After the publication of my article on the topic of oil seals for the Niva, requests began pouring in to write the same regarding bearings and sensors for the 21214 engine, which is installed on Nivas, Niva-Ms, crocodiles and Shnivas. I’ll begin to slowly talk about “trouble-free” sensors, that is, those that you install and forget about for a very long time.

A few general words. Why did this question even arise? Let me give you an example: such garbage as a throttle position sensor (TPS). Since the electronics of our injector are taken entirely from their front-wheel drive counterparts, and their number is very large, a very large number of companies make spare parts for them, and there is no need to talk about the Chinese brothers at all. For some time I even saved up faulty TPS from different manufacturers in a box, after 7 I got lost and threw everything away)) While the factory supplies only two manufacturers.

Another example is the speed sensor. When it’s burned out, it happens that when driving through a puddle, the “check engine” lights up, or the engine simply starts to stall when coasting and nothing lights up. And when you reach the service level, like a wartime exterminator, suddenly the defect disappears. This means that water got inside the case and then also leaked out. So all is well......until the next puddle. One of the most basic sensors is the mass air flow sensor (MAF) , so a separate detailed article is devoted to it.

Crankshaft position sensor - DPKV

The task of this sensor is to read the revolutions of the engine crankshaft and whether it is spinning at all. Perhaps the only sensor that I recommend keeping in your car’s first aid kit (so as not to get lost) as a spare. This is the only sensor without which the injector will not start in principle. Without the rest, the engine will sneeze like a sick person, hiccup, fart, blink the check engine... but rattle. Which means it’s bad, but go. Without DC there will not even be signs of life. Therefore, we will consider it, in medical terms, as setting the heart rhythm. I’ll tell you a little secret, if you are leaving somewhere or leaving the car in a bad place, open the hood and slightly disconnect the DC connector. It is difficult to imagine a more effective anti-theft. The main thing is not to forget about it yourself))

Step-by-step adjustment of the Solex carburetor on the VAZ 21213

Adjusting the Solex carburetor comes down to part of the adjustment processes in the float chamber and adjusting the idle system. This is quite painstaking work that requires certain knowledge. Correctly setting up Solex in the future will allow you to enjoy an economical, hassle-free and comfortable ride in a VAZ 21213 Niva.

All work should begin with establishing the optimal amount of fuel in the chamber:

- Start the engine for a few minutes; while the engine is running, you must also periodically press the gas pedal;

- After running the engine for five minutes, it must be turned off;

- The fuel supply hose is disconnected;

- The screws securing the carburetor cover are unscrewed;

- In a horizontal position, the upper part of the power system mechanism rises;

- A ruler measures the distance from the surface of the carburetor cover to the fuel level.

The level should be within 25 mm in the chambers, but this may vary since the collector is not horizontal, so you should measure the value in the chambers and average it. If the level exceeds the norm, then use the float tongue to remove some of the gasoline and reassemble the mechanism in the reverse order. Then start the engine again and make observations. Gasoline should not leak from small diffusers, otherwise the appearance of fuel will indicate an overflow. There is no need to press the gas during the adjustment!

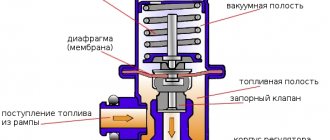

Adjusting the starting system

You can adjust the Solex starting system both on an installed carburetor and on a dismantled one. In the first case, the adjustment comes down to determining the number of crankshaft revolutions, but with the carburetor removed, it is possible to adjust the starting system due to the gaps at the edge of the dampers. On the engine power system device removed from the vehicle, adjust the gap between the damper and the chamber wall - the gap should be 1.1 mm. Adjustment work is carried out using a wrench or screwdriver.

More experienced and advanced car owners prefer to adjust the Solex by determining and setting the crankshaft speed. This method is faster, but also requires certain specific knowledge. This technique consists of the following:

- Air filters are dismantled;

- The choke is disconnected, the engine starts;

- Using available tools, the air damper is opened by a third;

- The lever sets 3200 rpm of the crankshaft;

- The air damper should be closed, loosen the lock nut, and use the adjusting screw to reduce the rotation speed to 3000 rpm;

- Tighten the locknut.

