Some car enthusiasts claim that when installing a throttle valve of increased diameter, the car's power increases by several percent. And if you also install a “zero” along with the “throttle”, the effect will be much better. In this article we will try to figure out whether there is any sense in a throttle valve with an increased diameter and why it is installed?

Let's first understand the theory of why an enlarged throttle valve is installed. The size of the standard throttle is 46 mm and is considered the narrowest point in the air path of the car. And if you install a throttle with a larger diameter, the passage opening will increase, and accordingly there will be a greater flow of air, which means the engine power will increase.

There are many options for oversized throttle bodies on the aftermarket tuning market, from “52” to “58” sizes. It all depends on the purpose of its installation. For example, on a standard motor without significant modifications, it makes sense to set the throttle to “52 mm” or “54 mm”. But more or “58” is used only for sports engines with increased engine displacement.

If you put a 54 throttle on a standard engine, it won’t get better, but it’s quite likely to get worse. Since when installing an increased throttle, you will need to work more carefully with the gas pedal, because if earlier, when you lightly pressed the gas, the throttle valve opened by 10-15 percent, then with an increased throttle it will be by 20-25%. And this will lead to jerking at low speeds!

Increased throttle only creates the illusion of increased power, when you have to put less pressure on the gas pedal and any response becomes sharper. Although some drivers may like this effect.

The increased throttle valve came to us from motorsport, when it was installed on sports cars not at random, but based on the performance of the car. First, the engine is made, power indicators are taken from it, and if there is a lack of air entering the engine, an oversized throttle valve is installed. If you install it on a standard engine, then it will be a waste of money. After all, the air supply with a standard throttle valve size is quite enough for a standard engine.

If we are talking about increased throttle, then we should not forget about such an operation as flushing the throttle valve. During operation, dirt accumulates on the throttle, which over time leads to worse response to the gas pedal. Even after the standard operation of flushing the throttle, the car begins to drive better, which I personally tested in practice.

Maybe then the effect of an increased throttle valve can be explained by the fact that instead of a dirty valve we install a new and clean one? Then, before buying a new large throttle body in a tuning store, it’s better to first wash the standard throttle body from dirt. This operation will not take much effort and time, you will only need to buy a can of “carburetor cleaner”, remove the throttle and rinse it thoroughly. Never use WD-40 to flush the throttle body!

No matter what anyone says, the car literally drives better after flushing the throttle body. This is not surprising, especially if no one has washed it before, and dirt has accumulated there.

One thing can be said about the “nulevik” or zero-resistance air filter; it is certainly a good thing if it is installed correctly. For it to work properly, you need to make a cold intake, otherwise it will “snatch” hot air right from under the hood. In this case, a standard air filter that takes air from a low point under the hood is preferable.

DIY throttle tuning

The price of MD tuning at a service station is from 3,000 to 7,000 rubles. As the experience of VAZ and LADA owners shows, it is possible to correctly modify the throttle assembly (CS) yourself, without having any special knowledge or precisely verified drawings. The only special tools you need are a 6 mm spherical cutter and a drill.

- Remove the throttle assembly.

- Make two recesses around the damper (approximately 2-3 mm, no more than 5 mm), as shown in the drawing (great accuracy does not matter).

- Remove burrs with fine sandpaper.

The process is also shown in the video:

The process itself is not complicated and will not take much time. The advantage of MD tuning is that there is no need to flash the electronic engine control unit.

How to replace TPS?

- Unscrew the 2 screws securing the sensor to the throttle assembly (see picture).

- Remove the sensor from the damper axis.

- We install the new sensor on the damper axis so that its leads are directed towards the partition of the engine compartment.

- Rotate the sensor relative to its axis until the mounting holes align.

- We wrap the sensor.

- We regulate TPS.

- We connect the sensor contacts.

- Reset the battery terminals for 5 minutes.

We open the damper by turning the sensor drive sector or pulling the accelerator cable. If this operation fails, the sensor is not installed correctly. In this case, you need to remove the sensor and reinstall it at an angle of 90 degrees relative to the damper axis.

