As you know, an engine requires two conditions to operate: a combustible mixture and a spark. The exception is diesel engines. In them, ignition occurs due to high air compression. However, in cars with a gasoline engine, of which the majority are on the road, the ignition coil often fails. Signs of a malfunction may vary. Well, let's pay closer attention to this mechanism.

Signs of a faulty ignition coil

- Unstable engine operation. Popularly this is called tripling. This word appeared back in the days of the USSR, when one of the cylinders on the Soviet “classics” did not work. And as you know, all VAZ engines had four cylinders. Accordingly, the phenomenon when one of them does not work is called tripling. In this case, characteristic vibrations may occur. The motorist will also hear uneven operation of the engine - as if something is missing. This is understandable, because one of the cylinders is idling, that is, the combustible mixture in it does not ignite.

- “Tripling” motor. If one or more cylinders in the engine do not work, acceleration failures are possible. The car will twitch and vibrate. The car also picks up speed very slowly.

- Yellow lamp "Check Engine". Warning lights on the instrument panel may well be a sign of a faulty ignition coil. It is worth noting that this error is not necessarily related to this malfunction. The lamp only indicates general problems with the engine. If “Check Engine” lights up on the instrument panel, this means that a failure has occurred in some system. The car is subject to thorough diagnostics.

- High fuel consumption. Since one cylinder is not working, the remaining three (or more depending on the engine design) take on the entire load. Accordingly, in order to resume the previous power, the motor will require more energy. Fuel consumption can increase by 10 to 50 percent.

- Difficulty starting the engine. If there is a malfunction with the coil, the driver may experience problems of this kind. Moreover, they occur both when the engine is cold and when the engine is warm. Difficulty starting the engine is especially common in wet weather.

Also note that if the car does not start at all, this is not a sign of a coil failure. The fact is that there are several of them in the engine. Usually each cylinder has its own coil. On older ones, voltage is generated on two cylinders at once. Therefore, the motor will work until the last minute. If the car does not start at all, all the coils could fail at once. However, this is unlikely. In this case, experts recommend checking the fuses in the unit and the corresponding relays. Why does this happen? The reasons for coil failure will be discussed below.

How to identify a faulty ignition coil

The procedure for checking the serviceability of the coil depends on how many ignition coils are in the car. If your car has individual ignition coils, in order to identify the faulty one with a high degree of probability, you can swap the supposedly faulty and known-good coils. If, as a result of this replacement, a spark appears in the cylinder in which there was no spark, and disappears in the other, therefore, the bobbin is truly faulty. In the same way, you can check dual and block coils, but you will have to modify the circuit, which is not always convenient.

How to determine which ignition coil is not working without making changes to the electrical circuit

To do this, you need to stock up on thick dielectric gloves and a dry rubber mat. The use of only ordinary dielectric gloves is unacceptable: they can withstand a breakdown voltage of 6300 Volts; the voltage applied to the candle is approximately three times higher.

If your car has two or more ignition coils, if one of them malfunctions, the car should start, but struggle a lot. By removing the tips of the high-voltage wires of the spark plugs or connectors from individual coils one by one, the stability of the engine is assessed. If the internal combustion engine has not changed its operation as a result of removing the connector, then there is no spark in this cylinder. If the engine starts to shake even more, or stalls altogether, there is a spark, the bobbin is faulty, or it is not receiving impulses or power.

Insulation breakdown

Just like with candles, a breakdown in the insulation can occur here. What could be causing this? Often a breakdown occurs due to oil leaks that form at the junction of the valve cover, head and other elements. As the rpm increases, the oil pressure increases. Oil begins to get on all elements, including the ignition coil. Signs of malfunction: failures in acceleration, jerking and high fuel consumption. To prevent this, keep the engine compartment clean.

Please note that an insulation breakdown may also occur due to engine washing. Excess moisture gets onto the contacts, causing a short circuit. To prevent this, you should cover not only the battery, but also the coil itself. It is also recommended to insulate the distributor cap if it is an older car. By the way, a wet distributor is the most popular reason why a car won’t start at all. Sometimes you can limit yourself to drying contacts. But in 80 percent of cases, only replacement saves.

What types of ignition coils are there?

Based on their purpose:

If your car does not have a distributor, the spark plug coil is 100% contactless. For customized coils, only this type is provided. But if the distributor has special equipment - in the form of breaker contacts - you use a contact-type ignition system.

