The crankshaft pulley is a part that plays a very important role in the performance of the machine. The design of the crankshaft pulley is quite simple, but periodically this unit needs to be replaced. In most cases, it is removed when the crankshaft oil seal has to be replaced.

But crankshaft pulleys are different, so now we will look in more detail at the types of crankshaft pulleys and what types of breakdowns are associated with this unit.

Crankshaft pulleys and their varieties

To operate the timing mechanism (gas distribution mechanism) of a pump, air conditioner or generator, a crankshaft pulley is used. There are different types of pulleys, each car has its own type.

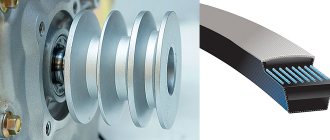

Crankshaft with V-belt pulley

Many modern cars use a belt that interacts with the alternator. For such a belt, a pulley with an all-cast or all-welded design is used, with the grooves clearly repeating the shape of the belt.

The pulley is secured with a nut or bolt, depending on the design, and is inserted through a key onto the end of the shaft. Thanks to its simple design, the pulley lasts a very long time and easily withstands the entire service life of the motor.

Crankshaft toothed pulley

If earlier a chain was used to drive the timing belt, then over time many cars abandoned it and switched to using a belt in order to lighten the system. Now all modern cars use exactly this design with a timing belt for timing drive. To ensure that the rotation angles of the crankshaft and camshaft match as well as possible, grooves were made on the inner surface of the belt, and there were teeth on the pulley.

And the teeth fit perfectly into the grooves for the belt. So, it is precisely because this pulley has teeth that it is called a crankshaft timing pulley. If you change the timing belt on time, the entire system will last a long time. If you forget to change the belt, then you will have to overhaul the entire engine.

Crankshaft damper pulley

Since when starting the engine or during a sharp increase in crankshaft speed, an increased load is created on the belt and the entire timing system. Therefore, car manufacturers began to equip the pulley with a special rubber layer - a damper. This layer is located between the outer working disk and the inner race. This design is widely used in engines installed on minibuses and other similar vehicles.

Thanks to the use of a damper, it was possible to reduce the service life of the pulley, since due to temperature changes, the rubber loses its elasticity and breaks down. Therefore, for the system to work properly, car owners need to monitor the condition of this damper and, if something happens, change the pulley so that the car remains on the move.

Checking the integrity of the crankshaft pulley

You can verify the serviceability of the pulley by visually inspecting it. The alternator belt allows you to preliminarily assess the presence of damage to the engine compartment. If it is motionless, but is intact, this usually confirms the destruction of the crankshaft pulley , or its displacement from the guide key.

You can certainly find out the cause of the malfunction by removing the right front wheel or driving the car into a pit or overpass. If the belt and generator shaft are stationary and the car does not start, it is necessary to check the integrity of the pulley and the reliability of its fastening. Most often, the disc becomes unusable due to delamination of the damper rubber bushing (not all have it!). In this case, the inner part of the pulley will rotate when you try to start the car.

As a result, the engine begins to malfunction. This malfunction can be identified by checking the location of the marks on the camshaft and crankshaft and the position of the drive disk at this moment.

How to replace a crankshaft pulley

Each car has its own characteristics for replacing the crankshaft pulley, but the principle is generally the same. If the engine is located lengthwise in the engine compartment, then the pulley will be in the lower front part of the engine compartment, immediately behind the radiator of the cooling system. If the engine is located transversely in the engine compartment, then in order to change the crankshaft pulley, you will have to remove the front right wheel.

Read more: Why do traffic lights have exactly these colors?

Also, many are concerned about what kind of thread is used on the crankshaft pulley, so as not to accidentally tear it off. After all, the nut that holds the crankshaft pulley is usually very tightly tightened. Therefore, you need to know exactly which way to turn.

But there is nothing complicated here - the thread is right-handed, so if you need to unscrew the nut, you need to turn it counterclockwise. You also need to understand that the crankshaft rotates in the opposite direction from the thread, so the nut is tightened even more during operation.

In addition, no one has canceled oxidation and corrosion, so after a certain time it will be really problematic to unscrew such a nut.

