify the reasons for its loss. This is due to the fact that there are slightly more factors influencing spark formation in injection systems and they look more multifaceted. If we summarize the general list of possible causes of the problem, then it is worth highlighting the following most common ones:

- The spark plug or spark plugs are flooded with fuel - there is either no spark or very weak, the spark plugs themselves are wet;

- The spark plug or spark plugs are faulty - there is no spark at all, deposits on the contacts are usually black or white;

- The crankshaft sensor, ignition module, ignition coil, switch or distributor is faulty - there is no spark at all, the engine shows no signs of “life”, the injector does not work correctly;

- High-voltage wires have broken through or there has been a loss of contacts - one or two spark plugs do not work, the rest are fully operational;

- The injector electronics (ECU or wires) are faulty - the unit does not work correctly, there is no spark at all spark plugs;

- The injector nozzles are clogged - there is no spark at the spark plugs of specific cylinders, the injector is not working correctly.

Please note that for a complete and most accurate diagnosis, it is necessary to carry out several procedures at once:

- Naturally, check for a spark;

- Assess for the presence of the symptoms described above;

- Check for relevant errors on the dashboard or on-board computer screen;

- Check the potentially faulty unit (disassembly, cleaning, diagnostics with a multimeter, etc.).

If, based on the results of all diagnostic procedures, the problem is not identified, then, most likely, a visit to the service station cannot be avoided. Otherwise, it is quite acceptable to carry out repairs yourself, of course, if you have the proper skills, abilities and tools.

Bringing the car back to life

As for why a spark disappears, everything is probably very clear. Now, it would not be amiss to consider the order of her return. The reality is that in most cases, getting the spark back is a simple matter and just involves carefully checking the broken car. To be more precise, to normalize sparking it is required:

- Firstly, check the spark on the injector using the method described above, make sure that it has disappeared, and, at least indirectly, try to determine the cause of the malfunction;

- Next, it is enough to assess the current circumstances and act based on them. As typical situations, we suggest considering solutions to the following problems:

- the spark plug is wet, the presence and strength of the spark are unimportant, the carbon deposits are correct (brick color) - wipe the part and screw it back in;

- the spark plug is wet (not always) and the carbon deposits are incorrect (white or black) - clean, dry the part and try to start the engine, if there is no result, change the spark plug and deal with problems in the fuel system (cleaning the injector, checking the ECU, etc.);

- the spark plug is wet, there is no spark at all, the color of the soot is not important - we try to change the part, if there is no result, we check the ignition system and the operation of the injector.

In principle, in theory there are no particular difficulties in repairs of this kind. Despite this, it often causes difficulties in implementation for inexperienced motorists. To solve these, you need to act in the order described above, but if something doesn’t work out, it’s better to turn to professionals at a service station. This approach to repairs will not only save time, but also guarantee trouble-free operation of the car in the future.

Perhaps this concludes the most important information on today’s issue. We hope that the material presented was useful to you and provided answers to your questions. Good luck in operating and maintaining your car!

Checking the spark on the injection engine

Among the common malfunctions of an injection engine or carburetor engine is when the spark is lost on the spark plugs. In this case, the engine may not start or after starting it may function intermittently (triple), since there is no spark at one of the spark plugs and the cylinder actually does not work.

In such a situation, diagnosis should begin with checking the ignition system. In parallel with this, it is worth taking into account certain features and nuances depending on the type of engine installed. Next, we will talk about available ways to check the ignition for spark in relation to engines with a carburetor, and also consider what to do if the spark on an injection engine is lost.

How to check the spark on an injector by color

Even on modern cars, equipped with a lot of electronics and injection units, problems often arise. This is due to the operation and there is nothing you can do about it. In most cases, car enthusiasts are advised to learn how to inspect the spark on the injector, because its disappearance leads to difficulties when starting and unstable operation of the engine.

With all this, it is important to know that you can check it yourself. This is great, but you can get quite a charge of electricity and damage the ignition module or controller if you don’t know all the intricacies of diagnostics.

Why the spark disappears: the main reasons

On different types of engines, there is a fairly wide list of reasons why there is no spark at the spark plugs. Among the main experts are:

- Problems with spark plugs (destruction of the spark plug body, defects in the electrodes, etc.). It is also worth noting that the spark plugs may be filled with fuel or oil, which indicates a breakdown of the engine itself.

- Malfunctions of high-voltage wires associated with insulation breakdown or lack of contact.

- Failure or errors in the operation of the crankshaft position sensor.

- Problems with the ignition module, ignition coil, switch;

- Malfunctions or malfunctions of the distributor.

- Deterioration or absence of ground contact.

- Errors related to the operation of the electronic engine control unit (ECU);

