Where to put it with benefit?

You will be surprised, but even from an old, rusty bathtub you can benefit; see how to do this below.

Removal for scrap metal

You can scrap it and get some good money. Some companies even offer free dismantling and removal services, this will save you a lot of time and effort. Read more about.

Second Life

If you apply a little imagination and “direct hands”, you can make truly amazing things from cast iron baths. Furniture, ponds and even barbecues. More useful inventions from a cast iron bathtub in our article.

Dismantling and removal of a cast iron bathtub by specialists

To simplify the task, while saving time, effort and money, you can seek the help of professionals. Today, in almost every city there are similar services - you just need to fill out an application, and the construction team will quickly and accurately complete this work. As a rule, the cost of dismantling a bathroom with the help of professionals depends on the following factors:

- from the material from which it is made;

- floor of the room;

- from the region.

If we are talking about a cast iron bathtub, then the service for removing it and removing it from the apartment will, in most cases, be free : the labor of the workers will be paid by delivering the cast iron to the metal collection point, and since such a bathtub weighs a lot, the proceeds will be worthy of them compensation. In other situations, when it is not possible to dismantle and remove the bathtub for free, it is quite possible to do this work yourself - you just need to listen to the advice and recommendations of specialists.

Technological process

First you need to disconnect the old bathtub from the fastening elements with which the bathtub was attached and dismantle the drain. If the drain cannot be disconnected, it is cut with a grinder. You should also remove all objects that may interfere with dismantling the bathtub (both under and above the bathtub) and remove the faucet. To dismantle a bathtub, the edge of which is embedded in the wall, you need to dismantle the legs of the bathtub (starting with the farthest ones) and, after that, pressing on it from above, “drop” it onto the floor. Before dismantling an old cast-iron bathtub in this way, you need to place a thick layer of some soft material under it to soften the impact of the bathtub on the floor.

Breaking a cast iron bathtub will not be easy. This job requires a strong man and a sledgehammer. Before you begin demolition, you need to clear the space around the bathtub, lay a soft cloth on the floor (to protect the floor), and lay the bathtub itself on its side so that it can be easily accessed from both sides. Breaking a cast iron bathtub is quite a dangerous job: there is a high risk of injury from flying bathtub fragments. To protect yourself from these fragments, you should wear thick clothing, shoes, a hat, construction gloves and a protective mask. To protect your ears from fairly loud noise, you can wear sound-isolating headphones.

To minimize the risk of injury from bathtub fragments, remove household members from the premises

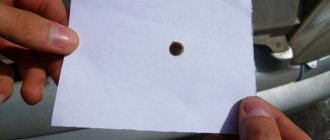

How to break a cast iron bathtub without using extra effort? The weakest point of the bathtub is near the drain hole. To break it, you should apply a series of blows from the inside to the bottom near the drain hole.

Lay the bathtub on its side, this will make it easier to break.

Once the bottom has been broken, the bathtub should be covered with burlap and struck with a sledgehammer, widening the gap along the entire bottom. Do not forget that the bathtub should lie on its side during the entire process of breaking through the bottom, because the vibrations of the bathroom, which, when the bottom is broken, lies upside down, can contribute to the fall of the plaster in the apartment located below you. All blows must be struck from the side.

Once you have managed to break the bottom, turn the bathtub upside down and continue to strike the walls from the side, trying to break it into pieces. If necessary, large pieces can be broken into smaller pieces: the smaller the fragments, the easier it is to remove them from the apartment. At the end of the work, collect the fragments in bags: they can be taken to a scrap metal collection point.

A cast iron bathtub, according to professionals who do professional renovation work, is the most durable accessory. However, there comes a time when it needs to be replaced. Many owners of old bathtubs try to delay this moment as long as possible by covering the product with new layers of enamel. Some take a radical approach to solving this issue. This category prefers to completely remove the old bathtub from the house rather than install a new one in its place. It can be dismantled with or without preservation. Having tried to remove this accessory intact, beginners encounter difficulties and wonder whether it is possible to break a cast-iron bathtub. Or will I have to take it out whole? In this case, you will have to hire a team or call someone for help.

