Hot method

This is the highest quality, but most expensive galvanizing method. What is its essence? The entire body is placed in a zinc bath at a temperature of about 500 degrees. The metal is evenly enveloped in a protective layer.

Zinc penetrates into all cavities. Experts say that this is the most correct and durable way of protection. But the process is quite complicated and requires huge financial costs. This technology is mainly used on premium cars. These are Bentley, Porsche, Lamborghini, and so on (there were also Volvos with this treatment). On a Lada-Vesta car, the body is not processed in this way. This would significantly affect the cost of the car, which would reduce its popularity.

Car interior

Inside, the car is made of embossed plastic, as well as elements of soft fabric upholstery, the same as all the seats are equipped with. The car turned out to be quite spacious and comfortable to stay in. It is worth noting that both tall passengers and drivers feel comfortable here: their heads do not rest against the ceiling, and their legs do not rest against the back of the front seat or the dashboard.

The interior design is quite modern and ergonomic. The instrument panel is designed in a way that is convenient for the driver - all components are easy to reach with your right hand, and the steering column is already adjustable as standard, as is the driver's seat. As the cost of equipment increases, the ease of use of all the functionality proposed by the designers only grows.

Of course, the price of this proposal was slightly higher than expected in 2014, after the pre-production demonstration of the X-Rey concept model. At that time, the price was announced at 500 thousand rubles for the basic configuration of this Lada, but now it costs 589 thousand rubles. This has given rise to numerous debates among car enthusiasts about whether this car is worth the money demanded for it. As experts' calculations show, the car is clearly worth buying. However, if the buyer needs a car that feels confident on gravel roads and off-road, it is better to wait for the all-wheel drive version of the X-Ray to go on sale.

Electroplating

What is the essence of this method? The operation involves the use of zinc ions, which are deposited on the body with negative polarity. The method uses the energy of direct electric current. Zinc ions are positively charged, and the body is negatively charged. In this way, the protective particles evenly coat the metal, protecting it from future corrosion. What cars use the electroplating method? These are German Mercedes, BMW, Japanese Honda, Toyota, and Mitsubishi. The Koreans from the Hyundai concern also practice electroplating. But Kia uses zinc metal technology. This coating consists of two layers. Used mainly on Optima and Serato.

Cold galvanizing

Unlike the hot method, here the body does not fit into the bathtub. Zinc is applied from a spray bottle.

The surface treatment process is identical to painting. The method is very simple and economical. Used by the following manufacturers:

- "Chevrolet".

- "Kia" (below the C-class).

- VAZ (including Lada-Vesta).

After this treatment, the body metal is protected from corrosion. But this method has its drawbacks. Thus, with cold galvanizing it is impossible to achieve such a uniform and seamless coating as with hot galvanizing.

Technology for applying a protective coating to the Lada Vesta body

Considering the method used for galvanizing, a type of additional treatment suitable for the car is cataphoresis priming. This is a complex process consisting of several stages.

- Removing protective covers from the machine body;

- Removing fats from metal;

- The body is immersed in a bath of cataphoresis solution;

- Washing off the remaining solution;

- Drying cataphoretic soil.

After passing the last stage, the body has a new, tight-fitting primer layer that protects the outer parts of the body and the internal cavity.

Peculiarities of Vesta processing

Whether the body of the Lada Vesta is galvanized or not, we already know. It is processed using the cold method. But it is worth noting that this zinc is not applied to the entire surface. After processing, there are still a lot of hidden cavities, including the interior. To protect such areas, the plant uses an anti-corrosion primer. The manufacturer calls this technology cataphoresis.

As stated, “Vesta” is treated with this primer in two layers. This allows you to completely eliminate the access of air into the cavity between the damaged paintwork and the metal.

About myths

Almost everything has been clarified, but again, many skeptics who are accustomed to saying that there is nothing good at AVTOVAZ can put forward some theses:

- Foreign cars are made from fully galvanized sheets . Perhaps someone does this (in their barn in particular), but in most industries around the world such sheets are not used. They are soft (do not have the required strength), do not weld well (easily burn through), the cost of the body will go through the roof

- The cold method is used only at AVTOVAZ . This is also not true, for example Chevrolet, KIA, HYUNDAI, TOYOTA, MITSUBISHI use it on many of their cars (even if they are of a budget class, but still). For example, CRUZE is covered worse than VESTA, it does not have sill treatment and some front power struts

- The layer is so thick that it falls off . I really don’t understand who comes up with this idea. If you check with a micrometer, it turns out: the roof is about 105-125 microns, the doors are about 145 microns, the wings are 140 microns, the hood is 110 microns, the trunk lid is 120 microns. This is a complete “pie” that is applied to the steel. It is approximately the same as on many foreign cars of this class and nothing falls off on anyone.

