Why is oil leaking?

The main reason for this lies in the malfunction of the head itself and the gasket under it. The oil line and coolant pass through the cylinder head, so if the oil line is damaged, oil will begin to flow into the cooling system and will leak from under the head. This type of leakage is also an indication of a damaged head gasket. The consequences can be the most unpleasant - as the oil decreases, the lubrication of the engine's rubbing parts will deteriorate, which will very soon lead to their jamming. And this will entail, at a minimum, a major overhaul of the engine.

What to do if oil leaks from under the cylinder head? The most important thing is to establish the cause - after all, oil may be leaking from under the valve cover. As soon as the cause of oil leakage is established, you need to immediately take measures to eliminate it - simply wiping off the oil stains and calming down will not be enough. If oil is leaking from under the valve cover, then the gasket is most likely damaged. Although it is made of high-quality oil-resistant rubber, nevertheless, this sometimes happens. If oil leaks directly at the junction of the cylinder head and the block, then there may be several reasons - improper tightening of the bolts, damage to the gasket, and, most unpleasantly, damage to the head itself. If in the first case it is enough to tighten the bolts correctly, and in the second case to replace the gasket, then with the head it will be more difficult, here it all depends on the degree of damage. It also happens that oil leaks from under the spark plugs - this also indicates damage to the cylinder head - oil should not get into the cylinders.

Some car owners, having discovered that oil is leaking from under the cylinder head, do not understand the seriousness of the situation. And the lack of oil is compensated for by periodically adding it. Such a solution is completely unacceptable - after all, at the most inopportune moment the engine may fail. And no one can say when this will happen. But even after eliminating the malfunction, it is advisable to monitor the oil level not only by the sensor, but also by checking it with a dipstick. It might seem like a harmless drop of oil, but if you don’t take action, it can lead to major troubles. Therefore, it is strongly recommended to take corrective action as soon as possible upon detection.

Types of Gasket Defects

Oil leakage from under the cylinder head is most often caused by damage to the gasket. The main reasons for its destruction can be: rupture by gases; overheat; coolant leak; mechanical influences.

Violation of integrity by gases. One of the common causes of damage is associated with strong penetration of the exhaust gas composition between the second and third cylinders (during the exhaust cycle). The elastomer of the gasket is destroyed in the area of the hole for the passage of the coolant. This phenomenon is caused by the following reasons: the penetration of gases into the cooling liquid due to poor tightening of the bolts; lowering the cylinder liner; deformation of elements; surface roughness of parts; Incorrect adjustment of the start of fuel supply.

Engine lubrication system.

Another manifestation is damage in the form of delamination in the area of the pusher hole. The most common reasons: frequent engine overloads; incorrect installation of the sleeve protrusion; non-flat surface of the cylinder head. Breakthrough of a two-layer metal shell by gases occurs as a result of weak tightening of bolts or deformation of elements during thermal overload. Increased pressure in the cooling system due to the penetration of exhaust gases leads to damage to the gasket near the water channels in the form of linear imprints. Such defects are caused by poor-quality processing of the head surface, air remaining in the cooling system, blocking the supply of coolant, and high exhaust gas pressure.

Read more: Spare parts for Volga 2410

Damage due to overheating. Thermal overheating of a two-layer gasket leads to rupture of the seals. This type of heat load is caused by too low a fuel octane number, too high a compression ratio, incorrect spark plug adjustment, or poor-quality bolt sealing. Quite often, overheating causes swelling of the gasket material near the holes for the coolant to pass through. Main reasons: engine overheating as a result of excessively high coolant temperature; malfunction of the pump or thermostat; interference with the movement of fluid through the cooling system.

Liquid leaks on the surface. Typically, gaskets that combine metal and elastomer are used. Grooves are formed in the cylinder head with dimensions designed to be sealed by the sealing elements of the gasket. If such grooves are poorly cleaned of dirt or carbon deposits, then oil leaks through them. In addition, careless installation can sometimes cause the elastomer layer to collapse, which increases the likelihood of depressurization.

In some cases, oil leakage is caused by the quality of the surface grinding of the mating units. The surfaces of the cylinder block and cylinder head must be very carefully processed; no waviness is allowed on them. Different types of gaskets - a combination of metal - soft material, metal interlayers and metal - elastomer, have specific requirements for the quality of the surface of the parts, and they must be strictly met.

