Tachometer glitch

#1 DimadriLL

- Advanced Members

- 220 messages

- Car make: PRIORA hatch

- From: Naberezhnye Chelny

#2 AnDmitrAl

- Car make: HYUNDAI CRETA + LADA 21102

- From: Orsk, Orenburg region

View Garage

Good afternoon everyone. I recently became the OWNER of a 2008 Priora Hatch. There is a tachometer glitch (which the previous owner warned about right away). The fact is that the tachometer needle always points to 1000 rpm. more. Those. at idle approximately 1800, etc. What could be the reason?

#3 DimadriLL

- Car make: PRIORA hatch

- From: Naberezhnye Chelny

#4 AnDmitrAl

- Car make: HYUNDAI CRETA + LADA 21102

- From: Orsk, Orenburg region

View Garage

No, the shooter always stands at a little over 1000. Even with the ignition off.

what is there to think? return the needle to zero by hand. (I did it at ten) and that’s it).

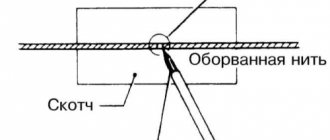

I didn't remove the tidy. I only removed the visor and stuck a wire into the gap between the tidy and the glass. and she pushed the needle to zero. but it's at ten. But on the Priora, the tidy may need to be removed. I do not know

Didn't you do a tidy test? turn on the ignition with the odometer reset button pressed on the dashboard

#5 DimadriLL

- Car make: PRIORA hatch

- From: Naberezhnye Chelny

what is there to think? return the needle to zero by hand. (I did it at ten) and that’s it).

I didn't remove the tidy. I only removed the visor and stuck a wire into the gap between the tidy and the glass. and she pushed the needle to zero. but it's at ten. But on the Priora, the tidy may need to be removed. I do not know

Didn't you do a tidy test? turn on the ignition with the odometer reset button pressed on the dashboard

#6 DimadriLL

- Car make: PRIORA hatch

- From: Naberezhnye Chelny

what is there to think? return the needle to zero by hand. (I did it at ten) and that’s it).

I didn't remove the tidy. I only removed the visor and stuck a wire into the gap between the tidy and the glass. and she pushed the needle to zero. but it's at ten. But on the Priora, the tidy may need to be removed. I do not know

Didn't you do a tidy test? turn on the ignition with the odometer reset button pressed on the dashboard

#7 AnDmitrAl

- Car make: HYUNDAI CRETA + LADA 21102

- From: Orsk, Orenburg region

View Garage

Did a tidy test. All arrows move within their limits from minimum to maximum. And the tachometer needle runs beyond the maximum. In short, I think that the needle somehow stupidly jumped to 1000 and now it stays that way. If, for example, it has a gear drive, then the teeth may have skipped.

#8 DimadriLL

- Car make: PRIORA hatch

- From: Naberezhnye Chelny

she stupidly jammed once. return it to zero with your hands.

Nexia does not turn the starter - SOLVED (ALARM)! — logbook Daewoo Nexia on DRIVE2

Some car models may have differences in structure. This should not be taken as a deviation; this happens often. If you are purchasing a part, you must inform the seller about the model of the part that was previously used.

If you select the element incorrectly, difficulties may arise with its operation, and it will quickly fail. If the starter does not respond to the rotation of the key and is in silent mode, then the test is divided into the following stages: The battery charge level is detected.

THIS IS INTERESTING: Ford Fiesta clutch replacement

It won't start, the starter won't turn. tell me what the reason is

The ignition switch contacts are being checked. The traction relay is being diagnosed.

The operation of the part of the starter responsible for torsion of the clutch and the mechanism itself are checked. Daewoo Nexia does not turn the starter and clicks If the engine does not start from the starter, then there is a possibility of various breakdowns of this mechanism.

One of the most common failures is that it makes shooting sounds or acts up, but does not turn on the engine. That is, the motorist turns the ignition key and hears sounds and clicks instead of the sound of the engine.

The same reasons, together with oxidation of the battery terminals, can also occur if, when turned on, the traction relay is activated, but the armature rotates too slowly. The starter turns on, but the armature does not rotate and the flywheel does not work? The problem can be solved by replacing the clutch, drive or flywheel, depending on the breakdown.

If it seems that when you turn on the starter you hear excessive noise, then perhaps the whole reason is excessive wear of the bearings, which will only need to be replaced. It is possible that only the teeth of the drive gear or flywheel are damaged; replacement will suffice.

This is the result, although I and other Drive participants assumed that with the replacement of the retractor everything should be solved. But as you can see, the problem was solved by cleaning the contact group.

Peace and obedient cars to everyone! A regular starter relay from VAZ is suitable, connected according to the diagram between contacts 15 and the New contact group.

Contact terminals. Let's understand the connection diagram: Connect the wires to the terminal block.

We get to the ignition switch by removing the steering column covers. We assemble an electrical circuit.

Why Daewoo Nexia does not start and does not turn the starter

Another reason for a non-working starter is a discharged battery or oxidized contacts at its terminals. The malfunction can also affect the starter itself, because when the Daewoo Nexia starter does not work, the graphite brushes wear out, and if at least one of them decreases in size to such a size that the spring cannot press it to the commutator, the supply of electric current to the armature winding will stop, and it will refuse to rotate.

In addition, the cause of starter failure may be burning of the traction relay contacts, since a large load current flows through them.

deunenexiaworksstarter

Source: https://yastalamamoy.ru/daewoo/nexia-2/%D0%BD%D0%B5-%D1%80%D0%B0%D0%B1%D0%BE%D1%82%D0%B0% D0%B5%D1%82-%D1%81%D1%82%D0%B0%D1%80%D1%82%D0%B5%D1%80-%D0%BD%D0%B0-%D0%B4 %D1%8D%D1%83-%D0%BD%D0%B5%D0%BA%D1%81%D0%B8%D0%B8.html

Communities › Lada Priora Club › Blog › We are scratching our heads or the tachometer is buggy...