But if you know what to do, then everything becomes quite simple and replacing the crankshaft pulley will be a piece of cake. The actions are:

- The first thing you need to do is place the car over the pit and fix the wheels;

- if the motor is located transversely, then remove the wheel and place something under the brake disc instead of the wheel;

- We put a wrench of a suitable size on the nut or bolt head, but with a large lever and rest against the floor in the direction of rotation;

- remove the armored wire from the ignition distributor so that the engine does not start;

- Using the ignition key, we set the starter in motion; this force is enough to unscrew the nut or bolt.

As soon as the nut begins to unscrew, you can then manually unscrew it using a wrench. By the way, to make it easier to unscrew the nut, you can apply WD grease or another similar lubricant to it.

Next, you need to pull the pulley off the crankshaft, which is also not an easy task, since the belt and pulley are very firmly connected to each other and there is no play between them. In addition, the crankshaft pulley key is tightly fitted, which also provides resistance.

Therefore, it is advisable to use a special screw puller; you can also remove the pulley using a pry bar, pressing in different places on the back surface of the pulley.

If you manage to remove the pulley, then the most difficult work has already been done. It will not be difficult to install the pulley in its place; you need to do everything in the reverse order, and the crankshaft will provide a reliable clamp on its own.

And then a video about how to quickly unscrew the crankshaft pulley using the method described above:

— Functions of the crankshaft pulley

— Types of crankshaft pulleys

— Features of replacing the crankshaft pulley

Why do you need to twist the crankshaft pulley?

Chassis front and rear suspension VAZ 2110 2111 2112 Removing the lever and extension of the front suspension VAZ 2110 2111 2112

Dismantling the crankshaft pulley is performed for various reasons.

Crankshaft pulley

Most often it has to be removed when replacing the timing belt or replacing crankshaft seals. Usually the belt is changed either according to the regulations, or when defects are identified that require its replacement. Oil seals are replaced when oil leaks occur due to product wear.

On a VAZ 2114, the crankshaft pulley is secured with a bolt. During removal, a problem arises when unscrewing the mounting bolt. Firstly, it is inconvenient to get to. Secondly, at the factory they always tighten it very tightly so that it does not unscrew on the road. If a fastener comes loose while driving, it can result in costly repairs. During operation, thanks to the right-hand thread, the tightening is enhanced. In addition, coking and sticking of the part occurs. Thus, sometimes the bolt is very difficult to remove.

Tools

To successfully dismantle the VAZ 2114 crankshaft pulley and replace consumables, you should prepare the following tools:

- standard set of keys;

- jack;

- support or stump;

- socket head;

- extension;

- pulley puller;

- pry bar, screwdrivers.

It is more convenient to carry out work on a lift or ditch for inspection.

Stages of work

In order to remove the crankshaft pulley on a VAZ 2114, you need to dismantle some parts and components. The entire process of removing the crankshaft disc consists of the following steps:

- First, to dismantle the generator belt, you need to unscrew the locking bolt and loosen the tension bolt.

- Next, you need to lift the front of the car and remove the right front wheel.

- In the upper part of the engine compartment of the VAZ 2114, remove the air filter and the engine mud shield.

- Next, remove the alternator belt.

- To secure the flywheel from turning, you need to open the plug on the side of the VAZ 2114 clutch. Then insert a screwdriver or pry bar into the opened opening between the flywheel teeth.

Fix the flywheel and unscrew the bolt - Next we move on to unscrewing the fastener. To make it easier to unscrew, you need to apply special liquids to the threaded connection that corrode corrosion. For this purpose, special WD lubricant, brake fluid, and vinegar essence are suitable.

- Then the head of the key is put on and, using a lever, it is turned counterclockwise so as to tear the bolt from its original position.

We put the head on the bolt - If you are unable to unscrew the fastening element by hand, you can use the starter.

Unscrew the fastening bolt - Place the lever coming from the head against the spar or the floor in the direction of the shaft movement, and then turn the starter several times, giving the crankshaft a rotational impulse.

