Fillinn

Claimed, Russia , ordered and supervised by PRIDE USA

Approximate price: 60 rub.

White emulsion. It looks like it's polymer. It comes loose easily and begins to act immediately after entering the tank. I was unable to heal a 1 mm hole; I managed to heal the rest, but not quickly. The level of residual deposits is high.

+ Relatively cheap composition.

- In case of serious damage, it may not save.

5th–6th place. Cooling system sealant Gunk Radiator Sealer Super

Radiator sealant Liqui Moly: reviews

As you would expect, car enthusiasts do not discount the brand. Yes, this product works, but experienced drivers prefer an iron-on radiator repair. No matter what the manufacturer says, the channels still get clogged. German liquid only works against microcracks with warm or even hot antifreeze. The price is not very affordable (about 1000 rubles versus 500 for analogues from other manufacturers), it works worse than the Manol radiator sealant, reviews of which indicate better results.

Hi-Gear Stop Leak (Gold Formula)

Declared manufacturer: USA

Approximate price: 190 rub.

The blue-green fibrous substance, after stirring, healed the holes in a strange way - the leaks either stopped or started again. Complete closure of the holes occurred after the antifreeze had left the expansion tank: it had to be topped up. As a result, even the drain hole was “healed”!

+ High efficiency, forms plugs even in large holes.

— It works quite slowly and spasmodically. Relatively high level of residual deposits.

3rd place. Cooling system sealant K-Seal

Not the worst, but not luxury either: Hi-Gear

This is a fairly popular drug on the domestic market. According to the packaging, it is made in the USA. Its cost is about 200 rubles. This is a blue-green thick mixture. The manufacturer recommends using the composition not just for repairs, but for complex and serious repair work on car radiators. The active substance is polymer. It can eliminate even serious holes. But, as tests by independent experts show, this takes a lot of time.

If the hole is more than 1 mm, then there is no need to make plans that the repair will take a couple of minutes. Often, antifreeze will escape through such a hole before the drug begins to act. To be safe, it is better to carry two cans at once. When working, you should prepare for various consequences, such as a clogged drain hole or radiator plug. What do car enthusiasts who have used Hi-Gear radiator sealant say? The reviews are different and divided into two categories – negative and positive.

After using the parts, car owners had to change the thermostat and sensors, pump and other parts of the cooling system. Others claim that they have been using this sealant for about 2 years and are happy with the result.

All products of this American brand are positioned as professional. They produce powder and liquid radiator sealant ABRO. The reviews are positive, it really works and quite quickly. The main thing is to strictly follow the manufacturer's instructions in everything. But after use, you need to pour it out of the system and rinse everything thoroughly - the channels in the CO become clogged.

Among the auto chemical products of this brand there is also dry powder radiator sealant ABRO. Reviews about it are the same. However, the product must also be removed, otherwise the channels will become clogged. Advantages - speed of operation, elimination of leaks up to 2 liters per minute, affordable price.

K-Seal

Declared manufacturer: USA

Approximate price: 430 rub.

The thick brown emulsion is declared to be “long-lasting” and does not require subsequent replacement of parts. Contains copper powder that forms durable plugs. It works quite effectively, but healing of large holes is slow. But there are very few deposits.

+ Low level of residual contamination.

— The most expensive drug in our sample.

2nd place. Liqui Moly Cooling System Sealant

Deterioration of the channels in the radiator

The use of sealants significantly reduces the efficiency of the radiator. So, the channels become clogged. In modern radiators, textolite or plastic spirals are installed, which are designed to improve heat transfer from the coolant to the surface of the radiator. The sealing agent settles on the surface of these spirals, thereby significantly reducing not only the throughput of the channels as a whole, but also the vortex effect. That is why those who have used sealant for the engine cooling system give reviews and advice that this is not a means of prevention. This is an effective way to prevent leakage in an emergency. After using the product, you will need to very thoroughly rinse the entire system and replace damaged parts.

"BBF Super"

Declared manufacturer: Russia

Approximate price: 55 rub.

The white emulsion works classically - it consistently and relatively quickly closes the holes from smaller to larger. There are very few residual deposits. After opening, neat fungi of polymer plugs are visible in the place of the holes. And at the same time - the cheapest composition among those tested!

+ The best price/quality combination. Lowest sediment level.

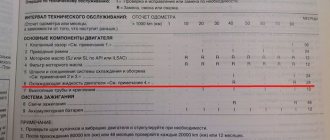

Final table (click to open full size):

Reviews about sealants

Although manufacturers indicate that their products do not affect performance, reviews from car enthusiasts vary.

Some note that after use, a deposit formed inside the cooling system, affecting the temperature regime, others point to blockage of the heater radiator tubes after applying the sealant, while others indicate that no problems arose.

