* unfortunately, collapsing under cut does not work.

Over time, vehicles equipped with electronic throttle control

, a malfunction appears -

loss of response to pressing the gas pedal

,

a short-term increase in engine speed when changing gears

, accompanied by the display of a Check on the dashboard,

The reason for this is the failure of the Clutch pedal sensors

and

Braking

,

located on the pedal assembly

, more details about them in the logbook gosharik73

The cause, most often, is the mechanical nature of the damage.

Clutch pedal position switch

: VSPPS

1. Absence of the sensor itself, due to various circumstances - Logbook Romul-ua, Logbook aligator013

2. Open circuit, short circuit - Material VORON36

3. Burning, oxidation, sticking, (gap), or other damage to the contact part of the sensor, preventing the formation of a stable electrical circuit - Maxxiss Logbook

The clutch pedal position signal switch has one group of contacts

, switching electrical circuit.

Based on the signals from the clutch pedal position sensor and the brake light switch, the controller distinguishes between pressed and unpressed pedal positions

:

— clutch pedal released

— contacts are closed, circuit switching — ECM signal supply.

— clutch pedal pressed

- opening of contacts, interruption of the electrical circuit - signal emission from the ECU: (instantaneous)

removal of the engine load

- conditions:

the speed is not equal to zero (DSA), the engine speed is in the range (DPKV), while the signals supplied from the gas pedal module are taken into account.

Characteristic manifestation of a malfunction

—

an increase in engine speed

when moving the gearbox to the neutral position (or otherwise operating the clutch pedal), which is also characteristic of a faulty TPS with a cable-operated throttle valve. Material by AndreiCherniy

In other cases, there are also positive aspects of delaying speed - Logbook sochinec93

The clutch status is transmitted to the vehicle's ECU via the clutch switch

.

This signal allows the ECM to process sudden changes in load

on the vehicle's engine. Pressing the clutch pedal while driving takes the load off the engine.

If the clutch switch is faulty

The ECU believes that there is a load, since it receives signals from the VSS sensor (DSA) and, therefore,

controls the unloaded engine as a loaded one

. Since in this case the optimal control of fuel injection is disrupted, the engine speed becomes uneven and smoke is generated.

In addition, the clutch switch signal, along with vehicle speed and engine speed signals, is used to determine which gear is engaged.

Trouble code - P0830 is set if no change in signal from the clutch switch is detected: 1) within 2 seconds after changing gear while driving 2) after four gear changes at a speed of more than 10 km/h and a speed of more than 1000 rpm.

The reason for this may be: 1) a malfunction of the clutch switch; 2) open or short circuit in the circuit or 3) incorrect clutch pedal height. The ECM recognizes the engaged gear based on data received from the crankshaft and wheel speed sensors.

If the malfunction persists over a certain number of trips, the controller generates an error and lights up a malfunction indicator in the dashboard - error code - “P0830 - Clutch pedal switch, circuit faulty.” Read more about the error in the Logbook gosharik73

Design and principle of operation

The principle of operation of the electronic gas pedal is not very complicated in theory. Essentially, this device works on the principle of a rheostat that monitors the position of the lever. Inside there are track contacts that duplicate each other for greater reliability. Depending on the position of the lever, data is transmitted to the electronic control unit - ECU, which controls the position of the carburetor damper, opening or closing it. This is done by a small electric motor with a gearbox. Of course, the design of an electronic gas pedal is much more complex than such a simple circuit. It includes many sensors and control mechanisms. They control the fuel supply even when the pedal is in one position, adapting to the slightest change in the vehicle's speed and environmental conditions. Today, there are no problems starting the engine in any season and maintaining its optimal operation, since almost all modern cars have an electronic gas pedal. Thanks to this simple device, the life of car enthusiasts has become much easier.

So how does it work?

And here everything is quite simple. To put it in words, the driver presses the gas pedal, sensors that are built into the base of the pedal see the angle of deflection and transmit the position of the pedal to the throttle valve via wires, it in turn bends to the desired angle, thereby either supplying more fuel or less.

Now a little more detail...

The electronic pedal is not a simple “piece of hardware”, which was the usual “cable” pedal. In fact, this is an entire electronic module. If you don’t go into complex technical terms, but put it in a language that is more understandable to everyone, then you can compare an electronic pedal with a kind of rheostat. The pedal has special tracks along which a group of contacts runs, and these contacts are duplicated for accurate readings. These contacts move along the track, thereby changing the load on the sensors, and these sensors send information to the throttle valve unit.

