Installation of special modules

The power characteristics of a diesel engine can be increased using special blocks. This method is most popular among car enthusiasts. These modules interact with the fuel system. They do not participate in the operation of the ECU, but together with it they monitor electronic sensors.

Installing the modules is not difficult, but you must follow the specific instructions that come with each unit. There are 4 categories of blocks in total:

Block for changing injector control signals.

It is designed to control the activity of the injectors - it slows down or stops the needle from rising. As a result, fuel consumption is optimized and combustion efficiency increases. The block is connected to the injectors using wires. Compatible with all diesel engines with a modern fuel supply system.

Block for changing the fuel pump operating system.

Interacting with the fuel mixture compression sensor, this unit underestimates the readings coming from it. This leads to a decrease in pressure in the fuel injection pump and increases engine dynamics. In this case, the engine resource does not suffer in any way. The unit is connected to the fuel pump and the ECU using wires. It may well be combined with older diesel engines that were manufactured before 2008.

A block that changes the readings of the fuel rail pressure sensor.

Using this device, the ECU is “deceived” - it is informed that the pressure in the fuel rail is reduced. The control unit “thinks” that the engine speed has dropped and begins to change the dynamics of the injectors. This leads to a reduction in fuel consumption and an increase in engine power. The unit is connected to the ramp pressure sensor using wires. It can only be combined with modern engines.

ECU CPU optimization block.

With its help, fuel pressure is determined. When it increases, an impulse is sent to the ECU to increase the injector timing. The module has a built-in special program that corrects engine operation without an ECU. The sensor readings do not change. The block can be combined with all types of modern engines.

Positive aspects of using modules:

- Motor power increases.

- Fuel consumption is reduced.

- Installation is simple and will not cause any difficulties for anyone.

Negative sides:

- The service life of the cylinder block is slightly reduced.

- The service life of the fuel pump is also reduced.

- Harmful substances begin to be released more actively.

How to boost 2106

You will need

Instructions

There are a number of technologies aimed at boosting engines. Starting with chip and MD tuning and ending with changes in engine design.

At the first stage, a new camshaft with modified cam geometry is installed in the cylinder head. There, the valves are changed, the plates have a larger diameter, and the combustion chambers are bored. The intake and exhaust tracts are ground and polished. The simplest engine boost usually ends there.

In-depth engine tuning involves replacing the factory crankshaft (installed with an enlarged crank). The cylinder block is bored on a milling machine for pistons of larger diameter. These parts are equipped with connecting rods of the appropriate size and T-shaped compression rings.

After design changes and engine assembly, the process of adjusting its systems and mechanisms begins, as a result of which the compression ratio in the working cylinder is increased. The required parameter depends on the valve timing angle and the opening position of the throttle valve. Changing the position of the timing shaft is carried out by an adjustable drive gear, which helps fill the combustion chamber with an enriched fuel mixture, which during combustion releases more thermal energy, which is then converted into kinetic energy.

The “aerobatics” of tuning a VAZ 2106 engine is installing a turbine on the engine and equipping the car with a direct-flow exhaust gas removal system. Having a car with a forced power plant, you can easily compete on the road with many famous brands of the foreign automobile industry.

Video on the topic

www.kakprosto.ru

Options for deep engineering tuning

Efficiency of an internal combustion engine.

How much is approximately equal, as well as power as a percentage? An effective way to increase engine power is to install turbocharging, which allows you to increase engine power by 50% or more. In this case, in addition to the turbine itself, a new injection system, a reinforced crankshaft and pistons are installed, and other necessary work is also carried out. It should be said that despite the complexity of such an increase in engine power, installing a turbine is popular, which is explained by the excellent efficiency of such tuning.

Boring the cylinders and installing a new crankshaft. This is one of the engineering tuning options, in which the cylinders are bored, with the installation of new pistons and a reinforced crankshaft. In fact, with such operation, the physical volume of the engine increases, which has a positive effect on its power and torque. If we talk about the disadvantages of this method of increasing power, we note the increased fuel consumption, high cost and complexity of such tuning. In the future, you also need to be careful about engine maintenance, the service life of which will be significantly lower than that of a standard engine.

Installing a modified camshaft will allow you to adjust the valve timing, which increases engine power, without any other profound change in the design of the power unit. The only drawback of this method of increasing the power of a power unit is the need to use gasoline with a high octane number, since otherwise detonation occurs, which can lead to a significant deterioration in engine performance.

You can increase the power of your car by using gasoline with a high octane number. This is a quick and simple tuning method, which at the same time will require a corresponding reconfiguration of the injection system, and the pressure in a running engine increases significantly, which negatively affects its reliability indicators. Simply pouring 95 or 98 gasoline into a gas tank without any additional reconfiguration of the fuel system is not recommended.

Installing a zero resistance filter. This is a fairly simple and effective way to increase engine power by about 10 horsepower. Due to its special design, such a filter improves the supply of the air mixture, reducing fuel resistance at the inlet. The increase in power in this case will not be too large, but this is a cheap method that does not require contacting special workshops.

