I bought the car a week ago and noticed instability in the engine at idle. The car pulls basically well. The consumption is small, but there are surges when working at XX 700-1000 and vibration in the car. With what it can be connected? (the car with e-gas has already covered 1200 km)

I think, like mine now, the problem lies in the XX sensor, my on-board vehicle has already given an error on it a couple of times, but anyway it is necessary to do diagnostics

you're right, it's Danish XX. It's easier to change than to clean and adjust!

rather not the XX sensor but the throttle position sensor

Do these sensors affect the traction of the car?

What about the service? The car is new, everything is under warranty

I can always get to the service in time. I have to go 100 km to get there. If the reason is cheap, why drive it away? Yes, in addition, judging by the reviews, there is no guarantee

At 1100 km, my coolant sensor is constantly glitching. There are vibrations too. Then I will resolve these issues.

The coolant sensor also lights up every once in a while. Are you in Ryazan Lada for maintenance or to another dealer?

and mentya stupidly had a hose from the canister purge valve fall on the manifold and burned out in 2 places and the rpm was 1100, then a check came out, and if you reset it, the car started to trip, and like a fool I changed the phx and the dpdz, but I just had to be a little more careful

I had a similar problem. The bortovik generated about 13 errors. I ran diagnostics and everything seemed to be fine. It turned out that 2 plugs had fallen off the injector and air was being sucked into the system. After fixing this problem everything was fine!)

Because I work for dealers, so I can say with a 99% probability that you need to change the ignition harness. Over the last six months, this has been a common occurrence in Samara and even in grants. So go to the officials. Good luck.

What is the most normal official in Ryazan? I just rented a Lada from Ryazan and somehow they don’t inspire much confidence.

they're complaining anyway. With us, it depends on who you end up with. Andrey will change the harness. He will do it quickly and well. And every mechanic does something better, something worse.

As I understand it, this Andrey from Ryazan Lada is on the Biryuzov 1G? By the way, I looked at what kind of harness I have... written Ekaterenburg. Is he bad too? or what?

no. we are not working properly. We are nearby. And they are changing the Ekaterinburg VAZ vehicle harnesses. But I don’t remember which ones. I don't do Lada cars.

new car what for. go to the dealers, tell them what kind of bullshit they are, let them change it, do diagnostics, etc.

Flash it in the automode and everything will be fine, the same thing happened, although initially they changed the gas harness for me under warranty

What does this mean after replacing the harness, nothing has changed? Why did you flash it then?

because it was recommended by a good friend. and the vibration is gone, the revs don’t fluctuate, it eats less, and the pedal response has become much better

Triple

This popular “term” means that one of the cylinders is not working, that is, out of four (the most common number of cylinders on passenger cars), only three are functioning - hence the word. This can be understood by several symptoms:

- the engine starts hesitantly;

- after warming up, the vibration does not disappear;

- the car pulls poorly and jerks;

- increased fuel consumption.

The situation should be corrected as soon as possible. When one cylinder is not working, the load on the others increases sharply. In this case, unburned fuel washes away the lubricant from the walls, thereby wearing out the cylinder bore. There is also a gradual coking of the channels, which sooner or later leads to premature engine overhaul. The main reasons for tripling:

- defect, broken spark plug;

- malfunction of high-voltage wires;

- breakdown of the ignition distributor (distributor), module (on front-wheel drive cars);

- severe wear of one of the elements of the CPG.

It is very easy to check that the cylinders are working properly. To do this, start the engine, put on a rubber glove and remove the high-voltage wires from the spark plugs one by one. If in one of the cases the nature of the engine operation has not changed, then you have found the “culprit” cylinder.

Replacing pillows and preventing spark plug malfunctions

It is worth learning to deal with the most common causes of body vibrations: engine mounts and spark plugs. In the first case, replacing parts cannot be avoided - the rubber from which the parts are made simply wears out and loses its elasticity. There's nothing you can do about it. Replacing pillows is similar to other car models and should not cause problems. To replace you will need:

- Socket wrench 17 with cardan.

- Socket wrench 13.

- Keys for 15 and 19.

- Hydraulic jack.

Read more: What are the wheel sizes for a Hyundai Accent?

If replacing parts yourself causes you difficulties or you lack the necessary tools, the best solution would be to contact a car service center. At the same time, you can select the pillows you need in advance, so as not to wait for mechanics to find them and order them for you.

However, spark plugs, unlike engine mounts, can avoid replacement for a long time if they are properly cared for. If you regularly clean them and monitor the gap between the electrodes, you can significantly increase the period of stable operation without uncomfortable vibrations of the case.

In addition, you need to monitor the appearance of carbon deposits on the cone.

Excess oil in the crankcase, insufficient vehicle load, early ignition - this may be indicated by different colored soot on the spark plugs. Paying attention to this detail can greatly help you diagnose problems.