No spark on Priora reason

No spark on Priora reason

Download file - No spark on Priora reason

Problems with starting the engine occur if one or more elements of the system malfunction. The table lists possible reasons why the Priora does not start. In some cases, flashing the ECU (electronic engine control unit) helps solve the problem of poor starting. And regular car maintenance will help eliminate problems of poor engine starting. HAVRA, your question is not in the appropriate article. Lada Priora 1.6 years old does not start well when cold I replaced all the sensors during diagnostics and the fuel pump still has a problem! Tell me what could be the matter? Oleg, according to your symptoms, there is no enrichment of the mixture at startup. First of all, check the fuel pressure and the condition of the fuel filter. Good evening, the problem is this: when cold, it starts well, both with the key and with autostart. Or sometimes it will start and the speed will fluctuate. Start and turn off a couple of times and everything becomes normal. Roman, if you changed the wire of the crankshaft position sensor DPKV, try changing the poles. Also clean the sensor contacts. It is also possible that the cause is a faulty coolant temperature sensor. If the ignition coil connection block comes loose, will the fuel pump operate when you turn the key and make a buzzing noise for 2 seconds? Hello, the problem is this: with the onset of cold weather, the VAZ Priora began to start only the second time. I turn the ignition key, wait for the pump to pump up pressure, then I start turning the starter, you can turn it for 5, 10 seconds, the engine doesn’t even catch. I turn off the ignition and turn it on again, start with the starter and the engine starts right away. I tried turning on the pump twice without starting the starter. When you turn the key, the pump runs for the same amount of time, about seconds. It feels like when you turn the starter for the first time there is either no spark or no fuel is supplied because the engine shows no signs of life at all. I tried to slowly press the accelerator pedal when turning on the starter, as they say, zero emotions. I turn off the ignition and immediately turn it on and everything starts right away. No warning indicators light up on the instrument panel; in BC State X1 there is only one error P Oil pressure sensor circuit, high signal level. Denis, perhaps the problem is in the oxygen sensor or its poor contact. There may also be a reason - a faulty ignition module, or poor contact of high-voltage wires. In some cases, replacing the ECU firmware helps. LadaOnline, Well, it seems to me that flashing the ECU can be immediately crossed out, since the problem occurs at temperatures close to zero and below. But with positive ones, such a problem is not observed. It seems to me that the faulty ignition module can also be crossed out, since after the car starts, the engine runs without any complaints or loss of power. I have an assumption that at the time of the first start, the brains of the ECU do not work at all and therefore the BC cannot issue an error report. Perhaps the main relay that supplies power to the ECU does not work. It is prohibited to use profanity, insult other site users, or advertise products or stores. The Lada Vesta 1 station wagon has appeared. The first video review of the Lada Vesta station wagon has been updated. AvtoVAZ introduced Lada Vesta station wagons to dealers. AvtoVAZ almost reached the break-even point in the first half of the year. Rating of dealer networks by the number of auto centers for July Statistics of car sales in Europe by model for the first half. Which generator is better to put on a Niva VAZ, Which accessories for Lada XRAY are better to choose. About additional protection of bumpers and sills on Lada XRAY. Yes, I am considering purchasing Yes, I want to see No. Online is the largest Russian-language resource on automotive topics with a daily audience of many thousands, which is dedicated mainly to cars of this brand, the domestic automotive industry and the automotive world in general. Copying of material is permitted only with a link to the source. Adding comments and registering on the site are temporarily suspended due to work on the server. Why Lada Priora won't start, causes of malfunctions. I had problems starting the engine of a Lada Priora and the problem was.. Please indicate another reason in the comments. KHAVRA October 11 LadaOnline October 11 Oleg November 2 LadaOnline November 2 Roman November 5 LadaOnline November 6 Denis November 12 LadaOnline November 13 Denis November 13 XRAY Vesta Largus Granta Kalina 2 and 1 Priora Niva 4×4. This site is not the official LADA website. In this case, a crash may be heard under the hood. The starter switching circuit or starter relay is faulty, the wires are damaged, or the ignition switch contacts do not close. When turning the key to position 'II', the starter traction relay does not operate; a clicking sound is not heard under the hood. The starter traction relay is faulty, there is a short circuit or break in the retractor winding, the relay armature is stuck. Remove the relay and check its operation. When the starter is turned on, a clicking sound is heard under the hood, but the starter armature does not rotate. Using an ohmmeter, check the resistance of the Battery-Starter circuit, as well as the ground wire. The battery voltage is within normal limits. Burning of the starter commutator, sticking of the brushes or their severe wear. Break or short circuit in the starter armature winding. The starter armature rotates slowly or does not rotate at all. Check the traction relay by applying voltage to the starter contact bolt directly from the battery. When trying to start the car, a crashing sound is heard from under the hood. Increased resistance to rotation of the crankshaft, scuffing on the shafts, bearing shells, parts of the cylinder-piston group, deformation of the shafts, frozen engine oil, jammed generator, jammed coolant pump. If you hear extraneous noise when starting the engine, check the free rotation of the pump and generator pulleys. Malfunction of the computer brain, its circuits, crankshaft position sensor or coolant temperature. Check the idle air control. When starting the engine, lightly press the gas pedal. When the ignition is turned on, there is no sound of the pump running. Apply voltage to the pump from the battery. Check the pressure in the fuel rail and the condition of the fuel lines. Inspect the joints and fittings of the hoses and clamps. During start-up, turn off the vacuum brake booster and plug the receiver fitting.

Why Lada Priora does not start, causes of malfunctions

DIY MK chandelier

Everything for cars Saratov store catalog

No spark and no power to fuel pump

Bus route 780 Moscow

Atb the summer translation

How to set up an asus wl 520gc router

How to spend an interesting evening in St. Petersburg

Won't start, no spark VAZ Priora

Design and other reliability and safety characteristics

How to take a screenshot on Lenovo A 319

Kangertech mini instructions in Russian

Priora has no spark.

Slippery shoes what to do

Poems about love for children by great poets

Retro stories ero

No spark on an injection engine or an engine with a carburetor: how to check

Checking the spark is possible using several methods: to ground, using a multimeter, or a special tester on a piezoelectric element. The first method is the simplest. The body of the unscrewed spark plug is brought to the metal (usually the engine cylinder block), after which the engine is cranked by the starter and the presence of a spark is analyzed.

Please note that this verification method cannot be used when diagnosing fuel-injected vehicles. The fact is that a car with an injector has an ECU and other electrical equipment that is quite sensitive and can be damaged.

Checking the ignition coil for spark

To diagnose the performance of the coil, remove the wire from the distributor-breaker. Next, the test is carried out similarly to testing high-voltage wires, that is, the wire is brought to a metal surface and turned with a starter. The presence of a spark will indicate in this case a problem with the ignition distributor; if there is no spark, then the problem lies in the coil.

First you need to check the distributor contacts. These contacts may oxidize, insulation damage is also possible, and the rotor itself may be faulty. Detecting problems with the rotor allows you to eliminate the problem by replacing it. When checking the ignition coil, you should identify possible defects in the integrity of the winding, burnouts and other signs that a short circuit is occurring inside. If such signs are found, the coil should be replaced or the ignition coil should be repaired.