Installation of a direct-flow exhaust system. By replacing the standard exhaust system with a direct-flow one, you can get about a 15% increase in power. In addition to directly improving the dynamic characteristics, you will be able to get a pleasant roar from the engine, and the car itself will be more responsive and faster. Just remember that you need to install a direct-flow exhaust system that fits your car model. All such work should be performed exclusively by a professional.

Use of exhaust pipes with increased diameter. Such work will optimize the movement of exhaust gases; as a result, the engine becomes approximately 5% more powerful. It is only necessary that all elements of such a modernized exhaust system be selected exclusively by a specialist.

Installation of new pistons and connecting rods. By reducing the mechanical losses of the internal combustion engine, you can get a small increase in the power of the power unit. Typically, such work is carried out in conjunction with other tuning, which allows for the maximum possible increase in engine power.

Conclusion

Today there are many different ways to increase the power of a car engine. You can choose either a relatively simple chip tuning, in which the control system is reconfigured or additional units are used that control the operation of the engine, or a complete engine overhaul, with the installation of a turbine, a new injection system, crankshaft, connecting rods and pistons. In each specific case, the choice of one or another tuning technology will invariably be up to the car owner. Just remember that such work must be performed by a professional, which guarantees subsequent trouble-free operation of the car engine.

19.12.2017

We boost and increase the power of the VAZ 2106 engine

Many adherents of classic Lada models are trying in every possible way to improve the characteristics of their favorite cars. One of the main questions that arises is how to increase engine power, how to do this on the VAZ 2106 and on the VAZ 21063, the power of which is lower than the “pure six”?

Return to contents

Description of common actions

Increasing power is a whole set of measures aimed at increasing engine power in VAZ 2106 and 21063 models without causing harm to the unit. It should be noted that if the complex for “boosting” the VAZ 2106 engine is completed completely, then modernization of the brake system will inevitably be required. Let's consider simple technical tuning activities.

- Installing a zero resistance air filter. This operation does not increase engine power. Installation of this part facilitates the operation of the unit, releasing some of the energy that was spent on overcoming the resistance of the standard filter.

- Replacing a conventional muffler with a direct-flow muffler produces the same effect. The only difference is that gas flow resistance is eliminated at the exhaust. Together with the previous operation, installing direct flow gives a noticeable increase in engine power. The disadvantage is increased noise from the exhaust system.

- Installing an electronic ignition system will ensure stable operation of the unit, and good sparking will contribute to better and more complete combustion of fuel in the cylinders.

- Polishing the internal surfaces of the intake manifold will also reduce the resistance to the flow of the mixture of fuel and air, and the unit will “breathe deeply.”

- Replacing a carburetor has its own nuances. If you have a standard DAAZ 2105 or DAAZ 2107 carburetor, then it is better to replace it with a Solex from a VAZ 2108 with an engine capacity of 1.5 liters. On older “sixes” there are Weber carburetors with forced opening of the secondary chamber. They are completely repairable and it does not always make sense to change them, since these carburetors are structurally capable of working with an engine of increased power.

Of course, to get the desired effect from the changes, your car’s engine must be in good technical condition. By completing all the points on this list, you are guaranteed to experience an increase in engine power.

Return to contents

Measures to refine the power unit

Over time, many car enthusiasts want to get more from their car and are thinking about the question of how to boost the engine of a VAZ 2106. How to ensure that the power on a VAZ 21063 is equal to that of a “pure six”? Let us remember that boosting an engine is an increase in power by increasing its displacement and compression ratio. This requires deeper technical tuning; disassembling the engine is indispensable. Here is a list of measures that will allow you to boost the VAZ 2106 engine and give a significant result (an increase of up to 110 hp and more).

- Milling the cylinder head over the entire plane to a thickness of up to 1 mm. As a result, the combustion chambers of all cylinders are reduced, the compression ratio increases, and subsequently the engine power. You must understand that after such an operation it will not be possible to drive on fuel with a low octane number, at least 95. When using such gasoline, the combustion process in the chamber will significantly accelerate, detonation will occur, an impact on the piston, piston pin, and so on. Detonation significantly accelerates engine wear and can lead to serious damage.

- Installation of a sports modification camshaft. It will ensure increased valve lift and high-quality filling of the cylinder with fuel.

- Boring of cylinders for piston size 82 mm. Make sure that the sleeve wall will allow this operation.

- Installing lightweight forged pistons and connecting rods and a lightweight flywheel will free up even more engine energy, which it spends on internal resistance.

Design of the internal combustion engine modification of the VAZ 2106

Return to contents

Features of modification of 1.3 l units

There is a modification of the VAZ 21063, the power of the unit is significantly lower. The reason is the standard 1.3 liter engine, which is quite fixable. In modification 21063, engine power can be increased in the same ways as for the “pure six”. However, it will still not be possible to achieve the same power; the difference in the working volumes of the units is too large.