Hmmm...lately, breakdowns of the priors have been bothering me... About 3-4 months ago, when I started the car in the morning, I noticed that the tachometer was at zero - then it was cold -30 and I thought that the motor had frozen... then after warming up, the tachometer started working... Well, and rode until the autostart switched off (that is, it stopped working)... I reconnected the autostart to the tachometer signal (before that it was on the generator) I thought it would work, but no, it didn’t work... But the remote control began to see the engine working... So on the weekend I was riding and the tachometer was again at zero (temperature is about -12)

Why the speedometer on the Lada Priora does not work and what to do

Unfortunately, Priora owners quite often ask themselves the question: why did the tachometer or speedometer stop working and is it possible to find out the cause of the breakdown on their own or will they still have to visit a service station?

First of all, every car owner must understand that if the speedometer or tachometer does not work at the proper level or it is noticed that the power steering starts to turn off periodically, it is strictly prohibited to operate the car until the defect is completely eliminated. This is explained by the fact that even minor malfunctions in the speedometer, for example, if the needle is sometimes at the zero mark, can lead to an accident, since the driver will not be able to obtain important information. Therefore, you need to find out why the speedometer on the Priora does not work, and sometimes the electric power steering turns off, as quickly as possible in order to repair your own car yourself and according to the rules.

Malfunctions on Priora

If the speedometer on a Priora stops working, the first thing you need to do is temporarily remove the terminals from the battery.

Did not help? – Then look for a fault in the device circuit. First, check the integrity of the instrument panel fuse.

If it burns out, replace it (but first make sure that all contact connections are intact).

If the problem persists or the fuse is normal, check all the wires on the path from the speed sensor to the instrument panel. This can be done using a multimeter.

If there are no complaints about the wiring, check the motion sensor with a special scanner. If there are malfunctions, the element must be replaced.

The serviceability of the motion sensor can be determined by the behavior of the odometer. If the speedometer does not work, but the odometer counts kilometers, then the sensor is working, and the breakdown must be looked for elsewhere.

For example, problems may be in the soldering on the dashboard circuit board or, even worse, in the gearbox. But this can only be found out at a service station with the help of a qualified technician.

As for the tachometer on the Priora, there are three causes of malfunctions:

- violation of the tachometer supply circuit. In this case, you need to carefully crimp all the tips and replace damaged wires (if any);

- violation of the functionality of the controller (the signal does not reach the tachometer). Only replacing the device will help here;

- failure of the tachometer itself. This option is the most expensive, because it is not possible to change the device separately - you need to buy a new panel.

Checking the speedometer functionality

The first thing car owners need to do if they notice that the speedometer or tachometer, and sometimes the electric power steering, will begin to work intermittently or stop functioning altogether is to check the car's electrical system for serviceability. The check is done in the following sequence:

- the battery is disconnected from power for 5-7 minutes;

- disconnecting from the power will allow you to reset all settings of the on-board computer;

- If after connecting the wires to the battery the fault cannot be eliminated, the cause of the breakdown must be sought in one of the elements that is used in the operation of the speedometer.

Experts recommend finding out the cause of a speedometer malfunction using the fuses.

Checking fuses

Often the cause of a speedometer malfunction is a blown fuse. Most often, a fuse fails due to water getting on it, which flows onto the contacts, which leads to an interruption in the operation of the electrical circuit. If the check reveals that the fuse responsible for the operation of the dashboard has blown, then the car owner will simply need to replace it with a new one. Finding the right fuse is quite simple by marking “IG/METER”, but if the replacement process does not help solve the problem, then you will have to check the integrity of the wires that go to the dashboard from the speed sensor.

Checking the condition of the wires

When operating the car on not very good roads, one of the wires that goes to the dashboard from the speed sensor may break, which leads to damage to the speedometer. A special tester will help determine the integrity of the wires; if the wires are not damaged, the device will notify you of this with a signal, but if the signal does not arrive, the wire must be replaced with a new one.

Experts recommend not only checking the integrity of the wires, but also analyzing the functionality of the following elements:

- Check whether the contact goes to the column that connects the wires to the speed sensor. Quite often, contact is lost due to oxidation, and it will be possible to resume the operation of this element after the plaque has been thoroughly removed.

- Check the functionality of the motion sensor using a special scanner. If during the test the device reveals interruptions in operation, the element will need to be replaced with a new one.

- Check the functionality of the dashboard. To do this, you need to remove the printed circuit board from the dashboard and visually inspect its condition. If traces of oxidation are noticed at the connection point or a so-called “track break” is detected, the board must be replaced.

Most often, the measures described above help restore the functionality of the speedometer, but if the desired result is not achieved, car owners will only have to check the operation of the speedometer itself, or more precisely, the functionality of its needle drive. If during the test it is confirmed that the arrow drive is faulty, the speedometer will have to be replaced.

It will be much easier to carry out automotive repair work if you use a video tutorial as a hint, which is taught on the Internet resource at any time of the day or night by real professionals in their field.

The tachometer does not work on the Daewoo Nexia - Auto repair

As practice shows, failure of the speedometer and tachometer is a fairly common occurrence.

On the one hand, such breakdowns do not affect the basic functions of the car, but on the other hand, the driver does not receive important information, which can lead to more serious malfunctions or even an accident.

Therefore, if your speedometer stops working or the tachometer needle begins to “take on a life of its own,” you need to urgently take some action.

In this article we will look at what and how to do.

General faults

Speedometer.

During operation, have you noticed that the needle in the car’s speedometer is inactive (at any speed)?

The first thing to do is to check the tightness of the fastening nut of the speedometer tips, as well as its drive.

If, after checking, no comments are found or the work performed does not bring the desired effect, then there is a risk of damage to the speed indicator drive or breakage of the flexible shaft.

In the latter case, the part will have to be changed. At the same time, do not forget to apply high-quality lubricant to the area near the seal (Litol-24 may be suitable for these purposes).

Once the work is done, thread the shaft through the seal - this will help distribute the lubricant over the surface of the cable.

The appearance of a knocking sound while driving may indicate a malfunction of the speedometer flexible shaft.

The reasons for this phenomenon include large bends in the cable under the instrument panel, dents, and so on. Make sure that the radii of the roundings do not exceed 10 centimeters.

Sometimes while driving you may notice a “growling” sound, approximately in the front of the car. The reason may be the speedometer cable, which often makes noise in the absence of proper lubrication.

Tachometer.

This is one of the most important car devices. Its task is to show the number of revolutions of the engine crankshaft at a certain point in time.