How to break cast iron This question becomes very relevant for those who have decided not to use the old accessory anywhere else. Coping with this task will not be difficult. You will find information on how to quickly break a cast iron bathtub in this article.

Using a grinder

How to break a cast iron bathtub using an angle grinder (grinder)? If you have an angle grinder at home, you can cut the bathtub with it. However, this is such a long, labor-intensive process with a large amount of construction dust (which will cover both you and the entire surrounding area), that the leader in demolition still remains a sledgehammer. And to make the work easier, you can use a grinder to make several cuts on the sides of the bathtub. This will help you split it much faster.

And do not forget that the process of breaking a cast iron bathtub is quite noisy, so all work can only be carried out during the daytime. And to minimize the discomfort of neighbors, it is advisable to warn them in advance.

Using the tips from this article, you can break a cast iron bath yourself without any problems. Before you break your bathtub because it doesn't fit into the doorway, consider how you'll move the new one in.

The best posts

- How to make a plasterboard ceiling in the kitchen with your own hands

- Painting drywall - step-by-step instructions

- How to join drywall in corners and the process of building a decorative niche

- Sealing drywall joints - recommendations from professionals

- Epoxy resin, application

- How to seal a doorway with plasterboard - installation diagram

- DIY plasterboard ceiling installation

- How and how to glue a foam plastic ceiling plinth

Related article: Where to start laying laminate flooring: installation instructions

About dismantling methods

There are two ways to replace an old bathtub:

- With saving. The bathtub is carefully disconnected from the rest of the communications in the house and taken out. It can be used in the future. Judging by the reviews, this method is complex and time-consuming.

- No saving. In this case, you can either break the cast iron bathtub or saw it using an angle grinder. The bath pieces are then taken out. Due to the fact that the product now weighs much less, one person can handle this work. According to experienced craftsmen, if necessary, they mainly resort to this method. The disadvantage of this method is that the procedure is accompanied by a very large roar.

Where should I start?

Before breaking a cast iron bathtub, it must first be disconnected from all communications. The first step is to disconnect the overflow. According to experts, cast iron pipes were installed in many old houses. Therefore, after many years, they become very rusty, covered with scale, and the master may have difficulties dismantling cast-iron plumbing fixtures. The situation is better if communications are represented by metal-plastic components. In this case, they simply unscrew. The master only needs to prepare the pliers. There are often cases when the overflow grate gets very stuck.

Before breaking a cast iron bathtub, you need an element. Many craftsmen clamp it with pliers and turn it counterclockwise. If it is not possible to dismantle the overflow in this way, it is cut off with a grinder. Judging by the reviews, fasteners often have heavily rusted threads, which can only be dealt with after cutting them. First, several cuts are made on the grate, and then the overflow is knocked off with a chisel. Then the crosspiece under the grille is knocked out. As a result, the siphon should hang freely, connected to the rest of the sewer line. To remove it, the master needs to get rid of the coupling. Some beginners wonder if it is possible to break a cast iron bathtub with a sledgehammer. According to experts, this is quite possible to do. You just need to adhere to a clear sequence of actions.

General recommendations for dismantling old bathtubs yourself

To ensure that no unforeseen situations arise in the process of removing an old bathtub that has expired and then installing a new one, experts advise adhering to a certain sequence of work:

- First, the drain pipe is disconnected. If over time it has become, as they say, “tight”, it is better to immediately replace such communications with modern plastic structures.

- If the bathtub is dismantled only for the duration of the repair and then put back, special care should be taken during the work so as not to damage its outer covering, especially if we are talking about fragile acrylic surfaces.

- During the removal process, you need to collect and save all the components, mechanisms, and fastening materials - without them it will be extremely difficult to install the bathtub.