If the criterion is the number of spark plugs available, they are divided into:

There are also differences in winding insulation options . They are:

- Filled with oil. The housing contains metal; transformer oil is used to insulate the windings. If the housing loses its seal, this device will simply stop functioning. The leakage of such oil leads to interturn electrical breakdown of the windings (since they are absolutely not protected).

- Dry (filled with compound).

Natural wear and tear

The ignition coil is designed for a long service life. There are often cases when an element worked even after a run of 150–200 thousand kilometers without a single replacement. But with every kilometer, the life of the coil decreases. The installation of low-quality spark plugs or careless cleaning of the engine compartment can contribute to the breakdown. At one point, the part may simply not withstand the load.

How to check and replace the ignition coil

Published by Oleg Kuprin - 06/27/2015

Recently, interest in the issue of replacing the ignition coil has sharply increased. Acting on a par with the distributor as the basis for the full and efficient functioning of any vehicle, in the event of a breakdown it becomes the cause of both “local” problems and can completely stop the entire operation of the engine.

We will not now advise trying to check the ignition coil by having a spark between the car and the spark plug - it is not safe and often leads to even worse consequences. The surest way is to arm yourself with a dual-mode multimeter (a device that allows you to test for resistance and voltage).

What is an ignition coil, its functions and purpose

Let's first focus on the design of the car. An element of the ignition system, the distributor is located at the top of the engine and is a “receiver” of low-voltage current. The ignition coil (or bobbin) serves as a converter of this current into high voltage current. However, before it is converted, the current travels its way from the battery through the on-board network to the distributor. This is exactly the place where the final “transition” of the generated high-voltage current to the main wire going to the spark plug takes place.

Then everything looks like this: carefully screwed in spark plugs supply a spark to the fuel combustion chamber, resulting in a flash. The quality of the supplied current solves a number of problems:

- Timely ignition of fuel caused by prompt supply of current;

- Providing the necessary “voltage”.

Situations arise when, due to problems with the coil or the ignition system as a whole, the current is supplied ineffectively. As a result, the engine refuses to start, and you can discern an unpleasant smell of gasoline coming from the muffler. In such cases, the driver decides that it is time to check the ignition coil.

"Why is that?" - causes of ignition coil failure

Sometimes it is necessary to change the ignition coil for various reasons. However, the main “trouble” lies in the following points:

- Wear of the coil assembly or its parts;

- Violation of the ignition circuit;

- Defective parts - spark plugs;

- Broken wires.

The most popular method of testing a coil involves performing a series of steps in sequence. First, one of the spark plugs and the high-voltage wire are unscrewed. Then the spark plug is threaded into the wire and applied to the car body to check for a spark. At the same time, the engine starts. And if at this time a spark jumps between the vehicle and the spark plug, everything is in order with the ignition coil. If not, the element requires replacement.

This method of checking the performance of the coil travels from motorist to motorist and is still in demand to this day. However, few people realize that this “method” is not suitable for every ignition system, and in some cases it can even damage the working coil. A striking example is the 2001 Honda.

Remember - the ignition coil is not always the cause of a stalled engine. Before “conducting experiments on it,” make sure that the wires and spark plugs are in working condition. In general, novice drivers, due to their lack of experience, may “sin” to break the ignition coil if there is no fuel in the tank. Be that as it may, if you really doubt the efficiency of the ignition coil, test it in a garage.

How can you check the ignition coil with an electrical measuring device?

So, all other reasons have been eliminated, and it’s time to test the operation of the coil. Let's get to know her better! First of all, the body that does not allow current to pass through catches your eye - it is made of ebonite. On top of this housing there is a cover containing a terminal. As for its internal contents, there is insulating material, screws, a core, a central terminal spring, etc. In most cases, one of the “internal” components of the coil fails, but breakdowns of the housing are also no exception.

Let's move from theory to practice! We test the ignition coil as follows:

- The latch bends

- The wiring harness block is disconnected from the distributor

- Take a multimeter and switch to the measurement mode in volts

- The tuned device is connected to the coil on one side, and to the car body on the other.

The normal reaction is a voltage of 12 V. If there is a deviation from the norm, the root of all evil lies in a malfunction of the ECM or the electrical circuit of the distributor.