Now let's take a closer look at ways to check the main elements of the ignition system. To do this, let's go back to the coil. As already mentioned, the most common cause of a malfunction is a damaged winding. Then an insulation breakdown occurs and a short circuit occurs. It is also important to understand that the coil can fail due to overload. Such increased loads occur as a result of problematic spark plugs or spark plug wires. For diagnosis you should:

- put the car in a dry parking, repair or other box. You can also use the garage. The main thing is that the humidity is not too high;

- Next, you will need to clean the distributor cover from dirt, after which the specified cover must be removed;

- then you need to turn the engine crankshaft so that the distributor contacts are closed;

- Now you can turn on the ignition and bring the high-voltage wire of the distributor 3-7 mm to ground;

After evaluating the spark, you can decide whether the ignition coil needs to be replaced. Please note that repairing this element is often impractical. Also, when installing a new spare part, you should strictly adhere to the required polarity. If this is not done, then the new part will quickly become unusable after unqualified installation. Please note that car service centers use a special stand to check coils. Such equipment allows you to check the coil taking into account various operating modes.

To check the spark on the spark plugs if the distributor is working properly and there are no problems with the condition of the high-voltage wires, you need to unscrew the spark plugs from the engine. In addition to the contacts, you should look at carbon deposits, the degree of oiling of the electrodes, etc. For normal sparking, contamination must be cleaned. You should also check the gap between the electrodes, which is usually between 0.7 and 0.9 mm. If the gap is broken, then you can carefully bend the side electrode. This method is a temporary measure, but in some cases it allows you to drive from several tens to hundreds of kilometers without tripping the engine in case of problems with the spark plugs.

We also add that there are special pistol devices for checking spark plugs. Typically, such solutions are available from spark plug sellers in car dealerships or automotive markets. If there is such a possibility, then the spark plugs can be checked on similar equipment.

No spark on VAZ 2106

Sparking is an important process that ensures the startup and stable operation of the power unit, for which the ignition system is responsible. The latter can be contact or non-contact, but the essence of its work remains the same - to ensure the formation and distribution of a spark to the desired cylinder at a certain point in time. If this does not happen, the engine may either not start at all or run intermittently. Therefore, it is worth dwelling in more detail on what kind of spark there should be and what the reasons for its absence may be.

Why do you need a spark?

Since the VAZ 2106 and other “classics” are equipped with an internal combustion engine, the operation of which is ensured by the combustion of the fuel-air mixture, a spark is required to ignite the latter. To obtain it, the car is equipped with an ignition system, in which the main elements are spark plugs, high-voltage (HV) wires, a distributor-breaker and an ignition coil. Both spark formation as a whole and the quality of the spark depend on the performance of each of them. The principle of obtaining a spark is quite simple and comes down to the following steps:

- Contacts located in the distributor provide low voltage supply to the primary winding of the high-voltage coil.

- When the contacts open, a high voltage is indicated at the coil output.

- High-voltage voltage is supplied through the central wire to the ignition distributor, through which sparks are distributed to the cylinders.

- A spark plug is installed in the cylinder head for each cylinder, to which voltage is supplied via explosive wires, as a result of which a spark is formed.

- When a spark appears, the combustible mixture ignites, ensuring the operation of the engine.

What should be the spark?

Normal engine operation is possible only with a high-quality spark, which is determined by its color, which should be bright white with a blue tint. If the spark is purple, red or yellow, this indicates problems in the ignition system.

Signs of a bad spark

The spark can be either bad or completely absent. Therefore, you need to figure out what the possible symptoms are and what could be the cause of problems with sparking.

No spark

A complete lack of spark is manifested by the inability to start the engine. There can be many reasons for this phenomenon:

- wet or failed spark plugs;

- damaged explosive wires;

- break in the coil;

- problems with the distributor;

- failure of the Hall sensor or switch (on a car with a contactless distributor).

Video: searching for a spark on a “classic”

Weak spark

The power of the spark also has a significant impact on the functioning of the power unit. If the spark is weak, the combustible mixture may ignite earlier or later than necessary. As a result, power decreases, fuel consumption increases, failures occur in different modes, and the engine may also misfire.

Tripletion is a process in which one of the cylinders of the power plant works intermittently or does not work at all.

One of the reasons why the spark may be weak is the incorrect clearance of the ignition distributor contact group. For classic Zhiguli cars this parameter is 0.35–0.45 mm. A gap less than this value results in a weak spark. A higher value, at which the contacts in the distributor do not completely close, can lead to a complete absence of a spark. In addition to the contact group, other components of the ignition system should not be overlooked.

An insufficiently powerful spark is possible, for example, when spark plug wires break down, i.e., when part of the energy goes to ground. The same thing can happen with a spark plug when the insulator is pierced or a significant layer of soot forms on the electrodes, preventing the breakdown of the spark.

Spark to the wrong cylinder

Quite rarely, but it happens that there is a spark, but it is supplied to the wrong cylinder. At the same time, the engine runs unstable, troits, and shoots into the air filter. In this case, there can be no question of any normal operation of the motor. There may not be many reasons for this behavior:

- the explosive wires on the distributor cap are mixed up;

- the cover on the distributor is installed incorrectly;

- The spark plug wires are not connected correctly to the spark plugs.

The last point, although unlikely, since the length of high-voltage cables is different, is still worth considering if problems with ignition occur. The listed reasons arise, as a rule, due to inexperience. Therefore, when repairing the ignition system, you need to be careful and connect the explosive wires in accordance with the numbering on the distributor cover.

If there is no spark: ignition module

The following symptoms indicate possible problems with the operation of the ignition module:

- at idle speed the engine troits;

- power decreases, the car accelerates poorly;

Engine vibration is most pronounced in two nearby cylinders, and the drop in thrust is more strongly felt during attempts to sharply accelerate the vehicle, that is, when the accelerator is pressed hard and sharply. In such a situation, the “check” light usually lights up on the dashboard of most cars.