The controller automatically uses the sensor's low idle voltage as a reference point. But it happens that after replacing the sensor, the controller uses the values for the old sensor, which causes the throttle valve to open a few degrees. In this case, you need to reset the controller parameters either through the on-board computer or remove the battery terminal for 5 minutes.

Sources

- https://nadomkrat.ru/elektrooborudovaniye/datchik-polozheniya-drosselnoy-zaslonki-vaz-2114

- https://zarulemvaz.ru/zamena-datchika-polozheniya-drosselnoj-zaslonki-vaz-2114/

- https://vaz-2114-lada.ru/2012/11/kak-proverit-i-zamenit-dpdz/

Reviews about MD throttle tuning

Advantages of MD tuning:

- The gas pedal becomes more informative (more responsive).

- Increase in power in the range from 1000 to 3000 rpm.

- Reduced fuel consumption.

Disadvantage of MD tuning:

1.

Checking the effectiveness of MD tuning in practice (

cable

):

- The gas tank was filled to maximum.

- We drove about 20 km.

- Once again we filled the tank to the maximum and got a consumption of 2.01 liters.

- We did MD tuning on a throttle body with a diameter of 46 mm.

- We drove along the same section of the road.

- We filled the tank to the maximum (gasoline consumption was 1.61 liters).

Thus, fuel savings after modification of the throttle assembly amounted to about 20%. During the experiment, an increase in low-end power was noted. Watch the experience in the video above from 12 min 30 sec.

2.

Testing the effectiveness of MD tuning in practice (

E-Gas

):

A similar experiment was carried out on a car with E-Gas. Fuel economy in this case was about 9% (was 1.5 liters, now 1.37). There is a faster response to the gas pedal. See also how to adjust E-Gas.

ps If after MD tuning there are problems with idle speed, then most likely the tightness of the closed throttle valve was broken (the chamfers were made too deep).

Have you modified your car this way? What feedback can you leave about MD tuning?

Let us remind you that we previously talked about other modifications that can improve engine performance. For example, installing a PCV valve in the crankcase ventilation system, as well as installing capacitors in the car’s ignition system.

Purpose of the throttle position sensor and its principle of operation

Injection engines required the installation of a large number of automatic devices that regulate and monitor the activities of all power plant systems. The drive principle of one of the main mechanisms regulating the fuel supply to the engine - the throttle valve - has changed. The drive became electric, electronically controlled. Its difference from mechanical is as follows:

- there is no mechanical connection between the gas pedal and the throttle valve itself;

- Idle speed is regulated by moving this very damper.

Since there is no longer a rigid connection between the pedal and the damper, all control is carried out through the operation of electronic systems. In this scheme, along with the control unit, the throttle sensor plays an important role.

The device itself is installed on the same axis with the throttle valve. It works like a potentiometer:

- One output of the sensor receives a 5 V electrical signal, the opposite is connected to ground. The third channel, from the moving contact, sends an electrical signal to the controller. When the damper is turned, the voltage coming from the current collector slider to the output changes;

- when the ignition is turned off, you can measure the voltage supplied to the TPS using a measuring device. To do this, you need to install the probe needles on the input contact and ground. If the throttle valve is closed, then the tester should show no more than 0.7 V and no less than 0.5 V. When the engine is running, the voltage should increase as the valve opens and, at its maximum open position, show 4 V (+0.3);

- when the throttle valve opening angle changes, the voltage going to the controller from the TPS slider changes and it regulates the fuel supply;

- TPS is associated with the operation of the idle speed control device (IAC). At startup, if the damper is in the closed position, then when the controller receives such a signal from the sensor, it connects the IAC and additional air flows into the engine, bypassing the closed damper.

The performance of the TPS must be monitored by measuring the resistance using an ohmmeter. To do this, the device is connected to the input and output contacts of the sensor. When you press the gas pedal, there should be a smooth change in resistance, but if the device shows zero or the resistance goes to infinity, this indicates a malfunction of the TPS on the VAZ 2114.

Experienced motorists recommend buying TPS VAZ 2114 from Moscow, OJSC "Schetmash" Kursk and OJSC "Avtoelektrika" Kaluga (Avtoelektrika is a contactless TPS).