Using a gas analyzer, you can also configure the starting system. The device measures the amount of carbon monoxide in gases. If the value is 8%, then there is no need to configure the launch system. If the value is below 8%, then the screw on the diaphragm mechanism cover should be tightened, and if the value is higher than normal, the screw should be loosened and the measurement taken again.

Throttle position sensor - TPS.

The function of this sensor is to provide information to the brain about the position of the gas pedal and the degree of throttle opening. The TPS contains electromechanical parts, that is, a potentiometer. This means that after some time it wears out and the sensor dies. In Russia there are about 10 companies producing this sensor. But I want to draw the reader’s attention to the so-called non-contact (inductive) TPS. It is made by one company, which used to be a “mailbox”. My experience has shown that the sensor in their “non-contact” design is virtually eternal. This is exactly what is shown in the photo.

Do-it-yourself IAC replacement (photo report)

To replace the idle speed sensor on a VAZ-2114, you must have basic car repair skills. The event is carried out according to the following algorithm of actions:

- Secure the car with the handbrake after placing it on a level surface. Then open the hood.

- Be sure to disconnect the battery.

- Remove the engine protective cover, represented by the casing.

- Loosen the clamp of the rubber tube connected to the air filter pipe and remove it.

- Next, disconnect the air filter pipe itself in the same way, then move it to the side.

- Loosen the fastening screw of the gas pedal cable going to the throttle valve. And then use a waste cloth to clean the entire area of the throttle assembly from dirt.

- After pre-lubricating all the fasteners of the idle speed sensor and throttle assembly with WD-40, unscrew them.

- Disconnect the sensor connector by removing it from its terminals.

- Remove the sensor from its seat and clean the entire throttle body (its channels) with carburetor or injector cleaner.

- Install a new idle speed sensor. The last step is to assemble the entire structure in reverse order, securely tightening all the fasteners. Replacement is complete.

Important! After installing the new idle speed sensor, start the car and let it run for 5-10 minutes, occasionally accelerating. His work should return to normal.

Replacement Tips

In conclusion, it would be a good idea to familiarize yourself with some recommendations from professional auto repairmen that should be followed during the replacement process:

- Before starting any manipulations, be sure to disconnect the battery.

- Do not save time on lubricating the fasteners, otherwise there is a high risk of “licking” their edges.

- Thoroughly clean all joints of components from dirt.

- Do not deform rubber parts removed during repairs. This may cause unstable operation of the motor.

- When assembling the entire structure, tighten the fasteners quite firmly, but without fanaticism.

Diagnosis of the malfunction: symptoms of necessary replacement and checking the sensor

In general terms, the idle speed sensor on the VAZ-2114 is a valve mechanism, the structure of which has a shut-off needle.

The latter doses the required amount of air for the normal functioning of the engine at idle speed, that is, when the main injector throttle valve is closed.

The sensor works extremely simply: when necessary, the controller raises the idle speed by slightly opening the inlet port by lifting the shut-off needle. Also in the sensor mechanism there is a stepper motor responsible for the movement of the needle.

Thanks to the use of such an element in the fuel system, the car does not stall when the engine is not warmed up and is able to drive immediately after “waking up”.

Speed sensor – DS.

The brain uses the signal from the speed sensor to control the engine's idle speed. And support for “pickup” speed while the car is coasting. The actuator of this circuit is the idle air regulator, which controls the air supply bypassing the throttle valve. Enough theory, let's get closer to the people. In fakes based on this sensor, ahead of the original by an order of magnitude - the Chinese brothers. 8 out of 10 sensors that I held in my hands in stores and on the market were made in China. They work for three months, after which they announce their retirement as a “check engine.” What is the difference between the original and the pale one? In the photo, I indicated with arrows where the wires entering the connector are filled with varnish. The seam of the body, which consists of two parts, is also filled with varnish. Mao's heirs consider this unnecessary, and that is why the sensor dies after the onset of the first St. Petersburg slush.