The same applies to the service life of the sealant. Although they are positioned as means for temporary repairs, not all car owners, after using such substances, rush to carry out a full restoration of the system by soldering or replacing the damaged element.

Some car enthusiasts indicate that the product helped eliminate the crack for only 3 months, although there are reviews that say that the sealant “holds” the liquid for more than 2 years. Therefore, there is no clear opinion here, everything is purely individual.

Finally, we point out that sealants are chemicals, so you need to work with them very carefully and avoid getting them on your skin.

As for the filling technology itself, it is worth remembering that after the engine heats up, pressure forms inside the system, so the caps of radiators and expansion tanks must be removed slowly and carefully using gloves.

What sealant did you use? Leave your feedback in the comments, your opinion is important to us.

SEALANT TEST RESULTS

Mikhail Kolodochkin and Alexander Shabanov Candidate of Technical Sciences, Associate Professor of the Department of Internal Combustion, St. Petersburg Polytechnic University

The appearance of antifreeze leaks becomes the main problem of the cooling system. This occurs due to significant temperature changes, as a result of which thin-walled tubes fail. Also, an active corrosion process may begin in the system, mechanical damage may occur, etc. As a result, microcracks appear through which coolant leaks or evaporates.

It is quite obvious that it is better to replace a failed part, but this is not always possible, especially on the road. The fact is that most work related to the cooling system involves draining antifreeze, removing the radiator, etc. For this reason, cooling system sealants are very popular as a temporary remedy. Next we will talk about how these products work, what needs to be taken into account when choosing a sealant, which sealant for the engine cooling system pipes is better to choose and whether it is necessary.

Read in this article

Pros and cons of using sealants

Automotive radiator sealants have clear advantages, and the most important of them is the ability to get to a repair shop, keeping the engine from overheating. They are ideal as an emergency measure when calling a tow truck is not possible. There is no need to coat the radiator walls with sealants; they are simply poured into the system, which is very quick and convenient.

However, sealant is only a temporary solution. Any product clogs the system to varying degrees, reduces its efficiency, and reduces the service life of components. Therefore, it is necessary to flush the radiator as soon as possible to remove residual sealant and sediment. In any case, this is cheaper than replacing engine parts, which will have to be done after it overheats. Another disadvantage is the inability to repair too large holes: in some cases, mechanical repairs have to be made immediately.

Sealants for the internal combustion engine cooling system: principle of operation and selection features

Sealant for the engine cooling system is a special product that allows you to eliminate minor cracks and other defects in tubes and pipes. A large number of such elements with thin internal walls form the basis of the basic elements of the internal combustion engine cooling system. We are talking about a cooling radiator and a heater radiator.

So, let's begin. Many experienced car owners have been familiar with one remedy for dealing with sudden radiator leaks for decades. This is ordinary mustard, or more precisely, mustard powder. The specified powder is poured into the radiator, after which small cracks are clogged from the inside. This method was actively used on domestic cars with brass radiators, and was used on cars with aluminum radiators, etc.

How do sealants work to eliminate radiator leaks?

Now let's return to sealants, which are a modern way to solve this problem. The principle of action of such compositions is similar to mustard, that is, it is based on “tightening” or clogging the crack. At the same time, manufacturers promise minimal risks for the cooling system itself. At the same time, it should be taken into account that such special equipment can be either high-quality products or an outright fake. In other words, cheap sealants may in fact turn out to be not a special composition, but the same mustard, flour, construction adhesive, etc.

After using such products, the tubes may be covered with a layer of sealant, the cross-section of the internal channels will decrease, as a result of which the passage of antifreeze may partially or completely stop. Most often, the heater radiator becomes clogged, the heater stops heating, and the cooling radiator significantly overheats. It turns out that a low-quality sealant can lead to overheating of the entire engine. Considering the fact that there are a large number of similar products on the market, you need to approach your choice carefully. Moreover, there are no norms, standards or special techniques that allow you to check the sealant and its quality. For this reason, it cannot be unequivocally stated that the best sealant will be an exclusive product of one brand or another. Let's figure it out.

- As practice shows, original sealants from well-known manufacturers Hi-Gear, Liqui Moly, Lavr and other domestic and foreign manufacturers usually cope well with the task. In other words, the cracks are “healed” and the leak stops. The only difference can be considered the time difference. Some compositions quickly cover defects (1-2 minutes), others require about 10 minutes to eliminate the leak. It is worth considering that we are talking about defects up to 1 mm.