- Only VESTA is processed; other VAZs are not treated ! This is again a myth. Galvanization is applied to the following models: GRANTA (LIFTBACK) - fifth door, fenders (here is the bare minimum of galvanizing), KALINA2 - all external surfaces, except the hood, roof, front and rear side members (fender liners are needed here), PRIORA (since 2009) - everything except the roof, hood. X-RAY - everything outside, except the roof, VESTA - the entire external surface, with the bottom, sills and arches additionally treated with anti-gravel.

As you can see, a lot of things are far-fetched, now I’m providing you with a video version, let’s take a look.

I’ll end with this, I think it was useful, read our AUTOBLOG, subscribe to the channel.

( 13 votes, average: 4.00 out of 5)

Today, all leading car manufacturers are increasing the reliability and durability of their products, including galvanizing their bodies. This technology significantly increases the level of body protection from rust. Accordingly, the car becomes more durable. The Volzhsky Automobile Plant also tries to protect its products from corrosion. However, the introduction of such technologies at the enterprise began relatively recently.

Layers of paint

In order to protect the Lada Vesta from corrosion as much as possible, the manufacturer paints it in five layers. The first is cold applied zinc. The second and third are anti-corrosion primer. It is applied, as we said earlier, in two layers.

Next comes the base enamel. The finishing layer is clear varnish. Thus, the total thickness of the layers is 90-100 microns. Among them, zinc occupies ten microns. But due to the unevenness of the coverage, it can be reduced to eight.

Is Lada Vesta's paintwork reliable?

Anti-corrosion treatment of the machine The quality of the paint and varnish coating is also at the highest level. Amateurs and automobile experts checked whether the Lada Vesta's paintwork was reliable. No imperfections, scuffs or various coating defects, which often happened on previous models, were noticed.

Although the small thickness of the Lada Vesta LPC may raise doubts. But this trend is characteristic of many modern cars - environmental standards impose restrictions on the depth of the paint and varnish layer. High-quality soil protects the iron well, and corrosion is unlikely to spread due to ordinary chips.

How long will it last?

Along with the question of whether the body of the Lada Vesta is galvanized or not, many are interested in the validity period of this protection. The manufacturer itself provides a six-year warranty. Before launching into mass production, such a body was tested in a salt fog box. The body was in this room for about two and a half months. As the result showed, the body of the Lada Vesta coped well with the test. But how long will the metal last after the warranty period? Experts present their calculations. If one hundred microns of zinc is enough for 80-100 years, then a factory layer of 8-10 microns will last about seven to ten years. What to do after this period has expired? It is necessary to regularly monitor the condition of the paintwork and take preventive measures. We will talk about them further.

How to maintain the integrity of the Vesta body for a long time?

Knowing whether the body of the Lada Vesta is galvanized or not, you should not neglect preventive measures. First of all, this concerns washing. It should be regular, especially in winter. Many will say, why spend money and wash off dirt if it will protect the paint in an even layer from the same deposit. This belief is completely wrong. The fact is that in winter this dirt contains reagents that are sprinkled on the road by public utilities. And the larger the layer, the higher the risk of corrosion. This is especially true for areas that are treated only with a primer, without zinc. When washing, we pay special attention to arches and other hidden cavities (sills, bottom of wings). These places begin to rot first. Periodically check the drainage holes (at the bottom of thresholds and doors). They shouldn't be clogged. Otherwise, this will significantly accelerate the corrosion processes.

You can also protect the body from sandblasting by gluing a transparent protective film. It will not only prevent corrosion, but will preserve the color and integrity of the body in its original form.

Painting Lada Vesta

Painting of the car begins after the application of primer has been completed. Step by step, the car is prepared for the painting procedure. Since painting is done with an aerosol in several layers, robot labor is used. A solution is applied to the surface, strengthening the seams and protecting the body from corrosion. Then noise-insulating mastic is used, which adds silence to the car on the roads.

When applying primer coating with robots, many hard-to-reach places remain and have to be processed manually. The inner sides of the pillars, the edges of the roof covered with doors, are finished manually. The primer comes in two tones: light or dark. Choose depending on the color of the car.