A tachometer breakdown is not so critical. But in the long term, it is precisely this that can cause engine malfunction and new costs for the car owner.

So how to deal with a breakdown, and what could be the main causes of the malfunction?

In fact, there are not many of them. In the case of an electronic tachometer, the LED screen of the device most often fails. Repairs in this case are problematic - it is better to replace the display.

Nissan Qashqai tachometer contacts.

Malfunctions of the tachometer are often caused by poor contact quality or faulty wiring (in this case, impulses from the engine to the device may not arrive at all).

To eliminate such troubles, you need to carefully inspect all wires for cracks and breaks. If you find a crack, simply solder it, and if a break is detected, replace part of the wiring.

The cause of a tachometer malfunction may be a failure of the engine speed sensor.

It is not difficult to diagnose the problem - the tachometer needle begins to “jump” in different directions. There is only one way to return the tachometer to “life” - by replacing this element.

Please note that the above malfunctions and methods for eliminating them are of a general nature. Each car model may have its own nuances, and we will talk about some of them in more detail.

THIS IS INTERESTING: How to disassemble the dashboard

Malfunctions on VAZ

The speedometer on the VAZ stopped working.

Most domestic autospeedometers and odometers are mechanical. So, when a mechanical odometer fails, the main reason (almost always) is a broken cable.

This problem can be easily diagnosed by a characteristic noise in the front of the dashboard.

After breaking, the steel wires begin to touch the inside of the shell and “ring.” The main reason for the break is the large radius of curvature during cable installation.

POPULAR WITH READERS: How to clean a car's fuel system

A mechanical speedometer malfunction can manifest itself in different ways. For example, the needle on the device often lies as a “dead weight” or, conversely, shows deliberately false information.

In such a situation, you need to make sure that the speed sensor is working and that there is voltage on it. Also inspect the terminals for moisture penetration.

If there is voltage at the sensor, then the problem must be looked for in the device itself. In such a situation, it is easiest to replace it.

It happens that a sensor malfunction is associated with some kind of mechanical damage. In this case, you can try to disassemble the drive and fix the problem yourself.

If there is no voltage on the sensor, it is necessary to check all electrical connections on the way to the device - wires, blocks, terminals. It is likely that the contacts are broken or oxidized.

New cars have electronic speedometers and odometers, which receive data from the speed sensor at the gearbox.

Consequently, there can be two breakdowns - either in the odometer itself (in this case it is necessary to change the entire dashboard).

Or in the sensor (we talked about it above).

THIS IS INTERESTING: Lada Largus will not start

VAZ tachometer malfunctions.

In the VAZ tachometer, the causes of the malfunction may differ, depending on the type of engine.

On a carburetor car there are three wires from the tachometer.

One wire is connected to the “K” terminal of the ignition coil, and the other two supply power (respectively, “plus” and “minus”).

To find out the cause of the breakdown, you need to disconnect the terminals going to the tachometer and connect the latter directly to the battery (terminal “K” remains in place).

Now you can try to start the engine. If the tachometer does not come to life, then the problem is in the device itself or in the ignition. If the engine speed indicator works normally, then the fault must be looked for in the wiring.

On a car with an injector, four wires are connected to the tachometer.

Of these, the first goes to the ECU, the second to the crankshaft position sensor, and the third and fourth to power.

In this case, the fault can only be identified through computer diagnostics. Without this work, all that is available is to inspect the pad and try to replace the crankshaft sensor.

If you replaced high-voltage wires with silicone ones, this can also cause the needle to jerk.

Malfunctions on Priora

Speedometer.

If the speedometer on a Priora stops working, the first thing you need to do is temporarily remove the terminals from the battery.

Did not help? – Then look for a fault in the device circuit. First, check the integrity of the instrument panel fuse.

If it burns out, replace it (but first make sure that all contact connections are intact).

If the problem persists or the fuse is normal, check all the wires on the path from the speed sensor to the instrument panel. This can be done using a multimeter.

If there are no complaints about the wiring, check the motion sensor with a special scanner. If there are malfunctions, the element must be replaced.

The serviceability of the motion sensor can be determined by the behavior of the odometer. If the speedometer does not work, but the odometer counts kilometers, then the sensor is working, and the breakdown must be looked for elsewhere.

For example, problems may be in the soldering on the dashboard circuit board or, even worse, in the gearbox. But this can only be found out at a service station with the help of a qualified technician.

Tachometer.

As for the tachometer on the Priora, there are three causes of malfunctions:

- violation of the tachometer supply circuit. In this case, you need to carefully crimp all the tips and replace damaged wires (if any);

- violation of the functionality of the controller (the signal does not reach the tachometer). Only replacing the device will help here;

- failure of the tachometer itself. This option is the most expensive, because it is not possible to change the device separately - you need to buy a new panel.

POPULAR WITH READERS: Reasons for failure when pressing the gas pedal

Malfunctions on Nexia

Problems with the speedometer.

Has the speedometer stopped working on the Daewoo Nexia? The first thing you need to do is check the engine index (depending on the year of manufacture, it can be of four types).

This parameter is very important, because each of them has its own speedometer features. For example, in engines with index F16D3 and A15SMS, information to the speed indicator comes from a sensor, and with index A15MF and G15MF - through a conventional cable drive.

For cable-driven speedometers, the main problem is the breakage of the cable ends (over time, their edges simply wear off and stop working normally). To determine the problem, you need to remove the instrument panel and unscrew the nut that secures the cable.

If everything is fine with the tip, pick up the cable and try to ride a little. If there is no rotation in your hand, you need to climb under the hood and twist the nut that secures the cable to the gearbox.

Here, faults such as a poorly tightened nut, cut teeth on the gears of the gearbox, or a damaged cable tip can “pop up”.

For F16D3 and A15SMS engines, where there is an electronic speedometer, the main fault may be the speed sensor.

Popular reasons are moisture ingress or failure of the unit itself. To check the sensor, you can try to remove it and twist the shaft with a drill or screwdriver. If the speedometer works normally, then the reason is in the plastic gears of the gearbox.

The tachometer does not work.

The most common malfunction of the tachometer on Nexia is breakdown of high-voltage wires.

Often, a malfunction with a twitching arrow on the device disappears after the first pull of the wire between the distributor and the ignition coil.

