Cars admin26.02.2020

Today we will touch on one important question, the answer to which I am already close to. It's a matter of optimal engine speed. What are they? Someone says that you shouldn’t turn it more than 2000 rpm, they say we don’t overload the engine. Others say that you can’t choke the engine at low speeds and need to rev it up. Opinions are diametrically opposed, as in matters of warming up. Today we will try to understand the issue and not without the arguments of authoritative persons.

I found an interesting article in Za Rulem magazine. I will write the main points here. We take the VAZ eight-valve 8-valve engine as a basis and drive it well. We get these results.

So, at speeds of 2000-3500, wear is minimal. This has 2 important consequences:

Corollary 1. The most optimal speed is the speed of maximum torque. For the mentioned eight-cylinder engine this is 2800-3200 rpm

Corollary 2. The closest to optimal operating conditions are driving along the highway at the above speeds. In traffic jams, accordingly, everything will be the other way around. The revolutions are low and constantly changing (either rising or falling).

And finally, another video on the topic from Evgeny Travnikov.

EGR valve

The EGR valve is a rather complex exhaust gas recirculation device. The sensor is designed to return some of the gases to the exhaust manifold. The system is widely used in diesel and gasoline engines, reducing pumping losses, preventing detonation and harsh idling of the power unit. In engines on VAZ cars, the EGR closes at idle, providing no more than 10% oxygen at light loads. One of the advantages of the valve in question is the reduction in emissions into the atmosphere.

EGR extremely rarely causes the VAZ 2114 to jump in idle speed, but the valve seat requires periodic cleaning.

Otherwise, the injection engine will exhibit unstable operation. Cleaning is carried out using special sprays. Typically, such substances are used for carburetor engines.

During the cleaning process, it is necessary to avoid contact of the substance with the EGR sensor diaphragm.

Carburetor engine VAZ 2114

There is no ECU on the “fourteenth” model with a carburetor engine. But such versions also have problems with floating speed. Such situations are less common than when operating an injection engine and are due to the following reasons:

- Idle speed control failure. The driver will need to adjust the speed within 800-900;

- Damage to the solenoid valve. The problem is solved by repairing or replacing the part in question. A breakdown is indicated by stable operation of the motor with the choke extended;

- contamination of idle channels. In this case, the mixture does not receive the required amount of air. To fix the problem, you need to clean the channels;

- nozzle contamination. Solved in a similar way;

- the filter gets clogged. It is necessary to replace the consumable.

Other reasons

There are a number of problems with idling that arise from drivers who do not service their vehicles in a timely manner. These include:

- refueling with low-quality fuel. First of all, this applies to underground gas stations selling illegal fuel;

- failure of spark plugs. Experienced drivers check spark plugs regularly. The working surface should have a slight soot;

- driving with a half-empty tank. Pouring fuel from a canister (usually in small quantities) causes debris to enter the system.

Vibration of the power unit on the “fourteenth” model is usually not a problem. For carburetor engines, vibration is quite normal during cold starts.

After the power unit warms up to operating temperature, the vibrations disappear. Engine shaking is caused by low temperature and inefficient combustion of the mixture. Therefore, at the slightest increase in temperature, the vibrations stop. Sometimes the cause of vibration is the wear of the cushions used as supports for the power unit. This problem occurs on injection and carburetor engines, and is solved by replacing the supports.

Floating speed at idle speed of the VAZ 2114 must be eliminated immediately after they appear. Prolonging the problem can lead to costly repairs.

Ways to eliminate the “sore”

If such a problem occurs, you need to look for which node is to blame analytically, checking all the specified sensors. First, let's consider the following option for correcting the problem situation. Let's assume that a VAZ 2110 has high revs. An examination of the suspected components for faulty components showed that the throttle position sensor has traces of rust. It is located directly above the throttle valve. Measurements with a voltmeter showed that when the engine is idling, the voltage on it remains high - which means it does not close the damper.

How to fix the problem? For this we only need a screwdriver. Let's begin the procedure.

- By disconnecting the terminal block and also unscrewing two screws, we dismantle the assembly.

- We notice that traces of rust inside interfere with the movement of the wheel that regulates the position of the damper.

- We fill the insides of the defective device with a penetrating anti-rust aerosol.

- Use a development screwdriver to turn the wheel.

