A starter is an electro-mechanical unit that is involved in igniting a car. If it fails, you simply will not be able to start the engine. In this situation, repairs are necessary, but first the cause of the breakdown must be determined.

The main symptoms of a breakdown are as follows: the starter does not turn, but the relay clicks. Often, the problem occurs due to sudden braking, as a result of which the starter bendix engages with the flywheel, and the starter receives high current for a long time. But this unit is not designed for long-term operation under voltage, and due to excessively long operation it fails.

Battery, wiring, terminals

As a rule, relay clicks indicate that the device is working. When the relay clicks, but the starter does not turn, the car does not start most often due to the fact that the starter does not have enough electric current to spin the crankshaft. If there was no power supplied to the starter at all, we would not hear any clicks.

Most often, this situation arises due to a banal battery discharge (or simply a low charge level). It is not difficult to identify this problem; if, when you turn the ignition key, the solenoid relay clicks and the lights on the instrument panel go out, then the problem is in the battery.

Remember that sometimes you won’t be able to solve the problem by simply charging the battery. First of all, it is worth finding out the reason for the battery discharge, so as not to encounter this problem in the future. It’s good if the cause of the discharge was a light that was not turned off or another source of consumption, but if the problem is, for example, in the generator or the battery itself, then no amount of recharging will help you.

We also recommend reading the material on the topic: how to extend the life of a car battery. After reading this article, you will also learn about the reasons for battery discharge and signs that the battery will soon fail.

The next most common cause of starter inoperability is damage to the ground wire going to the engine or poor contact. If there is not just one click, but a whole series, this is probably the problem.

And if only one click is heard, then the problem should be looked for in the contacts of the starter, or rather its relay. The starter is powered by a current of approximately 200 amperes, but due to poor contact in any place, the current can reach much lower values. It may be enough to trigger the retractor relay, but this current strength will not be enough to ensure the rotation of the crankshaft.

In some cases, the contacts of the starter relay may burn out, as a result, there is no spark necessary to ensure correct operation of the starter. Actually, a click is not a characteristic sign of serviceability of the starter relay, it only indicates that the relay core is retracted, but the holding winding sometimes cannot fix it.

Troubleshooting

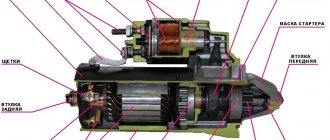

The main load in the operation of the starter falls on the relay. Therefore, when they say that the starter does not click or turn, they mean the operation of the traction relay, which makes characteristic clicking sounds.

These symptoms occur in the following situations:

- the stator or rotor windings are short-circuited;

- the electric motor shaft or bushing is jammed and does not rotate;

- The “mass” of the rotor touches the positive charge of the stator.

Without removing the housing from this electrical appliance, it will not be possible to identify these breakdowns.

The sound heard by the driver is created by the movement of the core between the windings. One of them retracts for fixation, and the second holds the core in a given position. If the tension on the holding one is insufficient, then it returns to its original position. Therefore, each click most often indicates that the core made an unsuccessful attempt to fixate. It is in such a situation that the starter solenoid relay clicks, the starter does not turn, and it is impossible to move away.

You need to know that if the car starter does not start the first time, this does not mean it is broken; perhaps not all systems have “warmed up” to the fullest extent. You must try to turn the key in the ignition again.

Problems other than the traction relay can arise either from burnt contacts, which can be indicated by a characteristic smell, or from a poor-quality connection of the wiring to ground or a discharged battery. “Treatment” is provided individually in each case.

Starter malfunction

Sometimes, when the relay clicks, but the starter does not turn, the car does not start because the starter itself has failed. It is quite possible that the wire that connects the starter winding and its relay has burned out or broken, or that the starter winding has broken.

It is quite possible that a short circuit has occurred in the armature or stator windings, as well as in the brush holder. For example, you can determine a short circuit by looking at the headlights; when you try to start the engine, they dim greatly, and sometimes even go out completely even when the battery is fully charged.