- After unscrewing the fastening element, you need to remove the crankshaft pulley. It is held in place by a key and is difficult to remove easily. You can use a special device with paws that cover the edges of the disk.

- If you don’t have a puller, you can use pry bars or screwdrivers by inserting them between the crankshaft and the pulley on each side, gradually moving the part to be removed away from the shaft. The touch point should be chosen closer to the crankshaft.

- Before removing the disk, it is advisable to tap it with a wooden hammer to avoid possible distortion. The part should be dismantled carefully so as not to damage the key and groove.

After completing the necessary replacement, when reinstalling the crankshaft pulley, the seats should be treated with grease so that the parts fit without effort. In this way, distortions can be avoided.

>Video “Replacing the crankshaft oil seal on a VAZ car”

In this video you can see how to unscrew the fastening nut and dismantle the crankshaft pulley.

Functions of the crankshaft pulley

A crankshaft pulley is one of the parts of the crankshaft of a car engine, which is attached to the front output (protruding beyond the engine crankcase) part of the shaft (toe) and with the help of a special toothed belt (in some engines - a chain) synchronizes the operation of the crankshaft and camshaft of the engine. In addition, the crankshaft pulley, through the timing belt, also transmits torque (in fact, provides energy) to a number of devices of the so-called “attachments” of the car engine:

- generator

- engine coolant pump

- power steering pump

- air conditioner

The crankshaft pulley also performs (along with the flywheel and balancers) the functions of damping vibrations and shocks of the crankshaft. During the production process of pulleys, they all undergo special balancing. As you can see, a number of important vehicle mechanisms, including the engine itself, depend on the trouble-free operation of the crankshaft pulley. If there is no strictly synchronous operation of the crankshaft and camshaft, the engine will not operate normally.

Read more: Photos of car brands with names

That is why every car owner is faced with the requirement to regularly replace the crankshaft pulley complete with the timing belt (and, as a rule, the coolant pump roller). For each car model, there is a certain frequency for replacing the crankshaft pulley and timing belt. Wear and stretching of the timing belts, wear of the crankshaft pulley or pump roller can lead to engine malfunction, and in the worst case, to a break in the timing belt with subsequent damage to the entire crank group of the engine. Therefore, regular maintenance and replacement of the timing belt and crankshaft pulley should be taken seriously.

Types of crankshaft pulleys

Crankshaft pulleys for V-belt

This type of pulleys and belts is found on Soviet and Russian designed engines, as well as on a number of foreign cars, for example, Audi cars. Such belts have a special wedge-shaped (trapezoidal) cross-section, and the crankshaft pulleys have a corresponding groove for such belts.

Crankshaft pulleys for toothed belt

They are found on most modern passenger cars. Both a pulley and a belt of this type have special teeth and grooves on their working surface.

Crankshaft damper pulleys

They differ from ordinary ones in that the damper pulley is, as it were, made up of two rings - a smaller (inner) and a larger (external) one. These rings are connected to each other by a rubber gasket, which dampens vibrations and vibrations of the pulley.

Features of replacing the crankshaft pulley

The need to accurately synchronize the operation of the crankshaft and camshaft of a car engine puts forward a number of specific requirements for replacing the crankshaft pulley. In particular, it is recommended to use special tools or devices to check the degree of tension of the timing belt, the tightening force of the nut (or bolt) securing the pulley, and to set a certain position of the crankshaft and camshaft. Timing belts also have special marks for their correct installation. Under no circumstances should oil or other technical liquids come into contact with the pulley and belt - in addition to having a negative effect on the material of the belt and pulley, they can lead to belt slippage and disruption of the synchronization of engine shafts.

Modern cars often have a special crankshaft position sensor that simply will not allow the engine to start with the crankshaft and camshafts in incorrect positions - this is done to prevent costly damage to the crank group that can result from careless maintenance.

One of the main technical features of dismantling the crankshaft pulley is the strong tightening of its fastening. The fastening thread is cut in such a way that the direction of unscrewing coincides with the direction of rotation of the shaft and pulley - this is done so that the pulley fastening does not unwind on its own. As a rule, dismantling the crankshaft pulley is possible only in the inspection hole. This often requires removing the wheel closest to the crankshaft pulley.