- Along with installing a new bathtub, it is preferable to immediately replace all drainage systems - this way in the future you will minimize the risk of water leaks and get rid of additional costs for their elimination. At the joints it is necessary to apply waterproof glue - sealant.

Progress

Once the most vulnerable point in the product has been found, the following steps must be performed:

- The first step is to move the bathtub a little away from the wall. To complete this task, you will need a chisel and a hammer, with the help of which the plumbing product is removed from the cement mortar around the perimeter. The optimal distance of the bathtub to the wall will be from 100 to 150 mm.

- Using an angle grinder equipped with cutting wheels, make several cuts on the bathtub. The master’s task is to deprive the product of its strength. The cutting areas on the bathtub should be its curved edges on both sides. They are used as If the work is done correctly, then strong blows to the bottom of the cast iron product will cause it to fold.

- Break through the drain hole. There is no need to turn the bath over at this stage. The master only applies very strong blows with a sledgehammer to the drain from the inside of the bathtub. Judging by the reviews, after these steps the bath is divided into two separate halves. If this does not happen, then you will have to deal with its sides.

- Turn the bathtub on its side and cover it with old rags. Burlap also works well. The blows are applied to the outer part of the cast iron product. As a result, the previously broken drain hole in the bathroom should become even wider. After several blows in the bathtub, a long strip forms along its entire bottom.

How to dismantle it correctly with your own hands?

Below, we have provided detailed instructions for carrying out the work with all the nuances.

Remove the old siphon

The first step is to disconnect the siphon. As a rule, in old houses these siphons are made of cast iron, and under the influence of moisture and time, all connections sinter and corrode, so it is unlikely to be possible without special compounds that corrode rust. You can use, for example, WD-40 - popularly known as "Vedashka". You need to spray the connections and leave them in this state for 1 hour.

Then, using a wrench, you need to unscrew the nut, thereby disconnecting the siphon.

The diameter of the nut is most often very large, so for this work you will need a gas wrench.

If the nut does not give in and the “century-old layer” of rust is not corroded by any means, all that remains is to cut off part of the pipe with a grinder. Or not? There is one interesting life hack :

- insert the chisel into the hammer drill chuck (this is a special blade-shaped attachment);

- switch it to the “impact without drilling” mode;

- Press the chisel against the end of the nut and press the start button.

Most likely the nut will give way. Do this procedure several times until you can unscrew it with a key or by hand.

Release the sides

Often tiles in the USSR were laid from the side of the bathroom, or even a corner was made from it along the entire perimeter of the wall. In this case, pulling out the bathtub is simply not possible; first you need to knock off the tiles from the sides. For this, an already familiar hammer drill with a chisel is suitable, in impact mode without drilling.

Completion

At the very end, the cast iron bathtub must be completely turned over. The bottom of the sanitary ware should be directed upward. At this stage, the sides are processed with a sledgehammer. As a result, the bath is broken into several pieces, which can then be conveniently removed. In addition, the bath can be divided into smaller pieces. To do this you will have to work with an angle grinder. The gas cutting method is considered quite effective.

For those who do not know how to break a cast iron bathtub, professionals recommend following safety precautions. Mostly this work is performed by two people. Since the procedure involves a grinder and a sledgehammer, you can protect yourself from injuries if all actions are coordinated.

Due to the fact that particles of broken cast iron can get into the face from strong blows of a sledgehammer, the plumbing product should first be covered with burlap. This will also protect the bathroom itself. The speed of dismantling and safety directly depend on the proper organization of work.

A cast iron bathtub, according to professionals who do professional renovation work, is the most durable accessory. However, there comes a time when it needs to be replaced. Many owners of old bathtubs try to delay this moment as long as possible by covering the product with new layers of enamel. Some take a radical approach to solving this issue. This category prefers to completely remove the old bathtub from the house rather than install a new one in its place. It can be dismantled with or without preservation. Having tried to remove this accessory intact, beginners encounter difficulties and wonder whether it is possible to break a cast-iron bathtub. Or will I have to take it out whole? In this case, you will have to hire a team or call someone for help.