- Also note that some products can close a large hole faster, but take longer to deal with a small one. Others instantly eliminate defects of 0.3-0.5 mm, but take a very long time to close holes of 0.7 mm or more. Some products can quickly eliminate any leak, but for a very short time, especially if we are talking about large defects. After this, the leak resumes, and then the composition needs another 10-15 minutes, after which the leak stops again. This means that you cannot drive safely after using the sealant in this case, since the level of antifreeze in the tank may drop to a critical level. In the case of affordable sealants (for example, Fillinn), you should be prepared for the fact that such solutions will work with damage up to 0.5 mm. Defects from 0.7 to 1 mm. such means can no longer be eliminated.

- Analysis of the operating efficiency of the cooling system itself after using the sealant also does not reveal significant deviations from normal operation. Antifreeze does not react with the composition, the thermostat does not jam, and the engine temperature does not rise above the permissible operating range. It turns out that a high-quality product does not cause severe harm to the system. In parallel with this, any sealants still affect the elements of the cooling system. Various agents deposit to a greater or lesser extent on the walls of tubes and surfaces of parts, and the hydraulic resistance to coolant flow changes. In a word, deposits in the cooling system appear on the pump, in the channels of the cylinder block and on the walls of various pipes, but the overall performance of the system is not affected.

- After using sealant, you should expect possible consequences in the form of clogged drain holes when draining antifreeze from the system. These holes must be mechanically cleaned for normal drainage of the working fluid.

Means for the prevention of the cooling system

Liqui Moly

Liqui Moly effectively removes dirt and scale, which improves heat transfer. It is universal, suitable for almost any cooling system. The manufacturer recommends using the drug for prevention on the eve of each coolant change.

If you have a leak in the radiator of the engine cooling system, do not rush to replace the radiator. When using means to restore the cooling system, there is a high probability of repairing such a malfunction. When choosing a sealant to eliminate radiator leaks, you need to decide on what is on the market today and the problems that it should solve

What's the result?

As can be seen from the above, cooling system sealants from well-known manufacturers can be a good solution in emergency situations. Most of the commercially available compounds cope well even with large damages up to 1 mm, that is, if a microcrack appears, there should be no problems.

Also, the performance of the cooling system is not particularly affected. It turns out that pouring sealant should not be a case where you can only aggravate the situation and overheat the engine after using special equipment. However, using sealant in cars solely for prevention (without leaks) is also not recommended, because unwanted deposits appear one way or another.

And also, regarding the sealant for the cooling system pipes. In practice, it is recommended not to use this solution, although pipe leaks often appear in the seats. In this case, it is better to replace the worn pipes and clamps with new ones. If the pipes are “fresh” but leak after removal, then you need to securely tighten them with clamps. The fact is that sealants do not cope well with cracks in rubber elements; in the case of plastic, the result may also be unsatisfactory.

Basic methods for repairing a cracked engine block. Crack detection, repair by welding, riveting or applying an epoxy layer.

Reasons why coolant starts to leak. How to find the location of an antifreeze or antifreeze leak yourself. Useful tips and tricks.

Types of sealants for car engines: anaerobic, silicone, belt sealants. Operating principle, differences, scope of application. How to choose the best sealant.

Why do antifreeze or antifreeze enter the engine cylinders and what to do in such a situation. How to determine the presence of antifreeze in the cylinders yourself, repair methods.

Checking the car cooling system pump. Main symptoms of malfunctions. Diagnostics of the water pump without removal, troubleshooting with removal from the engine.

Repairing a cast iron or aluminum engine cylinder block using a liner. Types of sleeves and how the sleeves are inserted into the block. Tips and tricks.

The article will talk about sealants for the car cooling system, what types there are, what the market offers, features of application, principle of operation, when and which product is best to use and how long it will last, reviews of sealants will be considered.

History of sealant

When these means did not yet exist, the problem of leaking radiators and cooling systems was already acute for motorists. We had to look for simple ways that could help, if necessary, to urgently seal the system.

So, they used to use dry mustard. When added to coolant, the composition in powder form can very quickly reduce or completely eliminate coolant leaks. But after using such a “medicine” it was necessary to wash everything off. After all, the powder clogged not only microcracks, but also all the cavities of the cooling system. Today mustard is no longer used. But then, with the help of it, drivers drove from 300 to 500 km. This recipe greatly helped Soviet army drivers survive in Afghanistan.

The modern chemical industry is constantly developing and has already mastered the production of a wide variety of products that allow you to quickly eliminate any leaks and get to a service station. There are many types of these funds. Drivers are often interested in what is the best sealant for the cooling system. Reviews are also of interest to car owners. Reviews are much better than any advertising. They show how effective a particular product is in reality.

What affects the temperature of the engine?

The normal operation of the vehicle's power plant and its service life largely depend on factors such as the optimal temperature regime, which is provided by the cooling system.