Task No. 1 is completed, let’s move on to task No. 2 – checking the coil winding:

- The multimeter switches to Ohm measurement mode

- The configured device is placed with the leads to the coil (A/B, then B/C)

The correct indicator is 2 ohms for any measurements. With other values, there is a break in the winding, and the ignition coil should be replaced. The procedure for testing the secondary winding is similar. In this test, the standard is 5 ohms.

How to check the resistance of the ignition coil, watch the video:

Task No. 3 – testing the distributor for shorting two windings. The chain of actions is extremely simple:

- The multimeter is configured for measurement mode in Ohms

- The device is connected to the terminal of coil A and to the high voltage output

A properly functioning device will show resistance tending to infinity.

Features of the contactless ignition system

In the automotive industry, in addition to the contact ignition system, there is also a contactless option. The essence of this method is to generate a current by rotating a magnet winding.

As a rule, BZS has a longer service life and efficiency. It is able to withstand temperatures ranging from -40°C to +80°C. It itself is located under the hood, and the coil and sensor are located in place of the standard ignition system.

In order to determine whether it is necessary to change the ignition coil or not, in this case it is enough to test the wires connecting the sensor to the switch. However, sometimes there is a possibility of a tear in the wire between the commutator and the coil.

Finally, I would like to highlight the main points of the article:

- Eliminate the option of checking the functionality of the ignition coil by detecting a spark between the spark plug and the car body!

- Check the operation of the coil only with an electrical measuring device!

- The smell of a burnt winding will speak for itself - the coil cannot be saved.

How to remove the ignition coil using the example of a VAZ 21114:

How to remove the ignition coil using the example of a Peugeot 306:

How to check the ignition coil directly on a car:

How to change the ignition coil:

Subscribe to the auto magazine 2AUTO.su by e-mail, VKontakte, Facebook or Twitter, and do not miss interesting automotive news.

Photo

2auto.su

Ignition coil: prices

The cost of this element varies significantly. So, for domestic Ladas you can find a coil for 600–800 rubles. But for the tenth Lancer, which is so popular in Russia, a new element costs at least 3 thousand rubles. It's cheaper only from a showdown. But here you will not receive any guarantees or information about the residual resource. You can go another way - repair the ignition coil. This will save you a lot of money. But the ignition coil circuit is quite complex. You can only repair cracks with your own hands - seal them with specialized glue.

The term breakdown of an ignition coil or spark plug tip means a breakdown in the weakest point of the housing or wire insulation due to a decrease in resistance, occurring in short periods of time. This is mechanical damage that leads to the appearance of cracks or melting. On the surface of the case, the breakdown site appears as black, burnt-out dots, longitudinal tracks or white cracks. Such spark piercing areas are especially dangerous in humid weather. This malfunction leads not only to failure of the mixture to ignite, but also to complete failure of the ignition module.

Often such places are not difficult to notice visually, but sometimes it is necessary to check the ignition coil, not with a multimeter or oscilloscope, but with a simple device made of two wires. When a damaged area is identified, the part is usually completely replaced, although sometimes it is possible to delay the replacement using electrical tape, sealant or epoxy glue.

How to remove and replace the ignition coil on a VAZ-2114: photos and videos

Wear has no mercy, and this is the case with the ignition coil on the VAZ-2114. Many motorists have encountered the failure of this unit, but not every motorist knows how to repair it with their own hands.

The video below will tell you about replacing the ignition coil on domestic cars:

The video will tell you about the process of replacing the ignition coil, and also tell you about some of the nuances and secrets of the process.

The design of the ignition system on the VAZ-2114

Ignition coil

Before proceeding directly to the process of replacing the unit, the motorist needs to know how the system as a whole works. Therefore, let's look at the constituent elements of the ignition system.

Ignition system diagram

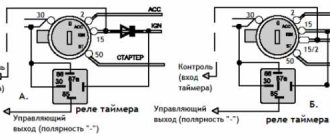

Diagram of a non-contact ignition system: 1 – non-contact sensor; 2 – ignition distributor sensor; 3 – spark plugs; 4 – switch; 5 – ignition coil; 6 – mounting block; 7 – ignition relay; 8 – ignition switch

Replacing the ignition coil

Now that the design features of the ignition system are known, you can proceed directly to the process of replacing the bridle. Let's look at the step-by-step instructions:

- We remove the “minus terminal” from the battery.