Once the priming stages are completed, the car is sent to the next conveyor for developing the secondary layer. Here, specialists eliminate paint coating application defects and coat the seams with brushes and paste. After all the procedures, specialists, with the help of robots, proceed directly to painting the car. The paint application process is not complicated. A common aerosol spray that motorists have dealt with. A layer of varnish is applied over the paint, and the finished painted and varnished body is sent to dry, which takes an hour. The entire painting procedure lasts no more than four hours.

When the body is dried and the varnish is applied, there are a few final steps left, after which we get the product in the form in which it ends up on the market. The final touches are polishing and applying anti-corrosion. The result is a durable, galvanized body of the Lada Vesta. Let us remind you that the thickness of the car’s paintwork is higher than that of other parts of the car, which makes it reliable and resistant to changing weather conditions.

About the primer

Is the body of the Lada Vesta galvanized everywhere or not? It is protected only along the outer perimeter. The salon remains “naked”. But this does not mean that corrosion will occur earlier in such places. After galvanizing, the entire body is placed in a bath of soil, in two passes. This eliminates the appearance of rust in hidden cavities. In addition, the zinc layer does not interact well with the base enamel. To fix it, use soil. It is a kind of connecting link that prevents the paint from falling off at the most unnecessary moment.

I'm spinning, I want to go

Lada Xray Cross is AvtoVAZ’s decisive step from the regular Xray towards off-road driving. However, VAZ took into account that crossovers from competitors are often ordered with single-wheel drive, and decided to completely abandon the 4x4 version. To compensate, here's Ride Select. By turning the control washer, you can turn off ESP within 58 km/h. There are also “Snow/Mud” and “Sand” modes. Moreover, “snow,” by which many companies mean a slippery, dense road and set the mode to the maximum severity of the electronics, is understood here in our way – precisely as a loose snowdrift, where it is useful to skid.

I twist and turn the puck, I want to go up a moderately steep climb. And I go in different directions. The “Snow/Mud” mode allows for fractional slipping in short impulses – this way, in loose conditions, you can “get to the bottom of it.” In the “Sand” mode, throttle responses are softened, and slipping is suppressed more strictly - on the contrary, so as not to bury yourself. When ESP is turned off, the rotation of the tires burns the snow down to the asphalt, and it is logical to take a well-rolled slippery slope with the help of stabilization.

Yes, choice is indeed useful here. Interesting point. Partly because of the Ride Select system, the new Cross is equipped only with the status 1.8 petrol engine (122 hp), and there is no version 1.6, as for the regular Xray. For a smaller 106-horsepower engine, the off-road modes would have to be recalibrated, which would greatly slow down the project.

The flagship 1.8 in combination with the French 5-speed manual transmission drives the Cross smoothly and confidently.

The flagship 1.8 in combination with the French 5-speed manual transmission drives the Cross in a familiar way - smoothly and confidently, although with some laziness at the bottom. At the end of the Ride Select roundel there is another new feature - the Sport button, but the sport mode does not bring any obvious improvements. At high speeds the engine is already noisy, and you regret the lack of sixth gear. As an option, an improved “robot” AMT is provided (it will appear a little later), automatic transmission is not planned - it is unprofitable.

Do they process only Vesta?

Many will now ask why the manufacturer began to think about this issue only with the release of Vesta. This is not entirely true. The fact is that other VAZ models were also galvanized. These are Priora (models after 2009), second generation Kalina and Lada Granta. But as before, the body was not completely processed. Thus, on the Kalina there was no galvanization on the rear and front side members, the roof and the hood. To eliminate corrosion at least partially, it was necessary to install wheel arch liners. The Priora was treated almost everywhere, with the exception of the roof and hood. But again, you can’t do without lockers here.

"Vesta" is treated with zinc over the entire outer surface (including the rear fenders), except for the roof. Additionally, some areas are treated with anti-gravel. These are the sills, the bottom and the arches.

Yes, AvtoVAZ has previously used cold galvanizing technology. But it is best implemented on Vesta.

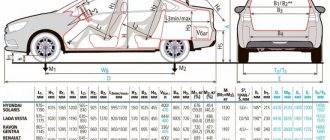

Vesta paintwork thickness

- On average 100-150 Microns throughout the bodywork;

- The thickness of the roof paintwork is 102 - 128 Microns;

- Doors 139 Micron;

- Front wing 140;

- Rear wing 144;

- Hood 104;

- Trunk lid 125.

— Vesta has durable and well-protected body elements. In production, they use the cold galvanizing method, which is not the most reliable, but is used by European and Asian brands. Lada Vesta has a good layer of enamel, compared to cars produced by the AvtoVAZ plant earlier. The presence of a good warranty period, confirms a job well done by the manufacturer.

Rate the article!