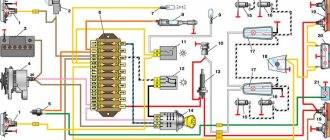

Pedal module (rheostat) circuit diagram

That is, there are no cables here, pure electrics! Let's look at the work diagram.

Many can say that the cable is much more reliable, because the more electricians, the more failures! And maybe they are right about something! However, statistics indicate the opposite; the electronic pedal is a very durable element! No, of course they break, but this happens extremely rarely! But the cable throttles broke much more often! Moreover, it was not the pedal itself that broke, but the cable that connected the throttle valve wore out - and everything broke, we pressed the pedal and there was no “gas”! Moreover, cable breakage occurred much more often than failure of the electronic gas pedal.

Another advantage is the “automaticity” of the system. The electronic pedal is controlled by the vehicle's ECU. You no longer need any “choke” during a cold start, you also don’t need to “pump” the pedal to start the car, the injector will do everything, it also automatically adjusts the throttle when starting (a kind of smart automatic choke) - very valuable when starting idle! With an injector it is much more difficult to fill the car's spark plugs!

At speed , the ECU can automatically adjust the throttle position for optimal performance, even if you hold the pedal in one position - a prime example of this is the cruise control system! You can see about his work in this video.

If we summarize the electronic gas pedal, we can understand that this is a modern step forward, which provides much more comfort and possibilities for using electronic systems than the old cable mechanism.

( 8 votes, average: 4.75 out of 5)

E-Gas (electronic gas pedal) is an electronic gas pedal that replaced the cable-operated throttle valve. Email The gas pedal controls the throttle electronically rather than physically. AvtoVAZ began producing models with E-Gas at the beginning of 2011, the reason was the environmental standards Euro-4 and Euro-5, which must be observed.

In this article you will learn what E-Gas is, how it works, why it was introduced, and what advantages and disadvantages it has.

Advantages and disadvantages of an electronic pedal

When this device was created, there was no talk about driver convenience. It simply made it possible to increase the environmental friendliness of the car and free up space from cables and other mechanics, which made it possible to simplify the design. But a lot of time has passed, and now the electronic version can be found in almost all cars. During this period, all the advantages and disadvantages were revealed.

- Environmental friendliness - electronic engine control reduces the amount of exhaust gases, as speed is strictly controlled.

- Smooth operation - the electronic control unit does not allow the engine speed to change too sharply.

- Greater efficiency - again, due to strict speed control, fuel consumption is reduced.

- Easy engine starting in any season. A “cold start” in winter is easy and simple, without manual shamanism with the throttle, which can end in flooding the spark plugs.

But there are also disadvantages:

- Impossibility of repair. If any unit breaks down - the pedal itself, the ECU, or the damper control unit, the entire unit will have to be replaced.

- The delay in response is also an advantage. But some drivers don’t like the fact that some time passes from the moment they press the pedal until the speed increases. Although this doesn't bother most people. This problem is often solved simply by adjustment.

- Gentle pressure - almost no resistance is felt. Some people don’t like this, especially those who are used to “feeling the car.”

The disadvantages are not very significant. The most serious is the first, but we must take into account that in general this device is much more reliable than a mechanical one with a cable. Therefore, it breaks much less often.

The history of electronic gas pedals

Previously, gas pedals were cable driven. That is, you press the gas pedal and pull the cable, which on the other side is connected to the air damper drive (throttle valve). But when the engine is idling, the engine constantly requires different amounts of air, especially during a cold start. And then the engineers made a choke - an additional air damper that opened when the engine was cold so that it could work when it was cold. Time passed, and the next step was an air damper with an electronic assistant, that is, you still pulled the cable, but if the cable was not tensioned, the damper could change the opening angle within certain limits, which made it possible to automatically adjust the idle speed of the engine and warm it up on its own. Then cruise control systems appeared, when the car began to be able to regulate the speed of movement, which affected the ability of the air damper to operate over the entire range of opening angles. But the engineers still held out and left the damper drive by cable. However, later anti-slip systems for the drive wheels began to appear with the removal of engine power, and the fun began. The driver could no longer control the air damper directly, but only began to give commands to the computer, which itself set the required opening angle. It may be, of course, that cruise control and traction control were not the reason for the appearance of fully electronically controlled throttles, but you must admit that it is much easier to delegate control to a computer than to come up with engineering solutions that allow you to combine a cable drive and free electronic throttle control.