Such a malfunction can be diagnosed in the dark, when sparks are clearly visible.

If everything is fine with the coil and wires, but the tachometer still refuses to work, look for a problem in the switch or the wires leading from it to the tachometer.

conclusions

In the article, we only briefly examined the reasons for the breakdown of the tachometer and speedometer of the VAZ, Nexia and Priora, as well as ways to eliminate them.

THIS IS INTERESTING: VAZ 2110 central locking does not work

THIS IS INTERESTING: Replacing stabilizer bushings for Renault Megan 2

But often this knowledge is enough to feel more confident when diagnosing faults and carrying out minor repairs.

Source: https://555-shop.ru/remont/ne-rabotaet-tahometr-na-deu-neksiya.html

What to do if the tachometer on a VAZ-2114 does not work

The tachometer installed in any car, and the VAZ-2114 should not be considered an exception, is designed to take into account the revolutions made by the crankshaft. This information allows you to monitor the operation of the power unit in real time and change gears in a timely manner. If the device fails, this is not a reason to stop using the machine, since it does not in any way affect traffic safety, etc. However, the cause of the failure still needs to be found and, if possible, promptly eliminated. What to do if the tachometer on the 2114th VAZ model stops working, we will tell you further.

The tachometer does not work on the Lada Kalina

On the left side of the instrument cluster of the Lada Kalina passenger car, there is a tachometer, from which the driver can determine the engine speed. Malfunctions in the electrical circuit of this device can lead either to a complete cessation of its readings (the tachometer needle is at zero when the engine is running), or to jumps in the needle on the scale, which does not allow determining the exact number of crankshaft revolutions.

The first thing drivers do in this case is open the hood and remove the negative terminal of the battery for a couple of minutes, thus trying to clear errors from the controller’s memory. If this does not help restore the tachometer to working order, then it is necessary to conduct a diagnostic test to identify error numbers. To do this, use your finger to press the button, which resets the daily mileage in the instrument cluster odometer. And without releasing it, turn the key in the ignition switch to the “ignition on” position.

All instrument needles must begin to move from the zero position to the final position and back. If the tachometer needle does not start moving or starts moving but does not return to its original position, this will indicate that the malfunction is located inside the instrument cluster. Considering that the stepper motors, with the help of which the tachometer needle moves, and circuit boards are not available for retail sale, the entire instrument cluster assembly will have to be changed.

If the tachometer passes the test, then the fault will have to be looked for outside the instrument cluster. On their own, most drivers can only check the condition of the terminals in the tachometer electrical circuit blocks, since this can be done visually. First of all, you need to check terminal No. 30 of the low-voltage tachometer input, which should be connected to the brown-red wire coming from the electronic control unit (ECU). To do this, you will need to remove the instrument cluster by disconnecting the wiring harness block from it. Terminal No. 30 should not be bent or show signs of corrosion.

You should also check the terminals of the low-voltage circuit of the ignition module, since it sends a signal to the electronic control unit about the engine speed. If everything is in order with these terminals, then all that remains is to check the ECU, but it is better to entrust this to a competent specialist who is well versed in automotive electronics.

Share this article with your friends:

helping-auto.ru

Typical faults

VAZ-2114 has a standard electromechanical tachometer. If it stops working, then most likely some kind of purely physical damage has occurred. These are:

- wire break;

- loss of contact;

- fuse blown;

- damage to the device itself.

Any, even minor, breakdown leads to failure of the device.

When an electronic tachometer is mounted on a VAZ-2114, it most often does not work due to exactly the same reasons.

VAZ-2114 - searching for the cause of tachometer failure

To find out why the device in question does not work, diagnostics should be carried out. For this you will need a multimeter. With its help, first of all, ring the wire that supplies power to the VAZ-2114 tachometer, and then ground. This way you can easily detect a break in the electrical network. The tester should be set to ohms.

Before testing the circuit, make sure the multimeter operates at up to 20 volts forward. Please note that the minus is always present in the circuit, but the plus appears only when the ignition is started. In this case, the tester will show pulses (regular voltage surges) if the crankshaft is spinning. During this process, be sure to inspect all connectors and make sure that the wires attached to them are held properly.

A blown fuse is the most obvious reason when the tachometer suddenly fails, and along with it they “die”:

- odometer;

- speedometer;

- sensor that monitors coolant temperature;

- fuel level indicator.

In this case, they function normally:

- panel lighting;

- indicators;

- multimedia center;

- optics;

- ignition.

With such symptoms, you should first look at the fuse, indicated in the diagram as F3. Its location is the mounting block. Keep in mind that installing a new one without finding out the reason for the burnout of its predecessor is pointless. Most often the culprit is a short circuit. Experts have noticed that old VAZ model 2114 very often puzzles its owners with this breakdown after washing.

Even if you do not find a short circuit, do not rush to forget about the fuse. Check the condition of its connector. It may burn, oxidize, or become dirty. All this creates a high contact resistance, which overheats the fuse-link and contributes to its destruction.

Tachometer VAZ 2106

A tachometer is used to measure engine speed of exclusively carburetor cars.

This is a device located on the front panel.

It cannot be called super important, but for a novice driver who does not yet “hear” the engine of his car, it helps to calculate the number of engine and crankshaft revolutions.

It also plays an aesthetic role.

Many car owners like to show off modern instruments on the control panel.

The VAZ 2106 has a four-stroke four-cylinder engine, and during 1 revolution of the ignition distributor rotor, the contacts of the breaker, the so-called distributor, open and close four times.

Connection diagram

2 – ignition coil;

3 – ignition distributor:

The tachometer TX-193 of the VAZ 2106 works on the principle of measuring the frequency of voltage pulses occurring in the primary circuit of the ignition system. In a four-stroke four-cylinder engine, during one revolution of the ignition distributor rotor, the breaker contacts open and close four times. That is, four voltage pulses are generated per revolution of the rotor (or two pulses per revolution of the crankshaft). Thus, the pulse repetition rate is directly dependent on the engine crankshaft rotation speed, which, in fact, is reflected in the instrument readings.