Loose engine mount

In this situation, vibration occurs throughout the entire body, since the motor is attached through cushions (they are also called supports), which play the role of not only fasteners, but also dampers that dampen vibrations. There are not many reasons for this problem; pillows can be:

- incorrectly installed;

- worn out;

- damaged during repairs (for example, during installation of the power unit).

Checking the condition of the pillows is easy; you will need an assistant to do this. Open the hood and start the engine. Ask your partner to alternately engage reverse, first and neutral gears. At these moments, look at the engine: with each switch it should deviate slightly, and at the same angle. If the slope is significantly greater or less in one direction, the problem is a bad pillow. It should be replaced.

It is recommended to install a set: a car with front-wheel drive usually has 3 airbags, with a rear-wheel drive (“classic”) – 2.

Features of the internal combustion engine

Any four-cylinder, four-stroke engine is unbalanced. It would seem: two pistons go down, two go up, everything is balanced. But second-order inertial forces remain uncompensated, which try to shake the entire engine up and down with a frequency twice the crankshaft speed. To combat this phenomenon, a scheme was invented with two balancing shafts rotating in opposite directions twice as fast as the crankshaft. These shafts, with their vibrations, make it possible to completely compensate for vibrations caused by the imbalance of the connecting rod and piston group. An example would be the Nissan MR20DE engine, which is found on our popular X-Trail and Qashqai crossovers.

The balancer shafts are strictly synchronized with each other by gears, and the drive from the crankshaft is carried out by a chain.

The balancer shafts are strictly synchronized with each other by gears, and the drive from the crankshaft is carried out by a chain.

Why don’t VAZ motorists use this solution? The fact is that such systems are installed on engines with a displacement of 2 liters or more. For such a motor, the mass of the piston and connecting rod assembly turns out to be quite large. If the working volume is smaller, then the piston diameter and connecting rod length are also smaller - as is the total weight of the parts. As a result, there are fewer vibrations. The largest mass-produced engine in Togliatti has a displacement of 1.8 liters. Therefore, there are no balancing shafts here.

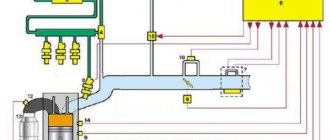

Disorders in the nutrition system

Ultimately, they come down to improper formation of the composition of the combustible mixture. Typically, vibration at idle is a consequence of its depletion. It is possible to understand exactly which node or element is the source of the problem only with the help of special equipment. There are many reasons, below are just a few of them:

- fuel pump failure;

- contamination of the filter and (or) fuel line;

- clogged jets in the carburetor or nozzles in the ramp;

- incorrect carburetor settings, faulty sensors in the injection engine, etc.

Brakes

For some this sounds strange, however, the braking system has its own connection with the engine. We are talking about a vacuum booster. It is connected to the intake manifold through a special hose. This is necessary in order to create a vacuum inside the amplifier. The vacuum is formed due to the “suction” of air from this unit by the engine pistons. If the tightness of the connecting hose is broken, excess air begins to enter the cylinders, depleting the combustible mixture. Verification steps:

- When the power unit is not working, slowly press the brake several times (3-4) and hold the pedal, which should be elastic.

- Start the engine: the pedal should gradually fall down. If this is not the case, air leaks occur.

- To check the hose, it must be removed. Test by blowing. If the tube is leaking air, it will need to be replaced, and if it is intact, check the fitting screwed into the amplifier. Take a medical bulb and put it on the fitting. When you press on it, the air should flow only in one direction (there is no reverse “move”). Or you can simply blow: first into the wide part of the fitting, then into the narrow one. If air passes in both directions, you will have to buy a new spare part.

Sensor malfunctions

This is also one of the reasons that causes engine vibration at idle speed. Mass air flow sensor, lambda probe, idle air control, TPS - failure of these spare parts has a negative impact on the stable operation of the engine. As a result, the control unit receives incorrect information and forms the wrong composition of the combustible mixture. If the DPKV, knock or phase sensor stops functioning, the same picture results: vibration. You can find the faulty part using the on-board computer or controller using the error code.

Signs of unstable operation of the VAZ-2114 engine at idle

The first thing that catches your eye is vibration. Indeed, it is impossible not to notice it - it is transmitted to the steering wheel, to the gear shift lever, and sometimes the entire body begins to vibrate . Not only is vibration itself not the most pleasant phenomenon, it can signal a breakdown or the need for maintenance of many components and systems.

Causes of engine vibration VAZ-2114

If the engine operates quite normally in transient modes and at medium and high speeds, do not rush to draw conclusions about the malfunction of the idle system. First of all, let’s analyze the symptoms, and they can be like this:

- After starting, the engine vibrates when cold, and the speed can fluctuate from 800 to 2000 revolutions spontaneously. In this case, after warming up, vibration may be absent and the idle will be in the normal range, 800-850 rpm.

- After the engine warms up, the vibration does not disappear.

- When cold the idle is normal, after warming up the speed fluctuates and the engine knocks.