- We reassemble in reverse order.

Check to see if the engine idle speed is now high. The problem should go away.

Now let's look at another case. Let's say we have high idle speed in a VAZ 2114. This is what we do when faced with this situation.

When clarifying the circumstances of the problem under investigation, we always initially check the operation of the idle speed sensor. This device consists of a needle built inside an electromagnetic coil. The needle either moves inside the coil, moving away from the hole in the throttle pipe, or moves out, closing this hole, thereby stopping the supply of air for combustion of the mixture.

Also read about adjusting engine idle speed and repairing a Tavria car muffler with your own hands.

This element is located at the throttle valve, opposite the gas pedal cable. To diagnose it, we pull out the terminal block from it, start the car, after which we see that we still have high engine speeds that have not changed at idle. Then we remove this defective unit, then clean it or replace it. For work we take:

- Unscrew the two screws. We take out the broken node.

- We connect the wiring to it. Turn on the ignition. If the needle of the device moves slightly inside the coil to the touch, then it is working.

- If the needle does not react when an electric current is applied, wash the device with a toothbrush using gasoline.

- We do the assembly in reverse order.

When you cannot restore the functionality of this unit with your own hands, it is better to purchase a new one. Moreover, the cost of spare parts is low.

Other fixes

Of course, the options considered do not exhaust the possible ways to correct the shortcoming when high speeds are noticed precisely on a warm engine. To further study the most common situations, let's look at the case of a malfunctioning mass air flow sensor. This device is responsible for supplying the correct portions of air for combustion of the mixture, and also provides data to the electronic control unit about these portions, so that the unit proportions the supplied portions of gasoline.

This node can be diagnosed as follows. It is necessary to disconnect the terminal block from our mass flow regulator, and then start the engine, after which it is necessary to drive the crankshaft speed above 2000 rpm.

How to adjust idle speed on a VAZ 2114 injector

In order to successfully cope with this task, you should make sure that the idle speed regulator is working properly. What engine speed should the VAZ 2114 be at idle?

Most importantly, they should not float. This is one of the main conditions. In a situation where floating engine speeds occur or the normal functioning of the engine is disrupted when the driver puts the car in neutral, you should think about the causes of the malfunction.

In some cases, the speed increases while the engine is fully warmed up. All this indicates problems associated with the operation of the idle air regulator. The reason may also be a lean mixture.

Another malfunction that may be a consequence of improper operation of the regulator is too low speeds on an engine that is not yet sufficiently warmed up.

IAC sensor

The cause of the malfunction is often too much air supply.

In order to make the adjustment, you will need a computer capable of collecting data from a wide variety of sensors installed on the car. It is impossible to do this manually. This means that you won’t be able to do it on your own. Repairs require special equipment.

Additional information: How can you save on repairs? To ensure that the adjustment does not cost too much, you can look for a private mechanic who has the necessary equipment for repairs.

Using a computer, you can open one or another valve. It is almost impossible to do this otherwise. Under no circumstances should you try to open the valve manually, because this can be dangerous not only for your health, but also for the car, which will completely fail if repaired incorrectly.

It is necessary to open the valve using a computer only with a certain value. If you do not comply with this indicator, then the adjustment will also not work.

IAC adjustment using a computer

Renault Logan stalls at idle

Renault Logan power units must be diagnosed at a service center

As with any other injection engines, Renault Logan power units must be diagnosed at a service center, since there can be many reasons for stalling. But Renault-Nissan experts admit that most often such a malfunction is caused by a failure (jamming) of the idle air regulator (IAC) or the leakage of foreign air through loose connections of the hoses going to the intake pipe.

When replacing the IAC and tightening the hose clamps failed to restore stable idle, it is better to go straight to the service station.

Problems with sensors and electronic control unit

A common situation is when floating speed occurs as a result of the failure of a certain sensor. As a result, the electronic control unit receives unreliable information, and the power unit exhibits unstable operation.

To diagnose the ECU you will need the appropriate equipment and skills. It is recommended to immediately contact a car service, since it is quite difficult to do such work on your own.

If the engine does not operate in neutral, the following sensors may be the cause:

- DMRV;

- RXX;

- EGR.