In order to figure out how to connect a tachometer to a VAZ 2106, you just need to find out the purpose of the connected wires:

The white wire is used to connect the device backlight;

The red (thick) wire is connected through a fuse to the ignition switch; it receives power when the ignition is on;

White wire with a black stripe - for connecting to ground in any convenient place;

Brown goes to the “K+” terminal of the ignition coil, signals from this wire control the tachometer readings;

The black wire connects to the relay for turning on the charging current indicator, which is located on the right side under the hood;

The gray wire with a black stripe contacts the oil pressure sensor located on the left side of the engine.

Doesn't work, reasons

First of all, you need to check whether the tachometer is connected to the ignition coil. The second reason: the plus and minus contacts in the battery may have been accidentally mixed up. A malfunction may occur if the ignition wires are silicone. In this case, you need to change the value of the resistor on the board. If your car is fuel-injected, the circuit from the ignition module to the fifth contact of the gearbox, and then to the tachometer, may be broken.

The arrow twitches

If the tachometer needle twitches, we recommend that you carry out an initial troubleshooting in the following sequence:

1. Check the check light on the instrument panel, if your car model has one. If it does not light up, then most likely the diagnostics will not show an error.

2. Check the wiring, and check not only the voltage level on the “positive” and “negative” wires, but also the quality of the contacts. Also be sure to check for the presence of “mass”, this is often what is overlooked. Usually other consumers, in this case, begin to work incorrectly.

3. A common cause of jerking of the tachometer needle is poor contacts of the distributor or failure of the capacitor located on the distributor; it very often breaks through - this is the most common cause of tachometer failure.

4. Check the ignition system. Often, malfunctions in this circuit lead to malfunctions of the tachometer, especially to a twitching needle.

5. If malfunctions in the tachometer appeared after disassembling or replacing it, then it may be necessary to adjust it. First, check its position: is it positioned correctly. Secondly, check the zero position. You can adjust it with the toggle switch on the back of the panel.

6. If the needle twitches at high speeds, then this is the first sign of the “death” of the commutator.

Malfunctions

Blown fuse #2 (10A) - Check for short circuit and replace fuse

Tachometer faulty - Check tachometer

Damaged electrical wiring - Restore electrical wiring

The tachometer in any vehicle, including the VAZ 2106, is a device necessary for reading crankshaft revolutions. With its help, the driver will be able to determine not only the speed of movement, but also various malfunctions in the operation of the engine, the symptoms of which are associated with jumps in speed. Read more about the principle of operation and malfunctions below.

More complex breakdowns

When, along with the tachometer, absolutely all the electrical equipment of the panel fails, you will have to look beyond the fuses.

There is a risk that the problem lies in the ignition system. In particular, here the contacts on the lock are often charred or the track on the board of the VAZ-2114 mounting block is damaged. In the first case, the mechanism must be removed and cleaned, and in the second, the element is replaced with a new one.

The tachometer needle began to twitch - such a malfunction is far from uncommon. To find the cause, it is recommended to use the self-diagnosis mode of the standard on-board computer. It will show a list of errors, and all you have to do is start fixing them.

If there is no ECU, then first check the wiring, since a jerking arrow often indicates poor contact.

Also carefully inspect the mass of the VAZ-2114. This is all the more necessary to do when other panel devices are functioning with obvious disturbances.

Be sure to find out whether the contacts of the distributor are clean and whether the capacitor installed in its cover is still working. The latter loses capacity over time, which disrupts the operation of the entire vehicle ignition system.

Sometimes problems arise immediately after replacing the old tachometer of the 2114 model with a new one. Usually this is not a malfunction, but a bad setup. Do this:

- adjust the zero position (the vernier is on the back side);

- make sure the connection is secure;

- ring the wires.

How to replace the tachometer on the 2114th model

Installing a new device is easy. To do this, first connect its negative wire to ground (it is usually black). The power cable (red) is connected to the ignition switch. The latter has a separate contact.

The third wire, going to the measuring mechanism, is connected to the ignition coil through a distributor breaker.

Some new tachometers have a separate backlight. For it to work, it must be connected to the VAZ-2114 side light switching circuit.

Speedometer does not work on Priora

AvtoVAZ cars have a low price, which often leads to a decrease in the quality of their assembly and early failure or damage of some components. One of the most common problems with Lada Priora cars is speedometer failure. According to traffic rules, it is prohibited to drive a car with a faulty speedometer, so it must be repaired as soon as possible. In this article, we will look at what to do if the speedometer on the Lada Priora does not work.

Malfunctions on VAZ

The speedometer on the VAZ did not work.

In most Russian autospeedometers and odometers, they are mechanical. So, when a mechanical odometer fails, the main reason (almost always) is a broken cable.

This problem can be simply diagnosed by the corresponding noise in the front part of the dashboard.

After breaking, the iron wires begin to touch the inside of the shell and “ring.” The main reason for the break is the large radius of curvature during cable installation.

A mechanical speedometer malfunction can manifest itself in different ways. For example, the arrow on the device often lies as a “dead weight” or, on the contrary, indicates incorrect information in advance.

The speedometer on the VAZ has stopped working

In such a situation, you need to make sure that the speed sensor is working and that there is voltage on it. Also inspect the terminals for water ingress.

If there is voltage at the sensor, then the problem must be found in the device itself. In such a situation, it is easiest to change it.

It happens that a sensor malfunction is associated with some kind of mechanical damage. In this case, you can try to disassemble the drive and remove the problem yourself.

If there is no voltage on the sensor, you need to check all electronic connections on the way to the device - wires, connectors, terminals. It is entirely possible that the contacts are broken or oxidized.

New cars have electric speedometers and odometers, which receive data from the speed sensor at the transmission.

As follows, there can be two breakdowns - or in the odometer itself (in this case, you need to completely change the dashboard).

Disassemble the VAZ panel device

Or in the sensor (we talked about it above).

VAZ tachometer malfunctions.

In the VAZ tachometer, the reasons for the malfunction may differ, depending on the type of engine.

On a carburetor car there are three wires from the tachometer.

One wire is connected to the “K” terminal of the ignition coil, and the other two supply power (respectively, “plus” and “minus”).

To find out the cause of the breakdown, you need to disconnect the terminals going to the tachometer and connect the latter directly to the battery (terminal “K” remains in place).

Now you can try to start the engine. If the tachometer does not “come to life,” then there is a problem in the device itself or in the ignition. If the engine speed indicator works normally, then the fault must be found in the wiring.

