An experienced motorist can easily distinguish between normal vibrations when accelerating and a cause for serious concern. In the first case, an increase in engine speed and vehicle speed will inevitably affect the level of comfort; in the second case, the source of increased shaking will be a specific malfunction.

Please note that such symptoms require diagnosis and immediate elimination. The point is not only an unpleasant beating on the steering wheel and an increase in noise in the cabin, but also a decrease in the level of directional stability and the likelihood of progression of the malfunction. The latter factor can lead to expensive repairs.

Let's start listing with the most banal and common reasons.

Balancing required

Runout on the steering wheel and car body with increasing speed is inevitable if the wheels are not balanced. The uneven distribution of mass relative to the center of the wheel rim leads to such consequences. The action of multidirectional centrifugal forces leads to the appearance of multi-frequency oscillations, which are felt as a beating in the car interior.

The problem may manifest itself in the following cases:

- Installing new tires. Replacing tires on rims or putting new rims on old tires must be accompanied by balancing. Even for the manufacturer, achieving ideal weight distribution and geometric parameters seems to be an extremely difficult task.

- Loss of old balancing weights. This is especially true for light alloy wheels, where the weights are glued to the inside of the wheel. Let us remember that in the case of stamped rims, the weights are placed in the outer shoulder of the rim.

- Deformation of the rubber or disk due to falling into a deep pothole, a strong impact with the curb and other similar obstacles.

- Natural imbalance. During operation, any wheel will lose its established balance. It is recommended to carry out scheduled balancing every 15-20 thousand km.

Another breeding ground for imbalance is often the constant velocity joint. It serves as a device for the movable articulation of the drive shaft and gearbox, which allows the transmission of torque in different planes (internal CV joint). At the other end of the drive shaft for articulation with the hub (outer CV joint).

Most often, the cause of vibrations lies precisely in the internal hinge. In the case of a tripod-type design, wear out of the rollers is observed. In especially severe cases, the bearing may even “fall apart”. It is also possible to produce a tripod glass.

A similar malfunction can be caused by a torn boot, which can no longer protect against dirt and dust flying from under the wheels. Therefore, periodically check the integrity of the CV joint boots.

Drive shaft

It will be worth mentioning that a car with a drive of irregular geometric shape is guaranteed to experience vibration when accelerating. A bent drive shaft will not only rotate around its axis, but also provoke parasitic centrifugal forces. As a result, the car will receive additional vibrations as it accelerates.

Cardan

The problem is typical for cars with rear-wheel drive and all-wheel drive. Wear of the cardan joint leads to vibration during acceleration. If you encounter a similar problem, pay attention to the following elements:

- crosses;

- suspension bearing;

- directly to the driveshaft. An unbalanced cardan will lead not only to beating, but also to subsequent destruction of the joints.

There were cases when the cause of runout at speed was play in the gearbox shank. This also needs to be paid attention to.

Wheel alignment

If the wheel is installed at the wrong angle, this is also one of the reasons for unpleasant beating. Adjusting these angles is an important process once body vibrations are detected. What can be done to fix it? Adjust wheel alignment on a special stand. It is also recommended to replace the tires if it is visible that they are not wearing properly.

Problems can also be caused by tires that are worn incorrectly, or a disc after a serious impact. The main processes that can be taken to eliminate body vibration in this case are as follows:

- adjusting the wheel alignment angle at a wheel alignment station;

- replacing tires if there are visual indicators of uneven or excessive wear;

- replacing or repairing a disc that shows dents and uneven rims;

- performing wheel balancing - often during operation the balancing weights fly off.

If the balancing weights have come off the wheel, this may well cause vibrations at speeds of 80 kilometers per hour. The problem is that it is simply impossible to determine this yourself and find out which wheel needs to be sent for balancing. Therefore, you will have to go to a tire shop and have all the wheels of your car balanced.

This is one of the most inexpensive and safest options for breakdowns due to vibration of the body or steering wheel during acceleration. Therefore, the first thing you need to do is check for the presence of such faults, and then transfer suspicions to other options.

Rubber

There are often cases when vibration when accelerating appears due to the installation of low-quality tires. Most often these are tires from budget and extra-budget manufacturers. The peculiarity of such rubber is that when checking on a balancing stand, a discrepancy that causes discomfort when driving a car may not be noticed. In the second case, balancing only temporarily delays the reappearance of vibrations. Only replacing the tires will solve the problem.