The breakdown must be looked for not only in the regulators. Damage to wires occurs quite often. Normal operation of the sensor does not guarantee that the ECU will receive reliable information. If everything is fine with the electrical wiring, then unstable engine operation can be caused by a clogged filter, failure of the spark plugs and other reasons.

Diagnostics of the injection system can be carried out in a car service center, as well as on your own. If a VDO system is installed, a self-diagnosis can be performed. To do this, press the odometer button, then turn on the ignition and release the button. After the arrows appear on the screen, the odometer button must be pressed two more times. If errors occur, the system will display the following codes:

- 1 - malfunction of the electronic control unit;

- 14.15 - failure of the coolant sensor;

- 44.45 - problems with the mixture;

- 33.34 – errors of the mass air flow sensor;

- 22.23 – throttle position sensor errors.

Unlike using a diagnostic scanner, this method of determining errors has a significant drawback. So, if several errors occur in the system, the codes are summed up

This is important to consider

Diagnostics can be done by eye. For example, if disturbances in the operation of the power unit are associated with braking or pressing the gas pedal, then the problems are caused by a failure of the throttle position sensor. However, the check must be comprehensive, and its result directly depends on the experience of the motorist.

Idle speed sensor. Operating principle, signs of malfunction.

The idle speed sensor (dhx), or more correctly called the “idle speed regulator” (irx) on the VAZ 2114 and on other Samara families is designed to stabilize and automatically adjust the idle speed. The idle speed sensor is an electric motor with a tapered needle.

Where is the idle air control (IAC) located?

The idle speed sensor is located on the throttle body. The idle speed sensor is located next to the throttle position sensor. The DXX is secured with two screws. It also happens that the sensor is mounted on the varnish.

Photo of idle speed sensor (рхх)

The idle speed sensor is located at number 3. Next to number 4

Operating principle of the idle speed sensor (IAC)

The moment we turn on the ignition, the rod on the idle speed control fully extends and rests against a special calibration hole in the throttle pipe. Afterwards, the sensor counts the steps and returns the valve to its original position. The position of the initial valve depends on the firmware: for example, January 5.1 - 120 steps on a warm engine, Bosch - approximately 50 steps on a warm engine.

On a warm engine at the time of adjustment, the sensor is at around 30-50 steps. As the steps increase or decrease, the volume of air passing through the calibration hole constantly changes. Moreover, if the rod is extended, then the steps increase and vice versa. The stroke of the rod is 250 steps.

At the time of purchasing an idle speed sensor for a VAZ, the distance from the rod head to the flange should be no more than 23mm. Carefully measure the length of the protruding head.

The engine receives a certain amount of air necessary for normal engine operation, thereby regulating the idle speed.

The incoming air is analyzed by the mass air flow sensor (MAF) and, in accordance with its quantity, the Controller supplies the required amount of gasoline to the engine through the fuel injectors. Using the crankshaft position sensor (CPS), the controller monitors the number of engine revolutions and controls the idle speed control. This is how the process of supplying the required volume of air occurs.

The car stalls due to sensors

The correct operation of the VAZ 2114 injector depends on several sensors:

- TPS (throttle position sensor);

- MAF (mass air flow sensor);

- DPKV (crankshaft position sensor);

- DTOZH (coolant temperature sensor).

If stalling of the car consistently depends on temperature (usually on a hot engine), the cause may be DTOZH. When cold, an enriched mixture is supplied to the injector. If, as the sensor warms up, it does not provide the correct data to the computer, the engine may become dull and stall.

The mass air flow sensor does not often manifest itself by stalling the car. Its “element”: failures when pressing the gas, increased fuel consumption, drop in power. But the VAZ 2114 may stall when pressing or releasing the gas if there are strong deviations in the real and measured amount of air. When you press the gas, the actual air flow increases. If the sensor gives the computer approximately the same readings as at idle, the mixture becomes very lean and the car may stall.

Mass air flow sensor VAZ 2114

Most often, the matter is solved by cleaning the mass air flow sensor. You can check it by disconnecting the chip while the engine is running. If the sound of the motor does not change, the source of the malfunction has been found.

TPS regulates the amount of fuel entering the engine. Contamination does not affect it as much as the mass air flow sensor, although sticking of moving parts is possible. Its main enemy is mechanical wear, which can only be corrected by replacement.