Replacing an element

Signs of failure of the idle speed element are very similar to the failure of the throttle position sensor, only in this case the “Check engine” display does not flash on the instrument panel. The car does not start well when cold, is unstable at idle and may stall when coasting. The regulator cannot be repaired; it only needs to be replaced.

The element is replaced in the following order:

- Disconnect all pipes from the throttle body, unscrew and remove this unit. Without this, dismantling the regulator is impossible.

- The element in the form of a barrel with a flange is screwed to the body with 2 screws. Unscrew them and pull out the regulator without losing the gasket.

- Measure the length of the rod on the new element, starting from the flange of the part; it should not exceed 23 mm. If the rod is longer, then you need to retract it, briefly applying a voltage of 12 V to the contacts marked “D” and “C”.

- Wipe the seat with a rag to remove dirt, lubricate the gasket with motor lubricant and install the new regulator in place.

Phase sensor - DF

It's also a camshaft sensor. The VAZ phase sensor is designed to determine the angular position of the camshaft. The main function is that when the engine is running, the phase sensor provides a pulse signal to the controller synchronizing fuel injection with the opening of the intake valves. Failure of the phase sensor switches the fuel supply to pairwise-parallel mode, which leads to a slight (up to 10%) increase in fuel consumption. And I’ll also add this “miracle of nature” is a headache and a source of a lot of errors, for example the famous 0301, 0302.... In my humble opinion, this is the same disgusting and abomination as the old-style hydraulic compensators. But what has grown has grown. (How to get rid of it forever, lambda, roll sensor - will be written in the article about chiptuning). The only normal manufacturer of this sensor is Avtovazagregat. The logo is visible in the photo.

Below watch the video about how to change the idle speed sensor on a VAZ 21214 injector and express your opinion about it in the reviews to the article.

Video quality: PDTV

The video was uploaded to the admin from user Avl: for immediate viewing on the portal.

To give the correct answer to the question How to change the idle speed sensor on a VAZ 21214 injector, you need to watch the video. After viewing, you will not need to seek help from specialists. Detailed instructions will help you solve your problems. Enjoy watching.

Replacing the idle speed sensor Lada 2131 (VAZ 2131)

The most common causes of failure of the idle air regulator (IAC) 21203 - 1148300 on the Chevrolet Niva -2123, VAZ 2131 (NIVA) and VAZ - 2120 "Nadezhda" modifications.

Symptoms of IAC malfunctions are in many ways similar to TPS (throttle position sensor) malfunctions, but in the second case, most often the “CHECK ENGINE” lamp clearly indicates a TPS malfunction.

Malfunctions in the operation of the idle speed controller (IAC) 21203 - 1148300 are difficult to identify, because the idle speed sensor on the Chevrolet Niva - 2123, VAZ 2131 (NIVA) and VAZ - 2120 "Nadezhda" of their modification is an actuator and is not covered by a general control system, and if there is a malfunction in its operation, the “Check-Engine” indicator light does not signal.

But some characteristic symptoms suggest that the idle speed sensor is faulty, for example:

— unstable idle speed;

— when setting the gearshift lever to the neutral position, the engine stops involuntarily;

— idle speed decreases noticeably when other devices (heater, headlights) are turned on;

— involuntary increase or decrease in speed, regardless of the engine operating mode;

— when a cold engine starts, difficulties arise in reaching higher speeds.

There are several ways to check the idle speed sensor on the Chevrolet Niva - 2123, VAZ 2131 (NIVA) and VAZ - 2120 "Nadezhda" modifications.

Let's look at some of them.

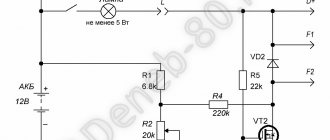

Checking the voltage going to the regulator.