Correct setting

Setting up the electronic gas pedal on different car models is different, since although the same principle is used, the design is different. Therefore, it is better to search for information on the Internet about your model. Let's take an example of how this is done for Lada cars; the differences are small:

- Remove the pedal from the bracket.

- Loosen the screws that hold the cover. One of them fixes the position of the cover; it must be completely unscrewed.

- Turn the cover clockwise until it stops and tighten the screws again.

Electronic gas pedal: how to find a breakdown and fix it video AvtoNovator

How does an electronic gas pedal work, how are its advantages and disadvantages manifested, what malfunctions are most common, and how to deal with them? All these questions are very relevant, because today many car manufacturers have replaced the traditional cable drive with a more modern electronic pedal.

Electronic gas pedal - how does it work?

Modern technologies are aimed at making our lives as easy as possible. On the one hand, this is a huge plus, but on the other hand, they simply deprive us of the opportunity to make any decision, or rather, they correct it, and in such a way that it is not always possible to achieve the desired result. This is clearly visible in the operation of the electronic pedal, which is so popular in the modern automotive industry. Although for those who feel insecure behind the wheel, and especially do not delve into the technical nuances of the car, this innovation is only a plus.

The principle of operation of the electronic gas pedal is as follows: after the driver presses the accelerator, data on pressure angles immediately enters the control unit through special sensors. Next, the ECU comes into play, which calculates the required opening angle of the throttle valve, and the drive, based on the data received, opens it to this angle. Moreover, if it suddenly becomes necessary to change the value of this angle (for a more economical mode or safety), the control unit does it itself, without receiving the corresponding command. It turns out that the driver cannot 100% regulate this process.

When is it necessary to replace the electronic gas pedal?

Due to the fact that this is an electronic drive, the main faults in it are related to the electronics. There are two sensors built into the pedal bracket that transmit commands to the control unit. If one of these sensors fails, a light on the panel will light up, which is responsible for the serviceability of the engine control system. In this case, the ECU goes into standby mode (the speed increases much more slowly). If two sensors fail, the emergency mode will turn on and the engine will operate as if idling. Since the sensors cannot be repaired, the electronic gas pedal must be replaced.

The wiring may also be damaged, and then the operation of the throttle will be disrupted. If the electric motor is worn out, then the monitor also displays an error indicating an accident. These damages can be eliminated, but if the accelerator of the electronic gas pedal, which is responsible for the dynamics of the car, fails, then this part should be immediately replaced with a new one. We'll look at how to do this below.

Electronic gas pedal repair – we fix the breakdowns ourselves

Basically, if any problems occur, the entire assembly must be replaced. But before taking such drastic actions, it would not hurt to find out the cause of the breakdown. To do this, of course, it is worth reading the information on how to check the electronic gas pedal. To do this, you need to disconnect the block and sensors, and then unscrew the fastening nuts and remove the pedal.

In some cases, it is also possible to repair the electronic gas pedal, for example, if the wiring is damaged. So, having discovered a defect (the insulation is broken, the wires themselves are damaged, etc.), you need to act according to the following scheme. Having freed the gear mounting axis, remove the harness. To do this, you need to unsolder the wires, release the bracket and pull out the cable. Then we replace the wires, and, having disassembled the connector under the pedal, solder them. Now you can assemble the damper and drive safely.

If the car reacts to pressing the accelerator, so to speak, “with a delay,” then a spur (electronic corrector) of the gas pedal is needed. This device allows you to reduce the interval between pressing and opening the damper to a minimum. This is a separate module that connects to the sensors and, through a microprocessor, converts the signals supplied from them, and then supplies them to the controller.

So we see that the electronic gas pedal, tuning of which is possible in any specialized center, on the one hand, is a clear result of progress, and on the other hand, it somewhat limits our desires. True, if you do not belong to the category of those people who need to “drive with the breeze”, but prefer to drive carefully with minimal fuel consumption, then this option will be just for you.

Malfunctions of the electronic gas pedal

All problems are usually associated with the electrical part; there is nothing else to break there - a minimum of mechanics is used. The pedal has sensors that measure its position, everything is connected to the control unit, and there is an electric damper motor. Therefore, malfunctions can be as follows:

- The failure of one of the sensors will be reflected in a slow increase in engine speed.