On a car with an injector, four wires are connected to the tachometer.

Of these, the 1st goes to the ECU, the 2nd to the crankshaft position sensor, and the 3rd and 4th to the power supply.

In this case, the fault can only be identified using computer diagnostics. Without this work, all that is available is inspecting the pad and trying to change the crankshaft sensor.

If you replaced high-voltage wires with silicone ones, this can also cause the needle to jerk.

Symptoms of a speedometer failure on a Priora

A car speedometer is necessary to measure speed, as every driver knows. From this we can conclude that its failure is diagnosed due to one of the following problems:

- When the car is moving, the speedometer needle does not deviate from zero;

- The speedometer incorrectly detects the vehicle speed or turns off during operation.

Most often you come to deal with the second option of speedometer failure. A typical problem for Lada Priora cars is a temporary failure of the speedometer, when while the car is moving the needle drops to zero, an exclamation mark lights up on the dashboard and the electric power steering also fails. After a few minutes, the problem disappears and the car’s electronics operate as before.

Please note: Lada Priora cars are equipped with an electronic speedometer, as a result of which there are two options for failure: mechanical or electronic, that is, a failure of the microprocessor that controls the device.

Speedometer does not work on Priora: reasons

If the speedometer on a Lada Priora car does not work, the first thing you should do is make sure that the problem is not related to bugs in the chip on which it operates. During operation, the chip's cache may become clogged with information, causing the speedometer to malfunction. To reset the speedometer chip settings, you need to reset the ground from the car battery and disconnect the power from the car's on-board network. Such simple manipulations will lead to resetting the settings of storage devices, including the speedometer chip.

When resetting the chip does not help to cope with the speedometer malfunction, you should conduct a full check of the power circuit. To do this you will need:

- Check the fuse plate installed on the fuse board in the speedometer power supply circuit. The required fuse is designated "IG/METER";

Next, the serviceability of the wiring in the area from the speed registration sensor to the instrument panel is diagnosed. Often in this section the wires are torn, pinched and get other defects, largely due to the constant shaking of the car while driving on not the best roads;

At this point, we can consider checking the speedometer power circuit complete.

If the problem cannot be detected, the problem may be related to the dashboard itself. To check this, you will need to remove the printed circuit board on which all the devices are located and carefully inspect it for damage, oxidation, melting, breaks and other defects. It is effective to check the board on a special diagnostic stand in a service center. When there are problems with the board, technicians can repair it.

Electronic failure options were discussed above, but we should also not forget that a possible reason for a non-working speedometer in a Priora is damage to the needle or its mechanisms. To verify this, you need to disassemble the device and inspect it for defects or their absence.

Lada Kalina speedometer does not work: reasons, repairs - Website about the domestic automobile industry

The speedometer of the VAZ 2114 does not work? A problem that is quite common not only for models of the fourteenth, almost every VAZ model suffers from this problem, from the classics to the new Prior, Kalin, and Grant. In today's article I will tell you about the three main reasons for the VAZ 2114 speedometer malfunction and how to fix them.

Diagnostics of speedometer operation at fourteenth

Troubleshooting begins by disconnecting the wiring block from the speed sensor harness and checking them using a test light.

To carry out the test, one wire of the warning lamp is attached to the ground of the body or battery, and the second is made with short, frequent touches to the middle contact of the DC connector.

If there are no faults in the connector-speedometer section, the speedometer needle will slightly tremble or rise.

If the needle shakes, the answer to the question why the speedometer does not work can be considered found - the speed sensor requires replacement.

In cases where the needle’s response to tapping on the central contact of the block cannot be detected, it is necessary to “test” the speedometer power circuit. The procedure is carried out using a multimeter (multitester), or by using the same light bulb - a control.

The wiring harness is first disconnected not only from the speed sensor block, but also from the speedometer itself. One terminal of the tester or warning lamp is connected to the end of the wire located under the hood, the other to the interior end of the speed meter current supply circuit.

If the tester in the “continuity” mode indicates a violation of the integrity of the circuit, further troubleshooting is carried out in this direction. It is necessary to check the fuses, the connection points of the wires, and their integrity inside the insulating braid.

In cases where the speedometer needle does not work, but there is no evidence of malfunctions in the electrical supply circuit, a logical conclusion is drawn about the malfunction of the device itself. Additional testing can be done by temporarily installing a known good instrument panel.

The main reasons why the VAZ 2114 speedometer does not work

Let's now look at the main reasons why the speedometer on the VAZ 2114 does not work and see the solution to these problems.

Speedometer sensor VAZ 2114 - failed

Speedometer sensor VAZ 2114

Unlike older AvtoVAZ models, the VAZ 2114 speedometer is not mechanical, but electronic, whose readings depend on the sensor installed on the car’s gearbox. It is this electronic device that most often fails, which can be caused by various factors:

- lack of contact on the connector block (for example, due to water getting there);

- break in the wire supplying the sensor;

- lack of current in the supply contact.

Since the VAZ 2114 is equipped with an on-board computer, the first thing you can do is try to detect a breakdown with its help: having turned on the self-diagnosis process, you need to wait until it ends. If the result of the test is the displayed error P0500, it means that the on-board computer does not receive the corresponding signal from the speed sensor.

How to check the speedometer sensor of a VAZ 2114

Speed sensor VAZ 2114

To check the status of the speedometer sensor, you need to do the following:

- Open the hood of the VAZ-2114.

- Get rid of the adsorber, it will be more comfortable to work.

- Determine where the wire to the sensor is located in the CV joint area.

- Locate the tool located under the throttle assembly.

Finally, you get to the sensor itself. Take a look at what it looks like and check the functionality of the device. What is it?

Look at the stem, it is made of plastic, this material often breaks and deteriorates. Failures also occur with the plastic rod. Pay attention to the plastic drive gear - ideally all the teeth should be in place. If they are cut off, then the sensor’s performance leaves much to be desired.

That is why, even at the stage of absence of breakdowns, service station specialists recommend replacing plastic parts with metal ones.

If the rod and gears are made of metal, the speedometer is unlikely to break soon. When changing the mechanism, take into account the following features: the VAZ-2114 can be equipped with units with different volumes.

Speed sensor VAZ 2114 – faulty

The gears are not the same color. The numerical values of the speedometer drive change in accordance with the different gear ratios of the main combination of pairs. This means that the shade of the gears must match and remain the same.