It is quite possible to increase engine power in modification 21063 by increasing the displacement. To do this, you need to purchase a new crankshaft from a VAZ 21213 Niva and a set of special shortened pistons and connecting rods. It is better to entrust the installation and adjustment of these parts to a specialist who has already performed such an operation. Result: in the VAZ 21063 model, power will increase significantly. This will happen due to a significant increase in the piston stroke.

You should pay attention to the following point: when increasing power in the VAZ 21063 model by replacing the crankshaft, it is not recommended to mill the cylinder head. The fact is that after installing a new crankshaft on the engine in question, the compression ratio will increase and a switch to 95-grade gasoline will be required. If you want to further increase engine power in modification 21063 by milling the head, the compression ratio will increase again, resulting in a switch to 98-octane gasoline.

All modifications that increase engine power on the VAZ 2106 and 21063 models inevitably lead to an increase in fuel consumption, since in both cases the working volume of the unit increases. Therefore, in everyday driving you should neglect simple rules for saving fuel and use the full resource of your engine wisely and thriftily.

expertvaz.ru

Some nuances to consider after installation

Engine torque and power. What is more important A few words about speed. In simple words formulas and videos

Like any other complex system, a turbocharger has features that are strongly recommended to be taken into account when operating it. Moreover, a negligent attitude to these requirements can reduce the service life to a minimum and the costs of tuning will never pay off.

Here are some highlights:

- It is necessary to monitor the oil and filters. Change it in a timely manner and do not use additives.

- It is advisable to use only oil recommended by the manufacturer.

- Avoid sudden starts with heavy loads.

- Avoid abrupt engine stops under load.

- Avoid idling for long periods of time.

- Tightness.

- Change the air filter promptly.

Budget-friendly ways to increase intake and exhaust power, chip tuning

Engine ZMZ-406 description and technical characteristics. Gazelle 405 engine capacity

Such procedures are performed when preparing a car for racing or to create collectible samples. Ordinary car enthusiasts do not order such tuning.

Budget-friendly methods for enhancing device performance:

- An air filter is installed to supply oxygen to the engine. This method increases productivity by 0.5-2%, but every car enthusiast can use it. Oxygen is poorly filtered, the power plant quickly becomes dirty.

- Removing the catalyst from the exhaust system reduces resistance to the release of combustion products. The internal combustion engine picks up speed faster and the dynamics increase. Adjusting the thickness of the pipes increases quality by up to 5%.

- Chip tuning is carried out on injection engines, the ECU binding is adjusted. Different engine models are chipped, increasing performance and torque.

- Replacing the motor is the most reliable way to improve. If the design of the car allows you to mount a large unit in the engine compartment, then the result will be obtained faster than when trying to squeeze out additional horsepower and improve torque on an old engine.

- Replacement alone does not solve the problem; often a new CV joint, exhaust pipe, suspension are installed, and gear ratios in the gearbox are reconfigured.

- A lightweight flywheel improves the performance of tuned engines and is often used. Less weight allows you to gain speed faster. Motor performance improves by 4%.

Every car enthusiast can make such a modification. For a lightweight flywheel they pay an average of 2000-4000 rubles. Together with updating the air filtration system and the removal of fuel combustion products, it is possible to improve the quality of internal combustion engine operation by up to 10%.

Reducing friction between the piston and the cylinder body is ensured not only by engine oil, but also by using various additives and additives. Efficiency increases by 7%, all components function more reliably, and gasoline consumption is sometimes reduced.

X

The desire of car enthusiasts to improve the engine is completely justified. In addition, the six engine can turn out to be quite a powerful unit if you put in some effort. Today we will touch on such a topic as the forced VAZ 2106 engine. The lack of electronics and simplicity of design are another plus in do-it-yourself tuning.

The result directly depends on you: what goals were set and how much effort and time you spent, this will be the result of the work done. If you follow certain rules, you can easily increase the power of the six engines to 150 horsepower. To obtain such power, you need a 1.6-liter engine; a larger displacement will cause an increase in load, and the car will have difficulty gaining speed.

We take a set of tools, in addition to this, a drill, cutters and don’t forget to grab polishing paste. You can proceed to modifying the main cylinder block. The procedure is not simple, but without it it will not be possible to achieve high-quality acceleration. First, the cylinder block channels are processed with a cutter - the elements through which fuel flows from the intake manifold. Please note that the channels must have a smooth transition and a larger cross-section. At the end of the work, all channels must be the same size. Similar work is carried out with the release, but here we use cutters of a smaller diameter.

If you wish, you can install valves from Mitsubishi Pajero, but you will have to bring the rods to the standard ones with your own hands. It was also time to modify the valve plates of the VAZ 2106, after which the valves were adjusted according to weight.

The next step to achieve a forced engine is working with the camshaft. We recommend installing a high lift camshaft. A split gear is used to fine-tune the valve timing. The intake manifold needs to be bored and polished. We also touched upon modifications to the carburetor, because after such tuning, significantly more fuel and air began to pass through it. The forced 2106 engine must breathe well, so it is necessary to install a zero-resistance air filter.