- Failure of both sensors will result in an alarm on the panel.

- Wiring faults can cause the damper to not operate properly.

- A breakdown of the throttle motor causes an alarm to appear on the panel.

So it is quite easy to detect and check the faulty part of the electronic gas pedal. Repair consists of replacing the damaged unit completely. After this, the operation of the pedal is checked.

When replacement is necessary

As already mentioned, this device is quite reliable and consists of different blocks. Replacing them all at once is usually not necessary. In the event of a breakdown, you can quickly identify the faulty unit and replace it. They cannot be repaired, only replaced. It’s not difficult to do this yourself, or go to a service station, where repairs won’t take much time either.

How does an electronic gas pedal work, how are its advantages and disadvantages manifested, what malfunctions are most common, and how to deal with them? All these questions are very relevant, because today many car manufacturers have replaced the traditional cable drive with a more modern electronic pedal.

How to check the electronic gas pedal

Possible malfunctions of the E-gas pedal, if necessary, are eliminated at a service station or service center of your dealer. If you have a good knowledge of the car's structure and have the necessary skills, you can replace faulty elements yourself.

How to check the electronic gas pedal:

- On the left side, remove the wiper and trim panel.

- Remove the expansion tank by removing the bracket fastenings and moving it to the side for easy access.

- Find and remove the rubber casing, behind which the device will be found.

- Remove the pedal housing and replace the faulty sensor.

- Carry out installation in reverse order.

The electronic gas pedal is adjusted if the sensitivity threshold is low or the system does not respond when the pedal is pressed. To do this, use a volt-ohmmeter to set the appropriate range of values. It is better to install it according to the instruction manual. The data for injection and diesel engines will differ, as well as for different types of internal combustion engines.

Electronic throttle is often found on modern brands of cars, because this system can significantly save fuel consumption, and also provides a smooth ride and “help” for inexperienced drivers when driving a vehicle. The system is not without some drawbacks, and also requires periodic inspection and adjustment. Details about the operation and the main nuances of using the E gas pedal can be found in the information provided.

Electronic gas pedal - how does it work?

Modern technologies are aimed at making our lives as easy as possible. On the one hand, this is a huge plus, but on the other hand, they simply deprive us of the opportunity to make any decision, or rather, they correct it, and in such a way that it is not always possible to achieve the desired result. This is clearly visible in the operation of the electronic pedal, which is so popular in the modern automotive industry. Although for those who feel insecure behind the wheel, and especially do not delve into the technical nuances of the car, this innovation is only a plus.

The principle of operation of the electronic gas pedal is as follows: after the driver presses the accelerator, data on pressure angles immediately enters the control unit through special sensors. Next, the ECU comes into play, which calculates the required opening angle of the throttle valve, and the drive, based on the data received, opens it to this angle. Moreover, if it suddenly becomes necessary to change the value of this angle (for a more economical mode or safety), the control unit does it itself, without receiving the corresponding command. It turns out that the driver cannot 100% regulate this process.

Lada Granta electronic gas pedal malfunction

Features of the Lada Granta throttle assembly

The throttle valve is turned by an electric motor through a gearbox. Both are built into the throttle body. When starting and warming up the engine, as well as during idling, the flow of air into the cylinders is regulated by opening the throttle valve. The throttle position is controlled by two sensors built into the throttle body.

The throttle valve opening angle is set by the electronic control unit (ECU) depending on the estimated amount of air that should enter the engine cylinders. This takes into account the operating mode of the engine (starting, warming up, idling, and so on), the temperature of the ambient air and the engine, and the position of the gas pedal.

Control commands are sent to the throttle assembly to the electric motor. At the same time, the ECU monitors the opening angle of the damper and, if necessary, sends appropriate commands to adjust its position. As a result of the fact that the ECU simultaneously regulates the amount of injected fuel and incoming air, the optimal composition of the combustible mixture is maintained in any engine operating mode.

The electric throttle body is sensitive to deposits that may accumulate on its inner surface. The resulting layer of deposits can interfere with the smooth movement of the throttle valve, jamming it (especially at low opening angles). As a result, the engine will operate unstably and even stall at idle, start poorly, and failures may also appear during transient conditions. To avoid this, as a preventive measure, deposits should be removed with special detergent compounds during regular vehicle maintenance. A large layer of deposits can completely block the movement of the damper. If flushing fails to restore the throttle assembly to operability, it must be replaced.