If the car has been used for a long time, the starter brushes may have worn out too much or the starter bushings may have worn out. As a rule, it is impossible to diagnose such problems in the shortest possible time, but if you have enough time, you can find out the cause of the starter failure.

Be sure to watch another video on how the starter works:

If problems arise with starting the engine, you should also not “drive” the starter for too long. The fact is that the starter is essentially a small electric motor, which, however, ensures the rotation of the crankshaft. To do this, it requires a very high current strength, so it is not recommended to operate the starter for a long time within one starting attempt - you run a high risk of damaging it (the contacts may simply burn out). It is recommended to make three short attempts to start the engine, and if they are unsuccessful, proceed to troubleshooting.

Lada Granta is a popular and reliable car of the Russian concern AvtoVAZ, which was developed on the basis of the Lada Kalina model.

This is an inexpensive “people’s” car with front-wheel drive, which has firmly won its niche in the market. Its factory marking is VAZ 2190, serial production began in October 2011.

Technical characteristics : in terms of body type, the Lada Granta is a five-seater four-door sedan or liftback (hatchback) with an engine capacity of 1.6 liters. Manual 5 or automatic 4-speed gearbox, depending on the model.

The car is equipped with front-wheel drive, independent front and semi-independent rear suspension. Available in “standard”, “norm” and “luxury” trim levels.

The “luxury” package includes electric power steering, an ABS system, power windows, air conditioning and a modern audio system.

The disadvantage of this car is flaws in the design, not always high-quality assembly and frequent problems with starting the engine.

How to fix a rattling starter

The method for troubleshooting depends on what is causing the problem. If the starter cannot work normally due to a discharged battery, it is enough to charge it to the required parameters. Typically, charging is carried out with a current of 0.1C, where C is the battery capacity in ampere-hours. At the same time, highly discharged current sources and calcium batteries should be charged with low currents (1-2 A) to at least 25% charge (this parameter is controlled by the density of the electrolyte). The gentle mode will take more time, but will protect the battery from many negative aspects.

Note! Often, when the battery is discharged, car owners try to start the engine “from a tow”. Note that this method is only suitable for the simplest power units, but not for injection engines. Launching the latter “from the pusher” often leads to a failure of the electronic control unit software.

In this case, the ECU begins to behave unpredictably - for example, request permission to start from a disabled immobilizer. The situation can only be corrected by reflashing the “brains”, and this, as you yourself understand, is an additional and completely unjustified expense.

In the case where the cracking of the solenoid relay occurs due to poor contact with the vehicle ground, it is enough to simply restore the electrical connection. To avoid problems in the future, it is recommended to remove the tire that connects the engine to the body and clean the contact pads with sandpaper. A thin layer of technical Vaseline or VD-40 universal lubricant will help prevent their oxidation.

If the source of the malfunction is the retaining winding of the starter solenoid relay, then try to repair it. If this is not possible, then a decision is made to replace the solenoid relay assembly. As you can see, even a novice driver can cope with finding the fault that is causing the starter to crack.

Video: Why the starter cracks. Useful advice from an auto electrician.

Problems with the immobilizer (APS)

Often the Lada Granta does not start due to improper operation of the APS. If it is activated, the key is read and the engine starts. The immobilizer (APS) identifies the “native” key by reading the code from it.

If it is incorrect, then the APS blocks the operation of all vehicle systems. Here it is necessary to immediately clarify that APS is not activated upon sale in all trim levels. Lada Granta sedan is equipped with an anti-theft alarm in models 023, 024 and 050.

Lada Granta liftback in the 711, 713, 750 and 751 configurations. Many car dealers cheat when selling and say that the immobilizer cannot be activated. But by law they must do this at the request of the car owner.

If the key is not registered, the indicator lights up continuously for about 20 seconds. without blinking, and then goes out. During training, blinking occurs at a frequency of 5 Hz, at the end of training at a frequency of 10 Hz. When problems arise in the system, a sound alert is added to the light indication; it appears at the 10th and 20th second.

