If you search on the Internet, you can come across the following types of questions posted on automobile forums: “Is it possible to use kerosene as a fuel for diesel?”, “Is it possible to add kerosene to diesel fuel?”, “I accidentally filled my diesel with kerosene. What could be the consequences?

The responses received are usually mixed. Half the people will say, “Don’t worry, everything will be fine.” The other half says that such fuel is dangerous for car systems. Let's figure it out.

The chemical composition and properties of kerosene are quite close to diesel fuel, which is not surprising, since diesel fuel is produced by distilling kerosene-gas oil fractions of oil. Kerosene is also called No. 1 diesel fuel, while regular diesel fuel is designated diesel fuel. fuel No. 2. Some people find these two fuel fluids similar enough to try using them interchangeably in their vehicle. Let's look below at why some car owners do this and what problems they may encounter.

How to lower the octane number of gasoline

So, to lower the octane number of gasoline, you can use kerosene, the octane number of which is 45, this number means faster combustion of the fuel mixture and a slower ignition delay. If we add kerosene to gasoline, we slow down the combustion of the fuel, which actually means a lower octane number.

But diluting gasoline to lower the octane number will lead to dirtier combustion, which in turn will inevitably lead to increased contamination of the spark plug and piston system (carbon deposits), as well as an increase in the temperature of the internal combustion engine.

We do not recommend lowering the octane number of gasoline: using fuel created in this way can ruin the engine!

Kerosene should not be taken for kerosene stoves, it is too dirty and there will be a lot of soot. Ideally, you need to take fuel for light aircraft.

Kerosene in diesel fuel. Benefit or harm?

The operation of diesel vehicles in the winter season has certain specifics. The most common problem that occurs in cold weather is poor engine starting due to the formation of paraffin crystals in diesel fuel and deterioration in its pumpability through filters. Experienced diesel owners are familiar with it firsthand and use different methods of combating it. The most popular of them is adding kerosene to fuel. The main feature of this method is the ability to significantly reduce the temperature threshold at which the fuel loses fluidity and begins to clog the fine filter. But there are also negative features when using kerosene to improve the low-temperature properties of fuel.

- More difficult to start the engine.

The main indicator of diesel fuel, which determines the ease of engine starting, is the cetane number. The higher it is, the faster the engine starts. It should be noted that winter diesel fuel has a lower cetane number than summer diesel fuel. And kerosene has an even lower cetane number than winter diesel fuel. Therefore, adding kerosene to diesel fuel leads to a decrease in the cetane number of the resulting mixture and, as a consequence, to a deterioration in engine starting in cold weather.

- Deterioration of the lubricity of diesel fuel.

The most dangerous disadvantage of using kerosene is a significant reduction in the already low lubricity of diesel fuel.

Improving the low-temperature properties of the fuel in this way leads to another problem - increased wear of the high-pressure fuel pump (HPF) and injectors due to a lack of lubricating components in the fuel. As a result, the service life of the main elements of the fuel equipment is significantly reduced, the likelihood of their failure increases, which leads to expensive repairs. How to compensate for the negative effects of kerosene?

If you prefer to improve the low-temperature properties of diesel fuel by adding kerosene to it, it is necessary to restore the deteriorated fuel properties - cetane number and lubricity. This can be done by adding cetane-increasing and anti-wear additives to the fuel, for example, from ASTROhim®, produced using German technology and from BASF® raw materials.

Using the ASTROhim® Cetane Plus additive for diesel fuel allows you to increase the cetane number of the fuel up to 5 units. This helps stabilize the engine and improves its starting in the winter. In addition, the additive ensures complete combustion of diesel fuel, reduces exhaust smoke and improves the acceleration dynamics of the car.

ASTROhim® diesel lubricant helps replenish the lubricating components in diesel fuel. This allows you to restore the life of the injection pump and fuel injectors, protecting them from premature wear and failure. In addition, the additive can extend the life of the engine and protect its parts from corrosion.

Both additives are compatible with all brands of diesel fuel and do not change its low-temperature properties. Recommended for any diesel engines (including turbocharged ones), especially for use in Common Rail and pump-injector fuel systems. The additives are absolutely safe. They do not harm particulate filters, catalytic converters and exhaust gas recirculation systems.

How to make 76 gasoline from 92

So, we decided that we will dilute 92 gasoline with kerosene. The calculator below will help you calculate exactly how much gasoline and kerosene need to be mixed to obtain the required amount of 76 gasoline.

This calculation uses a formula that can also be used to dilute gasoline with a different octane number.

Let's assume we have gasoline with octane number A, and we need to get B. We also have kerosene with octane number 45, let's calculate the proportion:

We need to take (AB)/(A-45) parts of kerosene, let's take this as the number K

Then you need to add (1-K) parts of gasoline to this amount.