We dismantle the battery terminal - Remove the top protective cover of the engine.

If the engine volume is 1.5 liters, then this part is missing and this step is skipped. Removing the upper engine protection strip - We remove the high-voltage wires from the coil.

Removing the BB wires from the coil - Now, using a 13mm wrench, unscrew the two fasteners.

- Using a 17mm wrench, loosen one bolt securing the coil.

- We take out the module.

We dismantle the ignition module - Use a hexagon to unscrew the coil from the holder.

- Assembly is carried out in reverse order.

Attention! Particular attention should be paid to the connection, since high-voltage wires must be located in the strict order provided for by the design. If this is not done, the car will stall or the engine may not start at all.

Product selection

Particular attention should be paid to the choice of product, since in the modern automotive spare parts market, low-quality products and fakes are often found. In addition to the original spare part, a number of manufacturers offer analogues that are in no way inferior in quality to the factory part, and in some cases even much better. Let's consider all the options for purchasing an ignition module for a VAZ-2114.

Original

2112-3705010 – original catalog number of the ignition module manufactured by AvtoVAZ. Factory part that is installed on the Lada 2110-2115 family of cars. The cost of a spare part is on average 3,500 rubles.

Possible analogues

Analogue part produced by Fenox

In addition to the original part, on the spare parts market you can find a number of analogues recommended for installation:

- Pekar 2112-3705010 – St. Petersburg plant of spare parts for domestic cars. It occupies a high market share and is famous for its quality. The average cost of a part is 2,500 rubles.

- Fenox IC16009O7 is a Belarusian manufacturer that offers a spare part for 3,500 rubles.

- Startvolt SC 0112 – Another one. The cost of the product is 4000 rubles.

- Fenox IC16009 is another option from the Minsk plant, the cost of which is 4,000 rubles.

Possible repairs

Not in all cases of failure of the ignition module, it requires replacement. As automotive practice shows, some motorists are able to repair this unit on their own. So, using a soldering iron and other radio electronics tools, you can carry out repair work.

Read more about ignition coil repair and diagnostics here.

Frequent failure of the ignition module on the VAZ-2114 (possible solution)

If the ignition coil often fails (see “checking the ignition coil”), then you should pay attention to the fact that the factory has not chosen a very good location for it.

Moving the ignition coil to a “better” location

A good option would be to move the ignition coil higher.

conclusions

Replacing the ignition coil on a VAZ-2114 is quite simple. Even a novice motorist can complete this process in his garage, but if everything seems too complicated, you need to contact a car service. Particular attention should be paid to the choice of product, since this will determine how well the engine and ignition system will work.

carfrance.ru

What is ignition coil breakdown and its causes?

Let's take a brief look at what coil breakdown is, what it affects, and what it looks like visually. First of all, it should be recalled that the coil itself is a transformer that has two windings (primary and secondary), isolated from each other. The definition of breakdown is a physical phenomenon when, due to damage to the primary and/or secondary windings of the coil, part of the electrical energy falls not on the spark plug, but on the housing. This leads to the fact that the spark plug does not work at full power, and accordingly, the engine begins to “trouble” and its dynamics are lost.

Ignition coil device

There can be many reasons for the breakdown of the ignition coil - damage to the insulation of one or both windings, damage to the tip body, damage to its rubber seal (due to which water gets inside, through which electricity “sews”), the presence of dirt on the body (similar to water, current passes through it), damage (oxidation) of the electrode in the tip. However, most often the problem lies in the “wired” insulator, and therefore, to eliminate the problem, this place must be localized and insulated.

An interesting reason for the failure of ignition coil tips is the fact that when replacing a spark plug, in some cases, car owners, through carelessness or inexperience, can tear their waterproofing. This can lead to moisture getting under them and problems with engine operation. The opposite case is that when the car owner tightens the top nuts of the spark plug cups too tightly, there is a risk that engine oil from the engine will begin to penetrate into the plug housing. And this oil is harmful to the rubber from which the reel tips are made.

Also, the reason that spark breakdown occurs outside the cylinder is incorrectly set gaps on the spark plugs. This is especially true if the gap is increased. Naturally, the spark in this case has a detrimental effect on both the spark plug body and the rubber tip of the ignition coil.