- The idle may disappear while driving, when coasting or at an intersection after a short vibration. In this case, you can catch the speed with the accelerator pedal.

Our editorial car! VAZ-2114. If you don't adjust the valves, it will vibrate!

In short, any engine vibrations at idle require the most prompt diagnosis. And we will check those systems and components that can lead to malfunction most often.

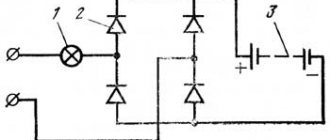

Vibration at idle. At gunpoint - ignition

One of the main reasons for vibration at idle in an injection engine is incorrect operation of the ignition system.

Read more: BMW E60 steering angle sensor

Even in the case when the fuel-air mixture is supplied to the cylinder in the required quantity and on time, the passage of a spark, constant or periodic, will certainly lead to vibration. Moreover, at medium and high speeds the engine can operate stably, with nominal fuel consumption and good dynamics.

First of all, we check this:

- Any gaps in spark formation will lead to uneven emission of exhaust gases; you can check this simply by placing your hand near the exhaust pipe of the muffler; the gaps will be immediately audible.

A good engine should have uniform exhaust

Breakdown of high-voltage wires can cause engine vibration

We check the spark plugs by removing the caps one by one

Changing the ignition module

In addition to these problems, difficulties may arise in the operation of electronics , this mainly applies to injection engines. And only these were installed on the VAZ-2114, with the exception of the Samar-2 line being the VAZ-2115 - there were carburetor versions.

Electronics and sensors as causes of vibration

Another suspect in the story of engine vibration at idle is the electronic engine control unit. No one will repair it; most often it must be either replaced or re-flashed. For example, in injection engines with a Bosch 7.9.7+ controller, flashing ER19 instead of the standard ER16 often helps, fuel consumption remains within normal limits, and vibration disappears.

In addition to the ECU, the following sensors may be to blame:

- Idle speed regulator . The regulator sensor is mounted on the throttle body, and to check it you need to remove the terminals and use a multimeter in ohmmeter mode to check the resistance between the contacts. The nominal value is 60-80 Ohm. If the sensor does not produce the required resistance, replace it with a new one.

Checking the idle air control

Checking the mass air flow sensor

Diesel vibration at idle

At first glance, everything is simpler here: there are no spark plugs, no distributors. However, the “shaking” of a car equipped with a diesel engine indicates more serious and “costly” problems:

- Failure of the injection pump, which can only be checked using special equipment.

- Injector contamination. Their cleaning is carried out in specialized technical centers.

If vibration occurs at idle, checking the diesel unit should begin by determining the compression in the cylinders. If it does not meet the standard, the mixture will not ignite and the engine will begin to shake. The second stage of testing is to check the alignment of the marks on the power unit cover and the camshaft pulley. If the injection angle is incorrect, the diesel engine will operate unstably.

Messages: 242 Registered: June 21, 2011, 00:00 From: Tyumen Experience: 2002 Car: FF2

| Rating: 252 |

| Reputation: 0 |

Post by Diesel85 » 10 Dec 2012, 21:01

Messages: 322 Registered: Aug 21, 2010, 00:00 Experience: 2008

| Rating: 322 |

| Reputation: 0 |

Post by novenkiy » Dec 10, 2012, 9:05 pm

Messages: 469 Registered: Aug 31, 2011, 00:00 From: tyumen Experience: 2004 Car: _Sport Car_

| Rating: 969 |

| Reputation: +3 |

Thanked: 8 times Thanked: 4 times

Post by motul » 10 Dec 2012, 21:24

Messages: 322 Registered: Aug 21, 2010, 00:00 Experience: 2008

| Rating: 322 |

| Reputation: 0 |

Post by novenkiy » Dec 10, 2012, 9:27 pm

Messages: 261 Joined: Feb 12, 2011 00:00

| Rating: 301 |

| Reputation: 0 |

Thanked: 2 times

Post by 13k » 10 Dec 2012, 21:37

Messages: 551 Registered: March 04, 2010, 00:00 From: Tyumen-Uporovo Experience: 1999 ABCDE Car: sedan

| Rating: 571 |

| Reputation: 0 |

Post by DENEG » 10 Dec 2012, 21:39

I had a 2006, the same crap, I changed the spark plugs, adjusted the valves, etc. nothing helped, the steering wheel was already shaking, at 16,000 miles the catalytic converter was thrown out and the sore was almost gone, but on a car of those years it was under the body and replacing it with an insert from a 9k cost me 450 rubles and 20 minutes of work on the overpass, and the engine after that I didn’t require any flashing. Now it’s in a spider and costs much more, who knows if this procedure will help your car. My brother also has a fresh 14ka, it shakes like . but I haven’t touched the catalytic converter yet. At the service station they generally say that the 8-valve is supposed to work like that, maybe the rather weak engine is really being choked with all sorts of environmental things?