If checking the spark plugs and high-voltage wires does not reveal any problems, then the ignition module should be checked with a tester. The test consists of connecting one output of the tester to the module connector, and powering the other to ground. Then the engine can be started. A tester reading of 12 V is evidence that the module is OK. A deviation in the instrument readings from the norm may indicate either the need to replace the module itself or to check/replace the corresponding fuses.

Useful tips

Experienced car enthusiasts are well aware that spark plugs can fail at the most inopportune moment. For this reason, it is recommended to carry a spare set with you. The same can be said about the spark plug wires.

When working on the ignition system, extreme caution should be exercised as you may receive a severe electric shock. Insulated tools must be used.

Since spark plugs fail more often than other elements of the ignition system, checking for a spark always begins with them. Diagnostics can be done one by one. The procedure is carried out by unscrewing the spark plug from the cylinder head, then putting a cap and a wire from the coil on the spark plug, after which it is grounded to ground. The main indicator when checking while the starter is rotating is the spark itself and its quality.

When removing the spark plug wires from the ignition module, it is advisable to mark each wire. This will allow you to check and subsequently connect in a strictly defined order without the risk of mixing up the wires.

Signs of malfunction and checking injection nozzles without dismantling. Diagnostics of injector power supply, performance analysis. Tips and tricks.

Why does the starter turn normally, but the engine does not catch and does not start? Main causes of malfunction, checking fuel supply and ignition systems. Adviсe.

How to check engine performance using spark plugs. The main signs of engine malfunctions: the appearance of black, gray, red and white carbon deposits on the spark plugs.

Signs of malfunction or breakdown of the high-voltage spark plug wire of the ignition system. How to check car armored wires with your own hands.

Engine trouble: symptoms. Why does tripping occur and how to find the reason why the motor starts to trip. Checking power, ignition, compression, etc.

What does the color of carbon deposits on a spark plug indicate, and why does carbon deposits of one color or another form? How to clean spark plugs from carbon deposits with your own hands, tips.

The main reasons why there is no spark

- problem with spark plugs (flooded or faulty);

- breakdown of high-voltage wires or loss of contact;

- the reason is the crankshaft sensor (requires checking with a multimeter);

- malfunction in the ignition module;

- failure of the ignition coil;

- problem in the switch;

- Distributor malfunction (burned contacts, loss of clearance);

- poor ground wire contact;

- failure or malfunction of the ECU;

No spark injector

It is recommended to use a spark gap to understand at what stage there is no spark on the spark plugs (no spark from the distributor, no spark from the coil, or directly from the spark plug itself). If there is no spark in all cylinders at the same time, there may be several culprits:

- controller;

- entire module;

- coil or center wire.

If there is no spark from the ignition coil, then the reason may be hidden in many places. First of all, you need to check the high voltage wire, which must be in perfect condition and without damage to the insulation. Otherwise, the wire needs to be replaced.

No spark, check spark plugs

If the problem is not solved, then check the spark plugs. The spark plug contacts must be clean. The fact that there is no spark may be caused by dirty spark plug contacts. It is best to replace the spark plugs, but you can also clean the contacts. But before changing the spark plugs, check whether the discharge reaches the spark plugs themselves. To do this, remove the spark plug wire and bring it to the car body at a distance of 0.5 cm. Turn the starter several times and see if there is a spark between the wire and the body. The spark should be white with a slight blue tint. If it is absent or present, but with a different shade, we can say that the spark plugs are fine, and the problem is in the heart of the car’s ignition system – the coil.

No spark VAZ (injector, 8 valves)

The other day, out of the blue, the car (Kalina 1.6, 8 valves) began to shake terribly. Diagnostics showed misfires in cylinders 1 and 4. After a little checking (see how to check correctly here), I came to the conclusion that there was no spark. And only in cylinders 1-4.

Next, in order to find out the reason for the loss of spark, I will go in order.

The first thing to check is the spark plugs. The spark plug looked normal, so I didn’t have much hope that replacing it would fix the situation. And so it happened - the new spark plug still refused to produce a spark.

The second is checking high-voltage wires. They are checked with a conventional multimeter in resistance measurement mode. The resistance should be within 15 kOhm. The wires also turned out to be fine.

Third, and probably most important, is the ignition coil. She, like no one else, is responsible for the spark. Its operability is also checked with a multimeter in continuity and resistance measurement mode. First you need to check the resistance between pins 1-4 and 2-3. It should be about 4 kOhm. If the tester shows infinity, then the coil is broken and must be completely replaced. Next, check the resistance between pins 1a and 1b. There shouldn't be a break here. And the last thing is to check the central contact for breakdown to the housing. The tester should show infinity.

My reel passed the test perfectly. It seems that all the main parts are working properly, so why is there no spark? After digging a little on the Internet, I realized that I still need to check the circuit from the ECU to the coil itself.

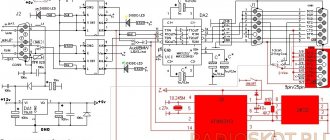

A 3-pin chip is placed on the ignition coil, therefore you need to check these 3 wires. The central contact is +12V, which is constantly supplied when the ignition is on. The extreme contacts - 1a and 1b - provide a control signal (negative) at the moment when a spark is needed. How can all this be checked? Very simple - using a regular light bulb.

You need a lamp with a power of 1-2 W or an LED with an additional resistance of 500-700 Ohms.

We connect the lamp to the central terminal and contact 1a and ask a partner to crank the engine a little (first remove the fuel pump fuse and relieve the pressure in the rail). When cranking the starter, the lamp should flash. The same procedure must be done with pin 1b - the lamp should also blink.

When I turned on the ignition, the lamp started to light up, just constantly on (pin 1b and central). This means that the control wire has a short to ground somewhere or that the transistor (VT1) in the ECU is broken. To find out, we need to find the ECU, disconnect the wiring harness from it, find the wires we need (1b) and test them for integrity.