Installation errors. The most common cause of oil leakage is poor tightening of bolts. In this case, there may be a general loosening of the tightening due to fear of pinching the material, as well as uneven tightening of the bolts when a local channel occurs. It is precisely because of the high probability of such defects that it is recommended that repairs or replacement of the gasket be carried out at a service station.

Another common cause is improper gasket selection. It was selected based on thickness and strictly according to the dimensions of the old part. However, there is often a discrepancy between the dimensions of the combustion chamber and the corresponding sample on the gasket. When installing such an element, it is damaged during vehicle operation. Even more common are completely prosaic reasons: the installation of non-branded gaskets purchased from someone unknown. As a result of poor installation, a significant oil leak occurs from under the head, which leads to unplanned fluid losses. If the level drop reaches critical values, the entire engine may be damaged, which will lead to the need for major repairs.

An oil leak in the cylinder head is a rather dangerous defect for a car. If such a malfunction is detected, it is necessary to urgently take measures to eliminate the causes. It is recommended to carry out such work at service centers.

The cause of the leak is damage to the cylinder head gasket.

If you find that oil is leaking from under the cylinder head, this means that the gasket is damaged. This happens in most cases due to repeated overheating of the engine. Damage to the gasket can result in oil leakage, coolant entering the cylinders or into the oil line, or exhaust gases entering there. Well, the cause of overheating itself can be different - driver inattention, malfunction of any mechanism - for example, a water pump, thermostat, radiator - the presence of leaks. In any case, if the engine overheats, this is a consequence of the driver’s inattention, since this can be prevented.

Very often, after engine repairs, car owners complain that oil or coolant is leaking. However, this does not always mean that the cylinder head or the gasket under it has failed - most of these cases occur due to the fault of unskilled craftsmen who either poorly cleaned the surface of the cylinder block and did not remove the remains of the old stuck gasket, or simply performed the cylinder head repair incorrectly. To eliminate the leak, you can try re-tightening the bolts according to the diagram, and if this does not help, you will have to remove the head again.

But in any case, if oil is leaking from under the cylinder head, you should not close your eyes; this is a cause for serious concern. Therefore, it is best to immediately go to a service station.

You can find out detailed information about prices, as well as sign up for repair work by calling:

An internal combustion engine consists of several parts. One of them is the cylinder head. It is installed on the block itself, which can be cast iron or aluminum. But regardless of the material of manufacture, a gasket is installed between these two components. It prevents gases from escaping into adjacent channels, including the cooling jacket. But sometimes it happens that the cylinder head gasket has blown. This is a serious problem. Why does oil leak from under the cylinder head and how to replace this element? We'll tell you in our article today.

When is it necessary to replace the cylinder head gasket of a VAZ 2114?

- The coolant in the radiator or expansion tank is constantly bubbling.

Bubbles are a sign of a leak, and since the cylinder head gasket is supposed to ensure this tightness, most likely this is the problem.

- Exhaust gases escape through the cylinder head gasket.

The situation is rare, but possible, especially for those motorists who like to tighten the fastening nuts.

- The exhaust pipe smokes.

- When checking the oil level, a white emulsion, like foam, is detected on the dipstick.

This can again occur due to a leak in the cooling system, which may be the result of a damaged cylinder head gasket or (less commonly) the presence of a crack in the block itself.

- Reduced engine power and increased fuel consumption.

They can be a sign of a variety of breakdowns, including a breakdown of the gasket between the cylinders.

- The coolant is oily.

Like all of the above symptoms, it does not require an unquestioning replacement of the cylinder head gasket, but calls for a thorough diagnosis.

The essence of the breakdown

As we said earlier, there is a sealing element between the head and the block.

- Poorly tightened bolts. This usually occurs due to poor quality repairs.

- Deformation of the gasket itself (unfortunately, no one is immune from defects).

It is not always the gasket that causes an oil leak from under the cylinder head. Reason #2 is engine overheating. As a result, the surface of the cylinder head becomes uneven. Even after replacing the sealing element, oil leakage from under the cylinder head does not stop. It is necessary to grind the cylinder head or replace it with a new one. The latter option is often applied to heads that have cracks. There is no way to repair them. The structure has already lost its strength and tightness.

Causes of damage to the lining

- Gases. Exhaust gases enter the area between the 2nd and 3rd cylinders. The gasket elastomer is deformed in the area of the coolant passage hole. This problem may be caused by the following: loose bolts; dropped cylinder liner; deformed parts; rough surface of spare parts; incorrectly adjusted start of fuel intake.