We multiply K by the amount of gasoline that needs to be obtained and we get how much kerosene needs to be taken.

Similarly, multiplying (1-K) by the amount of final gasoline, we get how much initial gasoline needs to be taken.

Calculation example of how to make 76 gasoline from 95

Suppose you need to get 10 liters of 76 gasoline out of 95

You need to take (95-76)/(95-45) = 0.38 parts of kerosene and (1-0.38) = 0.62 parts of 95 gasoline.

Which is equivalent to 0.38*10 = 3.8 liters of kerosene and 0.62*10 = 6.2 liters of 95 gasoline.

Oil is a complex mixture of hydrocarbon compounds. In its raw form, it is practically not used, and in order to obtain petroleum products suitable for use, it must be processed. The essence of crude oil refining is its decomposition into fractions and their further processing.

How is aviation gasoline different from automobile gasoline?

It is immediately worth noting that most types of air transport (commercial aviation) use aviation fuel for flights, which is also used for work. Direct aviation gasoline is used only for aircraft that operate using piston engines (this can be either midget aircraft or small commercial aircraft).

Read more: How to charge agm with a regular charger

This has led to the fact that the production of aviation gasoline has become a highly specialized activity with relatively small volumes of output. There are three main factors that are critical to the fuel used for aircraft:

- detonation resistance, which is significantly higher than that of automobile fuel;

- fractional composition (it is decisive for the boiling point of gasoline and its volatility);

- chemical stability;

It is also worth noting a higher octane number, the ability to perform the functions of a coolant, a lubricant for the rubbing elements of the engine, and a higher specific heat of combustion.

Direct distillation (rectification) of oil

Using this technique, gasoline began to be produced at the dawn of the development of the automobile industry. The process itself takes place in so-called distillation columns, but direct distillation can also be carried out at home, which we will talk about a little later.

The essence of this process is that crude oil is heated, and with a gradual increase in temperature it is divided into fractions having different boiling points.

The process can occur both at atmospheric pressure and in a vacuum of varying depths.

During the rectification process, volatile fractions evaporate from oil at different temperatures, such as:

- gasoline fraction (evaporates first at temperatures up to 180 degrees);

- kerosene (evaporation occurs in the temperature range from 150 to 305 degrees);

- diesel fuel (boiling temperatures - from 180 to 360 degrees and above).

The resulting gasoline and other vapors are cooled and condensed back into a liquid state.

Let’s immediately say that this method has a lot of significant disadvantages. These include:

- the amount of fuel produced is small (from one liter of raw gasoline, only about 150 milliliters comes out in this way);

- the quality of straight-run gasoline is very low, with an octane number ranging from 50 to 60 units;

- To bring straight-run gasoline to acceptable quality characteristics (up to an octane number above 90 units), a large number of various types of additives are needed.

Jet fuels [ edit | edit code]

Kerosene is a fraction of oil that boils away mainly in the temperature range of 200-300 ° C. Jet fuel, fuel for aviation jet engines, are usually kerosene fractions obtained by direct distillation from low-sulfur (for example, T-1) and sulfur (TS-1 ) oils. Currently, straight-run aviation fuel is scarce; hydrotreating and additives are widely used.

Kerosene is used for domestic purposes as heating and motor fuel, a solvent for varnishes and paints. Jet fuel is used as fuel for gas turbine engines of airplanes and helicopters of civil and military aviation, and in addition, fuel on board an aircraft can also be used as a coolant or coolant (fuel-air and fuel-oil radiators), and as a working fluid hydraulic systems (for example, controlling the cross-section of an engine jet nozzle). Jet fuels are also widely used as a solvent during aircraft maintenance and when cleaning contaminants manually or mechanically (for example, in an ultrasonic installation for cleaning filters, jet fuel is used as a working fluid). Aviation jet fuels undergo a total of up to 8 levels of quality control, and in the Russian Federation, in addition, acceptance by a military representative.

For jet fuels, the main quality indicators are:

- mass and volumetric heat of combustion

- fuel thermal stability

- saturated steam pressure

- kinematic viscosity

- compatibility with structural and sealing materials

- carbon deposit and anti-wear properties

- electrical conductivity

- sulfur

- acidity

Jet fuels are produced mainly from middle distillate fractions of oil, boiling at a temperature of 140-280 C° (naphtha-kerosene). Wide-fraction grades of jet fuels are produced using gasoline fractions of oil in the processing. To obtain some types of jet fuels (T-8B, T-6), vacuum gas oil and secondary oil refining products are used as raw materials.

Jet fuels consist of 96-99% hydrocarbons, which are divided into three main groups:

In addition to hydrocarbons, jet fuels contain small amounts of sulfur, oxygen, nitrogen, organometallic compounds and resinous substances. Their content in jet fuels is regulated by standards.