Decoding signals:

1 signal + flashing indicator – the code from the key cannot be read, possible reasons:

- problems in the communication coil circuit. In this case, you need to check the resistance and inspect the circuit;

- There is no transponder in the key. To eliminate the problem in the training key, you should check the presence of the transponder and its markings; if it is missing, then use a “clean” key and the CSUD to retrain the entire system;

- The transponder (located in the red key, you need to remove the red head) may be broken. In this case, for a training key, you need to retrain the system with a clean key, and for a working key with a remote control, you need to replace the remote control with a new one and train the system again;

2 beeps + flashing indicator – the relationship between the APS and the ICS is broken, possible malfunctions:

- There was a communication failure on the w line. In this case, it is necessary to eliminate violations in the chain between the APS and the ICS;

- violation in the APS and KSUD chain. It is necessary to replace them one by one to identify where the malfunction occurred;

- there is no voltage on the APS and KSUD power supply. In this case, you need to check and restore the voltage.

3 beeps + intermittent indication - “foreign” key or APS. In this case, it is necessary to carry out training using a “clean” key and a “clean” KSUD. For APS, you need to configure the system using a training key native to the ICS.

4 signals + flashing indicator – the controller does not provide confirmation to start the engine. This suggests that the KSUD has already been trained with another system; it needs to be changed to a clean one and retrained.

To find out exactly the cause, it is necessary to make a diagnosis. If the controller is broken, it must be replaced and re-learned.

If there is an APS, then you need to replace it and train it along with all the working keys, since structurally in the Lada Granta the APS is located in the instrument cluster.

The starter does not turn

If you are sure that the problem is not in the APS, then most likely the starter is not working. The Lada Granta is equipped with a cable-driven gearbox and the starter often acts up, especially with a new gearbox.

It is very easy to find out that the starter is not turning: when you turn the ignition key, you do not hear the specific sound of its operation.

Sometimes a car with a robot does not turn the starter, this is due to a weak battery, we recommend charging it and trying again, although sometimes it helps to simply remove and put on the terminals.

The main causes of starter failure are the battery, the starter itself, or problems in the switching circuit.

The main causes and troubleshooting of the starter:

- The battery is low or damaged. It is not difficult to check its condition: you will immediately notice this by the fact that the light bulbs and panel sensors do not light up, and when you start the engine, you hear a specific crackling noise under the hood. But if they light up normally, then to be sure, you need to turn on the headlights to high beam and evaluate their brightness; if the light is dim, then the battery is not completely discharged, but its power is not enough to start the starter. To resolve the problem, you need to charge or replace the battery.

- Problems with battery terminals, faulty wiring, insufficient contact with ground. The terminals may be loose, poorly seated, or oxidized. To fix this problem, you need to clean it, thoroughly coat it with machine Vaseline and tighten the bolt on the starter and the ground on the thermostat stud. Using a multi-meter you need to check the ground for breakdowns. To do this, you need to switch it to voltmeter mode and connect one wire to the starter “ground” on the thermostat pin, and the other to the engine; there should be no voltage.

- If everything is normal in the circuit, you need to remove the starter itself and look at the operation of the traction relay. If you turn the key to the second position, the relay does not work and you cannot hear a click. This can be checked by applying voltage to the contact of the traction relay. The relay, wiring or ignition switch needs to be replaced. If there is current, but the starter still does not turn, then the problem is in itself.

- Faults in the starter itself. It is necessary to inspect, there may be damage to the flywheel teeth or starter gear, repair or replace if necessary.

- The commutator on the starter was burnt, the brushes were severely worn, and there was a break in the armature winding. How to determine this? The armature does not rotate at all or too slowly. Inspect the traction relay and supply current from the battery to the starter contact directly. To fix the problem, it is necessary to repair or replace the armature or the starter itself.

- Poor performance and clutch slipping. This happens when the starter spins but the flywheel does not. In this case, change the clutch or the starter itself.

If the starter turns, but the car does not start, you need to look further.

Causes of malfunction

Before we begin to study the causes of the malfunction, we remind you that hereinafter we are talking about the crackling noise of the starter, which is most similar to the loud rattling of the contacts of an electromagnetic relay. If you hear an unpleasant metallic grinding noise from under the hood, then it appears due to poor engagement of the overrunning clutch (starter Bendix) with the flywheel teeth - that’s a completely different story.