- The section of the hole for the pusher has delaminated. This may be due to: high loads on the motor; incorrect installation of the sleeve protrusion; uneven surface of the cylinder head.

- Overheating. Thermal overheating of the lining causes the seals to rupture. Overheating can occur due to a low octane index of the fuel, increased compression levels, or incorrectly adjusted spark plugs. Typically, overheating causes the gasket material to swell near the antifreeze passage holes.

- Flow of lubricant over the surface. Typically, pads are used that consist of metal and elastomer. Grooves are formed in the cylinder head, which are sealed with gasket seals. If these grooves are not properly cleaned of dirt or carbon deposits, an oil leak occurs. If installation errors are made, the elastomer layer may become wrinkled. This increases the chance of depressurization.

- Installation errors. Most often, lubricant leaks from under the gasket due to poorly tightened bolts, so it is advisable to repair or change the lining in a specialized car service center whose employees you can rely on.

- Incorrect choice of pad. Often the dimensions of the combustion chamber do not correspond to the size of the lining. An unsuitable gasket, if installed in the motor, will soon be damaged. Also, you should not install products that are manufactured by an unknown company. The oil will continue to leak even after replacement if you use a low-quality lining.

An oil leak is considered a fairly significant problem. Having identified it, you need to immediately take measures to correct it. All procedures are best carried out in car services. This is especially true if you, for example, are a fragile girl in stiletto heels. Do not touch the power unit, much less dismantle it. This can lead to complete breakdown of the vehicle. It will be necessary to carry out major repairs, which are very expensive. It’s easier to immediately pay specialists to fix the oil leak. This way you will spend much less of your own money. The main thing is not to ignore the malfunction. A minor problem can very likely turn into a serious breakdown that makes the vehicle impossible to operate.

Oil leaking from under the cylinder head. Enough tolerating this!

What does this mean?

If the cylinder head gasket has broken, you need to fix this problem urgently. Otherwise, gases may leak into the cooling system. Outwardly, this manifests itself in white smoke from the exhaust pipe. The consistency of the coolant also changes. It will take on the appearance of a carbonated mineral water with many small bubbles. The candles begin to become coated with oil. Misfires appear. The oil level itself drops uncontrollably. If you overlook its level, you may encounter oil starvation. Because of this, the parts of the crank mechanism will work “dry”. The service life of the crankshaft is significantly reduced, and scuff marks appear on the cylinder walls.

Debugg

What to do if there is an oil leak from under the cylinder head? There is only one way out of this situation. This is a cylinder head gasket replacement. Its cost may vary. For VAZ cars, a new gasket costs about 400-500 rubles. The price of the product for foreign cars starts from 700 rubles and above, depending on the engine configuration. The cost of the replacement service is about one and a half thousand rubles. The operation requires the dismantling of many hanging elements. But if you wish, you can repeat this procedure yourself. Below we will describe the process of replacing the head gasket.

Video “Removing the cylinder head from a VAZ 2109”

This video demonstrates how to remove the cylinder head from a VAZ 2109.

— sealing the place where the cylinder block and the head itself are connected. It ensures tightness.

Do not try to save money during renovation by leaving the old one. This is not a part that can be used many times, and when repairing, replacing the cylinder head gasket is an essential procedure. This article will discuss how to change the cylinder head gasket.

Cylinder head gaskets are available in three types:

- asbestos;

- non-asbestos;

- metal.

Each of them has its own pros and cons, but, according to reviews from drivers, the majority prefer metal ones. But which one to choose is a purely personal matter for each car owner. For some, it is important how much the part costs, and for others, it is durability.

[Hide]

How is the replacement made?

Looking ahead, we note that an important condition during the replacement is the correct tightening of the head bolts. This is the only way to achieve a tight and high-quality surface fit. Otherwise, the integrity of the gasket will be compromised, and the oil will come out again, along with the exhaust gases. The tightening torque for each car is individual and is indicated in the operating instructions.

- Ignition coils.

- High voltage wires.

- Air pipes and intake manifold.

- Sensors (throttle position, idle speed, etc.).

- Vacuum booster hose.

Before removing the cylinder head, you need to drain the coolant. Otherwise, when dismantling, you will flood the entire engine with it. If the antifreeze is fresh, it can be reused. The main condition is a clean container for draining and the transparency of the liquid itself. If it has lost its color (remember, it can be red, blue or yellow) or has become cloudy, such a product cannot be reused.