How to break a cast iron bathtub in the bathroom? This question becomes very relevant for those who have decided not to use the old accessory anywhere else. Coping with this task will not be difficult. You will find information on how to quickly break a cast iron bathtub in this article.

What restoration methods exist?

Option #1 - acrylic coating

Restoring a cast-iron bathtub by pouring acrylic is considered one of the simplest. This is a fairly new method that has gained popularity among consumers. It consists of applying a liquid acrylic solution by pouring it onto the surface of the equipment. Its benefits include:

- Durability. The coating obtained in this way, when applied correctly, retains its properties for 8-15 years. This is due to the fact that acrylic is applied in a fairly thick layer of about 6 mm.

- Smooth glossy surface. The composition is quite thick. It spreads well over the surface of the device, filling possible irregularities, forming an almost perfectly flat and smooth plane.

- Relative simplicity and high speed of application of liquid acrylic.

- There is no unpleasant odor, which allows the work to be performed even in homes where there are people with allergies, children and the elderly.

There are disadvantages to this method. This includes the drying time of the composition. This usually takes about three days, during which it is recommended not to even approach the device. Because debris, dust particles or water accidentally falling on the drying surface can destroy it.

Despite the obvious ease of applying acrylic using the pouring method, it is a rather complex restoration method. Some composition skills required

Another negative point is the relatively high cost. This is higher than enamel. However, this price is justified by the longer service life and good quality of the coating.

Option #2 - do-it-yourself enameling

The oldest recovery method. This vaguely resembles painting, but you must clearly understand what special enamel is used in this case. This needs to be chosen, I wonder how to paint a cast iron bathtub. There are two types of such compositions: for professional use and for independent use. The first ones are very rare and require installation in several layers. This is a rather complicated procedure. The second one is thicker and, accordingly, easier to use.

READ Chainsaw Calm Preparing for Work

A correctly selected composition is applied to the prepared surface of the equipment using a roller, and often a brush. Advantages of this method:

- The cheapest restoration option.

- There is no need to disassemble and install additional drain and overflow.

- Suitable for both cast iron and steel bathtubs.

There are many more disadvantages of enameling:

- Service life of new enamel. About 5 years.

- The composition, folded on the surface of the equipment, dries for a long time. About 5-7 days.

- The coating is hard and therefore very sensitive to impacts. Over time, chips may appear.

- The enamel is applied in a fairly thin layer, so it is not able to cover various surface irregularities such as dents, chips, etc.

- Over time, the epoxy coating will turn yellow.

It should be understood that the enamel resulting from restoration is significantly different from that which was originally applied to the equipment.

Cold enamel. The cheapest and easiest way to restore. This is reminiscent of painting a surface with a special composition.

In order for the enamel to last as long as possible, you should follow simple rules. For example, to clean a refinished cast iron bathtub, you will need a mild soap solution rather than abrasive powder. Otherwise the enamel will be damaged. The device should be protected from impacts, especially sharp objects, and do not pour too hot water into it. When filling the tank, first open the tap with cold water, and only then with hot water.

Option #3 - “bath to bath” method

This is the name of the restoration method, which consists of installing an acrylic liner that completely follows its contours inside the old structure. The liner is attached to a special adhesive foam. With proper operation, the service life of the bath after restoration is about 15 years. Main advantages of the method:

- Durability of the new coating. Acrylic is much stronger than enamel.

- The smooth surface hides all the defects of the old design.

- The surface does not turn yellow over time.

- A successful combination of the advantages of acrylic and cast iron bathtubs.

The disadvantages of this method include the need to dismantle the drain siphon and the prohibition on installing liners in thin structures, which are called “light cast iron” or “thin cast iron”. This is because the hardware may bend and the adhesive layer that holds the liner in place will be damaged. The “bathtub for bathtub” method is very demanding on the quality of materials. Using a low quality insert or the wrong adhesive, the bathtub cannot be repaired.