If the TPS is faulty, the car usually stalls when changing gears. This can happen when the gas is released or the engine speed drops, if the supply of the fuel mixture is momentarily blocked by the damper.

Throttle position sensor VAZ 2114

As a rule, TPS problems are not solved by cleaning. The sensor is checked with a multimeter. It is better to perform the operation together. Select the multimeter mode on the tester and set the probes to ground and the input signal - it should constantly show 5V. Then place the second probe on the third output (signal in the controller line). Have an assistant step on the gas. The voltmeter readings should vary within the range of ≈ 0.5 – 4 V. If there is no 5V power supply, the problem is electrical. If the sensor does not respond to pressing the gas or reacts incorrectly, replace the TPS.

DPKV is one of the rare reasons why a VAZ 2114 car stalls. There are several “old-fashioned” (inaccurate, so we don’t list them here) ways to check it. Ideally, the performance of the DPKV is checked with an oscilloscope, so we recommend that you always keep a spare sensor in the glove compartment. If other options have been exhausted, replace the DPKV with a known working one.

If the DPKV is faulty, the ignition does not work correctly: the injection phases are confused, the operation of the injectors and spark plugs does not match. The car may not start (most often) or start extremely poorly, stall and immediately stall, or run on gas on two cylinders.

The worst case scenario for why the car stalls when you let off the gas or at idle is that the cylinder head gasket is broken or the head is misaligned. In this case, engine repair will be required. There are so many reasons for such a malfunction, and the symptoms are so similar that diagnosis is mandatory. But even this does not always give results, pointing to the symptoms and not the causes of the car’s “disease”. Replacing the sensor may help, but after a while the problem will return.

You need to check each element one by one: starting with simple options and ending with complex ones (electrical breaks, uneven engine compression and its causes).

>Why does a hot engine stall at idle, injector VAZ 2115

When starting the engine on a VAZ 2114, the speed does not rise - reasons

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Recently, problems with starting the engine have become more frequent.

Happens both cold and hot. The engine starts, but the speed does not rise, it tries to stall, as if the fuel pump has turned off. If this has started, you can start the engine over and over again - there will be a constant wobble, and the engine will tend to stall. When it’s hot, it’s usually enough to apply more gas, and the speed levels out, then everything works fine; when it’s cold, it doesn’t help, i.e. Even if you put on gas, it still stalls. But this trick with the ears helps (again, both cold and hot) - I turn off the ignition (a must), squeeze the gas all the way, release it, turn on the ignition and start it. Then it starts normally. Squeezing the gas while the ignition is on does not help. Judging by the sound, the fuel pump is working. According to BC, the TPS position at such moments is 0%, i.e. It seems like you can’t blame him, but why then does squeezing the gas help when the ignition is off? What ideas might there be?

Idle speed control

The first thing you should check is the idle speed control. To do this, you will need a tester (multimeter) set to ohmmeter mode.

The check is performed as follows:

- turn off the ignition;

- disconnect the block;

- measure the resistance between contacts A * B and C * D of the regulator. If it is working properly, the device will show a resistance value in the range from 40 to 80 Ohms;

- measure the resistance between contacts B * C and A * D. If the regulator is operational, the ohmmeter will go off scale (on some devices an “open circuit” may be indicated).

Dirty IAC VAZ 2114

If the results obtained during measurements differ from those given above, then the idle speed controller is broken. By the way, its failure is one of the most common reasons why the idle speed of a VAZ 2114 injector fluctuates. If a breakdown is detected, the part should be replaced with a new, similar one (since the IAC is not a repairable device). Do not forget that before starting to replace the device, you should disconnect the battery ground terminal.

After the new regulator is installed, it should be “calibrated”. To do this, turn on the ignition for 10 seconds and then turn it off. There is no need to start the engine.

The speed on the VAZ-2114 is floating - causes and methods of elimination

The five-door hatchback VAZ 2114 is a restyled model of the famous “nine”, which rolled off the assembly line of the car plant from 2003 to 2013. At various times, the manufacturer installed on the car power plants with carburetor or distributed fuel injection (injector) of its own making, and since 2007 the car has been equipped with an electronic engine control system. Note that all these engines have one common and very significant drawback - when they switch to idle mode, their crankshaft speed suddenly begins to “float”.