In Russia and the CIS countries operating Soviet aircraft, the following types of aviation fuel are used:

— TS-1

in the Russian Federation it is produced according to GOST 10227-86 as amended. 1-6. — straight-run fraction 150-250 C°, or a mixture of straight-run and hydrotreated fractions (the main limitation is the content of total sulfur and mercaptan no more than 0.2% and 0.003%). The most widespread type of aviation fuel in the Russian Federation and the post-Soviet space, intended for all old types of turboprop and subsonic turbojet engines, it is also used by aircraft of foreign manufacturers. In terms of its characteristics and scope of application, it approximately corresponds to foreign Jet-A kerosene. It is a backup in relation to RT fuel.

— RT

— high-quality fuel, oil fraction 135-280 C° with complete hydrotreating. Sulfur content: total - 0.1%, mercaptan - 0.001%. Due to hydrocracking, the fuel is “dry”, that is, it has low lubricating properties. During the production process, antioxidant and anti-wear additives are introduced into it. Intended for turbojet subsonic and some supersonic aircraft (Su-27, Tu-22M3, etc.), as well as as a fuel reserve for TS-1. There are no foreign analogues for this fuel.

—T-6

and

T-8V

- heat-resistant jet fuel for the engines of some supersonic aircraft (for example, MiG-25). They are produced using a very complex technology with hydrotreating and the introduction of additives. These fuels are produced only for the needs of the Russian Ministry of Defense.

Fuel octane number and its role

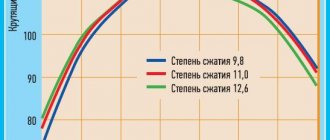

Octane number is a measure of the performance of a fuel. It is measured relative to pure isooctane, which is assigned a value of 100. The higher the octane number, the more compression required to detonate the fuel.

On the other hand, octane is not only a rating scale used to classify gasoline according to its anti-knock properties, but also a real-life paraffinic hydrocarbon. Its formula is close to C8H18. Normal octane is a colorless liquid found in boiling oil at approximately 124.6°C.

Regular gasoline is (if we exclude the influence of the ethanol component) a mixture of several hydrocarbons. Therefore, the octane number is calculated as the number of octane atoms in a gasoline molecule.

Read more: Cool poems about drivers

Is all of the above true for kerosene as a fuel?

Catalytic and thermal cracking

Let’s make a reservation right away: these processes cannot be reproduced at home, since they are quite complex and require special technological equipment. In order not to burden you with complex physical and chemical terminology, we will try to describe these processes by which oil is processed into petroleum products in as simple and understandable a language as possible.

The essence of any cracking process is the decomposition of petroleum components into components under the influence of high temperatures and the use of catalysts. In other words, complex hydrocarbon compounds decompose into simpler ones with a lower molecular weight (for example, gasoline).

The undoubted advantages of such technologies are:

| № | Helpful information |

| 1 | a significant increase in production productivity (the yield, for example, of gasoline increases significantly - up to 40-50 percent) |

| 2 | its quality compared to straight-run is much higher (the octane number is about 70 - 80 units, and with catalytic reforming - more than 90) |

| 3 | to obtain commercial petroleum products from gasoline obtained by such methods, a minimum of additives is required |

Often, cracking processes in production lines are used with other modern technologies - catalytic reforming, hydrocracking, isomerization, and so on. All these technologies pursue one goal - to obtain the highest quality fuel and increase the depth of processing of petroleum raw materials.

Main varieties

Many passengers are interested in what airplanes are fueled with, what fuel they fly on; modern airliners most often use the following types of fuel:

- aviation gasoline for piston engines - it can also be used as a solvent for maintenance;

- Aviation kerosene for jet aircraft is a highly processed fuel, its subtypes are designed for different operating conditions.

Aviation fuel

Aviation gasoline is practically no different from its automobile counterpart; the main features are related to the specific use. It is synthesized by oil distillation or catalytic cracking; there are two main types of composition, the difference lies in the octane number. Fuel of this type has been used less and less recently as aircraft fuel, this is due to the fact that piston engines are gradually becoming a thing of the past. Its main area of application is technical inspections of the engine and components.

- detonation resistance;

- fractional composition;

- chemical stability - resistance to chemical changes during transportation, use, etc.

Properties and composition

Density 0.78-0.85 g/cm³ (at 20 °C), viscosity 1.2-4.5 mm²/s (at 20 °C), flash point 28-72 °C, auto-ignition temperature 400 °C, calorific value is about 43 MJ/kg.

Depending on the chemical composition and method of refining the oil from which kerosene is obtained, its composition includes:

- saturated aliphatic hydrocarbons - 20-60%

- naphthenic hydrocarbons 20-50%

- bicyclic aromatic 5-25%

- unsaturated hydrocarbons - up to 2%

- impurities of sulfur, nitrogen or oxygen compounds.