Note! The camshaft and crankshaft should not be rotated until the belt has been reinstalled.

How to remove the cylinder head? Keep in mind that the cylinder head bolts may become stuck. To prevent the key from falling off, clean the edges as much as possible from dirt and deposits. Otherwise, you will not be able to unscrew the bolt. Due to the licked edges, it can only be drilled out, which is extremely difficult and dangerous for the engine block.

Next, inspect the head mounting bolts. They should not be elongated. If this is the case (for example, the length of the bolts on Lada Samara engines is no more than 135.5 millimeters), they are replaced with new ones. Before installation, the threads must be treated in oil.

Puff

As for tightening, it is done in four stages. Let's look at the technology using the example of the second generation Lada Samara engine. First, the bolts are tightened with a force of 20 Nm. Further, the force increases to 70-85 Nm. At the third stage, the bolts are turned by 90 degrees, at the fourth - by the same amount. After this, the replacement of the gasket can be considered almost complete. Now you know what to do if an oil leak occurs from under the cylinder head.

The most common causes of cylinder head gasket failure

The first thing you can do is overheat the engine. In this case, the gasket gradually burns out, becomes less durable and swells. This can also happen after replacing the cylinder head as a result of misalignment. In this case, it is necessary to prepare for a major overhaul of the engine. Therefore, you should always pay attention to the engine temperature. If it rises above 90 degrees, it is necessary to find out and eliminate the cause of this phenomenon.

What kind of scratch remover is this?

We constantly receive questions in the comments about what kind of “liquid glass” products this is, and in general what a bunch of auto-related advertising is now on the market. As a result, we decided to test in practice how true this is. Let's just say we used 3 means. One product proved to be so-so; after application, a burnt spot remained in this place. The second product, when applied, showed no effect at all.

Causes of oil leakage from under the valve cover

Oil leakage can occur through the oil filler neck, in the place where the valve cover adheres to the cylinder head, as well as in the places where the cover is attached to the cylinder head with bolts.

Less commonly, oil leaks can be found on the valve cover body itself. This indicates defects and cracks in the case, and there may also be a manufacturing defect.

As you know, motor oil in the engine lubrication system is supplied to various elements and components of the internal combustion engine under a certain pressure, which is created due to the operation of the oil pump.

- If an oil leak is noticed in the area of the bolted connection or lubricant leaks out of the neck, then experts consider the most likely cause to be an increase in pressure in the engine lubrication system.

- The presence of oil leaks at the junction of the cover and the cylinder head may also indicate an increase in pressure in the system. In parallel with this wave, wear of the gasket or insufficient sealing in the area of \u200b\u200bthe connection between the valve covers and the cylinder head is allowed.

Note that the valve cover gasket is a rubber product. Moreover, the operating conditions of this seal are such that the specified element operates taking into account a constant temperature difference (high heating and cooling). It is quite obvious that rubber under such conditions gradually loses its elasticity and hardens, and cracks appear in the structure of the material. As a result, the gasket no longer fits tightly to the surfaces of the cover and head. In this case, the problem is solved by replacing the valve cover gasket.

Let us add that the above statements also apply to the cylinder head gasket. Oil can also leak from under the cylinder head if the pressure in the lubrication system increases, and also as a result of defects in the head gasket. The only thing is that in this case you need to pay attention to the condition of the mating planes of the head and the cylinder block itself.

It should also be noted that traces of oil and grease drips on the engine can also appear when the leak occurs through the exhaust manifold gasket. It happens that craftsmen come to a hasty conclusion that oil is leaking from under the cylinder head, after which they immediately begin to change the cylinder head gasket.

Moreover, in many cases such a leak looks similar in appearance to a head gasket leak, although the oil actually leaks through the manifold gasket. During diagnostics, this fact must be taken into account; it is recommended to check this element separately.

Oil leak from under the valve cover: high pressure in the engine lubrication system

So, if everything is clear with the gaskets, then oil leaks as a result of high pressure in the lubrication system require separate engine diagnostics. One of the main methods at the initial stage can be considered to measure the oil pressure in the lubrication system.

To measure the oil pressure that is created in the channels of the oil system, it is necessary to clarify in advance what indicator is considered normal for a particular type and model of internal combustion engine. This information can be found in specialized technical literature, clarified on specialized auto forums, etc.

For measurements you will need a liquid pressure gauge. Next, the oil pressure sensor is unscrewed, after which a pressure gauge is installed in its place and the oil pressure in the engine is measured. If the pressure gauge readings indicate that the recommended value is exceeded, then an oil leak from under the valve cover will be a natural result.