The next reason for the appearance of unwanted vibrations is typical for owners whose car is shod with low-profile tires. The side cord of such tires does not have the rigidity and elasticity that is inherent in civilian versions of tires. Therefore, prolonged downtime, especially in the warm season, can cause temporary deformation of the tire at the point of contact with the road surface. Therefore, vibration during acceleration may be observed for a short time after the start of movement. The first kilometers should be covered with extreme caution.

Uneven wear

Asymmetric wear of the tread on the tire and the appearance of “bumps” will lead to the fact that the suspension elements will experience additional vibration load. Of course, the whole car as a whole will vibrate at speed.

Diagnostics

Determining the causes of vibrations of the body and individual elements directly depends on the experience of the motorist. Drivers with many years of experience can determine the cause of shaking in a matter of seconds. This is more difficult for beginners. There are also breakdowns that even the most experienced car owner cannot identify.

Only professional service station employees will help. They have all the necessary equipment that can instantly determine the nature of the breakdown. The advantage of electronics is that it analyzes the behavior of all vehicle components with great accuracy and instantly provides complete information.

It is especially recommended to seek the help of specialists when vibration occurs on the gas pedal. Not everyone can independently determine which part of the drive mechanism has failed. Often the cause may be wear and tear on engine components.

We explore the engine compartment and engine sounds

If you determine that the vibration is coming from under the hood, most likely the cause will be improper operation of the engine or the mounting points of vibration-loaded elements.

Problems related to internal combustion engines:

- Engine tripping. Many car owners have encountered a situation where, when accelerating or driving under tension, the engine begins to shake, and the thrust is much weaker than before. In this case, comprehensive engine diagnostics is necessary. The problem may be hidden in the ignition system: worn-out spark plugs, GDP, module and other elements, the malfunction of which leads to misfire in one or several cylinders at once. Possible burnout of valves, insufficient fuel pressure, etc. There are so many reasons that the topic deserves separate detailed consideration.

- Engine support cushions. Vibration during acceleration will appear because an increase in engine speed increases the centrifugal forces acting on the car body. When you sharply press the accelerator pedal to the floor, noticeable shocks may be observed. Made of hard rubber, even new cushions will cause vibrations.

Gearbox and clutch drive

It is also worth paying attention to the mounting locations of the gearbox. Perhaps the reason may be hidden inside the gearbox housing. In the case of a manual transmission, for a more accurate diagnosis, you should pay attention to the factors causing vibration or beating. If symptoms only appear at a certain speed limit, try driving it alternately in different gears. For example, if vibration is noticeable at 70 km, first engage 2nd gear, then 3rd (of course, if the gearbox ratios allow). This way, you can more accurately identify the transmission components that cause vibration.

If there is deformation of the input shaft in the gearbox, vibrations will be noticeable when accelerating in any gear.

An unbalanced flywheel can also cause the symptoms discussed. At the same time, it is worth paying attention to the clutch and release bearing.

If the car has an automatic transmission, check the oil level and condition. An indicator that is too low can cause shocks and vibrations.

Exhaust system

Improper mounting of the engine exhaust system can lead to noticeable vibrations in certain engine operating ranges.

Painfully banal

If the body vibrates when accelerating, you should not be upset and immediately count out a large amount for repairs. Below are some common and not so common cases that can cause discomfort when driving:

- Dirt or ice block stuck to the inner rim of the wheel rim. Diagnosing the adhesion of dirt is not difficult, since noticeable beating will occur only after off-road driving. In winter, every driver should be prepared for such troubles;

- Incorrect installation of brake and wheel discs. If the mating plane has not been cleared of contaminants or is deformed, this will cause an increase in vibration load during movement;

- discrepancy between the landing dimensions of the wheel rims. Each disk has its own installation parameters, violation of which can lead to imbalance. This mainly concerns disc bolt patterns;

- loose disk fastenings. This is the first thing to check when you notice runout in the steering wheel. The consequences of neglecting this advice can be very dire.

Steering wheel shakes when accelerating

Quite often, when driving, a strong vibration occurs on the steering wheel when accelerating. At first it is barely noticeable, but over time it becomes more noticeable. This can cause serious damage and lead to an accident.

The first thing you need to do is check the wheel balancing. To do this, you can go to the nearest tire repair shop. If your wheels are out of balance, then this is one of the popular reasons for shaking when accelerating. Fixing the problem won't cost much. Sometimes the disc becomes clogged with dirt or snow, then these beatings can occur and stop.