Having found the contact diagram, I found out that contact 1b goes to pin 5 of the ECU, 1a goes to pin 2, 3 goes to ground of the ignition circuit. I rang them for integrity - they were all intact. I called ground and everything is fine too. Therefore, you need to check the transistor in the controller itself.

My car has a January 7.2 controller. Inside there are 2 transistors that pass control signals to pins 1a and 1b of the ignition coil. So one of these transistors was broken, i.e. was constantly in the open position.

How to check the transistor for serviceability? It has 3 pins - 2 of which are soldered. It is necessary to ring each outer terminal with the central one. In both cases, the tester should not beep. The contacts must not be closed.

Now all that’s left to do is to unsolder the broken transistor (its marking is gb10nb37lz), solder a new one in its place and rejoice at the spark that appears.

No spark VAZ injector video

car-hobby.ru

How to check spark on ignition coil

To see if the coil is working at all, pull the wire from the breaker distributor that comes from the coil. The same test is carried out with it as with the spark plug wires, namely, they bring the wire to a distance of 0.5 cm and turn the starter. Now, regardless of the result, we can accurately talk about the cause of the breakdown.

In the first case, you need to check the contacts in the distributor-breaker for oxidation, insulation damage, and also check the serviceability of the rotor. If there is no spark due to it, the rotor must be replaced.

Checking the ignition coil

If, after checking, you realize that there is a spark in the car, but it does not start, then the ignition switch may need to be replaced.

How to check the spark

- How to check the spark

- How to check the ignition coil

- How to strengthen the spark

First you need to determine the reason for the refusal. Typically, to start an engine you need fuel, air, and a spark that will ignite the air-fuel mixture in the engine cylinders. If the air filter is ok and the fuel/air mixture is entering the intake manifold, it's time to check the ignition system. You can and should check the spark yourself, without putting this process on the back burner, or rather, before a visit to the service station.

The check is as follows: using a spark plug wrench, you need to unscrew the spark plugs from the cylinder head and carefully inspect them. The first thing you need to pay attention to is the gap between the central and side electrodes of the spark plug. It should correspond to values from 0.7 to 0.9 mm. If the gap is larger, it is necessary to bend the side electrode; if it is smaller, bend it. We also pay attention to the condition of the spark plugs: carbon deposits can also tell us about the operating mode of the engine. To check the spark, carbon deposits must be removed using fine sandpaper.

No spark at the injector

If the engine does not start, but you can hear the fuel pump in the tank turning on and running, in this case the spark on the injector most likely has disappeared. To determine the malfunction, you need to check for the presence of a spark discharge on high-voltage wires. In this case, be sure to use a spark gap. If you check for a break in the presence of a spark by placing the wire at a certain distance from the ground of the car, the ignition module or controller may fail due to the appearance of a large self-induction current with a large spark gap. In addition, you can get quite noticeable and unpleasant sensations when receiving an electric shock when the insulation breaks down. In the case when you check the spark discharge by placing a spark plug with a high-voltage wire on it on the engine body, also due to poor contact of the spark plug body with ground, a large self-induction current can form, which will lead to damage to the controller or ignition module. The use of a spark gap is also more convenient, since most injection engines use static ignition distribution with the simultaneous supply of high voltage to two spark plugs.

It is not difficult to make a spark gap yourself; here you can find several examples. A drawing of a spark gap for simultaneously checking a spark on four high-voltage wires and a photo for checking a spark on two high-voltage wires. After connecting the spark gap, crank the engine with the starter and observe the presence of a spark discharge. If the spark on the injector on one wire disappears, when high voltage is distributed simultaneously to two spark plugs, then this indicates a breakdown to ground of the wire or the output of the ignition coil (ignition module). If there is no spark at the same time on a pair of wires 1-4 or 2-3, then the ignition coil, ignition module or controller is faulty. Breakage of high-voltage wires also cannot be ruled out.

Checking ignition devices.

To check the integrity of high-voltage wires, it is necessary to check their resistance; it should not exceed 200 kOhm, and there should not be a large difference in resistance in a set of identical wires. To check the ignition coils or module, you need to check for the corresponding error codes in the controller's RAM. If the controller does not have a diagnostic function for the module or coils, then the easiest way is to replace the module with a known good one and repeat the test. If in this case there is no spark on the same wires, then the controller or the wires connecting it to the ignition coil (module) are faulty. When checking the presence of a spark discharge in a static ignition system with an ignition coil on each cylinder, if there is no spark on one of the coils, replace it with any serviceable one from any cylinder. If a spark appears, the coil is faulty, otherwise the controller or the wire connecting it to the coil is faulty. In the case when there is no spark discharge on any wire, it is necessary to check the presence of power on the ignition coil, and when using a module in the ignition system, also the presence of a minus. For example, on cars with an MP7 controller, you need to check for the presence of a plus on wire 68 by touching it with a test lamp connected to the minus and the presence of a minus on wire 66, with a test lamp connected to the plus. If the supply wires are in good condition, you need to check the serviceability of the crankshaft position sensor. This can be done in several ways, depending on the controller used and the vehicle. After turning on the ignition and stopping the fuel pump, if we start cranking the engine with the starter, if the sensor is working, the pump should turn on again. But it must be taken into account that some controllers turn on the fuel pump only when certain crankshaft speeds are reached. You can also connect a test lamp to the terminals of any injector. In this case, during rotation of the crankshaft, if the sensor is working, the warning lamp should flash. If the sensor is working, then the controller or the wires connecting it to the ignition coils or module are faulty. Evidence of the operation of the crankshaft position sensor can be provided by damp spark plugs removed from the engine cylinders. A controller malfunction in 99% of cases is associated with a breakdown of the control key (transistor), which connects the primary winding of the ignition coils to the minus. This is the same main reason for the malfunction of the ignition module. But if the ignition module is filled with compound and is practically beyond repair, then the controller can be repaired in this case. In some cases, anyone with soldering iron skills and a little knowledge of electronics can handle this. A sensor malfunction is quite a rare occurrence and is often associated with loss of contact in the plug connection to the sensor, due to its contamination and oiliness, and a break or short circuit of the wires, due to improper installation during repairs.