Our tuning was complex, so we decided to also replace the exhausts. The best option is a 4-2-1 spider with a pipe without a resonator and a direct-flow system. It is worth replacing the standard connecting rods in the engines. We purchased forged pistons with a pair of T-rings. We also change the bearings, installing faster ones that can withstand up to 10 thousand revolutions per minute. By making the advance angle in the ignition distributor larger, you can get 10 additional horsepower. Here's a modification: the boosted engine for the six is ready!

Ways to increase the power of a power unit

Let's take a closer look at how to increase the power of a carburetor engine.

- Reducing vehicle weight. This method is suitable for small cars. This is due to the fact that, according to statistics, if you remove unnecessary things, lighten the rims by replacing them with light-alloy ones, change the driver's seats to lighter ones, the car enthusiast can increase engine power by several percent (no more than 10). For small cars this is noticeable.

- Suspension. If the car does not have a rigid suspension, then when picking up speed or speed, a significant part of the energy will be extinguished by the fact that the car will seem to sit down when starting or picking up speed. In this case, strengthening the suspension or replacing it with a stiffer one increases horsepower.

- Increasing the amount of air in the combustion chamber. This is a universal method that adds power not only to the carburetor, but also to the injector. Everyone knows that the more air enters the combustion chamber and combines with the combustible mixture, the better it burns, releasing a large amount of energy. For example, increasing the power of a Niva engine (manufactured by VAZ), or on a Chevrolet Niva, can be achieved in two ways. The first is to purchase a special air turbine, which is designed for these power units. Its function is that it is connected to the flywheel pulley and has a special mechanism that, when the engine is running, takes a large amount of air, compresses it and supplies it to the combustion chamber. Thus, the flammable mixture is completely saturated with oxygen and burns completely, giving a strong explosion. When installing such equipment, the power of the power unit increases by 50%. The second way is to purchase a special filter. It differs from the usual one in that it contains a material that does not resist the air that passes through it from the atmosphere and goes into the combustion chamber. That is, the amount of air is greater, which means the force of the explosion increases.

Now let's move on to consider the question of what to do if the engine does not develop power with an injector.

Therefore, the best way to increase the power of such a power unit is to reflash it, the so-called chip tuning. That is, specialists use a special program to change the computer settings, increasing or decreasing the power.

But such tuning requires a certain approach. First you need to diagnose the power unit itself.

How to determine engine power. The dependent value will be indicated in the technical documentation, or when connecting a special program that will determine this while the engine is running. After this, you can decide whether to increase the power or not.

After all, sometimes violating the factory settings can lead to increased fuel consumption.

It is important to remember that any increase in the power of the power unit must occur after its complete diagnosis. This is due to the fact that its fall may be caused by some kind of malfunction in the engine itself

But if everything is in order, and the car enthusiast is confident in his driving abilities, he can start tuning.

To increase engine power, first of all, you need to check your engine for various faults. After this, you can carry out tuning yourself.

https://youtube.com/watch?v=-mxJI-eXYxQ

How to boost a VAZ engine - DRIVE2

Sometimes the engine power becomes insufficient for a VAZ 2106 car owner, then the question arises: how to boost the VAZ engine? A simple and effective method of creating forced modifications is to increase engine power by increasing the displacement. This method is quite often used in the production of serial engines of transitional models, for example, the development of the VAZ 2106 engine based on the 2103 engine.

Since it is not possible to increase the number of cylinders, a possible solution to this problem is to increase the piston stroke and cylinder diameter. However, in order to increase the piston stroke, the crankshaft will need to be replaced, so increasing the cylinder diameter is considered simpler. This is achieved by using a repair size piston group. In the future, to increase the working volume, a piston group of a different model is used. Please note that this will require boring the seats for the liners, as well as processing the sealing surface of the head gasket to ensure the required degree of compression.

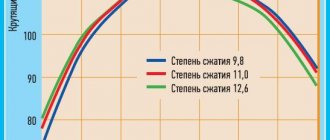

Increasing the compression ratio is one of the simple methods that allows you to boost the VAZ engine. Modern engines have this indicator at the level of values typical for sports modifications. Remember that the thermal efficiency of the engine will depend on the compression ratio. This figure increases rapidly as the compression ratio (e) increases to 12~13. After exceeding e=13, the efficiency increases much more slowly. It should be noted that as the compression ratio increases, detonation appears due to the fact that at the end of the compression stroke the temperature of the working mixture increases. The filling ratio can be increased by using several carburetors. It is recommended to use one carburetor for each cylinder. And in order to increase the filling coefficient in an injection engine, other methods are used, which will be discussed below. Highly forced engines are often equipped with direct-flow carburetors.