The most common engine failures

ICE 21213 has typical problems of VAZ engines:

- increased oil consumption due to carbon deposits on valves and cylinders;

- the appearance of vibrations at a speed of 90 km/h. The cause is a damaged head gasket or an unadjusted carburetor;

- when the timing chain is pulled, the valve bends;

- Excessive noise due to a broken timing chain tensioner or timing chain tensioner shoe, pump bearing creaking, or unadjusted thermal clearances;

- Overheating of the unit is caused by a faulty thermostat, a clogged radiator, or prolonged operation at high speeds. Due to the design features of the BC, the thickness of the coolant layer does not provide sufficient cooling, so it is necessary to operate the unit moderately. Increased engine temperature leads to cracking of the cylinder head.

Similar article 1NZ FE engine: technical specifications and reviews

The disadvantages of the 21213 engine include repair features. If the wear of the cylinders exceeds 0.15 mm, then boring is permissible only for the repair dimensions of the pistons, increased by 0.4 and 0.8 mm from the nominal value. Exhausting the limit threatens to completely replace the pistons and cylinders.

Regrinding of the crankshaft journals is possible with a diameter reduction of 0.25; 0.5; 0.75 and 1 mm. The limitation is due to the repair dimensions of the liners. If the axial clearance of the crankshaft increases by more than 0.35 mm, the part must be replaced.

Debugg

If you notice that the throttle has begun to perform its direct duties poorly, do not rush to go to a service station and hand over your money.

The problem with the damper can often be solved with your own hands.

Most often, a problem with the throttle occurs due to contamination, which leads to impaired functionality. To correct the situation, simply clean the element.

When Cleaning Is Required

The practice of "tens" car owners shows that on these cars the throttle becomes clogged literally just a few years after the start of active use of the car.

The biggest “pests” for the damper are particles of oil, dust and gases coming from the engine crankcase.

When the engine is running, dust mixes with air and oil, forming a kind of mixture that enters the throttle valve. Over time, this substance sticks to surfaces and accumulates on the idle rod.

Soon the thermal gap becomes covered with dirt, and access through the idle air regulator channel is significantly deteriorated. If you do nothing, the engine will begin to work incorrectly, the dynamics will drop, and the engine will respond late to pressing the gas pedal.

Signs of contamination

Problems with the throttle valve can be identified by characteristic symptoms.

Troubling the motor is a rather indirect sign, since this is how the engine can behave in various types of failure. But don't rule out problems with the throttle.

HeBmeH9IembIu › Blog › intake theory (4 throttles)

First, let's understand the terminology. The 4-throttle intake is a multi-throttle intake system for a 4-cylinder engine. that is, a multithrottle is the number of valves equal to the number of cylinders.

further. in English it is called ITB, that is, independent trottle body.

I know of 2 cases of factory-installed throttles on turbomachines: Nissan Pulsar. 4 cylinders, 4 throttle bodies covered by a receiver. and turbo. second: Nissan Skyline GTR. 6 cylinders, 6 chokes and a receiver bank, in addition there are 2 turbos.

Of the naturally aspirated cars with throttles from the factory, I know the BMW M3, M5 from the Japanese, Toyota Corolla Levin. their throttle bodies are also covered by the receiver.

In my opinion, there are no production cars with open throttles at all. it’s a “dumb sport” and an outdated one at that. Even in big modern sports, one way or another the throttles are closed by some kind of box.

some conclusions: do the throttles themselves give some kind of magical effect? NO!

if an atmospheric basin on the throttles develops 200 horses, this does not mean that all 200 there are obtained due to these same chokes. The maximum output of the engine on the throttles and the correct receiver with one damper is the SAME. the same applies to turbo engines on ITB.

then why is the throttle better? 1. stability in engine operation. 2. phenomenal response to the gas pedal.

Let me explain. From the point of view of filling the engine, a large receiver bank is better. less pulsations in the cylinders affect each other. (interfere with each other) but a large can means dead volume and worse throttle response.

that is, with one damper there will be a dilemma: either recoil or quick response. throttles solve this problem radically. both response and impact. that's all.