Lost spark on VAZ 2107, what could it be?

Hello everyone, the spark has disappeared on the VAZ 2107, what could it be?

31 comments on “The spark is missing on the VAZ 2107, what could it be”

Check the spark plugs, caps, armor wires, spool, switch and distributor cover for moisture.

Injector? Or a carburetor? What ignition? Contact? Without contact?

Pavel, what does the caps have to do with it?

Denis, they can break through, verified

Pavel, so what kind of caps?

Pavel, call the details by their proper names.

The candle doesn't work

candles from matches should then work. stearic. just be careful!

Look at the coil, is it not a coil of wires or spark plugs?

Contacts on the distributor, coil, capacitor, distributor cover, wires

How can you not find a spark on the carburetor?

look, the contacts on the distributor were pinched and there was no rupture, so the spark plug doesn’t let go with the pliers; the pliers can be very open in the reverse order. if it doesn’t help, look at the coil, but it’s best to spend money on contactless ignition and completely forget about the loss of spark

Zhenya, I can’t find a spark on the BSZ carburetor on the 2107 coil kamutator new wire for the hall sensor new what to do

Alexey, I can’t find a spark on the BSZ carburetor on the 2107 coil kamutator new wire for the hall sensor new what to do

***Wiring for hall sensor

and what kind of spark is on the carburetor? You can also look at the ignition relay, I have it above the clutch pedal under the panel, put your hand in and the wires from the ignition switch to this relay go because of it, it may also not give a spark, I suffered with it for a long time, changed everything, but it turned out the wire was oxidized and burned out

what the hell is the spark in the carburetor, you should look for it in a diesel engine

The carbure only supplies fuel through the intake manifold and already in the combustion chamber an explosion occurs with a spark. Look how a gasoline engine works.

There is a resistor in the distributor slider, most likely it has oxidized. Clean it or replace it.

Alexey, do you generally know the electronic device on a carburetor engine and what one is on the injector?

How to check the spark on a spark plug

Even modern cars with injection engines and an abundance of on-board electronics are not immune from periodic problems. Quite often there are interruptions in the engine idling, or difficulties in starting the engine are noted, regardless of the ambient temperature. If you hear the noise of the fuel pump when you try to start, the first thing you should do is check the functionality of the entire ignition system, without relying on the on-board computer and sensors.

First of all, as practice shows, you will need to check the spark plug spark, since its “disappearance” is the most common cause of poor starting and unstable engine operation. It is necessary to understand that when checking it yourself, it is important to take special care, since in addition to the possibility of receiving an extremely unpleasant electric shock, you can damage the ignition module or controller. Therefore, it is advisable to carry out the test using a special spark gap, which you can make yourself.

Why is there no spark at the spark plugs?

There can be several reasons for the lack of spark at the spark plugs. Most often the culprits of the malfunction are:

- Accumulator battery;

- High voltage wires;

- Ignition coil;

- Distributor;

- Malfunctions in the low voltage circuit.

Also, in the absence of a spark, special attention should be paid to checking the quality of contacts and electrical connections of the ignition system elements. You can check the condition of the contacts simply by rubbing them with your hand.

Carefully inspect the wires and blocks of the ignition system - if dirt, oil or water is found on them, they must be wiped with a dry cloth. After that, try starting the engine, it may start this time.

Checking the battery

A clear sign of problems with the battery is a dull and quiet horn signal. Also, if there are problems with the battery, the indicator lights on the instrument panel usually go out while the starter is rotating. In this case, the reason for the lack of a spark may be poor contact at the terminals or a low battery charge.

- If the terminals are oxidized, they must be cleaned and tightened tightly. In addition, you can use graphite lubricant, which will reliably protect the contacts from oxidation in the future.

- If the battery is discharged, it must be charged using a charger.

For information on how to properly charge a car battery and maintain it, read our battery charging instructions.

How to check spark on ignition coil

The ignition coil is not one of those units that constantly breaks down and causes other troubles, but in some cases problems are still noted. The most common cause of problems is winding damage. The subsequent breakdown of the insulation layer leads to a short circuit. The coil can also be damaged as a result of overloads caused by faulty spark plugs, or defects in the high-voltage wires themselves.

Before checking the spark on the ignition coil, it is advisable to drive the car into a dry garage. All work can be done independently, without the use of special equipment. The algorithm for such a check is standard.

- After cleaning the distributor cover from dirt, it is removed.

- By turning the crankshaft on the engine, it is necessary to achieve the closure of the distributor contacts.

- After turning on the ignition, the high-voltage wire coming from the distributor is brought to the ground of the vehicle. Particular attention should be paid to the distance - it should be 5 mm.

- To ensure the accuracy of the coil test, from time to time you will need to manually open the contacts of the distributor.

- You can say that the coil is working properly if a bright blue spark appears. If it is weak, uncertain, appears only periodically or is completely absent, the coil must be replaced, since its repair, as a rule, is simply impossible. When installing a new one, the polarity must be strictly observed, otherwise the new coil will also fail. At specialized service stations, coils are checked on a special stand, which allows testing the performance of the device in various operating modes. A very simple way to quickly check is shown in the video:

How to Correctly Check the Spark on a Chainsaw Partner

Content

Finding the reasons why the chainsaw does not start

Amateur and professional chainsaws are complex devices. The motor life of their two-stroke engines, components and assemblies has its limitations. For this reason, fairly reliable and expensive tools along with cheap Chinese units periodically fail and refuse to start. The situation when the chain saw does not start or stop is not very pleasant and sometimes confuses the user. How to identify and fix the problem, returning the tool to service.

Identify and correct obvious chainsaw problems.