Idle speed is the operating mode of a car engine with the gear in neutral. It is characterized by minimal engine load and low fuel consumption.

Idle mode is used:

- for delivering motor oil from the engine crankcase to friction units after a long period of parking the vehicle;

- to warm up the power unit in the cold season;

- in cases where turning off the motor is impossible or undesirable.

During normal engine operation, the crankshaft speed is idling at 2000 rpm. gradually decrease to 800, then maintaining at this level. However, it also happens that the power plant, when switching to this mode, operates unstably - it randomly changes the speed in the range of 500–1500 rpm, “chokes” and stalls. This tells us: a failure has occurred in the engine control system, the causes of which must be diagnosed and eliminated as soon as possible.

The movement of the arrow of the device shows the change in the number of engine revolutions

Determining the specific cause of the malfunction is not easy, but it cannot be ignored - this can lead to critical engine failure and the need for expensive repair work. In addition, driving a car with an engine that is unstable at idle speed distracts the driver's attention. He has to constantly monitor changes in the speed and keep his foot on the gas pedal, preventing the engine from stalling when braking or stopping briefly.

Among the reasons leading to improper engine operation in idle mode are problems with sensors that transmit information to the electronic control unit. These include sensor malfunctions:

- idle speed controller (IAC);

- mass air flow (MAF);

- crankshaft position (CPCV);

- throttle valve position;

- vehicle speed (VSA).

The appearance of floating crankshaft speeds also causes:

- malfunction of the idle speed solenoid valve;

- dirty air filter and spark plugs;

- damage to high-voltage wires;

- wear of gaskets and plugs at the junction of the intake manifold with the cylinders;

- malfunction of the EGR valve, which regulates exhaust gas emissions.

When starting to find and eliminate the reasons that cause unstable operation of the engine in idle mode, you first need to check:

- Condition of the air filter and spark plugs. If they become critically dirty, they need to be replaced.

- Integrity of insulation of high-voltage wires. If damage is found, they must be replaced.

It is recommended to make sure that there is no suction at the junction of the intake manifold with the engine cylinders. To do this, with the engine running, you need to sequentially spray all joints at the joints with carburetor cleaner or other flammable liquid. If atmospheric air enters there, the car engine jerks sharply, which is why, if a damaged gasket or plug is detected, the element is replaced.

Checking the tightness of the intake manifold (video guide)

Let's consider the remaining elements of the car, the malfunction of which can affect the smooth operation of the VAZ 2114 engine in idle mode.

Solenoid valve diagnostics

Cars with engines equipped with a carburetor are equipped with idle speed solenoid valves. Devices are checked as follows:

- Disconnect the power cord.

- Start the engine to warm up.

- Connect the wire. If a clear click is not heard, the part must be replaced.

Attention! To fully ensure that the valve is working properly, be sure to clean the nozzle and repeat the test.

Adjusting the idle speed on a carburetor engine (with video)

Note that the main reason for the appearance of floating idle speed in engines of this type is the incorrect operation of the carburetor. The device is adjusted by rotating the fuel quality and quantity screws.

Is the EGR system on the injector working?

"Floating" speed can be caused by jamming of the exhaust gas recirculation (EGR) valve, which is installed in the exhaust manifold. It is necessary to periodically remove dirt from the valve seat and its seat using a carburetor cleaning aerosol, avoiding liquid getting on the sensor diaphragm.

Keep the valve seat clean

Attention! If cleaning the unit does not give a positive result, the device must be replaced.

Is the idle air control valve working correctly?

The IAC is checked by measuring the electrical resistance at the contacts - to diagnose the device you will need a tester (multimeter) set to the “ohmmeter” operating mode. To check the details:

- Let's turn off the ignition.

- Disconnect the connection block.

- Let's measure the resistance on contacts A - B and C - D of the device. The optimal readings of the device vary from 40 to 80 ohms.

- Let's repeat the measurements with contacts B - C and A - D. In this case, the multimeter should show “infinity” or an open circuit.

Any violation of the normal resistance values means a malfunction of the regulator. IAC failure is a common cause of floating engine speed at idle, and if a malfunction is detected, the device must be replaced. Before you begin dismantling the part, you must disconnect the negative wire from the battery. After installation, the new IAC is calibrated - the removed terminal is returned to its place, the ignition is turned on and after 5-10 seconds (there is no need to start the engine).