But this will inevitably lead to increased fuel consumption, so this modification method is unprofitable for daily use. Other ways to increase the filling factor are to use a cylinder head with four valves per cylinder, as well as to reduce the loss of the speed of movement of the combustible mixture in power supplies, in the valve gap and intake pipes, and by cleaning the cylinders from processed gases. The magnitude of such losses is directly proportional to the speed of the mixture squared, so it is necessary to increase the flow sections of the intake tract on a forced engine. In addition, larger diameter valves should be installed, valve lift should be increased and valve timing should be expanded. Note that the inlet pipelines must have smooth bends, expanded flow sections, and high cleanliness of the internal surface. Inconsistencies between channels at the pipe connection points are absolutely unacceptable, otherwise turbulence will significantly reduce the flow speed.

Good cleaning of the cylinders from exhaust gases can be achieved by the same modification of the exhaust tract.

Improving the VAZ 2106 engine in terms of speed has the greatest impact on changing the gas distribution mechanism. Heat losses during the combustion process affect the relative efficiency of the engine. Heat losses decrease as the compression ratio increases. Mechanical efficiency increases if friction losses are reduced.

Piston friction occurs due to the lateral load on the piston, which occurs under the influence of inertial forces of progressively moving components. Mechanical processing reduces the weight of the piston. To reduce the weight of the connecting rod and piston pin, they are made of titanium alloys. In crankshaft bearings, friction losses are equal to 16% of the total balance of mechanical losses when using plain bearings. This figure can be reduced by replacing their rolling bearings. However, this will require correcting the design of the crankshaft, which is carried out by assembling individual parts fixed together by pressing.

www.drive2.ru

Pros and cons of installation

First, it’s worth understanding what a turbo kit itself is. A turbocharger for a carburetor is very rare due to the complexity of the system itself, which must work perfectly and harmoniously both as a whole and in each individual unit. And high temperatures undoubtedly require the use of specific and expensive materials. And this despite the fact that the carburetor engine, even at the design level, was not designed for supercharging. If we talk about the possibility of such a modification appearing on factory VAZ models, then the probability of this tends to zero due to the cost of the compressor itself, which will add at least 10% to the final cost of the car. Which, in turn, is not possible, given the price segment of these cars.

Possible consequences of increasing engine power

Before you start increasing power, there are some difficulties to pay attention to. The first difficulty is that when increasing engine power, you will have to spend more money on gasoline, since it will be consumed several times faster. And the second difficulty is the possible wear of the engine, and the oil will be changed more often. But if you doubt your abilities, then the best way is to contact the service station, because they know their job. But if you still have a desire to do this work at home, then you need to be prepared to buy high-quality gasoline and increase the volume of the cylinders.

Tuned engine

Increasing the power of a diesel unit

Diesel, when compared with a gasoline engine, has a number of advantages: efficiency and relative “tolerance” to fuel quality. An engine running on diesel fuel pulls better at the “lower” range. As for increasing power, most of the methods listed above are applicable to a diesel engine: boring cylinders, installing turbocharging, chip tuning, etc. But there are also features of improvement.

Modules for increasing power characteristics

We are talking about specially designed units that interact with the vehicle’s fuel system. They do not affect the operation of the electronic control unit in any way; they simply exercise additional control over the operation of the electronic sensors. There are four types of modules:

- A block that changes the pulses that control the operation of the injectors. Here the module’s task is to slow down or speed up the needle rise. This reduces diesel fuel consumption and improves its combustion. This happens due to a change in the ignition timing. The module is easy to install and can work with any modern diesel units.

- A block that influences the operation of the high pressure fuel pump. The module operates in conjunction with a sensor that provides information about fuel pressure. At the same time, the data is underestimated. This leads to an increase in pressure in the injection pump. The result is preservation of the operational life of the power unit while improving dynamics. The unit only works with diesel engines that use a mechanical method of supplying diesel fuel and were manufactured before 2008.

- A unit that works with the fuel rail sensor. This module is also engaged in “deception”, supplying the ECU with data about a decrease in pressure in the ramp. He begins to “think” that the dynamic characteristics of the engine are insufficient and changes the intensity of the injectors’ operation. Power increases and fuel consumption decreases.

- A module that optimizes the operation of the ECU (more precisely, its processor). The purpose of the block is to determine the pressure in the fuel system. If its value is large, a signal is sent “ordering” to increase the injector timing. That is, the module is capable of changing the engine operating mode without the participation of an electronic control unit. The unit is not “engaged” in supplying false information and is installed in a high-pressure system. Works well with any modern diesel installation.

The advantages of the above blocks include ease of installation, savings in diesel fuel consumption and increased power. However, this reduces the service life of the cylinder block, injectors, and fuel pump. At the same time, the emission of harmful substances into the atmosphere increases.

Common Rail

The task of this system is to supply diesel fuel to the combustion chamber, regardless of the current engine power and torque. In a conventional diesel engine, the fuel is compressed in the intake manifold, while in a common rail this occurs when the composition is supplied to the combustion chamber.

Increasing the working size of the VAZ engine

As is clear, one of the important characteristics in relation to internal combustion engines is the working size. Its power, throttle response of the unit, etc. depend on the size of the motor.