A malfunction or incorrect operation of the throttle assembly may be caused by a broken contact in its electrical circuit (oxidized terminals in the wiring harness connection block). In this case, it will be possible to restore operation by treating the terminals with a special compound for cleaning and protecting electrical contacts. There are other possible causes of the malfunction:

— no supply voltage is supplied to the throttle assembly;

— signals are not received from both throttle position sensors;

— The computer cannot recognize signals from the throttle position sensors.

In these cases, the engine control system goes into emergency mode. At the same time, the car retains the ability to independently move a short distance at a slow speed, which, in extreme cases, will allow it to be moved to a safe place

(move to the side of the road, leave the intersection, etc.).

The fact that the throttle assembly is operating in emergency mode may be indicated by a burning indicator lamp for a malfunction of the engine management system and an increased speed of the crankshaft at idle (about 1500 rpm, despite the fact that the engine is warmed up to operating temperature), the engine at this will not respond to pressing the gas pedal.

Each of the throttle position sensors is a potentiometer. During operation, gradual wear of conductive paths and moving contacts occurs. Over time, wear can reach such an extent that the sensor cannot function correctly. The presence of two sensors increases the reliability of the entire unit.

If only one sensor fails, the warning lamp will light up, but the engine management system will switch to backup mode. In this case, the engine will respond adequately to pressing the gas pedal, but with worse performance parameters

The reserve mode allows you to drive your car to the repair site under your own power.

Electronic gas pedal Lada Granta

On modern cars, instead of the usual cable drive for throttle control, a so-called “electronic gas pedal” is installed. In such cars, the throttle position is controlled electronically. When you press or release the gas pedal, information about this goes to the control unit (ECU) and only after processing and adjustment is a command given to the throttle module. The pros and cons of such a system, as well as signs of malfunctions, will be discussed in this article.

When is it necessary to replace the electronic gas pedal?

Due to the fact that this is an electronic drive, the main faults in it are related to the electronics. There are two sensors built into the pedal bracket that transmit commands to the control unit. If one of these sensors fails, a light on the panel will light up, which is responsible for the serviceability of the engine control system. In this case, the ECU goes into standby mode (the speed increases much more slowly). If two sensors fail, the emergency mode will turn on and the engine will operate as if idling. Since the sensors cannot be repaired, the electronic gas pedal must be replaced.

The wiring may also be damaged, and then the operation of the throttle will be disrupted. If the electric motor is worn out, then the monitor also displays an error indicating an accident. These damages can be eliminated, but if the accelerator of the electronic gas pedal, which is responsible for the dynamics of the car, fails, then this part should be immediately replaced with a new one. We'll look at how to do this below.

Electronic gas pedal gazelle business

Our service center is often visited by GAZelle cars, because this is a commercial vehicle that plows like a workhorse day and night. Every day, many GAZelles hit the roads of our country and sooner or later certain breakdowns arise, which we try to eliminate! Today is no exception. A GAZelle Business with a UMZ engine came to our repair zone! Well, let's help business!

After listening to the client: the car does not pull, the check light is on. After you turn the ignition off and on again, the car sometimes starts to work as it should, but then the problem repeats. The rpms don't rise above 2000.

Here it is, a workhorse!

Fig.1

Where to start repairs? Of course, with computer diagnostics. We connect the diagnostic equipment and read the errors that are registered in the engine control unit.

Fig.2

We are interested in the current error P2138 Throttle/Pedal Position Sensor/Switch “D”/”E” Voltage Correlation. What does it mean? This error literally stands for: P2138 incorrect voltage ratio “D” / “E” of the throttle position sensor or accelerator pedal . Our throttle valve is electronic, as is the gas pedal. That is, both the damper itself and the pedal may be faulty. In order to defect a pedal or throttle valve, you need to understand how they are designed, so first let’s look at their design features, structure and figure out what the difference is between a mechanical throttle valve and an electronic one.

The operating principle of the system with an electronic throttle valve and an electronic gas pedal.

And so, first of all, let’s look at the device of a mechanical throttle valve and figure out how the idle speed is adjusted.