There is a third factor: it’s easier to adjust the throttle than to build a receiver for the same engine output. one of the main reasons is the difficulty in placing the receiver under the hood.

what the receiver should be like can be seen on the BMW M3 and M5 or in WTCC.

someone will say that cars with a receiver drive normally. There are no problems on one valve. I thought so too until I installed the throttle. the difference is HUGE. This is the main reason why a peppy Atmotaz with 200 horsepower goes faster than a turbotaz with 250 horsepower. on a turbotaz with one valve and high boost, it’s either empty or thick. Every time you switch (even if just a little), the boost is lost and the car accelerates in a ragged mode. axle box... pause... axle box... pause... the atmosphere at the same time distributes its power much more evenly along the road. shifts without delay and generally has better engagement. stops slipping at a lower speed and, having caught on in the first meters, always takes the lead. all thanks to a more predictable delivery of more uniform torque. I don’t think it’s necessary to say that after 150 mph the turbo will always leave the atmosphere. pure power rules there.

Now about the design of the throttles. I can highlight 3 design options for pelvis throttles. 1. 4 separate axes for 4 dampers. 1a) the axes go one after another. like one cut axis

1b) the axes are parallel to each other but rotated 90 degrees relative to the first option

2. 2 axes, one for 2 dampers. This is an analogue of 2 double Webber carburetors.

3. 1 axle for all 4 dampers. I made this option on 2110.

In terms of the number of parts, option 1 is the most difficult. The easiest option is the 3rd option. In terms of manufacturing complexity, option 1 is the easiest, option 3 is the most difficult. the second option is something in between. all options have their pros and cons. For example, the throttles of the Toyota Corolla Levin Black Top are built on 4 separate axles. but everyone stands longitudinally in one line. and between them a connection with the possibility of adjusting the position of the damper.

pros: can be adjusted, nothing jams, because one axis rests on 2 bearings. and each damper has a separate stop for the zero position. The workmanship is very high, the resource is probably almost eternal. cons: the unit is bought in a trash heap and requires adaptation to the pelvis motor.

Option 2 is intermediate. This is how the throttles on motorcycles (superbikes) called Keihin are made. one axle rests on 4 bearings. 2 extreme ball ones. 2 in the middle seems to be a bushing. You can only synchronize pair to pair of dampers. individually - no way. disadvantages: it is much more difficult to install on the pelvis, since the cylinder distance on motorcycles is smaller. the unit is more compact. and it is not good to separate the double part. If you mess up, you'll ruin the knot. pros: fewer parts. easier. more compact.

Operating principle of the electronic pedal

E-gas is no longer a new thing. If previously the throttle valve was opened using a cable, today the gas pedal device is literally “tied” to sensors. The pedal module itself is completely covered with plastic, behind which (in the bracket) two sensors with a spring are installed. When the driver presses the lever, the spring is compressed, and sensors (potentiometers) read this position.

Its position is read by two sensors, transmitting the received information to the ECU - “reporting” on the work done. It would seem that the system has become much more complex and incomprehensible. It has become more environmentally friendly, since the ECU has an over-throttle lock - even if you hit the pedal, pressing it to the floor, the damper will not open “to its full amplitude”.

Superficial intervention or deep cleaning?

There are two ways to clean the throttle valve. The first is a superficial intervention that does not require complete removal of the entire device. And the second is a complete cleaning, which must be performed in cases where your car’s engine is not working well.

To perform the first type of cleaning, you will need a pre-purchased cleaning product and a fine brush. Open the hood, remove the corrugation, it goes from the air filter housing to the throttle valve. You will see a valve - it is easy to recognize by its completely round shape. Treat it with a chemical and let it sit for a few minutes, then remove the dirt with a brush. If necessary, use a rag. Repeat the procedure several more times until the flapper valve turns a bright color. This work can be carried out once every 3–5 thousand kilometers, fortunately, it does not take much time.

For more detailed cleaning of the throttle valve in a VAZ 2110, you need to completely remove the entire injector mechanism. It is also recommended to replace the gasket and O-ring, which are included in the throttle valve repair kit, which is easy to buy at any auto store. Before starting cleaning work, remove the terminals from the battery.

Then disconnect all air pipes connected to the throttle body. After this, remove the fastenings of the throttle cable and unscrew the throttle valve itself. It is attached to two bolts that are screwed into the engine housing.

Electronic sensors must be disconnected carefully to avoid damaging them.