It is more comfortable to operate the most powerful machine, since the supply of torque and power allows you to not “twist” the engine too much, since the applicable thrust occurs at the lowest speed.

When it comes to increasing working size, there are two main methods:

- change the diameter of the cylinders;

- increase the piston stroke by replacing the crankshaft;

These methods are intensively practiced for tuning serial AvtoVAZ engines, which are found under the hoods of various models. To be more precise, we are talking about the very first engine on the “penny” 2101 with a power of 60 hp. either the “eleventh” engine 21011, or the VAZ 2103-06 power unit with a power of 71-75 hp. Also, do not forget about the carburetor 80-horsepower 1.7 liter engine on the Niva model and other modifications of the internal combustion engines indicated above.

Let's get back to tuning. To perform modifications, you can use both serial parts and special elements for tuning. In the first case, the total cost of modifications will be noticeably cheaper, since serial parts are easier to find and cheaper to purchase.

So, let's look at a specific example. If you have a VAZ 2101 engine, you can bore the cylinders to 79 mm, then install the pistons from the 21011 engine. The working size will be 1294 cm3. To increase the piston stroke, it is necessary to have a crankshaft from 2103 so that the stroke is 80 mm. Then you will need to purchase shortened connecting rods (by 7mm). Ultimately, the size will be 1452 cm3.

It goes without saying that if you bore the cylinders and immediately increase the piston stroke, the end result will be the size of a “penny” engine, which will be 1569 cm3. Note that similar operations are carried out with other motors on “traditional” models.

Please note that, regardless of the block, it is not recommended to bore cylinders larger than 3 mm, since the dangers of powerful thinning of the walls and a decrease in service life, as well as damage to the channels of the cooling system, increase significantly.

It is also important to take into account that after installing another crankshaft and increasing the piston stroke, the compression ratio increases, which will require the use of gasoline with the highest octane number. Additional adjustment of the compression ratio may also be useful. The main thing is to choose the right shortened pistons, connecting rods, etc.

We also add that the most common and cheapest method can be considered boring for repair pistons. But even if you bore the block to the extreme repair size, the size increases by no more than 30 “cubes”. In other words, you shouldn’t count on a significant increase in power in this case.

What is laughing gas

Nitric oxide is an inorganic chemical compound that is colorless, nonflammable, with a faint odor and a sweetish taste. Its analgesic effect is short-lived, so it is widely used in anesthesiology, especially as a supplement or enhancement of basic anesthesia performed by other methods. Due to its relaxing effect, it is used in medicine, the food industry and other fields.

For entertainment purposes, food-grade laughing gas is used, which is filled into balls or supplied from a cylinder using a special valve and nozzle. The principle of operation is as follows: nitrous oxide enters the lungs and then enters the bloodstream, reaching the brain within 15 seconds. After inhaling the gas, a person experiences a feeling of slight intoxication and euphoria, which goes away on its own 15-30 minutes after the last use. Inhaling large amounts of nitric oxide at once can cause a feeling of weakness, and drinking pure nitrous oxide can put you in a state of medical anesthesia.

That is why it is important to correctly use only high-quality gas, mixed using special equipment and stored in compliance with temperature conditions

Calculation of required power

To determine how much electricity you need, you need to add up the power of all consumers. For example:

- water heating tank (boiler) – 1-2 kW;

- refrigerator – 1 kW;

- air conditioner – 2.5 kW;

- Computer – 0.4 kW;

- Lighting – 0.1-1 kW;

- And etc.

This is called Pust - installed power, i.e. sum of kW of all consumers. In this case, more than 5 kW is already needed, which means that the allocated power of 3 kW is simply not enough. To reduce current consumption at the same power, it is worth switching to a 3-phase network. This will make it possible to distribute consumers into three phases. And a powerful load (more than 5 kW) cannot be connected in one phase, this is prohibited by the PUE (and a modern electric stove can consume 9 kW).

Important! Do not increase maximum power by replacing automatic transmissions or larger plugs. More than 25 Amps should not be used at home at all, unless the wiring is replaced with new ones (with the appropriate cable cross-section)

The circuit breaker protects the electrical wiring; if it does not operate on time, the wiring will begin to melt and a fire may occur. If you have replaced the wiring with a more powerful one (in houses and apartments above 2.5 mm2 they are rarely installed) - this is not a guarantee of reliable operation. In old apartments, a 2.5-4 mm2 aluminum wire comes from the panel. It can burn out easily.

In this case, you should take into account how many devices you turn on at the same time. There is such a thing as “power utilization factor”; for residential premises it is 0.8-0.9. The numbers may vary depending on how you use your electricity. In non-residential premises and in production, Usage tends to 1.

Total:

Pout=Kisp*Pust

How to increase allocated power

Private person

The first step is to collect a package of documents. It’s worth starting with obtaining technical specifications and developing an electrical project. A power supply project for an installation is a set of technical documentation made in accordance with GOSTs and state regulations. It can only be performed by organizations with the required license. And here you will need a floor plan, it can be ordered from design studios, a certificate of the amount of allocated energy, technical specifications, etc. Certain points can be discussed individually or the designer will visit the site to familiarize himself with the task.