Installing an acrylic liner is a simple and effective restoration method. Particular attention should be paid to the size of the liner. This should fit the bathroom perfectly

All three methods require hardware upgrades. This step usually involves cleaning the cast iron bathtub of dirt and grease. Degreasing is carried out with oxalic acid or baking soda. All defects are thoroughly cleaned to ensure a smooth surface. Then grinding is carried out. The result should be a rough surface. When applying the desired composition, adhesion to it will be maximum.

About dismantling methods

There are two ways to replace an old bathtub:

- With saving. The bathtub is carefully disconnected from the rest of the communications in the house and taken out. It can be used in the future. Judging by the reviews, this method is complex and time-consuming.

- No saving. In this case, you can either break the cast iron bathtub or saw it using an angle grinder. The bath pieces are then taken out. Due to the fact that the product now weighs much less, one person can handle this work. According to experienced craftsmen, if it is necessary to dismantle the bathtub, they mainly resort to this method. The disadvantage of this method is that the procedure is accompanied by a very large roar.

Where should I start?

Before breaking a cast iron bathtub, it must first be disconnected from all communications. The first step is to disconnect the overflow. According to experts, cast iron pipes were installed in many old houses. Therefore, after many years, they become very rusty, covered with scale, and the master may have difficulties dismantling cast-iron plumbing fixtures. The situation is better if communications are represented by metal-plastic components. In this case, they simply unscrew. The master only needs to prepare the pliers. There are often cases when the overflow grate gets very stuck.

Before breaking a cast iron bathtub, you need to dismantle this element. Many craftsmen clamp it with pliers and turn it counterclockwise. If it is not possible to dismantle the overflow in this way, it is cut off with a grinder. Judging by the reviews, fasteners often have heavily rusted threads, which can only be dealt with after cutting them. First, several cuts are made on the grate, and then the overflow is knocked off with a chisel. Then the crosspiece under the grille is knocked out. As a result, the siphon should hang freely, connected to the rest of the sewer line. To remove it, the master needs to get rid of the coupling. Some beginners wonder if it is possible to break a cast iron bathtub with a sledgehammer. According to experts, this is quite possible to do. You just need to adhere to a clear sequence of actions.

Progress

Once the most vulnerable point in the product has been found, the following steps must be performed:

- The first step is to move the bathtub a little away from the wall. To complete this task, you will need a chisel and a hammer, with the help of which the plumbing product is removed from the cement mortar around the perimeter. The optimal distance of the bathtub to the wall will be from 100 to 150 mm.

- Using an angle grinder equipped with cutting wheels, make several cuts on the bathtub. The master’s task is to deprive the product of its strength. The cutting areas on the bathtub should be its curved edges on both sides. They are used as stiffeners. If the work is done correctly, then strong blows to the bottom of the cast iron product will cause it to collapse.

- Break through the drain hole. There is no need to turn the bath over at this stage. The master only applies very strong blows with a sledgehammer to the drain from the inside of the bathtub. Judging by the reviews, after these steps the bath is divided into two separate halves. If this does not happen, then you will have to deal with its sides.

- Turn the bathtub on its side and cover it with old rags. Burlap also works well. The blows are applied to the outer part of the cast iron product. As a result, the previously broken drain hole in the bathroom should become even wider. After several blows in the bathtub, a long strip forms along its entire bottom.

Removing a cast iron bathtub using a hammer

If you decide to scrap a cast-iron bathtub, we can recommend using such a simple method of removing an old product from the bathroom as destroying the bathtub body with a sledgehammer. This is the easiest and most rational option for dismantling. In order to reduce the likelihood of injury, it is necessary to adhere to a certain sequence of actions. Work should be carried out in this order.