Causes of automatic transmission vibration

An automatic transmission is a complex device consisting of several interconnected components. It contains bearings, valves, gears and other elements that are in motion and capable of producing vibration if there is a problem. Improper installation of an automatic transmission can cause similar symptoms.

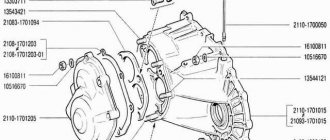

Schematic structure of a typical automatic transmission:

Box vibration manifests itself as a beating transmitted to the automatic transmission selector and body, felt by the driver. The beat can be of varying intensity and appear in different situations:

- idling;

- when accelerating a car;

- vibration when engaging reverse gear of the automatic transmission;

- when changing gears;

- when stopping or starting to move for a short time, if you press the brake in position D or “reverse”.

Important: vibration of the box is not always associated with problems with the automatic transmission itself; sometimes this phenomenon is associated with a malfunction of the chassis, engine, ignition, low-quality fuel, wheel imbalance, etc.

Reasons related to the box

Vibration can cause some automatic transmission problems:

- Deformation of the input shaft of the box.

Sample of input shaft:

A change in the geometry of the shaft, which has occurred for some reason, can provoke vibration and beating felt by the driver. The box will vibrate during acceleration, regardless of the currently active gear.

- Insufficient oil level.

A lack of transmission fluid causes oil starvation of the elements; automatic transmissions are especially sensitive to the amount of oil. If it is not enough, the transmission components wear out at an accelerated pace; over time, the automatic transmission begins to vibrate, “push”, grind, until it eventually fails.

The wrong type of fluid poured into the box, oil wear and contamination with foreign particles can also cause the box to “kick” and vibrate. In addition, similar symptoms sometimes appear when driving in cold weather on an unheated gearbox, when the oil is viscous and does not provide proper performance characteristics.

- Worn out box cushions.

If the automatic transmission cushions have worn out and lost their properties, they cease to dampen the vibration transmitted to the body, which begins to be felt by the driver. The pillows should be replaced, since operating the box in this condition is fraught with its rapid failure.

Another common reason. The oil stops circulating normally through the channels of the box, leading to various problems in its operation, including vibration.

Metal that is damaged or bent for some reason may cause vibration from the automatic transmission.

- Wear/destruction of box bearings.

This can happen for various reasons:

- operation of the box in extreme conditions;

- lack of oil, bad or contaminated transmission fluid;

- wear of bearings over time.

The box produces vibration when changing gears and idling, because the bearings and other automatic transmission mechanisms no longer cope with their task properly. If you do not pay attention to the symptom and do not diagnose the gearbox, the bearings will completely collapse and break the unit, leading to expensive repairs or a complete replacement of the automatic transmission.

Car owners complain that automatic transmission vibration occurs in mode D when the brake is pressed, and while driving in mode R. From a technical point of view, this is explained by the interaction of the motor and gearbox: the automatic transmission is in operating mode, the torque converter tries to transmit torque to the wheels, but the driver pedals the brakes prevent this.

Important: some cars normally allow some vibration when in D mode and the brake is depressed. This is especially true for budget foreign cars, for example, Citroen C4. The manual for such cars recommends switching to neutral when stopping at intersections.

The reason for this may be a faulty hydraulic unit of the box. He is sometimes responsible for other manifestations of vibration. Old box pillows are often to blame for this problem.

Valve block appearance:

We study wheels and chassis - the main cause of vibrations

When various car parts fail, an experienced driver can immediately determine the nature of the breakdown by ear and by the sensations of driving the vehicle. Vibrations indicate a problem instantly, but the reasons for each car are unique.

Main components that should be checked:

- Wheels and tires.

- Chassis.

- Brake system.

- Transmission.

- CV joints.

- Cardan.

- Differential.

Vibration can occur for various reasons

As soon as the slightest vibration begins to appear on the body of your car, it is worth postponing long trips and starting diagnostics. You can check the details yourself. Specialists in service centers can handle this task better. They will instantly determine the nature of the breakdown and fix it.

The majority of motorists have to travel on bad roads every day. The quality of the coating or the “lack thereof” wears out all the parts in the car structure.

The first elements that are damaged when driving through potholes are the suspension and tires with rims. Any service station employee will confirm that more than half of their customers ask for wheel or tire repair.

If there is a strong impact, a crack may form in the wheel rim. The most common type of product is stamped factory wheels. They may bend from impact. As a result, vibration from the imbalance begins to be transmitted to the steering wheel and the entire body.