The next step is coordination of the project with energy supply organizations. Next, the installation is tested and its compliance with the design. If the object does not comply with the project, it is necessary to either bring it into compliance or order a new project according to the actual situation.

After this, an approval certificate is drawn up, this is done by energy supervision employees. At the end, a complete package of documents with all permits is submitted to the energy supply organization and the connection or increase in the allocated power is carried out.

In total, to increase the allocated electrical power, you will need:

- Obtaining technical specifications.

- Development of a power supply project.

- Coordination of the project with the energy supply organization.

- Checking the installation.

- Drawing up an admission certificate.

- Transfer of a package of documents to the ES organization.

- Conclusion of a new agreement.

To draw up an electrical project you need:

- The act of delimiting balance sheet ownership (take it to the DEZ or comrades of home owners).

- Certificate of allocated power.

- A document that confirms ownership of real estate.

- A site plan showing ALL electricity receivers.

The cost of the increase is determined in accordance with the resolution of the Moscow Regional Economic Commission No. 121 dated December 22, 2008. of the year and FEC MO No. 10-R dated 04/09/2009. The applicant pays for connection work in the amount of 550 rubles. Additional costs will be:

- replacement of wiring;

- replacement of circuit breakers;

- changing the object layout;

- drawing up an electrical project;

- power cable installation services;

- a new electricity meter will need to be replaced and installed on a model corresponding to the number of phases and current consumption.

Applications for such services, both for individuals and legal entities, are submitted in a single window. You may be refused if there are no technical means to increase the established limit. This can happen if the transformer is already overloaded, and there is no free one nearby.

Enterprises and legal entities

If the allocated power in the premises is too small, a legal entity can increase it on preferential terms (one time) up to 15 kW. More than 15 kW there are no benefits, then these services are paid at tariffs for legal entities. When the allocated power increases, the consumption at nearby transformer substations (transformer substations) is analyzed and, if there is a power reserve, one of them is given the go-ahead for an increase, after approval. The procedure is called “MOESK capacity re-registration”, and if there are “free resources” it can be carried out free of charge.

The cost of the procedure for increasing the allocated power depends on:

- final power value;

- geographical location of the object;

- technical ability to connect to the line;

- energy supply categories.

We also recommend watching a video that discusses the idea of increasing power by using an inverter:

If the established electricity standards do not suit you, contact the company that supplies electricity for help. You will be able to clarify which method of solving the problem is suitable for you - increasing power or transferring the facility to a three-phase power supply system. Do not try to draw up a site plan and electrical design yourself - this should be done by specialized organizations. Otherwise, your documents will simply not be accepted, and you will waste your time. We hope now you know what the allocated power of electricity is, what it is and how you can increase the limit.

The principle of operation of turbocharging

The operating principle of turbocharging is quite simple. The exhaust gases emitted by the engine enter the turbine and cause it to rotate. The turbine, in turn, transmits torque to the compressor, which sucks in air and compresses it. The compressed air is then directed into the engine cylinders. Optionally, an intercooler (intercooler) is added to this circuit. It reduces the temperature of the air compressed by the compressor, correspondingly reducing its volume. This eliminates unpleasant effects such as detonation, and increases the overall efficiency of the system.

The meaning of pumping in additional air becomes clear if we recall the principle of operation of an internal combustion engine. The fuel-air mixture burns in its cylinders; this process pushes the piston, which turns the crankshaft

But, for efficient combustion of the mixture, it is important to maintain the correct ratio of fuel and air, so you cannot increase power simply by adding more fuel to the mixture. Along with increasing the amount of fuel, the amount of air must also be increased.

This can be done by increasing the volume of the cylinder so that more air can fit into it. But you can go the other way - increase the density of the air driven into the cylinders. Then you can extract significantly more power from the same unit of engine displacement. A good example is sports cars, where each liter of volume can produce more than 150 hp. Of course, in addition to turbocharging, they use a lot of tricks. But it’s quite possible to get 105-115 hp. per liter using turbocharging alone.

Improvement of the carburetor engine

Increasing the power of a car with a carburetor engine is much easier than perfecting a diesel engine. The main reason for this is the way the fuel mixture is ignited.

At the moment, there are several ways to increase the power of a carburetor engine. All of them are fundamentally different from each other, thereby increasing the power of the car to varying degrees. So, in order.

Chip tuning

This method of boosting the engine applies primarily to injection engines. The essence is as follows: in the firmware, which is stored in the memory of the control unit, the optimal algorithm for engine performance and the constants used are installed. In ordinary cars, all these values are set by developers who spend months of work to find the optimal solution for this brand. In sports cars, they try to neglect the “fuel consumption” parameter, since the end justifies the means.