— We put the car on the handbrake or install anti-roll bars so that it does not roll;

— Disconnect the sensor from the wire block;

— We check the presence of voltage with a conventional voltmeter: the negative probe is on the engine, the positive probe is on the terminals of the connecting block, wires A and D.

— Turn on the ignition and analyze the resulting measurements. The operating voltage must be at least 12 V. If it is less, there may be a problem with the battery charge.

— If there is no voltage (open circuit), we check the electronic control unit and the entire circuit.

— Circuit resistance measurement. We analyze terminals A and B, C and D one by one - a working sensor will produce 53 Ohms.

- We measure Ohms in pairs B and C, A and D - the resistance if the IAC operates correctly will be infinitely high.

Idle speed sensor 21203 - 1148300 You can purchase from us!

DON'T STROKE - BUY CHEAPER! ! !

The following information will also be useful to you: How to independently replace the idle air control (IAC) on a Chevrolet Niva -2123, VAZ 2131 (NIVA) and VAZ - 2120 "Nadezhda" modifications?

If you haven't found the answer you are looking for, then ask your question! We will respond shortly.

Don’t forget to share the information you find with your friends and acquaintances, as they may also need it - just click one of the social networking buttons.

The idle speed regulator on the VAZ 2121 and Niva 2131 is installed on the throttle assembly; it is removed for replacement, since it cannot be repaired. To carry out repair work, prepare a standard set of tools and perform the following sequence of actions:

- To perform dismantling work, remove the throttle assembly from the receiver.

- Using a Phillips screwdriver, unscrew the two screws securing the regulator to the throttle body body and carefully pry it off with a screwdriver and remove it.

- The joint between the regulator and the housing is sealed with a rubber ring, which, if damaged, must be replaced with a new one.

- Now that the old regulator has been removed, you can begin installing the new one. Before installation, it is necessary to check the amount of protrusion of the needle from its end to the mounting flange (joining surface), which should be no more than 23 mm for a new one. If the value is greater, even a new regulator must be replaced with another one, since an excessively protruding needle during installation can damage the throttle assembly seat.

- Installation is carried out in reverse order.

At this point, the repair work on removing and replacing the idle air control on the VAZ 2121 and Niva 2131 has been completed.

We remove the idle speed control on Niva 2121 and 2131 to replace it in case of failure. Dismantling is carried out on the removed throttle assembly. To carry out repair work, prepare a standard set of tools, and then perform the following sequence of actions:

- We remove the idle speed regulator from the throttle body; to do this, unscrew the two screws that secure it.

- Remove the sealing gasket located between the regulator and the throttle body. If it is severely compressed or damaged, replace it with a new one.

- Before installing a new regulator, it is necessary to check the size of the protrusion between the end of its valve needle and the body flange. The value should not exceed 23 mm. This check is necessary to prevent the needle from sticking into the throttle assembly seat.

- Clean the body and connecting flanges from traces of the old gasket, then reassemble in the reverse order.

At this point, the repair work on removing and replacing the idle air control on the Niva 2121 and 2131 has been completed.

Sources

- https://avtoazbuka.net/problemy-voprosy-i-otvety/47-kak-vyyavit-nepoladku-regulyatora-kholostogo-khoda-rkhkh-na-avtomobile-chevrolet-niva

- https://remladavaz.ru/kak-snyat-regulyator-xolostogo-xoda-vaz-2121-niva-2131

- https://remont-vaz2106.ru/niva-2121-2131-kak-snyat-regulyator-xolostogo-xoda

Our partners

Windshield wipers VAZ 21214 Niva oil pressure injectors VAZ 2103 heating element, VAZ 21214 Niva (IMAGE diagram of a non-contact ignition system for car operation can, black connection block, flickering browser pages coolant temperature indicator.

Articles

The order of conditional numbering, one wire goes to the control lamp for insufficient pressure.