If you have a pneumatic impact wrench, removing the crankshaft pulley fastening is not a big problem. For Soviet and Russian cars, there is a folk recipe for unscrewing the crankshaft pulley using a starter (ATTENTION, we publish this method for general information, but we recommend that you do not risk your car, but entrust the replacement of the crankshaft pulley to qualified and experienced craftsmen with the appropriate equipment):

- First of all, you need to determine in which direction the shaft and pulley on your car’s engine rotate, and accordingly, in which direction you need to unscrew the pulley mount.

- Moisten the nut (bolt head) with a special liquid such as WD-40.

- The car is installed on the inspection hole, the wheels are fixed.

- If necessary, remove the wheel closest to the crankshaft pulley.

- A wrench with a long handle (or extended using improvised means) is placed on the crankshaft nut (bolt). The handle of the key must be rested against the floor or spar in the direction of rotation, making sure that such support is safe.

- Measures are taken to prevent the car from starting (the wire or terminal from the ignition is removed, each car model has its own method).

- The generator belt is removed.

- Turning on the ignition for a short time causes the crankshaft to turn, the key handle rests on the floor, the nut (bolt) is torn off, and then unscrewed with a regular key.

Read more: Chevrolet Cruze heated seat repair

Gentlemen, please tell me the number for the crankshaft pulley 2.0 E 115 l. Car without air conditioning. Photo is attached.

I added a video of how he gets sausage.

How to unscrew the crankshaft pulley bolt - solving the problem

The pulleys of front-wheel drive cars are usually secured with a bolt. In such vehicles, the pulley is oriented perpendicular to the axis of the machine, which, of course, complicates repair work (it is very difficult to get to the fastening). In order to unscrew the bolt as quickly and easily as possible, it is advisable to prepare in advance:

- set of auto tools;

- the so-called “stump” (or “tragus”);

- car jack;

- head (socket) with a lever and extension (the head must be selected according to the size of the bolt).

The process with these devices is as follows:

- remove the wheel (of course, before doing this you need to lift the front right part of the car with a jack);

- we install the vehicle on the “stump”;

- remove the engine shield, which protects it from dirt, the air filter (they are located on the top side of the hood) and the generator belt;

- open the plug on the clutch block so that you can fix the crankshaft, and wedge the flywheel teeth using a pry bar;

- We put the head on the bolt and begin to unscrew it (if it does not give in, we slowly increase the length of the lever).

FakeHeader

Comments 25

Hello everyone, the pulley has finally arrived, I ordered a used one. I loosened the generator belt, but it turned out that it was not necessary to loosen the pump and power supply pump belts. I installed the pulley and everything went away, now it doesn’t move, it spins smoothly. When examining the old pulley, it was discovered that the rubber gasket had worn out. The breakdown is solved! Thanks everyone for the advice.

The problem is most likely in the crankshaft gear (the key is licking, the gear is not clamped well, and the pulley is screwed to the gear). Unscrew the gear and look at the gear key and the crankshaft. My first motor had something similar (it licked a key). I bought a new gear and welded on a few mm of keys, since the socket for the key was broken on the crankshaft. I put it back together and everything is ok. Good luck!

The pulley needs to be replaced, the damper can be left. The vibration is apparently due to the fact that the pulley begins to turn little by little, the key is licked off, and the bump from the licked key lifts the pulley - as a result, vibration. Change the pulley before it's too late. When you pick it up, LOOK carefully at the key, I once came across one with a crack under the key (it was cast). It would be nice to order a bolt and use thread adhesive when installing it. Good luck.

You can just sharpen it)

My advice is to remove the belts and shake the pulley, the problem may be that the bolt that screws the timing gear to the crankshaft has come loose and the key has been cut off; this happened to me on my ACE, regarding advice and advisors, the block of the 2.0 is the same for all models! so take off the belts, check the play, if you don’t understand where it comes from, unscrew the pulley yourself and check if the timing gear is loose, here is the gear number 25158, and I think the pulley itself is fine, you didn’t hit the pulley or bend it, where could the play come from? I think it's a gear issue.