Sports parameters can be quite easily installed on your car. By changing the ratio of air and gasoline, the process of starting the ignition of the mixture, as well as additional parameters, the power of your car will increase significantly. But you also need to understand the following: by setting non-factory parameters, you will significantly increase fuel consumption.

Increasing the car's power will require you to install a stronger braking system, as well as strengthening the suspension. The loads on the car body, as well as the speed of movement, will definitely increase, so it’s worth taking care of such nuances.

Ignition angle modification

Owners of carburetor engines can easily increase the car's power by changing the ignition angle. The air-fuel mixture in gasoline engines ignites when the piston position has not reached top dead center. By changing the ignition time of the mixture, you can significantly increase the power of your engine.

However, such actions will significantly affect the performance of the engine. Premature ignition is fraught with the formation of small detonations, and as a result, engine destruction. It is also worth noting that power can be varied by adjusting the carburetor, as well as using a variety of jets.

Using a filter with minimal resistance

To prevent small particles from entering the engine cylinders, cars have an air filter. Thanks to the filter, the engine remains operational much longer and does not require frequent repairs.

However, the air filter significantly prevents air from entering the combustion chamber. How can you get out of this situation?

You can reduce the engine power consumption for the resistance provided by the filter by replacing it with a more advanced one - using a zero-resistance filter. Using such a filter will slightly increase the power of your car. By ensuring free flow of air into the combustion chamber, you will receive up to a 10% increase in engine power.

Exhaust system

In addition to the air entering the car engine, all waste material must exit it with the same ease. If exhaust gas is retained in the exhaust system due to truncation of the exhaust pipe or the passage of certain obstacles or nozzles, this allows for the creation of reverse draft.

Your engine spends its useful power on such a process. In addition, the degree of exhaust gas removal is significantly reduced, and this is far from the best news for your car. This is not a difficult task and can be done quite easily on your own.

Turbocharging installation

This method of upgrading a car is suitable for both owners of carburetor and diesel engines. By providing an additional volume of air, as well as fuel, a significant increase in vehicle power can be achieved.

The principle is based on the recycling of waste gases. During the process of removing exhaust gas, the turbine wheel rotates. The torque is transmitted to the compressor, which sucks in air and supplies it to the engine. If, in addition, you install an intercooler, the result will improve significantly due to the entry of cooled air into the combustion chamber. The air in the compressor heats up significantly under the influence of pressure and it needs additional cooling.

Nitrous Oxide Installation

Using nitrous oxide is another interesting way to increase engine power. With the ingress of nitrous oxide into the combustion chamber, the amount of working oxygen in combustion processes increases significantly. This allows you to spend more fuel on combustion in the same time.

Although this method seems attractive, it is quite difficult to operate and requires additional knowledge and skills. Typically, nitrous oxide is installed on racing cars, where speed is the main tool for victory. Can I use this method of increasing power in my car? Can. But you need to understand: is it worth it?

Chip tuning

This method requires intervention in the car's electronics - it will have to be reprogrammed. The ECU receives all information related to the engine system. Based on it, the electronics determine the degree of crankshaft speed and the intensity of fuel supply. Factory electronics settings are calculated based on average performance of the motor and saving its resources.

By performing chip tuning, you can reconfigure the memory chip or completely replace it with subsequent flashing. Preparation for chip tuning includes the following steps:

- First of all, you need to purchase a scanner, which will be used to diagnose car components.

- The firmware has several versions - you need to choose the most suitable one for yourself.

- The flashing program should be installed on the laptop. It must be combined with the car's ECU.

- If you need to change the chip, you need to buy it.

- You will also need an ECU programmer. This device can also be bought or rented, and some craftsmen make it themselves.

- The last thing you will need is a K-Line adapter. It is necessary to connect the program to the machine port.

To carry out chip tuning, you should perform the following procedure:

- A scanner is used to look for errors in the system. If they are detected, they must be reset.

- The car is de-energized.

- The control unit must be removed by first removing its protective cover.

- The ROM chip is being replaced.

- After this, the control unit returns to its original place.

- The battery is connected.

- The laptop connects to the diagnostic port. You should make sure your computer is fully charged in advance. Even better if it is connected to the electrical network.

- After this, you need to turn on the ignition.

- A program is launched on the laptop to change the motor settings.

- After installing the program, the ignition is turned off and the cable is disconnected.

Positive aspects of chip tuning:

- The dynamics are increasing.

- Fuel begins to be used more economically.

- Speed limits are lifted.

- Travel modes change.

Chip tuning will be more effective in cars with diesel engines with a turbine. In this case, the engine power increases by a third, and the torque increases by half. But this action also has its downsides.

Negative aspects of chip tuning

:

- The motor power, of course, increases, but its service life is somewhat reduced.

- The warranty is void.

- The engine may well suffer some damage (the engine may begin to detonate).

So, from the above it is clear that replacing the chip may well increase the efficiency of the motor. But without special skills, performing this procedure is risky. Not every driver will be able to cope with this task. However, there is nothing super complicated in it, and you just need to be “friendly” with electronics.