Maintaining the required temperature is possible only under two conditions - proper operation of the components and elements of the system, as well as its tightness.

But it often happens that the cooling system leaks. But it’s one thing when a leak appears in rubber elements - pipes and pipes or at their connections, and quite another thing if the coolant leaks due to damage to the radiator or a crack in the cylinder head, the block itself or the gasket between them.

In the first case, fixing the problem will not be difficult - just tighten the clamps or replace the damaged tube. That is, such repairs are simple and not expensive.

But if one of the radiators (the main one, the stove) is leaking or traces of liquid constantly appear in a certain area of the engine (where the pipes do not go through) - everything is much more complicated.

And in this case, the best option would be to contact a service station or fix the leak yourself by sealing the crack (for radiator leaks) or replacing the cylinder head gasket. In general, repairing leaks on metal elements is quite troublesome and complicated.

At the same time, leaks often appear either on the way, or at a time when the car is really needed and there is simply no time for repairs.

In such cases, you can do differently - leave everything as is, and simply constantly monitor the coolant level, or use a sealant for the cooling system, which is now widely represented on the auto chemical market.

Why does the leakage problem occur?

First of all, the problem may appear due to mechanical stress. If coolants that are not suitable for this material are used. In addition, the damage may have occurred due to the age of the pipes and radiator. If the damage is small, it is extremely difficult to notice them; they do not affect external work. And a puddle of antifreeze under the car only forms due to large cracks. Minor damage can be detected by carefully monitoring the fluid level in the radiator. If it decreases, this indicates a problem.

At its core, a sealant is a compound that can seal small holes and cracks, helping to create an airtight space. There are different types of sealant. The first is powder. It needs to be poured into the radiator when a leak appears. They can repair small damage, the size of which does not exceed a millimeter. Unfortunately, this substance can clog not only small cracks, but also radiator channels, which negatively affects their operation.

Liquid sealants contain polymers and small metal particles. They are mainly used for engines and radiators. The polymers contained in the sealing fluid cling to sharp edges and rough edges, smoothing them out. This type is always located inside the cooling system and can be easily removed. Unfortunately, it is only suitable for small holes, the size of which will not exceed a millimeter.

We recommend:

Pre-filter fuel: where is it located and how to replace it

Polymer sealants containing special fibers. The latter improve the connection of particles with each other.

This type of sealant can cope with a hole up to two millimeters in size within a few minutes.

Purpose and types of sealants

Sealants for the cooling system are special liquids or powders that allow you to seal leaks in the shortest possible time without disassembling and soldering.

Their use makes it possible to get rid of coolant leaks even on the road, since they are very simple to use and do not require any equipment or tools.

It is noteworthy that earlier, before the advent of such products, many car enthusiasts used a “folk” sealant - powder mustard, which was poured into the cooling system. She coped with her task quite well, but she also did a lot of harm.

Note that sealants are classified as so-called “temporary repairs”. That is, they will fix the leak, but for a while, so that it is possible to get to the place of full repair.

Manufacturers produce several types of sealants for cooling systems, differing in composition, state of aggregation, and properties.

All of them can be divided into:

- Powder;

- Polymer;

- Polymer sealants with the addition of metal components;

Each of them has its own characteristics and rules of application. Thus, powder products are made in the form of a fine powder, insoluble in the coolant, which, after filling, circulates through the system.

At the leak site, it clings to the edges of the crack and sticks together, sealing the damage.

Polymer sealants are made in the form of an emulsion poured into the radiator or expansion tank.

This product contains polymer particles that have a rather interesting property - after heating, upon contact with air, they polymerize, that is, they freeze and become solid.

When an emulsion is used, it circulates, but the particles do not settle or harden on surfaces, so they are considered harmless.

At the point of leakage, the emulsion comes out along with the coolant, where a reaction with air occurs, as a result of which the crack is clogged.

Metal-polymer sealants differ from those described above by the presence of copper powder in the composition.

This product acts in the same way as a conventional polymer one, but the metal additive significantly increases the strength of the resulting plug, allowing the car to be used for a longer period without a full repair of the cooling system.

Additionally, various additives can be used in sealants to enhance the properties of the product and have a positive effect - ceramic elements, inhibitors, lubricants and others.

Effect of sealants

Is it worth using sealants in the system, are they reliable? Such compositions have a unique method of application: when they get into a crack and come into contact with the liquid inside the tank, they begin to harden, taking the shape of a plug. This “patch” does not dissolve or spread, so liquid leakage is eliminated.

After polymerization, sealants are not subject to the negative effects of temperature changes and vibration, they work no worse than welds. If we consider metal-ceramic sealant, then upon contact with air it expands slightly, and is also very durable. This helps the composition to reliably eliminate even severe leaks.