When checking the device is completed, it will not be superfluous to ring the contacts located in the block - this way you can fix the location of the break in the electrical circuit, then record the voltage of all contacts.

In order for testing to be completed effectively, arm yourself with a multimeter, available for sale in car dealerships, to carry out diagnostics, set the operating mode to “voltmeter”.

Next, determine the condition of the controller; if you don’t know how, it’s better to contact a specialist.

Wear or breakage of the VAZ 2114 speedometer cable

Speedometer cable VAZ 2114 - is responsible for transmitting speed from the box to the instrument panel of the car’s speedometer. One end of this cable is connected to the drive gearbox, which is located on the gearbox, and the other end is connected to the speedometer mechanism itself, which in turn is located on the instrument panel.

The speedometer cable of the VAZ 2114 is located near the bottom of the gearbox housing and is attached to the gearbox, for clarity, so that you have at least the slightest idea of where the cable is located, look at the photo below in which the arrow indicates the cable:

The speedometer cable is replaced in 2 cases:

- Failure, and therefore the speedometer will not show any values on the instrument panel.

- And also when it is deformed and when the nut that secures it to the gearbox or to the speedometer mechanism breaks.

If you have a nut securing the cable to the gearbox, or to the speedometer, then the speedometer needle will jump sharply when driving!

Replacing the speedometer cable of a VAZ 2114

In order to replace the speedometer cable on a VAZ 2114, you must perform the following procedure:

- At the beginning of the operation, you will need to remove the instrument panel from the car.

- Next, using pliers, completely unscrew the nut that secures the cable to the mechanism, and after unscrewing, disconnect the cable.

- Then move to the bottom of the car, and there, unscrew the nut that secures the cable to the gearbox (it is indicated by the arrow), and after unscrewing the nut, disconnect the cable.

- Now take the cable in your hands and pull it out of the car.

- Finally, untie the wire from the nut.

- Do the entire cable installation in the reverse order of removal.

Mechanical drive VAZ 2114 - checking functionality

Another common reason is the malfunction of the mechanical drive, and in particular, the one that is installed when the car is assembled at the car factory has an unreliable plastic rod on which the drive gear is located. There are cases of breakage of this rod and cutting of teeth on the gear.

When replacing them, pay attention to the color of the gears, since the VAZ-2114 is equipped with engines with different displacements and due to different gear ratios of the main pair, the gear ratios of the speedometer drive change. Therefore, the color of these gears must be the same.

If the speedometer drive fails, replace it with one that has a metal rod.

You can check the serviceability of the speed sensor by replacing it with a known good one. And in order to find out whether the drive is working, you need to ask a friend to push the car so that it rolls, and see for yourself whether its rod rotates.

The speedometer on the Lada Kalina does not work: causes, malfunctions

You can often hear from Lada Kalina car owners that the speedometer has stopped working. The most common reason for this is a faulty speed sensor. As a result, the speedometer needle may jump on the scale or simply remain motionless. It may also freeze frequently.

In the video, replacing the speed sensor (this is the main breakdown):

Main symptoms and causes of failure

There are obvious discrepancies between the speedometer and tachometer, and besides, the car is driving at first speed!

This happens both while driving and when the car is simply standing still. For such a malfunction to make itself felt, it doesn’t matter how long the car has driven.

Also, in some cases, a sensor may light up, which indicates a malfunction of the power steering. It would seem that these malfunctions have nothing in common, but the speed of a car has been measured electronically for a long time.

Speed sensor

Thanks to electronics, the car can regulate the fuel supply itself. The sensor operates based on the Hall effect . It transmits rotation impulses from the wheel to the controller. If the car is coasting and the speed is no more than 20 km. hour, the system will automatically stop supplying fuel.

Various sensors can be installed on the Lada Kalina. They have the same seats, but are different from each other. In the event that a sensor on a car breaks down, it will be impossible to measure the speed of the vehicle. This will also affect the deterioration of engine performance.

Source: https://vagflash.ru/prochee/ne-rabotaet-spidometr-lada-kalina-prichiny-remont.html

The tachometer does not work on the VAZ 2110 injector reasons

REASONS FOR A NON-WORKING TACHOMETER

The tachometer in a car is used to indicate the number of revolutions of the engine crankshaft. Let's look at why the tachometer doesn't work and how to find and eliminate the cause of the breakdown. We will definitely dwell on the device and principle of operation, which will help to find out why the tachometer stopped working, the needle twitches or behaves inappropriately.

CLASSIFICATION BY OPERATING PRINCIPLE

- Mechanical or electromechanical tachometers with direct drive. The revolutions are transmitted to the dial indicator through a flexible shaft, which, through a worm gear, receives rotation directly from the crankshaft or one of the transmission shafts. The operating principle of the indicator is based on the phenomenon of eddy current induction. The operation and design of a magnetic tachometer are extremely similar to the operating principle of a car speedometer. In modern cars, a similar tachometer design is not used.

- Electric machine. A distinctive feature is the connection to a generator. It is used primarily on diesel engines, but for the purpose of unification, a device of this type can also be used on gasoline engines.

- Electronic. The signal can be taken either from the ignition system or directly from the computer. Installed on gasoline and diesel internal combustion engines.

DEVICE AND PRINCIPLE OF OPERATION

Main components of electric machine and electronic tachometers:

- measuring unit, or signal converter. It can be based on elements of analog circuitry or built using special microcircuits;

- display unit with analogue or digital display of the number of revolutions;

- auxiliary elements.

The operation of electronic tachometers is based on the conversion of individual signals or pulses captured from the computer, ignition system or generator into a signal “understandable” for the display unit.