Fig.3 Mechanical throttle valve (rpm 840..900)

In a mechanical throttle valve (Fig. 3), the idle speed control (4) is responsible for idle speed (engine speed). The throttle valve itself (penny 1) does not participate in idle speed control in any way. The idle speed control sets 55. 65 steps (mikas 7.1) to maintain speed in the region of 800. 900 rpm. The more steps the idle speed control has, the higher the engine speed will be, because... more air will flow through the bypass channel (3).

Fig.4 Mechanical throttle valve (rpm 1300..1400)

To maintain the idle speed at 1300.1400, the idle speed regulator (2) sets approximately 115.120 steps (Mikas 7.1). In this position, the regulator rod (4) increases the flow of air through the bypass channel (3), thereby increasing the speed.

But how does idle speed control work with an electronic throttle valve, and what parts does it consist of? The GAZ electronic throttle valve consists of the following parts (Fig. 5): the valve itself (penny 1), a gear motor (2) that controls the valve (penny 1), and two resistive position sensors (3)

Fig.5 Electronic throttle (rpm 850..900)

Let us clarify that in cars with an electronic throttle valve there is no idle speed regulator as a separate part. The throttle valve itself is responsible for adjusting the idle speed (penny, 1). To maintain idle speed, the throttle valve is opened slightly by 5.6% and the air that is needed to maintain idle speed passes through the valve itself (1). The damper is controlled by a gear motor (2). Sensors (3) read the current position of the damper.

Fig.6 Electronic throttle (rpm 1400..1500)

In order for the engine speed to increase to 1400.1500, the motor (2) slightly opens the throttle valve by 10.12%. Thus, the electronic damper itself participates in the process of adjusting the idle speed. The electronic throttle valve must be kept clean, therefore, in order to prevent engine speed from floating, it must be cleaned much more often than a mechanical throttle valve.

Electronic gas pedal repair – we fix the breakdowns ourselves

Basically, if any problems occur, the entire assembly must be replaced. But before taking such drastic actions, it would not hurt to find out the cause of the breakdown. To do this, of course, it is worth reading the information on how to check the electronic gas pedal. To do this, you need to disconnect the block and sensors, and then unscrew the fastening nuts and remove the pedal.

To directly check, you will need a multimeter: by connecting it to different terminals, we monitor the change in electrical resistance. It should decrease smoothly, but if jumps are observed, then the part is faulty.

In some cases, it is also possible to repair the electronic gas pedal, for example, if the wiring is damaged. So, having discovered a defect (the insulation is broken, the wires themselves are damaged, etc.), you need to act according to the following scheme. Having freed the gear mounting axis, remove the harness. To do this, you need to unsolder the wires, release the bracket and pull out the cable. Then we replace the wires, and, having disassembled the connector under the pedal, solder them. Now you can assemble the damper and drive safely.

If the car reacts to pressing the accelerator, so to speak, “with a delay,” then a spur (electronic corrector) of the gas pedal is needed. This device allows you to reduce the interval between pressing and opening the damper to a minimum. This is a separate module that connects to the sensors and, through a microprocessor, converts the signals supplied from them, and then supplies them to the controller.

So we see that the electronic gas pedal, tuning of which is possible in any specialized center, on the one hand, is a clear result of progress, and on the other hand, it somewhat limits our desires. True, if you do not belong to the category of those people who need to “drive with the breeze”, but prefer to drive carefully with minimal fuel consumption, then this option will be just for you.

Features of the functioning of the electronic gas pedal

Mechanical control systems have been replaced by modern high-tech systems for adjusting and adjusting the supply of the fuel mixture to the cylinders of the power unit.

It is noteworthy that the invention of the injector brought the development of electronic control systems for vehicles to a fundamentally new level, since in these mixture injection systems it is simply impossible to do without the participation of electronics.

At the initial stage of technology implementation, certain difficulties were noted in the compatibility of modern injection systems with mechanical fuel supply control. electronic gas pedal was designed at that time , the principle of operation of which was radically different from the standard mechanical system.

The sensors record the position of the accelerator pedal and, after processing the information, transmit the corresponding signal to the fuel injection control system. After analyzing it, the ECU generates the appropriate command, which is sent to the throttle valve actuator.

This allows you to adjust the supply of the working mixture to the cylinders of the power unit as accurately as possible. In addition, the ECU constantly polls other sensors, which allows you to select the necessary parameters of the fuel mixture as correctly as possible in accordance with the vehicle’s driving modes.