Most often, the starter crackles when you turn the ignition key for three reasons:

Low battery

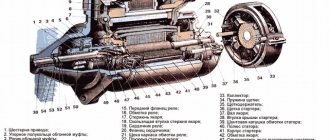

To understand the cause of the crackling noise due to a discharged battery, let's remember the starter device. When you turn the ignition key, the voltage from the on-board network is supplied to the coil of its solenoid relay. The electromagnetic forces that appear in this case cause the armature of the device to move. It closes the power contacts that connect the starter motor to the battery, and in addition, causes the Bendix gear to engage with the flywheel.

When the battery is discharged, its energy may be enough to attract the metal core - cranking the crankshaft is out of the question. As soon as the starter contacts close and power is supplied to its electric motor, the voltage drops to such an extent that the electromagnet is unable to hold the metal core. Under the action of the return spring, it tends to take its original position and opens the power contacts. The restored voltage contributes to the repeated retraction of the anchor, and the situation is recreated many times.

To make sure that the culprit of the problem is a deep discharge of the battery, just turn on several consumers (lighting, electric heater motor, etc.) and press the sound signal. The latter will either not turn on at all, or will be heard with wheezing, reduced amplitude or attenuation.

Poor engine ground contact

The picture of what is happening is practically indistinguishable from the case discussed above, with the only difference that the test for battery discharge ends with a negative result - all consumers, including the sound signal, are working at full strength.

At the same time, it is very simple to determine that the cause of the malfunction is poor contact between the battery and the engine - just pay attention to the oil pressure warning lamp, which is located on the instrument panel. If the voltage in the car’s on-board network is below normal, then turning the ignition switch to the “Start” position will lead to a gradual attenuation of the brightness of the warning lamp (like all others).

In the case where the cause of the crackling sound of the starter solenoid relay is a bad ground, an attempt to start the engine will lead to its complete extinction in time with the clicks of the solenoid relay. At the same time, other indicators practically do not change the intensity of the glow.

Everything is explained very simply - the “mass” of the oil pressure sensor, as well as the starter, is the housing. Therefore, as soon as the electrical contact between the engine and the battery is lost, both of these devices stop working synchronously.

Open or shorted starter relay winding

Another reason why the solenoid relay cracks is an interturn short circuit or a break in its holding winding. In other words, the efforts of the electromagnet become insufficient to keep the power contacts of the starter relay in the closed state and engage the overrunning clutch gear with the flywheel ring gear. Under the action of the return spring, the bendix tends to take its original position, and the contact pad located on the armature opens the electrical connection. After this, the retractor winding turns on again and the situation repeats itself many times, which causes the crackling noise.

to determine that in this case the starter solenoid relay has failed by the behavior of the warning lamps located on the instrument panel. At the moment when the loud clicks of the starter are heard, their brightness does not change - the switching of the starter motor occurs for such a short time that the battery voltage practically does not drop.

Something else useful for you:

- The starter does not turn the retractor, but clicks

- How to check the starter solenoid relay?

- Why doesn't the car start, but the starter turns?

Computer malfunction

The unit itself is very reliable and rarely fails without external intervention. But water can get on it, and this is the main reason for malfunction.

There are significant flaws in the body design; the drainage holes near the filter are often clogged with dirt and water gets into the block through them.

To do this, you need to check and clean the drainage more often. Also, water can flood the ECU after installing the alarm, when the plugs are not installed tightly or they are completely forgotten to be installed.

You can try to dry the block, but if this does not help, you will have to replace it. This problem can be partially solved by wrapping the block with film or filling it with sealant, but then this is fraught with the appearance of condensation inside the ECU.

It is not difficult to remove the ECU; it is located opposite the front passenger seat, under the glove compartment, behind the soundproofing upholstery, almost on the floor, near the passenger’s feet.

ECU removal sequence:

- Disconnect the on-board network.