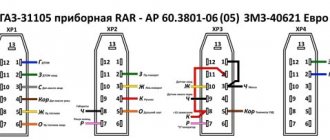

CONNECTION DIAGRAM

When looking for the reason why the tachometer does not work, it is first of all important to understand the connection diagram and the type of signal. There are 3 typical connection schemes:

- to a contactless ignition system (the tachometer wire is connected to the primary circuit of the ignition coil). The operating principle is based on measuring the frequency of voltage surges in the primary circuit of the ignition system. Calculating the ignition angle is impossible without focusing on the number of crankshaft revolutions, therefore the sparking frequency directly depends on the crankshaft rotation speed. On 4-cylinder internal combustion engines, a full revolution of the crankshaft corresponds to 2 voltage pulses in the primary circuit. Accordingly, the higher the crankshaft rotation speed, the greater the frequency of voltage surges;

- connection to the contact ignition system. The operating principle and connection diagram are similar to the BSZ, but the design of the measuring unit will differ depending on the voltage of the input circuit;

- connection to the engine ECU. The principle of operation is still based on recording voltage pulses in the primary circuit of the ignition system, but the signal to the tachometer comes from the engine control unit;

- connection to the generator (the tachometer signal contact is connected to terminal W of the generator). The rotation of the generator pulley is carried out by a belt drive from the crankshaft, so the rotation speed of the generator rotor will always be proportional to the crankshaft speed. The change in the number of revolutions of the crankshaft can be calculated by constantly measuring the amount of EMF generated on the winding. By its operating principle, an electric machine tachometer resembles a conventional voltmeter.

SPECIFIC FAULTS

If the mechanical tachometer on a car stops working, there is mechanical damage to any of the structural elements. A broken cable of a flexible shaft, wear of the worm gear elements, the appearance of backlashes, deformations - all these reasons can cause the engine speed indicator to fail.

What to pay attention to if the electronic tachometer does not work:

- integrity of electrical wiring. In this case, it is important to check not only the signal wire, but also the ground and power supply of the instrument panel;

- quality of contacts. The presence of oxides and loose contact inside the chips may well cause the tachometer to fail;

- the integrity of the elements of the measuring unit, which are located behind the protective glass inside the dashboard. Among mechanical damage to transistors, burnout of microcircuits, tracks or swelling of resistors, the most common reason for a non-working tachometer is a violation of solder integrity. For example, on the Mitsubishi Padjero II, the appearance of microcracks in the soldering areas of the tachometer elements is a generally recognized disease.

On vehicles with an alternator connection, a non-functioning tachometer may indicate a faulty alternator. In this case, the breakdown is accompanied by the lighting of the low battery charge indicator and the sporadic lighting of a “garland” of warning lights on the dashboard.

In some types of design, changes in the linear resistance of high-voltage wires can make adjustments to the accuracy of the engine speed indication.

HOW TO FIND THE CAUSE OF THE PROBLEM YOURSELF

In addition to a visual inspection, for DIY diagnostics you will need a universal measuring device. If you know how to use a multimeter, you can easily check the power supply, ground, and also test the signal wire for a break.

The power supply is checked in DC measurement mode, the measurement range is up to 20 V. “Minus” is constant, “plus” appears only after the ignition is turned on. Pulses on the signal wire should appear when the crankshaft rotates. To search for a break, the multimeter must be switched to resistance measurement mode - ohmmeter. Sometimes, to detect a bad contact, it is enough to move the connector or harness in which the signal wire of the speed indicator is laid.

TACHOMETER HANDLE JERKS

The problem of a twitching needle is best known to owners of the GAZ 3110 Volga.

The problem occurs on cars manufactured before September 1999 and equipped with instrument cluster 38.3801 (JSC Avtopribor). Due to design defects, the natural operation of a car generator, in which the amount of charging current is regulated by an alternating voltage supply to the excitation winding, leads to the twitching of the needle.

The tachometer needle may twitch due to weakened tension of the alternator belt, but in most cases it is possible to repair the tachometer on the Volga by replacing the dashboard and modifying the connection diagram.

If you find an error, please select a piece of text and press Ctrl+Enter.

Classification by operating principle

Design and principle of operation

Main components of electric machine and electronic tachometers:

- measuring unit, or signal converter. It can be based on elements of analog circuitry or built using special microcircuits;

- display unit with analogue or digital display of the number of revolutions;

- auxiliary elements.

The operation of electronic tachometers is based on the conversion of individual signals or pulses captured from the computer, ignition system or generator into a signal “understandable” for the display unit.

Connection diagram

When looking for the reason why the tachometer does not work, it is first of all important to understand the connection diagram and the type of signal. There are 3 typical connection schemes:

Typical faults

If the mechanical tachometer on a car stops working, there is mechanical damage to any of the structural elements. A broken cable of a flexible shaft, wear of the worm gear elements, the appearance of backlashes, deformations - all these reasons can cause the engine speed indicator to fail.

What to pay attention to if the electronic tachometer does not work:

On vehicles with an alternator connection, a non-functioning tachometer may indicate a faulty alternator. In this case, the breakdown is accompanied by ignition, sporadic lighting of a “garland” of warning lights on the dashboard.

In some types of design, changes in the linear resistance of high-voltage wires can make adjustments to the accuracy of the engine speed indication.

How to find the cause of the problem yourself

In addition to a visual inspection, for DIY diagnostics you will need a universal measuring device. If you know, you can easily check the power supply, ground, and also ring the signal wire for a break.

The power supply is checked in DC measurement mode, the measurement range is up to 20 V. “Minus” is constant, “plus” appears only after the ignition is turned on. Pulses on the signal wire should appear when the crankshaft rotates. To search for a break, the multimeter must be switched to resistance measurement mode - ohmmeter. Sometimes, to detect a bad contact, it is enough to move the connector or harness in which the signal wire of the speed indicator is laid.

Tachometer needle twitches

The problem of a twitching needle is best known to owners of the GAZ 3110 Volga. The problem occurs on cars manufactured before September 1999 and equipped with instrument cluster 38.3801 (JSC Avtopribor). Due to design defects, natural, in which the amount of charging current is regulated by variable voltage supply to the excitation winding, leads to the twitching of the needle.

The tachometer needle may twitch due to a weakened one, but in most cases it is possible to repair the tachometer on the Volga by replacing the instrument panel and modifying the connection diagram.

06.10.2016

Today, many cars are equipped with a device such as a tachometer. The task of the latter is to display the actual crankshaft speed. More precisely, the arrow shows how many revolutions the crankshaft makes in a certain unit of time (per minute). Such information is a chance to avoid accidentally exceeding the permissible speed. The problem is that at the very first breakdown of the device, car enthusiasts are lost. Many people have no idea what the reasons for the refusal are and how to act in such a situation. Let's consider these points in more detail.