After that, take a chemical and treat the entire body and all the grooves of the throttle body. Do this until you completely get rid of the dirt. You can also clean the air flow meter sensor. To do this, carefully treat its hairs with a cleaning product and remove the dirt with a brush. Give the entire device time to dry completely before reassembling. Do not forget to change the gasket and ring, which are located in the corrugation

Also pay attention to whether all air pipes are intact. Perhaps some require replacement with new ones

For maximum effect, you can also replace the air filter.

Description of the motor device 21213

The basis of the VAZ 21213 engine includes:

- cast iron cylinder block (BC) 21213-1002011;

- block head 21213-100301*;

- crankshaft 21213-1005015;

- connecting rod and piston group 21213-10040*.

The main difference between the 21213 engine and its predecessors was the increased cylinder diameter - 82 mm versus 76 and 79 mm. The center-to-center distance of 95 mm remains the same, and allows the block to be bored to a diameter of 82.8 mm. The design of the water jacket has changed. The working volume has increased by 100 cm3, but the engine dimensions have remained the same.

To install the crankshaft in the BC there are 5 supports: one each on the front and rear walls, 3 more on the ebb. The crankshaft parameters provide a piston stroke of 80 mm. The crankshaft is cast from cast iron and consists of 4 connecting rods and 5 main journals. The connecting rod journals have oil channels. The necks are separated by cheeks with counterweights. In previous VAZ engines, balancing counterweights were found only in the outer and central cheeks. The axial movement of the shaft is limited by thrust half-rings.

The piston group for the 21213 engine was developed anew. Pistons 21213-1004015 are cast from aluminum and reduced to a single mass of 347 g. The piston class (A, B, C, D, E) is determined by the outer diameter in increments of 0.01 mm. The shape of the piston is conical in height and oval in cross section. The hole for the pin is 22 mm, offset by 1.2 mm from the piston axis. The finger is locked with rings. There are 3 rings installed on the piston skirt:

- upper compression barrel;

- medium oil scraper with expansion coil spring;

- lower compression scraper type.

The connecting rod 21213-1004045 is forged from steel and processed together with the cover. A steel-bronze bushing is pressed into the upper head of the connecting rod. To fasten the connecting rod, M9x1.0x56 bolts are used.

The aluminum BC head is designed for the VAZ 21213 engine and is designed for compression from 10 bar. Installing a head from other motors may cause it to break. Cast iron seats and guide bushings for 4 intake and 4 exhaust valves are pressed into the head. The valves operate from the camshaft cams. The gap between the valve stem and the cam is adjusted with a bolt.

Similar article Technical characteristics of the Toyota 2AR FE engine

timing belt

The camshaft 21213-1006010 is made of cast iron and rests on 5 journals. The jaws are bleached to increase wear resistance. Axial movement of the shaft is limited by a thrust flange.

The timing belt is driven by a double-row bush-roller chain. In addition to the camshaft, the chain drives the oil pump. The drive is regulated by a semi-automatic tensioner with a shoe and damper. To prevent the chain from falling off when removing the camshaft sprocket, a limiter is provided next to the crankshaft drive sprocket.

Systems

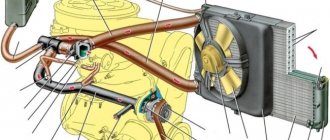

The power supply system in the Niva 21213 engine is a 21073 Solers carburetor. The carburetor unit is two-chamber, the throttle valves operate sequentially. When the first chamber is 2/3 open, the throttle of the second chamber is engaged. At idle, the economizer turns on. The carburetor device includes:

- float chamber;

- 2 dosing systems;

- crankcase gas suction system;

- heating the throttle zone of the first chamber;

- blocking the second camera;

- economizer;

- econostat;

- diaphragm accelerator pump.

The ignition system in the 21213 engine is non-contact. The system is controlled by a switch using distributor signals. In general, the system is classic, without any special features.

Cooling of the motor occurs according to a typical scheme: liquid circulates through the water jacket in the BC and the block head. The pressure is created by a centrifugal pump connected by a belt drive to the crankshaft and generator. The radiator fan impeller works on suction, so in winter the radiator has to be covered with cardboard.