How to test an ignition coil with a multimeter

The question arises: “How to check the ignition coil?” With a multimeter... This is probably the most accessible way. Let's look at how to test an ignition coil with a multimeter. It is necessary to check the resistance of the primary and secondary windings one by one. It wouldn’t hurt to check the resistance between the winding terminals and the housing. The resistance of the primary winding should be in the range from 0.3 to 2 Ohms, the secondary - from 6 to 15 kOhms. The resistance between the winding terminals and the housing should tend to infinity. If the values of the measured winding resistances deviate from the described ranges, an interturn short circuit is possible, but if the winding resistance tends to infinity, this is a sure sign of a wire break in the turn.

Symptoms of a faulty ignition coil

Signs of a malfunction of the ignition coil are that the engine periodically “trips” (triggering is especially important in rainy weather, and when starting the engine “in cold weather”), “failures” occur when accelerating the car, when visually inspecting the coil, “paths” of electrical breakdown are observed, burning of contacts, signs of thermal overheating, the presence of a large amount of dirt and debris in the coil body and other, smaller faults. The most common cause of coil malfunction is a break in its primary or secondary windings. In some cases, their insulation is simply damaged. At the initial stage, the coil will work more or less normally, but over time the problems will worsen and the symptoms described above will appear to a greater extent.

There are several typical signs of an ignition coil breakdown. It’s worth mentioning right away that the malfunctions listed below can be caused by other reasons, so diagnostics should still be carried out comprehensively, including checking the condition of the ignition coils. Thus, symptoms of breakdown can be divided into two types - behavioral and visual. Behavioral ones include:

- The engine begins to "trouble". And over time, the situation gets worse, that is, the “tweaking” is expressed more and more clearly, the power and dynamics of the engine are lost.

- When trying to accelerate quickly, a “failure” occurs, and when idling, the engine speed does not increase sharply. There is also a loss of power under load (when transporting heavy loads, driving uphill, and so on).

- “Tripping” of the engine more often occurs in rainy (humid) weather and when starting the engine “cold” (especially typical for low ambient temperatures).

- In some cases (on older cars), the smell of unburned gasoline may appear in the cabin. On newer cars, a similar situation may occur when, instead of more or less clean exhaust gases, the smell of unburned gasoline is added to them.

When dismantling the ignition coil if it malfunctions, you can observe visual signs that it has completely or partially failed. So, these include:

- The presence of “breakdown tracks” on the coil body. That is, characteristic dark stripes along which electricity “strikes”. In some particularly “neglected” cases, scale occurs on the tracks.

- Change (turbidity, blackening) in the color of the dielectric on the ignition coil body.

- Darkening of electrical contacts and connectors resulting from their burning.

- Traces of overheating on the coil body. Usually they are expressed in some kind of “drips” or changes in the geometry of the body in some places. In “severe” cases, they may have a burning smell.

- High contamination on the coil body. Especially near electrical contacts. The fact is that electrical breakdown can occur precisely on the surface of dust or dirt. Therefore, it is advisable to prevent such a state.

The main sign of a coil malfunction is the lack of ignition of the fuel mixture. However, this situation does not always arise, since in certain cases part of the electrical energy still goes to the candle, and not just to the body. In this case, it is necessary to conduct additional diagnostics.

Well, on modern cars, in the event of a breakdown of the ignition coil, the electronic engine control unit (ECU) will notify the driver about this by activating the Check Engine lamp on the dashboard (and a misfire diagnostic code). However, it can also light up due to other faults, so this requires additional diagnostics using software and hardware.

The symptoms of malfunction described above are relevant if the engine has individual ignition coils. If the design provides for the installation of one coil, common to all cylinders, then the engine will stall completely (this, in fact, is one of the reasons why several individual modules are installed on modern cars).

Causes of ignition coil failure

Let's look at the reasons why the ignition coil fails.

Natural wear and tear

Like all electrical and electronic units, the reel has a certain trouble-free operation life. The average service life of ignition coils is approximately seven to ten years of operation or 150,000 - 200,000 thousand mileage. The device is operated in extreme conditions with large differences in temperature, humidity, and the possibility of ingress of moisture, dirt, and foreign liquids. In this case, large currents flow through the primary winding, and a high-voltage pulse is formed in the secondary winding.