- Remove the screw that secures the upholstery.

- Carefully peel back the upholstery and sound insulation layer.

- Unscrew the three nuts securing the ECU.

- Carefully move the unit to the side and remove the two wire clamps one by one.

After unscrewing the computer, you need to disassemble it and assess the extent of the damage. We remove the board from the case and carefully inspect it. If it is partially burnt out and blackened, then nothing can be done about it; it needs to be replaced.

But if the board has no visible damage or only the output key has burned out, then in this case the key must be replaced, and the board must be washed and dried. First, you need to wipe it with a clean rag, then rinse it with WD-40 and blow it out with a compressor.

After this, rinse with alcohol several times and blow again. Now the most crucial moment is drying. Using a hair dryer set for a maximum of 1.5 hours, we blow through the board on both sides.

Recommendations

Comments 46

there is such a problem)) look from the engine to the body

Thank you all, I installed an additional relay, everything was fine

Throw some extra weight from the battery to the starter, it helped me, although I have 99

I have the same problem, while I’m flying, I’ll pull it out and insert the chip on the retractor several times. pin 50 in the photo is a red wire and everything starts up fine

The eternal problem of the tenth family is the lack of power to start the starter. Install a four-pin relay so that the positive comes from the battery. And also check the contacts on the retractor, if it works but the starter doesn’t turn, it could be them, two nuts, if I’m not mistaken, a key of 13.

I had a twin, I had the same problem, I tried everything. I changed the lock, relay, even changed the starter, the problem did not go away. then I came to a competent electrician, he installed some kind of additional relay on the starter and I never encountered this again. He said that it was a tenth disease.

and initially, when the bendex clicks, the first thing you should do is dig a lot, but if it is more than 3 years old, then most likely it needs to be replaced))

Engine and spark plugs

Often candles simply flood, especially in winter. This could be due to a weak battery spark, wiring problems, or unsuitable spark plugs.

The most primitive way to dry them is to press on the gas and crank the engine for 10 seconds using the starter.

But in winter this rarely helps, and the candles need to be dried. To do this, they need to be removed and thoroughly cleaned of dirt. This can be done with a toothbrush. In this case, you need to leave the same gap of 0.7-1 mm .

Fuel system

It happens that the tank simply runs out of gas, do not forget to monitor its level. You also need to pay attention to its quality. Due to low-quality gasoline, spark plugs often flood, the filter becomes dirty, and moisture forms.

If you have filled in with low-quality fuel, then in this case you need to remove the gas tank and change the coarse and fine filters, you can try to blow out the fuel pipes.

If the injectors are dirty, they can be cleaned using any available method. When there is a lot of water in gasoline, you can add a little alcohol to the tank.

But if there are a lot of impurities and dirt, then only strong cleaning will help. You see that the starter is spinning, but the engine refuses to work and you can’t hear the fuel pump pumping. It may fail, there is no tightness in the power system or the pressure regulator is malfunctioning.

The first thing you need to do is check the pressure in the rail, the normal value is 3.5-4 atmospheres .

Then you need to remove the hatch and measure the voltage in the connector; the light bulb can be inserted into the two terminals in the middle and cranked with the starter. It should light up and if the voltage reaches, but there is no pressure, you can try to hit it. The brushes could simply be stuck. If they are normal, then the coarse mesh may be clogged, it needs to be cleaned or replaced; in winter it may freeze up.

If electricity is not supplied, you need to check fuse F21 and relay k12. The relays (power coils) need to be removed, tapped on them a little, or simply warmed thoroughly in the palms of your hands.

Special case

No matter how funny it may be, very often problems with the starter arise due to contamination of parts. If you understand your car and were able to identify the cause of the starter failure, then first simply remove the part and clean it. There is a high probability that the VAZ 2109 starter does not work precisely because of dirt

, settled on the parts. At the same time, there are a lot of unique cases with the VAZ 2109, which are generally difficult to predict.

We will not consider each of them, but, for example, if it is -20°C

and after turning the key in the lock you do not hear any clicks, then most likely the fuse has burned out. Also inspect the wiring and the solenoid relay; if, of course, the battery is normal, then most likely the problem lies with them.