To determine the reason why a chain saw won't start or stop, you need to perform a tool defect. The essence of the procedure is to consistently monitor the condition and operation of the main working elements of the saw engine. At this stage we check:

- Presence of a spark on the spark plug;

- Fuel supply;

- Filter status;

- The operation of the breather is built into the fuel cap of the stunning unit;

- Functioning of the discharge channel.

to contents

Check the spark at the spark plug and eliminate the causes.

The first step in finding the reasons why a gas saw won't start is to check the spark at the spark plug. There are many factors that influence the operation of this element. However, the main defects of the device at the initial stage are:

- Incorrect carburetor setting;

- The presence of more than enough oil in gasoline;

- Clogged air filter.

All of them contribute to the formation of carbon deposits on the spark plug electrodes. In 50 cases out of 100, saws will not start in the cold due to lack of spark due to carbon deposits on the electrodes and their corrosion. The result is either a decrease in the gap or an increase in the gap.

Checking the spark plug on idle circuits

Checking for spark is quite simple. This will require:

- Remove the tip of the high-voltage wire;

- Unscrew the spark plug;

- Put the cup back on;

- Lift the spark plug with the skirt onto the cylinder;

- Start the starter.

spark between the electrodes when starting the chainsaw , everything is fine with the ignition unit. If this is not the case, then you should clean the element itself and check the electrode gap. If necessary, use a special probe to adjust the distance between the contacts.

For spark plugs from different manufacturers, the distance between the electrodes may vary. In some cases it may be equal to 0.5 mm. In others. 0.2 mm. Therefore, carefully read the manufacturer's recommendations.

The sparks on the spark plug may not be due to other reasons. Of the main problems associated with poor starting of the chain saw and unstable operation of the internal combustion engine at idle, from which the tool can stop, the following can be explained:

- Fuel channel overflow;

- Lack of contact between the high-voltage stand and the tip of the spark plug;

- Ignition unit failure.

READ Chainsaw Husqvarna 137 142 Video

How to start a cold chainsaw if the spark plug channel is constantly filled with gasoline? To fix the problem while running the tool, you can use the following algorithm:

- Unscrew the spark plug with a special wrench;

- Wipe it with a clean and dry cloth;

- Dry for 20.30 minutes;

- Remove the nail and adjust the gap between the electrodes;

- Drain the remaining fuel from the spark plug channel and dry it;

- Collect everything and try to start the mechanism.

Typically, these measures are enough to start the chainsaw and do the job. However, this last resort does not address the root cause of the engine not starting or stopping. Incorrect operation of the carburetor, requiring precise adjustment.

If there is no spark, when the high-voltage stand with the tip of the spark plug is in poor contact, it is necessary to check the connection. The test can be performed using a conventional tester. Once the defect is found and corrected, the chainsaw should start without any problems.

If the test shows that the contact is reliable and the saw does not start, look for the cause in the ignition unit. Generally, a faulty unit cannot be repaired and repaired. This will require a complete replacement.

Determine the availability of fuel and its supply.

First, you need to make sure that there may be a fuel mixture in the gas tank that doesn't want to start, and it's getting to the carburetor regularly. With the tank full, we check how the mixture is fed through the gas pipeline. We disconnect the fuel system pipe from the carburetor and try to swap places. In the case of a full order, when pumped, gasoline will be delivered in spurts in accordance with the standards set by the manufacturer. The consequence may be poor fuel supply or lack of fuel:

- The fuel supply channel is clogged;

- The fuel filter becomes clogged with debris.

Often the cause of poor starting of a chainsaw can also be a too full tank. In this case, you should pay attention to the presence of stains under the saw housing cover. If they are present, see Connecting the gasoline supply pipe to the carburetor. Most often, it is pressurized when the reservoir cap is pushed down the throat, which prevents the engine from starting.

Search for a chainsaw

The spark is gone

on the saw, and I tried to find it, and I succeeded. As it turned out, it was still a malfunction.

NO SPARK IN BENZOPILE, ignition coil replacement / NO SPARK in CHAIN CHALLENGE, ignition coil replacement

In this video, the ignition coil is damaged, replaced and the chainsaw

. And also look at mine.

The quality of the fuel mixture can also be one of the reasons why the chainsaw does not start. If, after completing work, you do not drain the remaining gasoline and leave the tool for a long period of storage (more than 2 weeks), the formation of resin and polymerization of the components will begin in the tank. Which can cause deposits on the piston, rings and cylinder liners. Therefore, always prepare the mixture before work only in the required quantity.

Check the condition of the fuel and air filters.

If the fuel quality is normal, the chain saw engine may not start due to clogged fuel and air filters. To diagnose these elements, it will be necessary to perform a number of manipulations related to their dismantling.

READ Adjusting the Husqvarna 236 Chainsaw

For fuel filter:

- Disconnect the gasoline supply line from the carburetor;

- Fuel fuel.

If the pressure is low or absent, remove the nozzle filter. Before doing this, empty the mixture reservoir and remove the filter element. Dismantling is carried out using a wire hook. A clogged replacement cartridge that has caused poor winding in the chainsaw motor can be cleaned, but it is better to replace it with a new one. When working in dusty conditions, cleaning should be carried out on a regular basis.

A clogged air filter can cause the chainsaw to run erratically, resulting in stalling or strong winds. Dust and dirt mounted on the adsorbent material make it difficult for air to enter the system, making the fuel mixture so rich that it is sometimes difficult to get a tool.

Checking the air filter is one of the first steps in finding the causes of poor starting.

Removing the air filter must be done with care, as dust accumulated on the surface of the saw during operation may enter the carburetor. And this can lead to more expensive repairs. After disconnecting the cartridge, thoroughly clean it of accumulated dirt and wash it with detergent. Dry the element and carefully place it in place.

Check your breath and clear it.

Breather. another element from the incorrect operation of which the chainsaw cannot start or die during the sawing process. This element is located on the fuel tank cap in the area of the air hole. This is a kind of valve that prevents gasoline from escaping and equalizes the air pressure necessary for the free flow of fuel into the carburetor.