Electrical breakdown

Let's figure out why the ignition coil breaks. Firstly, over time, as a result of high temperature changes, the dielectric insulation cracks, and salty moisture, which is a conductor, can enter microcracks. For voltages of more than 15,000 volts generated in the secondary winding, even pure undistilled water acts as a conductor. Secondly, during operation, the physical properties of the dielectric and rubber insulation of the tips of high-voltage wires, especially those of dubious production, change. High-voltage breakdown can be caused by the installation of non-standard high-voltage wires in which there is no distributed current-limiting resistance. A breakdown can occur as a result of severe contamination or waterlogging. Even in the event of a single breakdown, irreversible changes occur in the structure; further operation is not recommended.

Overheat

Some vehicles have ignition coils installed directly at or near the top of the engine. If there is no air access to their structure for natural ventilation (this is possible when installing additional equipment), the device may overheat and fail.

Mechanical load.

The coil mount must be standard. Some car enthusiasts neglect these requirements by “hanging” it on homemade structures.

Wear of spark plugs, high-voltage conductors

Despite the fact that the circuit has a limiting resistance, wear of spark plugs and high-voltage conductors can cause electrical breakdown in them. Then the load current increases and the bobbin may overheat.

Generator voltage regulator relay malfunction

Sometimes it leads to an increase in the voltage of the vehicle’s on-board network and failure of the electronic amplifier (switch).

Malfunction of the contact group of the lock, electronic switch

If, during parking, +12 Volts are constantly supplied to the coil in the event of an abnormal closure of the lock contact group, the device may overheat and fail. The same situation is possible if the switch is faulty.

To prevent premature failure, all possible causes of malfunction of the ignition coil in the car should be eliminated as much as possible.

Checking the voltage on the coil windings

How to check a coil for breakdown

You can check for breakdown of the ignition coil in one of 5 ways, but as a rule, the average car owner has the opportunity to use only three of them. The first is a visual inspection, because often the breakdown site is visible to the eye; the second is a check with a multimeter, and the third, and the most reliable quick method, if nothing is visually noticeable, is to use a simple ignition system tester (it’s easy to do it yourself).

Ignition system diagnostics

Recommendations for diagnosing the ignition system (spark plugs, wires, coils, module). Instructions on how to check the ignition units of a car with your own hands Read more

To check the operation of the ignition system, first of all, it makes sense to use a program to read errors from the ECU. Usually in such cases it shows errors from the P0300 group, indicating misfire in one of the cylinders. However, please note that in this case, errors can be caused not only by faulty coils or spark plug tips. Therefore, in order to make sure that the fault is with one of them, it makes sense to move the problem unit to another cylinder, erase errors from the ECU memory and carry out diagnostics again.

Other factors influencing the coil

All faulty coils cannot be repaired, they must be replaced.

— mechanical damage to the ebonite body;

— violation of its tightness;

— breakage of incoming and outgoing wires, loss of their contacts;

— oil leaks, contamination of the insulation in the spark plugs, which provokes additional discharges on the surface, disrupting the smooth ignition cycle of the fuel;

- prolonged or strong vibration.

If the problem is not resolved and the coil is in perfect order, it means that the distributor or the electronic system itself is faulty. To establish this fact, touch the coil with one end of the voltmeter, and the other - the car body, more precisely, its “mass”. A malfunction is proven by a zero reading on the measuring device.

Important! Be careful when diagnosing ignition coils and spark plugs. Don't forget that in some areas there is high voltage current!

The ignition coil is one of the most important modules in gasoline power plants. If it turns out to be faulty, then the engine simply does not start. At the same time, computer diagnostics do not always allow you to accurately determine the presence of a malfunction, and in such a situation it is worth checking the ignition coil with a multimeter. To date, this method continues to be very effective.

Adviсe

In order for the coil to work longer, follow the rules:

- install the device on standard mounts;

- do not clutter the device area, ensuring good ventilation;

- keep the body clean;

- check spark plugs and high-voltage wires promptly (before the start of each operating season).

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

The ignition coil is designed to create high voltage, which is then used by the spark plug to produce a spark. Therefore, its proper operation is necessary for the normal functioning of the ignition system. Essentially, the coil is a small transformer, the primary winding of which receives standard 12 V from the battery, and outputs a voltage of several kV. It is used in all ignition systems - contact, contactless and electronic. The reasons for coil failure are typical. As a rule, this is a wire break, insulation damage, or mechanical deformation. Next, we will look at the signs of a malfunction and methods for diagnosing the ignition coil.