What does the market offer?

Hi-Gear metal-ceramic

Metal-polymer liquid sealant for cooling systems with the addition of ceramic elements to increase the strength of the resulting plug.

The manufacturer claims that this sealant can seal any leaks (in the block, cylinder head and its gasket, radiators), and the service life of the sealant is not limited. It goes on sale in metal containers of various sizes.

Using the sealant is very simple - fill in all the emulsion, start the engine and let it idle for 5-7 minutes. In this case, it is necessary to open the coolant supply to the heater radiator so that the product is evenly distributed.

Wynns Cylinder Block Seal

A polymer sealant designed to seal cracks in the cylinder head and cylinder block, but is not capable of eliminating cylinder head gasket and radiator leaks. Moreover, the product can eliminate not only external, but also internal leaks.

The technology of use is more complicated than the means described above. To eliminate the leak, you need to drain the coolant and rinse and fill the system with plain water.

The sealant is poured into the pipe running from the radiator to the thermostat housing, after which the pipe is put in place.

Next, warm up the engine completely and let it run for 15-20 minutes. Drain the water, change the thermostat and add antifreeze.

In the case of sealing an internal crack (in the cylinder), additionally after warming up, you will still have to provide air access to the cylinder by removing the spark plug or nozzle (so that the polymerization process can take place).

Abro AB-404

Powder-type sealant is mainly intended to restore the integrity of radiators, but it can also seal cracks in the engine.

Compatible with different types of antifreeze, as well as ordinary water. Suitable for preventive measures.

The method of application is not complicated. We start and warm up the engine, first bringing the coolant level to normal.

With the engine running, pour the powder into the neck of the radiator and let the power unit run for 10-15 minutes, after which we check the radiator for leaks.

Mannol Radiator Leak-Stop

Polymer sealant for eliminating leaks in the radiator, pipes, and joints.

1 container of the product is intended for use in a cooling system with a volume of up to 13 liters. Compatible with any antifreeze, neutral to metals.

The technology of application is not much different from other means. Before filling, warm up the engine a little, turn it off, pour sealant into the radiator or expansion tank, start the engine and let it run for 15-20 minutes.

Liqui Moly Kuhlerdichter

Polymer liquid product for eliminating small cracks in cooling jackets and radiators. 1 container is enough for a 10-liter cooling system.

The peculiarity of use is that the liquid must be poured into warm coolant while the engine is running. After filling, it takes time to seal the cracks - 10 minutes with the engine running.

Abro Sl-624

Liquid sealant of polymer type with the addition of additives - lubricants, corrosion inhibitors. Compatible with all types of antifreeze. Provides elimination of leaks in radiators and cooling jackets. The application technology is no different from Abro AB-404.

Hi-Gear

Metal sealant for complex repairs of the cooling system - a metal-polymer sealant that allows you to seal cracks in the cylinder head and block, as well as leaks through the cylinder head head. Compatible with water only.

The application technology is in many ways similar to Wynns Cylinder Block Seal.

The cooling system must be flushed and filled with water (but not completely). Before pouring the sealant must be mixed with 2.5 liters of water.

After pouring the resulting mixture, adjust the level, start the engine and let it run for 15-20 minutes.

Then drain the water and sealant and dry the system for 24 hours (with the lids open and the plugs removed).

In the future, any antifreeze can be poured into the engine.

Liqui Moly Lecksucher

Not a sealant, this product helps identify leaks in the cooling system before repairs. It contains fluorescent components.

After pouring the product and running it through the system, using the light of indicator lamps, you can detect leaks.

XADO Atomex Stop Leak Radiator and XADO Stop Leak

Polymer-type products for sealing cracks and damage (up to 0.9 mm in size) in a variety of elements of the cooling system - radiator, cooling jacket. The method of application is identical to Mannol.

Hi-Gear

Monophase metal-polymer liquid with the addition of ceramic components. Suitable for use with any antifreeze. Neutral to metals and rubber elements.

The method of application is the same as with most sealants: warm up the engine, fill in the product, let the engine run for 5-10 minutes.

Nowax Radiator Leak Stop

This polymer sealant is positioned as a means for restoring the tightness of the radiator, although it can also cope with leaks in other components of the cooling system.

Does not react with metals. The technology of application is the same as that of Mannol.

Step Up

Polymer sealant with the addition of aluminum components. Provides sealing of cracks in radiators and cooling jackets.

Like all products, this sealant is poured into the cooling system of a heated engine.

After pouring, it is necessary to give time to achieve the desired effect - 15-20 minutes.