IAC failure is a common cause of floating engine speeds.

Attention! If the battery is not disconnected before dismantling the device, the electronic control unit will not calibrate the IAC.

Serviceability of the mass air flow sensor

To diagnose the mass air flow sensor, you need to switch the tester operating mode to “voltmeter” (20 V). We check the part by following these steps:

- Let's turn off the engine and turn on the ignition.

- Let's measure the voltage at the connection connector between the contacts of the green and yellow wires. The multimeter reading should be in the range of 0.99 - 1.02 V.

The device can be cleaned by “blowing” it with an aerosol for cleaning carburetors.

Attention! The device can be dismantled and cleaned using a carburetor aerosol, but this does not always help. In the event of a critical component failure, it will have to be replaced.

Video: Checking the mass air flow sensor

Cleanliness of the damper assembly

The throttle valve assembly is diagnosed by visual inspection for contamination. Clean the part with cotton swabs and a toothbrush moistened with a cleaning solution. For ease of work, the device is dismantled. After cleaning, it is recommended to blow out all channels and pipes of the unit with compressed air using a tire inflator.

To clean the part, it must be dismantled

Attention! It is recommended that the channel responsible for removing gases from the crankcase be completely filled with a cleaning solution before purging - the diameter of the element is very small and there is no other way to access it.

Video: How to clean the throttle body

Is it possible to diagnose DPKV and DSA?

A breakdown of the DPKV and DSA (Hall sensor) is indicated by the Check Engine indicator that lights up on the car’s dashboard. Testing these devices is only possible using special instruments (oscilloscopes). You can first check the integrity of the wiring; if it is broken, the damage should be repaired.

- The DPKV sensor is installed on a bracket located in close proximity to the generator drive pulley.

- The DSA is located on the speedometer drive mechanism of the gearbox.

For a more detailed introduction to methods for detecting faults associated with engine malfunction in idle mode, it is recommended to watch the following video.

Video: Computer diagnostics of VAZ 2114 idle problems

So, the main steps to rid the car of floating engine speed at idle are considered. Remember: if performing these operations yourself does not lead to a positive result, you will have to contact a service station with the necessary diagnostic equipment and qualified repairmen.

- Author: Alexey Romanov

Hello! My name is Alexey, I am 45 years old. I am interested in studying all types of technology and independently servicing personal vehicles, and I read a lot. I consider my favorite hobbies to be the most effective escape from stress: photography, numismatics and home renovation.

Materials: https://pol-z.ru/plavayut-oborotyi-na-holostom-hodu-vaz/

Working with a faulty injection engine

Composition and principle of operation of the injector

Injector composition:

- The electronic control unit is the brain of the car, a microcomputer that is responsible for processing the collected information, calculations and distribution of commands based on the analysis and calculation program stored in its memory. The speed of calculations allows you to quickly respond to adjustments in readings and change commands sent to the fuel system.

- Fuel pump - responsible for the forced supply of fuel to the engine through the fuel line.

- Injectors are actuators that dose the flow of fuel into the engine at the command of the control unit.

- Sensors - collect, record and send the necessary data about the operation of the system to the control unit.

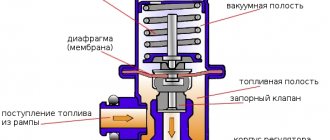

- The pressure regulator is a diaphragm valve that adjusts the pressure in the fuel line in accordance with the needs of the engine operating mode.

Brief description of the injection system

- the engine sucks in air, the required volume of which is determined by the force of pressing the gas pedal;

- the volume of air that enters the engine is recorded by an air flow sensor (AFS);

- the collected data enters the injector control unit together with information from other system sensors (engine temperature, spatial position and crankshaft rotation speed, position and speed of throttle valve opening);

- the control unit analyzes the received information and determines the volume of fuel that should enter the engine for co-combustion as part of a mixture with the incoming volume of air, and the optimal time to start supplying fuel;

- the computer sends a pulse of a certain duration to the injector nozzles;

- the injectors open under the influence of an impulse and fuel enters the engine;

- the time during which the injectors will be open is determined by the duration of the pulse sent;

- The fuel mixture entering the combustion chamber is burned, and the resulting energy ensures the operation of the vehicle’s mechanisms.