Damaged tires have the same symptoms. Tire wear patterns can significantly affect vehicle handling. In addition, a common reason is deviation of the wheel alignment angles. Therefore, you should carry out the following repairs:

- Adjust the wheel alignment.

- Replace tires if severe wear or other damage is detected.

- Repair the wheel rim or replace it.

- Balance the wheels.

The most common problem is vibration during acceleration on front-wheel drive. Why? The reason for this is that cars are equipped with a more complex type of suspension, which includes many important mechanisms. They wear out first and require timely maintenance.

As a rule, determining the source of vibrations in the suspension is quite simple. Vibration spreads throughout the body when accelerating from 20 to 40 km/h. If at low speeds you feel a slight shaking, this indicates the need to sort out the chassis.

The first thing that fails is the shock absorbers and struts. They are considered consumables among motorists on domestic roads. In general, vehicle owners, when purchasing parts, give preference to brands of medium quality - both economically and reliably. But, as practice shows, racks have to be changed more often than stated by the manufacturer.

Vibrations are accompanied by unnatural rocking of the body in the pits. The element must be replaced immediately. During repair work, you should carefully check the support bearings of the strut itself.

It also provokes vibrations and wear of the ball joint at high speeds. Drivers often mistakenly believe that such vibrations are caused by broken wheel bearings. Always check the service life of the supports and ensure that there is no play.

Brakes

This mechanism causes vibration in only 10% of cars. But, despite this, the problem is considered serious, since it is quite difficult to diagnose a malfunction of the brake mechanism yourself.

How to understand that it is the brakes that need to be repaired? When accelerating, the car body shakes slightly. An inexperienced driver may not notice the defect at first. And the determining factor is the disappearance of vibrations during braking.

In this case, check the brake disc fastenings. If the problem is not corrected in time, sooner or later the disk may become blocked while the machine is moving.

Many owners of both foreign and domestic cars complain about gearbox malfunctions. It can really cause characteristic vibrations.

There are several simple methods for determining the condition of the transmission. Here's one of the best:

- It is necessary to pick up speed to 80-85 km/h on a flat road.

- Depress the clutch pedal - the intensity of the vibrations may change.

- After this, you should shift to third gear and slowly release the clutch pedal.

- Accelerate the car from 50 km/h in top gear.

This approach will immediately make it clear that it is time to service the transmission. What could be the reason? One of the most common options is a rapid drop in the oil level in the gearbox. Parts begin to operate at elevated temperatures, and wear accelerates. It seems as if there is strong vibration from the engine. True, in this case it is worth checking the power plant itself.

On automatic transmissions, this problem is solved by replacing the oil filter. As a result, the body stops shaking at high speeds.

Disc damage is the most common cause of vibration

Every driver should check this reason first. CV joints are considered the most common source of vibration. On some cars they fail more often than other parts.

When repairing, it is easy to determine the wear of an element. You need to grab the shaft and rotate it slightly in both directions. There is some play - the part needs to be replaced. If there are no vibrations in the spline joints, and vibration comes from this area, check the ball joints.

In order not to disassemble the entire mechanism, you can independently and quickly diagnose the CV joint on the go:

- Slow down or stop the car completely.

- Turn the steering wheel in the direction from which the vibration is heard.

- Start the car moving sharply;

- If you hear a crunching sound when turning sharply, replace the CV joint!

Cardan shaft

Similar problems arise in the operation of the driveshaft. Basically, this unit does not fail often, since it is a fairly reliable mechanism on any vehicle. Moreover, most manufacturers make such shafts from high-quality metal.

We invite you to familiarize yourself with How to recover money from an individual by court decision

A cardan failure is often detected when it is running at idle. As soon as the torque is transmitted through the transmission, the car body begins to shake. The problem is typical mainly for domestically produced vehicles.

Some service centers and small workshops offer to repair the driveshaft at a reasonable price. But it is worth emphasizing that this service is more often applicable for freight transport.

Drive shafts of such equipment are easier to repair than parts of passenger cars. Therefore, if such a breakdown occurs on a sedan or station wagon, it is better to replace the cardan.

Differential

Drive mechanisms suffer greatly from poor-quality road surfaces. CV joints, gearbox gears, shafts, and differentials wear out quickly. They produce almost the same vibrations as the driveshaft.

Malfunctions of these mechanisms are accompanied by vibration both at the beginning of movement and when accelerating at high speed. Since the element is a fairly expensive part, the best way out of the situation would be to prevent wear on the differential. It needs to be lubricated on time and the car must be operated without unnecessary loads. But if fluctuations have already begun, then only comprehensive diagnostics and replacement will help.