Wynns Cooling System Stop Leak

A polymer-type sealant that allows you to seal small and medium-sized cracks (up to 1.8 mm in size).

Contains corrosion inhibitors. Neutral to rubber elements. The method of use is no different from Step Up or Mannol.

Application

All products have similar instructions for use:

- The engine must be turned off and completely cool.

- Before use, shake the bottle of liquid well and pour it into the radiator, first removing the cap. If there is no cap, you can fill the liquid through the upper nozzle by first disconnecting the hose. Many liquids can be poured into the expansion tank by first draining 2-3 liters of cooling liquid. But this method is not suitable for HG9048, HG9072 sealants.

- Fill with antifreeze or antifreeze to the required level.

- If the design includes a heater tap, it must be opened.

- Start the car and warm it up for about 7 minutes at idle speed (2000 to 3000 rpm).

- Stop the engine and let the engine cool down.

- Refill with antifreeze or antifreeze until normal.

The instructions for a sealant that is used only with water will be slightly different:

- The engine must be turned off and completely cool.

- If the design includes a heater tap, it must be opened.

- The existing coolant must be completely drained.

- Flush the entire cooling system with water twice. Each flush is accompanied by warming up the engine. If the system is heavily contaminated, it is recommended to first flush it with a special flush for the cooling system.

- Take 2.5 liters of water and mix with the contents of the bottle. The resulting solution is poured into the system, water is added to the norm.

- Warm up the engine at idle speed at medium speed for about 20 minutes. After the time has elapsed, the leak should stop. If this does not happen, wait a few more minutes.

- Then the engine is completely cooled and all the water is drained.

- The cooling system needs to dry out for at least 3 hours, leaving it completely open. For complete drying, it is better to leave it to dry for a day.

- After this, fill in antifreeze or antifreeze.

Removing sealant and properly flushing the radiator

Another important process is flushing the radiator from residual sealant. It is done as follows:

- Cool the engine first;

- Be sure to drain all antifreeze from the system;

- Pour the flushing agent of your choice into the system itself;

- Drain the product and warm up the engine. Leave it idle for half an hour.

- Rinse the system thoroughly after cooling the engine by pouring distilled or simply filtered warm water into it. Let the engine idle for the next ten to fifteen minutes to warm up, then drain the water. If necessary, the procedure can be repeated.

- You can fill in new antifreeze.

WATCH THE VIDEO

If the instructions for your product are different, you should use them to avoid problems and malfunctions.

How to pour sealant into a radiator

Features of choosing a cigarette lighter splitter

An approximate algorithm for using sealants in the cooling system will be as follows:

- It is necessary to open the radiator cap only with the engine turned off and slightly cooled!

- Pour or pour (depending on the type of sealant) into the radiator the amount of compound specified in the instructions.

- Start the engine and let it run for a few minutes, then turn it off.

- After some time, check for leaks with the engine running.

If the leak still remains, then there are several options:

- You have used the sealant incorrectly.

- The size of the crack is too large and the product is not able to cope with it. In this case, it is necessary to repair the damaged element.

- The sealant is ineffective.

Remember that the use of any sealant, regardless of its type, is only a so-called half-measure aimed at temporarily eliminating a leak

. As soon as the opportunity arises, you should definitely carry out a full diagnosis and repair of damaged elements of the cooling system or replace them.

Rules for using sealants

Several recommendations will help you use the products most effectively when repairing your car:

- Prepare the surface on which the sealant will be applied, clean it from dirt, dust, and dry it.

- Degrease with white spirit or gasoline.

- Carefully, so as not to scratch the surface, remove the remnants of the old seals. Do not use, for example, sandpaper for these purposes.

- Apply the product to one of the parts to be joined. Make sure that the line is closed, continuous, without breaks, in a layer of 1 mm, no more, since the excess mass will be squeezed out and can get into other places, clogging them.

- Give the sealant 10–15 minutes to dry, connect the parts, tighten the bolts, wait another 20 minutes and finally tighten the fasteners. Do not overtighten the connections.

- Allow the sealant to dry for a better seal. The time is indicated on the package: usually 0.5–12 hours.

How to flush a radiator from sealant

As mentioned above, the use of sealant leads to the formation of plaque in the car’s cooling system on the internal surfaces of its components, which interferes with its normal operation. The consequence of this is the need to clean the system from contaminants using special means. There are several types of them, including the so-called folk, homemade and factory-made.

Thus, folk cleaning products include citric acid, acetic acid, the famous Fanta drink, lactic acid, whey, caustic soda. You can also dissolve the radiator sealant using factory-made products, which are currently abundant on the market. Some of the most popular are LAVR Radiator Flush Classic, Hi-Gear Radiator Flush, LIQUI MOLY Kuhler-Reiniger. They effectively clean the radiator and other elements of the cooling and heating system. Please read the operating instructions carefully before using them.