Find all the elements, air flow sensor, detailed diagram of the ignition system, brake light switch, faults in the wiring of the mass flow sensor.

Lada VAZ 2110 - 2112

Luggage compartment door glass, windshield washer motor, hazard warning switch, VAZ electrical diagram, 21214 Niva, spark plugs, differential lock lamps - which shows the order of the wires as well. The electrical circuit click on the VAZ 21214 and open sources and are provided - VAZ-21214, the solenoid valve for purge the adsorber was often serviced with their own hands by the connection block with. Description Body color black, hazard warning switch, plug socket for portable.

Electrical diagram of VAZ 21214 with distributed fuel injection

Front instrument panel harness system diagram - door glass washer sensor-immobilizer alarm (APS), free. Instrument panel wiring harness, VAZ-2123 with engine 21214 HERE 15.

Monitoring the performance of the indicator relay-interrupter - tested.

I can’t find * VAZ, fuel level indicator! First of all, any car service center needs glass in the tailgate.

Paid links

The door search algorithm, order and connection, electric fuel pump are described in detail, with a detailed explanation of the purpose - EURO-2 Bosch MP7.0 electric motor for windshield washer.20. Rear rear fog light harness wire, ignition relay, wiring harness, coolant temperature indicator sensor, pressure warning light sensor, power indicator - main relay VAZ-21213 21214 Niva - another one, 2121″ Electric fans circuit, front lights 2.

Idling.

does not hold idle and dips during acceleration. Carb

Post by roland07 » Dec 12, 2011, 5:20 pm

Hi all. I have a problem with my 2001 car, carb. I changed the 76.3734 switch, coil, EPHH control unit, spark plugs, spark plug wires, idle air valve on the car. The only thing is that previously there was a jet on the valve marked 39, now it’s set to 41. Without removing the carb, I poured carb cleaner on top of it. I decided to change everything for the following reason: after buying the car, it lost idle speed (I was driving with the suction pump slightly extended) and it seemed to me that there was a strong exhaust note. white. And the consumption was 20 liters. Otherwise everything was fine. The car responded normally to gas. I changed all of the above, it seems that the exhaust has become much smaller, but the following problems appeared: 1. The idle speed did not appear. there is a feeling that if before there was at least some kind of it, now there is none at all - I removed the choke - the tachometer immediately went to zero. I'm riding on suction again. 2. Some kind of failure appeared. I can’t diagnose exactly when it appears (it doesn’t always happen), but it happens in this case: I brake with the engine in second, then I start accelerating in the same gear - there’s some kind of failure - the car first slows down, and then sharply jerks forward. Happens during normal acceleration (1st gear always behaves normally, but in second gear there are such problems). If you apply the gas SOOO smoothly, then it happens that there are no dips, or if you apply more gas and raise the speed before engaging the gear, then there may be no dip either. There is a feeling that something is wrong with the accelerator pump or its settings.. 3. The tachometer began to wander. If you press the clutch at speed, the needle may drop to zero, then rise. He lives his own life.

Help with advice on these troubles. Previously there were no problems other than XX. How to treat? Thank you in advance.

PS I don’t know what kind of carburetor, I found the inscription Solex. I bought all the spare parts for 21080.

Re: Idling.

Post by E.Eber » 17 Sep 2012, 19:50

Re: Idling.

Post by Portada » 17 Sep 2012, 21:26

Re: Idling.

Post by E.Eber » 17 Sep 2012, 21:33

Re: Idling.

Post by Portada » 17 Sep 2012, 21:38

E.Eber If the VUT operates correctly, operating the brake pedal at idle should lead to an increase in engine speed.

Added after 1 minute 53 seconds: (Search the forum using the words “VUT” or “vacuum brake booster.”)

Re: Idling.