Unstable operation becomes most noticeable on a cold engine, while it is warming up, especially in the winter. At this moment, the standard gradual decrease in speed is replaced by arbitrary fluctuations in the tachometer readings, the amplitude of which varies in the range of 500-1500 rpm.

If the idle air injection valve is working properly, a characteristic click should be heard at the moment of contact; its absence means that the device is faulty

Prolonged operation of a vehicle with jumping engine speeds at idle is fraught with consequences:

- the engine stalls;

- the threat of detonation increases;

- power and performance decreases;

- fuel consumption increases.

Why is the engine idling high?

Owners of front-wheel drive VAZs have enough troubles throughout the entire operation of the car. One of the most annoying is high idle speeds, moreover, on an already warmed-up car. This problem usually causes annoyance because there are too many reasons for its occurrence, and finding them is not easy.

Let's list them.

- The most basic is a malfunction or failure of the mass air flow sensor.

- No less common is the breakdown of the idle air control valve.

- A crankshaft position sensor providing incorrect information to the control unit can also be the root cause of a high or floating idle.

- The throttle position sensor may also be to blame.

- It happens that for some reason the gas pedal does not return all the way back. Moreover, this happens both because of a banal malfunction of the cable, and because of something completely ridiculous - for example, after washing the car, they covered the driver’s mat in such a way that the tip of the mat began to touch the pedal.

- The air filter is very clogged. Because of this, the combustion mixture is too rich in gasoline, again resulting in high idle speeds.

- The cable came off the throttle valve.

- Engine temperature sensor faulty. It gives the car’s “brains” incorrect values, which increase the crankshaft speed, thinking that the engine is cold.

As you can see, we have before us a whole forest of very different reasons why high revs appear! Next, we will take a closer look at the most typical, plus the most common problems associated with the problem described. At the same time, we’ll figure out how to eliminate them with our own hands.

Idling

Idling of a car is the operation of its engine when the gear is in neutral. At the same time, the fuel load, as well as the load on the engine, is minimal.

Idling is used in several cases:

- To “bleed” the oil after the car has been parked for a long time.

- To warm it up during cold weather.

- To keep the engine running for a long time without driving the vehicle.

Idling VAZ 2114

Engine idle operation looks like this: first, the speed quickly rises to 2,000 or even 2,500 rpm, after which it gradually decreases and stops around the 800 rpm mark.

This type of engine operation is absolutely normal. If, in idle mode, the VAZ 2114’s revolutions jump (either sharply increase or drop sharply, and the interval of “jumps” can be up to 1,500 rpm), then a malfunction has occurred in the engine system. In most cases, such a sharp fluctuation in speed leads to the engine stalling.

Despite the common opinion, driving a car with “floating” speed is unacceptable, as this can lead to serious consequences, including engine damage. When the first signs of this phenomenon appear, travel should be stopped and urgent repairs performed.

Throttle valve

If after all the checks and measurements carried out above it was not possible to identify a malfunction, then all that remains is to check the condition of the throttle valve assembly. To do this, the part should be dismantled and then cleaned of dirt using cotton swabs. The cleaned part (or rather, all its pipes and tubules) is blown with compressed air using a compressor.

Cleaning the throttle VAZ 2114

Special attention should be paid to the channel that serves to remove gases from the crankcase. Before starting purging, it should be filled with a cleaning compound and allowed to stand for some time, after which the purging itself should be carried out.

This is caused by the extremely small diameter of the internal channel, as a result of which other methods of cleaning it are simply not available.

In addition to all of the above breakdowns, a breakdown of the DPKV sensor, as well as the Hall sensor, can also lead to “floating” speed. If they fail, the Check Engine light will light up on the car panel. If such a malfunction occurs, it is best to contact a service center, since special equipment is required to check these sensors.

>Useful video

You can glean additional interesting information from the video below:

The following two tabs change content below.

- Bio

- Latest Posts

admin1

I am a professional in the field of Auto Electrics and Auto Diagnostics. Work experience more than 10 years. I will identify and eliminate faults of any complexity. (Even with cars that Dealers and services cannot handle, as it were, of the highest class). We carry out all types of work on the installation of additional electrical equipment (xenon, multimedia system, special signals, etc.)