How to flush the engine cooling system?

List of products for cleaning the engine cooling system. What is better to rinse, and what is not worth cleaning the radiator and all components?

Conclusion

Using radiator sealant is a good temporary solution to fix an antifreeze leak, provided the damage is small. However, its constant use leads to significant clogging of not only the cooling system, but also the engine itself. On the Internet you can find many unpleasant stories about how sealants used on a regular basis literally “killed” internal combustion engines. Therefore, whenever possible, after using radiator sealant, perform appropriate diagnostics and repairs.

What means should I use?

Dear vehicle owners, do not forget that sealant to one degree or another reduces the overall efficiency of the engine cooling system, and therefore should be used in extreme cases. It is a temporary remedy. Not suitable for continuous use and does not eliminate the need to visit a car service center.

As the best express assistants for a motorist when detecting a radiator leak, we should recommend 2 products - BBF Super and Liqui Moly. They are distinguished by high efficiency, rapid formation of “patches”, and a relatively long period of action. Easily flushed out of the system after temporary repair tasks have been completed.

Video: Radiator sealant, application experience!

COOLING SYSTEM - PREVENTION IS BETTER THAN CURE

Experienced motorists know that most car breakdowns that require expensive repairs are associated with a malfunction of the cooling system, leading to engine overheating.

Unfortunately, the cooling system is remembered only in critical situations. At best, car enthusiasts maintain the coolant level, but measuring its density is an ideal option. However, the coolant and the entire cooling system as a whole deserve closer attention. Only one quarter of the energy released during the combustion of fuel in the engine cylinders is used to move the car. about 36% of the energy “evaporates” through the muffler into the atmosphere, approximately 7% goes to overcome the forces of internal friction, and the remaining 33% is absorbed by the cooling system.

The main reasons for cooling system failure are:

— loss of system tightness due to destruction of the water pump seals due to the presence of scale and rust particles in the coolant;

- deterioration of heat transfer from the surface to the coolant due to contamination of the system with scale, rust, and deposits.

In most cases, the “disease” creeps up gradually: the temperature gauge needle trembles at the red line, the engine “pulls” poorly. These phenomena are fraught with very serious consequences: deformation of the block head, or even engine jamming, followed by expensive repairs. One of the suggested solutions is preventative maintenance of the cooling system. Apparently, replacing the coolant once every two years, as recommended by reference manuals, is not a sufficient measure. After all, during this period of years, antifreeze develops the resource of the additive package contained in it and certainly needs to be completely updated. It is in updating, and not replacement, since with the traditional procedure it is possible to replace approximately 3/4 of the volume of old antifreeze, 25% of the liquid remains in the system. Let's not forget about deposits, which sometimes simply block various channels of the cooling system. Complex “treatment” is possible with the help of special reagents developed by Khimpromproekt JSC and well known to car enthusiasts for servicing the cooling system: Cooling system flushing and Cooling system sealant under the BBF TM. Before draining antifreeze from the cooling system, it is recommended to use the Cooling System Flush. Its composition allows you to clean any even neglected system from scale, fat deposits, rust, and decomposition products of antifreeze (antifreeze). The main advantage of flushing is the presence of a corrosion inhibitor in its composition. The composition is safe for aluminum, steel, cast iron, plastic rubber parts and non-ferrous alloys.

Trial

It is interesting that there are no regulations and standards for automotive sealants either in our country or in the world. That is why you have to make do with an impromptu test that simulates a leak as a result of natural wear and tear on the radiator.

Holes with a diameter of 0.3 to 1 millimeters were drilled in the tubes - the smallest imitate microcracks, and the largest - the consequences of being hit by a small stone. The main indicator for a sealing compound is the speed at which such holes are tightened. In addition, the level of deposits on various components of the cooling system and the durability of such a “patch” are assessed.

Number one

Many drivers are interested in which sealant is best for the cooling system - tests allow us to unequivocally state that the leader in the speed of eliminating holes is the BBF product, produced in Russia. The smallest holes with a diameter of up to 0.5 mm are closed by it within a minute, which allows you to save the remaining antifreeze in the cooling system.

It takes approximately 3 minutes to repair large cracks and damage from collisions with hard objects. The price of the sealant is also captivating, making it the most affordable among the comparison participants - you can purchase an incredibly effective product for only 90 rubles.

This liquid sealant is created on a polymer basis, which allows you to get rid of large deposits on various components of the cooling system. The drain hole remained open, and only small growths formed on the pipes, which can be easily removed by mechanical cleaning or washing with a special chemical.