Timing belt, valves and damper

The gas distribution mechanism often breaks. The belt breaks only when the car is moving. Unfortunately, no one is immune from rupture, and to prevent this from happening to you, you need to pay attention to its rubbing more often and change it in time.

Sometimes the valves come into contact with the pistons and they bend. To solve this problem, you can install pistons with special grooves. Sometimes the engine does not start due to the damper being turned several teeth, in which case the sensor makes a mistake and shows the wrong phase.

To check the damper, you need to unscrew it and check that its marks match the marks on the timing belt cover. If the marks do not match, you need to turn the pulley until they match.

Why do you need a starter?

For many years, since the appearance of the first “self-propelled strollers,” which later became known as cars, the engine was started by rotating the starting handle. As long as the engine had one or two working cylinders, this was not difficult to do. An increase in the number of cylinders and their volume required a significant increase in effort to start the power unit. Therefore, the efforts of designers were aimed at solving this problem. The result of their work was the invention of the electric starter.

The appearance of such an “assistant” made it possible to start the engine without leaving the car, simply by turning the ignition key or pressing a special button. The starter is a complex electrical device in which the energy accumulated by the battery is converted into rotational movement of the armature. A gear is mounted on the armature shaft, which, when engaged with the engine flywheel, starts it.

Crankshaft sensor

If the starter turns normally, the fuel pump works, the spark plugs and the “brains” are normal, you need to check the sensor. You need to look at the tachometer; if there is a failure, the revolutions are not visible.

You need to remove it and connect it to a multi-meter. You need to quickly wave a screwdriver in front of the sensor.

If there are no power surges, then it has “died” and needs to be replaced.

You can check it by testing the resistance; it should be approximately 750 Ohms.

If jumps are still observed and the resistance is normal, you need to look carefully to see if contamination has appeared and, if necessary, cleaning should be done.

Ignition coils

Custom ignition coil

The Lada Granda has two types of ignition coils: individual and four-terminal, they are controlled by the engine controller.

One of the signs of poor coil performance is poor idling, a drop in power and high gasoline consumption. The car starts poorly or stalls.

If the coils are partially broken, then paired misfires and ignition in the cylinders often occur. To remove the coil, you need to reset the terminals from the AMB and remove the leads from the controller. Then disconnect all high voltage wiring.

After this, the coil must be disconnected from the bracket by unscrewing the mounting screws. If you plan to replace the coil, make a note of its markings.

There are several ways to test the coil for faults:

- Testing a short to ground. To do this, using an ohmmeter, you need to connect the wire from the coil to the first end of the ohmmeter, and the body to the second. It should show an infinite value, if you see a specific value then there is a leak.

- We check the primary winding for a break. To do this, you need to connect the ends of the device to the contacts; if the device shows an infinite value, then one of the coils is broken and needs to be replaced with a new one.

- We check the secondary winding (for a 4-lead coil). To do this, first test the winding on the 1st and 4th cylinders using an ohmmeter. If it shows an infinite value, then the coil is working. Repeat these steps with the winding on the 2nd and 3rd cylinder.

- Checking high voltage wiring. The wires are checked one by one. To do this, connect an ohmmeter to the wire, measuring the resistance with a maximum value of 20 kOhm. The normal value is approximately 3 to 8 kΩ. If it shows infinity, then the wire must be replaced. It is advisable to carry out such a check annually.

After installing the coils in their place, you must strictly observe their markings; the cylinder number must match the number on the wire.

If the Lada Granda started and immediately stalled. The most common reasons:

- Damage to the ignition coil connections. Needs to be repaired or replaced with new ones.

- Low fuel pressure.

- Poor sealing in parts of the catalytic manifold or receiver.

- Poor performance of the engine control system.

The Lada Granda has many design flaws, but if you know all the weak points of this car, then finding the cause of the breakdown will not be difficult. Carefully monitor your car, undergo regular maintenance, replace parts in a timely manner, and the Lada Granda will serve you for many years.