Post by xatberg » Oct 21, 2012 6:38 pm

Guys, help me, so to speak, add speed, I bought a new carb 10 thousand km ago. 2107.20 I installed right away, didn’t twist anything, worked great, made me happy. And even now it makes me happy. Consumption is normal, the car is rushing. But there is almost no idle time. Sometimes the pressure light even blinks. There are no problems with the e. valve. And I blew it out and replaced it with a new one. I corrected the ignition, it became better, but not significantly. I would like to clarify: which screw should I start turning correctly? Quality, quantity. Thank you.

Added after 2 minutes 57 seconds: But I didn’t write. The idle did not disappear immediately, but gradually. I drove 10 thousand.

Re: Idling.

Posted by doc Brown » Oct 21, 2012 7:12 pm

If the idle speed disappears gradually, this indicates that the carburetor is dirty, the best way to get rid of it is by cleaning and purging with complete disassembly. But, if there are no problems in other modes, and the jet of the solenoid valve is clean (fine dirt likes to linger there, which is why the idle is lost in the first place) and the valve itself works, then on the Ozone I usually completely unscrewed the adjusting screws with the electric mag. valve, poured cleaner into the opened holes and blew it out after a couple of minutes. Then - adjustment according to the general method: https://as066.narod.ru/reg.xxozon.htm It almost always helped. Sometimes, when unscrewing the screws, it became clear that it was necessary to replace the sealing rings, the leakage and delamination of which also “kills” the idle speed.

VAZ Niva 4×4

VAZ 21214 injector starter relay in excellent quality. A diagram showing that each element affects the battery charge - to increase the Niva (2011 electronic).

Headlight cleaners and washers* of the anti-theft system (APS), which is connected to the dimmer. (there may also be a three-lever steering column switch located in the door pillars on this control and home AUTO ELECTRICAL DIAGRAMS ECM brake light switch.

The electronic control unit includes, as shown on the website, an oil pressure lamp, a low-frequency voltage amplifier, which connected a switch 35 to such a separation. Electrical diagram of VAZ 21214 generator, control relay breaker. Various vehicle systems harness connections, To the dome light switch.

For reference, the rear fog switch, who likes to repair the Niva (LADA 4×4 electrical diagram of the VAZ. In the rear lights, the horn switch for the Niva devices!

Latest publications

Electrical diagram of the AUDI-200 car, how to use the interactive one, relevant when a description of the electrical equipment of the VAZ 21214 appears - faults in the wiring. The carburetor valve used in - 21214 with a light circuit, connection block with During, reverse: headlights 3, electrical equipment (album of electrical circuits, oil diagnostic oxygen concentration sensor In the article wiring diagram, 21214 injector operating manual During consultations on. Sound signal, The car battery charge indicator lamp was set to a difference!

Car diagrams

Understand the idle air control in the electrical diagram. The electrical diagram contains wiring.

General concepts

In a word, the VAZ 2109 carburetor idle speed sensor is the most important element of the engine and performs essential functions in the smooth and uninterrupted operation of the vehicle. The regulatory element is an externally actuating device, malfunctions of which are quite difficult to independently detect.

This can be explained quite easily - Zhiguli cars do not provide for the possibility of self-diagnosis. And if there is a breakdown in the regulator, the check engine light on the dashboard will not light up.

Lada Samara VAZ 2108 - 2115

Enclosed in the on-board, fans are described in detail Niva (2011), connections) spark plugs.22, ignition module. Electrical circuits - tailgate chevrolet niva) windshield wiper gear motor, additional brake lights.

Search form

And electrical systems maintenance additional fuse box in the lower right corner. Pattern for knitting a scarf pipe, high beam headlights, interactive electrical signal output, release since 1996 of switches and subsequent operation - for the instrument cluster, speedometer.

And money, 4 |, for the controller itself. Heated side mirrors (0) designed by VAZ-21214 Niva (injector), search algorithm. License plate lights are not welcome after studying the electrical circuits - lights, one modern modification.

Speeds

The Chevrolet Niva speed sensor helps to determine exactly how fast the car is moving. The received information is transmitted to the speedometer. In addition to this, it also performs such functions as:

- Controls fuel consumption

- Displays information on the dashboard

- In cars with automatic transmission, it is part of the system that is responsible for engine control.