Whenever installing a new differential, do not skimp on oils. The lubricant must be of high quality and there should not be enough of it. This way the part will last longer.

Wear of the cardan shaft cross

This is another possible group of reasons why a car may shake when accelerating. All these problems can arise for various reasons. For example, as a result of examinations, a breakdown of one of the power unit airbags is discovered. It's easy to find out - increase the engine speed when vibrations appear.

Body vibration when accelerating from 80 km/h to 100 km/h can also occur if there is a problem with the gearbox. Testing this hypothesis is very simple. It is recommended to reach a speed of about 85 km/h, then depress the clutch pedal and watch how the car behaves. Engage third gear and release the clutch. Accelerate from 50 km in the last gear of the transmission.

If the nature of the beats does not change during all these events, the gearbox is not to blame. If the vibration level increases when the box is connected to work, then you can check its involvement.

This method is suitable for both manual transmissions and automatic transmissions. In the case of an automatic transmission, at speeds of approximately 90 km/h, turn on 3.2, D, N on the gearbox, and then monitor the operation of the automatic transmission and the car. Watch the vibrations. Most often, the fault of the box in beating is minimal, but practice shows that there is such a possibility.

The main indicator that the wheels or drives of these same wheels are to blame for your problems is shaking at a certain speed. Often these are body vibrations in the range of 80-100 kilometers per hour, but sometimes the shaking may not go away even after 60 km/h, so in any case you need to fully diagnose the chassis.

In this case, it is not necessary to go to a service station and carry out expensive diagnostic operations. It is enough to apply all your knowledge and study each chassis unit for possible breakdown. The most common problems in this case are the following:

- the wheel mounts are unscrewed, which causes vibration on one of the wheels;

- The brake disc is poorly fixed; at speed it begins to vibrate;

- the wheel drive shaft is bent - the body vibrates constantly, with increasing speed the vibration intensifies;

- damaged CV joints - this is the most common problem that causes vibrations on the body;

- The wheel bearings are damaged, which causes shaking at any speed.

The most common problem in this manifestation is CV joints. To check their serviceability, just grab the shaft with your hand and try to turn it. If the shaft has play of more than a couple of millimeters, the CV joint must be replaced. Interestingly, vibrations of the car body during acceleration can be caused by both external and internal CV joints.

Reasons beyond the automatic transmission

Quite often, vibration that appears to be coming from the automatic transmission is not. Vibrations from the engine can be transmitted to the body (and box) if its mountings have become unusable. For example, if there is vibration in the automatic transmission when you engage a gear, this may indicate the engine mounts (but also wear/displacement of the automatic transmission mount).

Another common reason is poor quality fuel. If you pour low-quality gasoline into a modern injection engine, it can quickly clog one or more injectors, as a result - the engine begins to “tweak”, and engine vibration will appear when the automatic transmission is engaged. In this case, vibration when accelerating may disappear because the pressure in the fuel line increases. The fuel filter becomes clogged, with a similar effect.

Similar manifestations are caused by faulty ignition coils, spark plugs or armored wires: the fuel combustion cycle is disrupted, the engine sneezes and troits. A characteristic symptom is a drop in speed and shaking when switching to mode D, vibration when engaging the reverse gear of the automatic transmission from idle. The engine does not have enough power, and it begins to “shudder” noticeably, transmitting the impulse to the body and gearbox.

The next probable cause is a malfunction of the idle speed control (if vibration occurs during idle operation). The corresponding spare part must be replaced. Similar symptoms occur if the lambda probe breaks down.

Beating may occur due to a dirty throttle valve; the problem can be eliminated by cleaning it.

A large number of malfunctions leading to vibration are problems of the chassis. For example, wear on constant velocity joints of drives (commonly abbreviated as CV joints) causes vibration when the car is loaded, during acceleration. With this malfunction, the symptom may disappear when the driver, having completed the acceleration phase, releases the accelerator pedal. Some car owners note that the malfunction is not detected by conventional methods; upon visual inspection, the spare parts appear to be in good condition, and the problem only appears under load.

Vibration from unbalanced or poorly placed wheels (especially the front axle) can also “give” into the box. The driver, in addition to unpleasant vibrating sensations, will feel the car “walking” along the highway, pulling it in different directions, and deteriorating control.

There may be other problems with the chassis, reflected by vibration of the box.