In the case of a break, the working chain saw stops and when started it refuses to start. The problem is that air does not flow through the hole. As a result, negative pressure (vacuum) is created inside the fuel tank, preventing gasoline from entering the carburetor.

Identifying the problem is quite simple. Disconnect the fuel supply hose from the carburetor and see what happens to the gasoline. If he freely follows a good flow, then everything is in order. If it is absent, or it occurs weakly and intermittently, the cause is identified. soot is clogged with dirt. Solve the problem by clearing the air hole with a normal needle or a powerful jet of compressed air.

Checking the chainsaw output.

One of the reasons for the chainsaw to start poorly may be a clogged exhaust channel or its muffler. At the same time, when sawing lumber and logs, a decrease in power is observed. Most often this occurs due to the freezing of deposits on the spark groove or muffler channel, which are formed when a low-quality mixture of gasoline and oil is burned, which prevents the exhaust gas from escaping.

A clogged resonator resonator can cause the gas saw to start poorly.

Eliminate the cause of the chain saw's poor starting, in this case you can remove the accumulated combustion products. To do this, perform a number of manipulations:

- Remove the muffler by unscrewing the screws;

- Remove the cooling plate and gasket;

- Remove the spark arrester;

- Disassemble the resonator body;

- Wash all carbon elements with detergent;

- Let them dry completely;

- Reassemble everything in reverse order;

READ Chainsaw Doesn't Maintain Speed Stalls

To prevent dust and sand from entering the cylinder when cleaning the muffler, cover the chain saw motor exhaust duct with a clean rag.

What if the chainsaw doesn't start again?

If the initial inspection turned up nothing, or the defects were eliminated during the search process, and the chainsaw does not start later, then you need to look for more serious reasons. It is best to identify and repair such damage at a service center. However, with experience, you can find and fix them yourself. What to diagnose and check?

- Compression in the cylinder;

- Compression in the crankcase;

- Carburetor work.

In the first case, a compression test in the cylinder will allow you to find out the condition of the cylinder-piston group (CGP) of a chainsaw that does not want to start cold. For this you need a compressor. The device is screwed into place of the spark plug and the engine does not run. Measuring the readings allows you to judge the status of the GPG. In the absence of a compression gauge, the compression in the cylinder can be determined as follows:

- Attach your finger to the candle hole;

- Try running the chainsaw.

By placing your finger in the spark plug hole and jerking the starter, you can check

cylinder compression

If you feel your finger being pulled firmly into the spark plug channel, the compression is fine. The absence of vacuum in the chamber indicates a malfunction. For the piston group of cylinders, a more detailed inspection is required, which will give an idea of the condition of the piston and cylinder, piston rings and bearings.

Do not run the chainsaw on a cold can or due to lack of compression in the engine crankcase. The main reason. damage to the gasket located between the cylinder and the crankcase. Determining the lack of compression is quite simple:

- Disconnect the top tube from the carburetor;

- We pour gasoline into an ordinary traffic jam;

- We load the remote tube into fuel;

- We pull the starter several times.

If fuel is sucked out of the cap when the starter of a gasoline engine is turned on, then compression is fine. If not, see gasket.

If the fuel is drawn in, everything is fine. the gasket remains intact. Otherwise, you will have to purchase a repair kit and make a replacement. How to do it, watch the video, why not start a Chinese chainsaw:

Starting the tool may be complicated by malfunctioning carburetor or breakdown. It often happens that during the sawing process the mounting screws become loose and air is sucked into the cylinder. Make sure the carburetor is securely fastened. Inspect it for fuel leaks. The cause of the malfunction can be a lot. You can determine the malfunction, eliminate it and fine-tune the carburetor only at a service center.

After the step-by-step troubleshooting of the chainsaw engine, you can find the problem, fix it yourself and successfully start your work tool. Do not accept jobs you are not confident in. Refer troubleshooting to service center specialists.

How to check if there is a spark at the spark plugs

If the ignition distributor is working properly and produces a good spark, the reason may be the lack of the same spark directly in the spark plugs. Especially if there are no problems with the supply of the fuel mixture and the air filter is not clogged. Checking the ignition spark on the spark plug itself will not be a complicated or lengthy procedure, and can be done on your own in a very short time. When checking the spark plugs on your own, you will need to first inspect the wires leading to them from the distributor to detect any insulation damage.

Then, using a special wrench, you will need to unscrew all the spark plugs and assess the degree of carbon deposits - the excess should be cleaned off before checking the spark. Be sure to check the current distance between the spark plug electrodes. It should not exceed 0.7-0.9 mm. If the current value is incorrect, there are two ways to go. The first has been widely used since Soviet times, when the gap was regulated by simply bending the electrode. Of course, the method has outlived its usefulness, but as a temporary one it has the right to exist. It is best to replace the spark plugs with new and modern ones, for example, iridium ones, which, along with excellent performance characteristics, can reduce fuel consumption.

After removing the candles, you need to tie them in one row using steel wire. One end of the wire must be left long in order to ground it to the ground of the body of the vehicle being tested. After the starter starts cranking the engine, you must carefully monitor the “behavior” of the spark plugs. A weak, dull spark, or its absence, is almost guaranteed to indicate a failure of the electronic switch. If the spark is different, dim, then this may indicate a number of problems at once:

- damage to the wire going to the spark plug;

- an existing defect or deterioration of the runner of the distributor itself;

- poor contact of the spark plug wire;

- defectiveness of the candle itself.

Thus, a seemingly serious question for novice car enthusiasts, “how to check the spark on an injection engine,” can be resolved quite easily in practice.

How to check the ignition spark

What needs to be done and where to start if the engine stops starting? This is the philosophical question that vehicle owners face. First of all, you need to identify the cause of the failure. Typically, for an engine to start, it requires gasoline, air, and a spark that ignites the fuel-air mixture in its cylinders. How to check the ignition spark - our recommendations.

If no malfunctions of the air filter have been detected and the fuel-air mixture flows through the intake manifold, then you should carefully check the functionality of the ignition system.

How to check the ignition spark