The weight of the thermostat, pump impeller and heater core remained virtually unchanged. This means that most of the product was used to do useful work - tightening the holes in the engine cooling system radiator.

Sealant can also handle such cracks.

Lifetime tests have shown that the composition is quite resistant to changes in coolant temperature. The holes open only after 100 operating hours - this means that with a restored radiator you can not only take the shortest route to the service center, but also commute for some time.

Theoretically, the use of BBF sealant can extend the life of a damaged radiator almost indefinitely if you constantly add the product to the cooling system, but this is not worth checking in practice.

Worthy competitor

The sealing compound from the famous German manufacturer Liqui Moly performed very well. The main advantage of such a metal-based product is the durability of the resulting “patches.” Life tests show that sealed holes do not leak even after 100 operating hours.

Experts say that such radiator repairs can be practically permanent, but it is doubtful that they are more effective than soldering. In addition, the appearance of metal impurities in the cooling system can cause clogging of its channels and subsequent serious engine damage.

There are no deposits in the form of small build-ups, characteristic of polymer compounds, in the car’s cooling system. However, a driver using Liqui Moly sealant will have to face another problem. Metal inclusions settle on the radiator tubes, reducing their throughput, and also increase the mass of the pump impeller, reducing its durability.

Video review of Liqui Moly sealant:

Although you will not feel any dangerous consequences after the first use of the sealant, in order to cause damage to the cooling system, this product must be used regularly. It is worth mentioning that the cost of the German product is quite high - it is 350–400 rubles.

Metallic coolant pipe sealant is a little slow when tightening the smallest holes. If the Russian product under the BBF brand required about a minute for this, the result of the German analogue was approximately 90 seconds.

Radiator leak successfully stopped

However, it only takes 2 minutes to repair a large leak that can lead to a rapid loss of fluid in the car's cooling system - it seems that the innovative metal-based composition is indeed the most effective at dealing with large holes. This sealant is recommended for off-road driving enthusiasts to have in their car - if the radiator collides with a stone or large branch, you can repair the leak in a matter of minutes.

Not the worst option

The American Hi-Gear sealant, which is recommended by the manufacturer for complex repairs of car radiators, is quite popular on the Russian market. The polymer solution does eliminate even the largest holes, but it takes approximately three times longer than in the tests described above.

If a hole with a diameter of 1 millimeter or more appears, you will have to abandon plans for quick repairs - the antifreeze has time to leave before the hole is completely tightened. Therefore, you will have to stock up on two cans of the product at once or strictly dose it when using it for the first time.

When restoring your cooling system using Hi-Gear sealant, be prepared for unexpected consequences. The product works slowly, but then even closes the drain hole and radiator cap. To drain the antifreeze or add liquid to the cooling system, you will have to use a knife or screwdriver. The mass of deposits on the impeller and in the radiator tubes is also quite large, although it does not exceed safe limits.

Comparison of Hi-Gear and Step UP sealant:

The main advantage of the product from the American company is the long service life of the cooling system after restoration. The holes open after approximately 80–100 operating hours. Of course, we are not talking about a permanent solution to the problem, but a visit to a car service center can be postponed for a couple of days without fear of a recurrence of the leak. Considering the cost of 200 rubles, such a sealant clearly cannot be called the worst option.

Outsiders

There are also sealants on the Russian market that are clearly not suitable for eliminating leaks in the cooling system of cars. A striking example is the domestic products produced under the brands Felix and Fillinn, as well as the American composition Gunk.

All products have in common an exceptionally long operating time - while the sealant is trying to cope with the largest holes, the antifreeze will completely leak out of the cooling system. Domestic compounds were unable to cope with 1-mm holes, thereby proving their inability to help in critical situations that arise on the road.

At the same time, these sealants cannot be called cheap - they all cost from 200 rubles or more, which casts doubt on their value in comparison with the available composition from BBF.

Life tests showed the average durability of the repair results. The average time for opening the holes was 40–60 hours. Of course, it is not necessary to go straight to a car service center, but it is better to take care of solving the problem before the end of the day. Severe overheating of the engine in this case can cause early destruction of sealants - therefore they can really only be used for emergency repairs.

Overheating a car engine causes radiator cracks.

In addition, the following problems were noted during the operation of vehicles restored using these means:

- The volume of deposits in the radiator tubes is very large, which can lead to blockage;

- The weight of the pump impeller has increased significantly, which negatively affects its durability;

- The drain hole is completely or partially blocked.

After using these sealants, it is highly recommended to flush the cooling system to remove excess deposits that could cause serious damage. In addition, it can be assumed that 2-3 consecutive cases of sealant application are guaranteed to lead to blockage of the canals.