First you need to cut the sides of the bath in half with a grinder

First of all, it is necessary to cut off the connection of the bathtub to the sewer with a grinder and free the sides of the plumbing fixture from the layer of tile mortar and the remains of cladding along the entire perimeter. The tank should be moved from the wall approximately 10–15 cm.

To easily split the bathtub body into two parts with a sledgehammer, you should use a cutting machine to make cuts on certain areas of the surface. The cuts must be made on the rounded part of the container strictly in the middle of the product on both sides.

The sides of the bathtub must be completely cut through, since in this case they act as a load-bearing element in the structure. Now one good blow with a hammer on the bottom of the tank will be enough to divide it into two equal parts. In this case, the bathtub will fold downwards.

A heavy hammer can be used to break bath debris into small pieces so you can carry it out in bags alone

Fulfilling these conditions will be enough to facilitate the dismantling of the bathtub. Two workers can remove parts of the old product from the premises, although this can be done alone. To do this, it is advisable to split the parts into small fragments, collect them in strong bags and take the bath to a scrap metal collection site or a landfill. In order to break apart parts of the bathtub body, you do not need to make cuts with a sander.

Cast iron is a fairly brittle material, and the remaining parts of the structure can be easily broken into small pieces with a sledgehammer.

Completion

At the very end, the cast iron bathtub must be completely turned over. The bottom of the sanitary ware should be directed upward. At this stage, the sides are processed with a sledgehammer. As a result, the bath is broken into several pieces, which can then be conveniently removed. In addition, the bath can be divided into smaller pieces. To do this you will have to work with an angle grinder. The gas cutting method is considered quite effective.

For those who do not know how to break a cast iron bathtub, professionals recommend following safety precautions. Mostly this work is performed by two people. Since the procedure involves a grinder and a sledgehammer, you can protect yourself from injuries if all actions are coordinated.

Due to the fact that particles of broken cast iron can get into the face from strong blows of a sledgehammer, the plumbing product should first be covered with burlap. This will also protect the bathroom itself. The speed of dismantling and safety directly depend on the proper organization of work.

Methods of removal from the apartment

When removing cast iron plumbing from the apartment, you will need the help of another person. If the entire bathtub needs to be removed, it is placed vertically. One person grabs the top legs and tilts the container slightly so that a partner can grab the bottom supports. Plumbing fixtures are carried diagonally through a narrow doorway. The front legs are brought out first, then the hind legs.

If the supports are cut off, the container is placed on its side and moved along the floor. After carrying it through the doorway, one person grabs the front end, the second - the back. If there is no assistant, the bath must first be destroyed.

Removing the bathtub from the apartment.

Chop or smash with a sledgehammer at home

The work is carried out as follows:

- Cover the container with a damp cloth; you can use a sheet or tablecloth for this. The amount of debris and dust generated will be minimal.

- They strike from the side. If the metal does not break, additionally use a crowbar or wedge, which is hit with a sledgehammer.

- Remove construction waste.

This method of destruction has its drawbacks. Removing small fragments and dust takes a lot of time. Also, when hitting a sledgehammer, it will not be possible to avoid loud sounds.

Saw with a grinder and break

You can destroy the container without creating a lot of unnecessary noise using a grinder.

Cut the bathtub with a grinder.

Perform the following actions:

- make cuts on the body with a metal disc;

- insert metal wedges into the resulting slots;

- hit with a sledgehammer until the bowl breaks.

It will not be possible to completely get rid of the noise, but this method makes the operation less noisy.

Cutting is also performed using another method:

- Wear a mask and goggles to protect against dust and debris.

- A metal disc is installed on the grinder. Use a nozzle with a diameter of 23 cm. This will speed up the sawing process.

- Work begins from the middle, moving the disk from the sides to the bottom. When the cut reaches the center of the bottom, the nozzle is placed at the opposite edge. The cuts should form a single line. Wooden blocks are first placed under the bath so that the halves do not squeeze the disk.

- If the parts do not separate from each other, press on the bottom. The cuts are made until pieces are obtained that can be easily pulled out alone.