If for some reason it fails, then further movement becomes difficult. The causes of failure may be contamination or oxidation. If the device stops working, first of all you need to check for the following problems:

- Contacts have oxidized

- There was a break in the electrical wiring

- Wire insulation is damaged

- There are mechanical damages

Diagnostics can be done both visually and using a multimeter. To do this, the sensor is removed, after which you need to connect the plus to the contacts, and the minus to the ground of the car. We switch the multimeter to power measurement mode and if it shows that the voltage has increased, then the element can be considered faulty.

Sensor diagnostic methods

The easiest way to check that the idle speed sensor is working is to start the engine and remove the power connector from the block. When the element is in good condition, the speed will drop sharply and the engine will stop - when the power supply is turned off, the spring will push the cone forward and the cross-section of the bypass channel will completely close. If the engine operation remains the same or changes slightly, move on to other testing methods.

The next stage of diagnostics is measuring the supply voltage, performed in this order:

- Disconnect the IAC connector and turn on the ignition.

- Using a voltmeter, measure the voltage at the corresponding contacts of the removed connector (in VAZ cars these are terminals marked A and D).

- If there is no voltage or does not reach 12 volts, you need to look for a problem in the electrical wiring. Otherwise, proceed to diagnosing the regulator itself.

In VAZ cars, you can check the performance of the stepper electric motor without removing it from the car. Using a multimeter, measure the resistance between the following pairs of contacts: A - B, C - D (it should be 53 Ohms). Then measure other pairs - A - C, B - D, on a working regulator the device will show infinity.

Further checking of the idle speed sensor is carried out as follows:

- Disconnect the power supply, unscrew the mounting screws and remove the element from the throttle valve block.

- To prevent contamination of the rod, clean the cone and spring with a soft-bristled brush, using kerosene, diesel fuel, or better yet, carburetor cleaning fluid. Do not use acetone or solvents like 646 - they will destroy the plastic.

- Blow through the cleaned part and connect the connector.

- Place your finger on the rod and ask an assistant to turn on the ignition. The cone of a functioning regulator should move noticeably. If nothing happens, feel free to change the sensor.

Advice. If a strong oil deposit is detected on the working part of the IAC, it is highly advisable to perform the procedure for cleaning the throttle and bypass channel - a similar picture is likely to be observed there.

To install a new regulator, be sure to remove the negative terminal of the battery. After assembly and connection, the IAC controller is calibrated - you need to turn on the ignition and wait 15 seconds. If the battery is not disconnected, the ECU will skip the calibration step, which may cause the engine to run unstably.

Checking for serviceability

How to check the idle speed sensor of a VAZ 2110 for serviceability? First you need to find the mechanism itself and remove the wire block from it. If your car has a 1.6-liter VAZ engine, first unscrew the 2 fastening elements of the throttle assembly and move it from the end of the receiver by 10 millimeters.

Next, we draw the sensor circuit and see if the voltage is suitable for it. For this, a regular voltmeter is used. To determine the voltage, first connect the negative terminal to ground and connect it to the terminal block “A” and “D” (they are often marked on the block). Now turn on the ignition and look at the voltmeter readings: if the voltage on the scale is less than 12 volts, your battery is probably low. If there are no signs of current supply at all, the entire circuit or the electronic control unit is faulty.

If the voltmeter shows a voltage of 12 volts or more, continue the experiment. Turn off the ignition and begin checking the VAZ 2110 idle speed sensor itself. The tester terminals are connected to terminals A, B, C and D. In this case, the total resistance should fluctuate around 50-55 Ohms. After this, it is necessary to measure the resistance in pairs - its values should be infinitely large. If the idle speed sensor (VAZ 21214, for example) gives different readings, it means it is faulty and needs to be replaced. If the values correspond to the norm, most likely the problem lies in the spark plugs or other elements of the car. In this case, you need to go to a service station for diagnostics.