High oil pressure can occur for various reasons. Among the main ones it is customary to highlight the following:

- problems with crankcase ventilation. In this case, the crankcase ventilation does not work properly, gases accumulate in the engine and excess pressure is created. As a result, the engine oil “presses” from under the valve cover. Note that with such a malfunction, oil also enters the air filter housing. Frequent causes of the problem include a clogged oil separator mesh, as well as clogged fittings to which the crankcase ventilation hoses are attached. To eliminate the malfunction, the oil separator mesh must be washed and the fittings must be cleaned.

- contamination in the engine lubrication system. In some cases, the accumulation of deposits in the channels of the lubrication system can lead not only to a decrease, but also to an increase in pressure. The possibility of clogging of the oil lines after the oil pump should not be excluded, which causes a decrease in throughput and an increase in oil pressure. In such a situation, it may be necessary to flush the lubrication system, change the oil and oil filter.

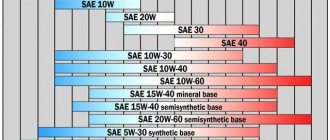

- use of oil with high viscosity, excess oil level, strong thickening of the lubricant at low temperatures. As you know, motor oils should be selected not only taking into account the internal combustion engine manufacturer’s tolerances and various properties, but also pay attention to seasonality. This means that all-season motor oils have different viscosity indexes. It turns out that in winter, especially in regions with severe frosts, it is better to use a less viscous oil from the recommended list. It should also be taken into account that after the engine warms up, the oil will thin out. For this reason, selection should be made taking into account the general condition of the engine, the degree of its wear, the tightness of oil seals and gaskets. It is also not recommended to exceed the engine oil level.

- sticking of the oil pump pressure relief valve. The oil pump of the engine lubrication system always has a certain performance reserve. This is done in order to prevent a gradual decrease in oil pressure, taking into account the natural wear of the pump itself, the accumulation of contaminants and the occurrence of other problems in the oil system during engine operation. For the same reason, this device has a special pressure reducing valve in its design, which allows you to always maintain pressure within specified limits.

Useful tips and tricks

- It should be remembered that high-quality elimination of oil leaks from under the valve cover requires the correct choice of gasket under the valve cover. To do this, it is optimal to purchase original products or high-quality recommended analogues from well-known manufacturers.

- Before purchasing, the gasket should be carefully inspected, checked for elasticity, and made sure there are no sagging or other defects. The element should not be hard or overdried; even the smallest cracks are not allowed.

- For vehicles that use sealant on the valve cover, only recommended or proven sealant compounds should be used. In this case, it is imperative to strictly follow the application technology.

What's the result?

Taking into account the above information, as well as the characteristics of the engine lubrication system, it is necessary to follow several basic rules to extend the life of the gaskets and prevent oil leaks.

First of all, the engine oil and oil filter must be changed in a timely manner, without exceeding the service interval. The engine should only be filled with oils that are recommended by the engine manufacturer and are a high-quality product. In this case, it is important to take into account not only the basic parameters, but also the viscosity, as well as individual operating conditions (seasonality, engine operating modes, loads, etc.)

In the process of selecting gaskets, it is necessary to purchase high-quality products, as well as follow installation recommendations (placement of the gasket, tightening torque of the valve cover bolts). If a sealant is used, you must also adhere to the recommended application technology.

During scheduled maintenance, attention should be paid to the condition and performance of the crankcase ventilation system. Periodic cleaning allows you to avoid possible problems that lead to an increase in pressure inside the internal combustion engine.

When and why does it become necessary to replace the valve cover gasket. How to replace the valve cover gasket with your own hands. Tips and tricks.

Purpose and principle of operation of the breather. Why are breathers installed on internal combustion engines, gearboxes and axles? When it is necessary to clean the breather, useful tips and recommendations.

Types of sealants for car engines: anaerobic, silicone, belt sealants. Operating principle, differences, scope of application. How to choose the best sealant.

Hydraulic compensators: what they are, what function they perform, hydraulic compensator malfunctions and symptoms. Do-it-yourself repair and washing of hydraulic compensators.

How to determine a burnt engine valve yourself. The main symptoms of a burnt valve, exact clarification of the causes of engine tripping. Diagnostics, useful tips.

What are valve seals (valve seals). What signs can be used to determine the need for replacement, how to change valve seals yourself.