All about pressure in the fuel system of a car

Fuel pressure in the car system is one of the important parameters that is used in engine diagnostics.

The behavior of the car in various operating modes depends on the pressure. We answer the questions: how to measure the pressure in the fuel rail and how to use it to determine a car malfunction. To provide information more conveniently, we will divide the article into two large parts:

How to measure the pressure in the fuel system with your own hands

to find out the pressure in the fuel rail . For example, buy a device to check fuel pressure. A kit with a fuel pressure gauge, adapter and drain will cost you 1200-1300 rubles. Pay RUB 300 to the service station and take measurements there. You can also measure the pressure in the fuel system with an air pressure gauge , which is used to measure tire pressure. I will dwell on this point in more detail. Since the site is dedicated to cars of the tenth family, then further figures and some nuances will relate specifically to the VAZ 2110. Otherwise, the procedure is similar to any other car.

I’ll make a small digression right away. The peculiarity of pressure gauges is that their initial scale values have relative inaccuracy. What does it mean ? If the air pressure gauge has a scale of up to 16-20 atm (when the measurement limit for fuel is 5-7 atm), then pressure measurements will not be accurate due to this error, which will fall within the initial values of the instrument scale. Therefore, it is correct to check the fuel pressure with a fuel pressure gauge with a limit of 6-7 atm.

Take a pressure gauge (in the photo a device for measuring tire pressure). We wind the foam (plumbing flax) under the pipe and put on an oxygen hose with an internal diameter of 9 mm. Secure with clamps. Place a rag on the generator (so as not to start a fire under the hood). Unscrew the plastic cap on the fuel rail.

Under the cap there is a hole with a nipple. Unscrew it from the wheel cap. Due to the residual pressure in the rail after removing the nipple, gasoline will splash out.

If desired, you can relieve the pressure in the vehicle's fuel system . To do this, you need to remove the fuel pump fuse (under the right trim of the center console near the ECU, where there are 3 relays and 3 fuses. Usually the fuel pump fuse is on the far left) and wait until the car is running and does not stall.

We put the second end of the hose on the ramp hole and secure it with a clamp. We remove the rag from the generator and start the engine. Don’t forget to cover the generator with a rag again before removing the hose from the ramp. That's it, now you know how to check the pressure in the fuel system in the field .

By the way, instead of clamps, you can use the bushing of the classic adjusting bolt (item 27 in the figure). It screws perfectly onto the “tens” ramp fitting. To seal, we put a suitable rubber ring on the fitting. On the other side of the bushing we solder a fitting onto which we put a hose with a pressure gauge.

What pressure should be in the VAZ 2110 fuel system ? 2.8–3.2 bar (2.8–3.2 atm)

How to measure fuel pressure in a system where there is no return ? On VAZ 2110 with 1.6 liter engines, the pressure in the ramp is constant and amounts to 3.6-4.0 atm. Otherwise, the measurement technique is similar. Alternative ways:

- It is measured at the outlet fitting of the fuel pump module - this is the one with one tube. You will need a flexible gas-resistant hose with an internal diameter of about 8 mm and a pressure gauge (you need to remove the tube and put on a hose with a pressure gauge instead). The pressure should be 5-7 atm.

- Close the return line, as is done on an internal combustion engine with a drain ramp, but you must turn it off again at the fuel pump itself. We pull off the second hose (double) and insert a plug into the removed hose, made, for example, from an old fuel filter (saw off the nipple from it and plug it). A single hose must be put on the pump fitting, and now the measurement must be made at the fuel rail. According to the power system diagram, everything will be clear.

1 – fitting for checking the pressure in the power system;

2 – fuel rail; 3 – nozzles; 4 – fuel line; 5 – fuel tank; 6 – fuel pump module (in the fuel tank); 7 – fuel filter; 8 – tee. Video showing the process of checking the pressure in the fuel system of a car:

Car diagnostics using fuel pressure

Problems in the operation of the car's fuel system are expressed by failures at high speeds, jerking of the car, or the car does not move when you need to accelerate sharply, and sometimes it simply stalls. Now knowing how to check the pressure in the fuel system of a car, we can diagnose the car ourselves. We can determine which component of the fuel system has failed (fuel pump, fuel pressure regulator (FPR), injectors, filters, etc.), but first we need to understand how the fuel system works: The fuel pump continuously pumps fuel while the engine is running. Excess gasoline is stupidly dumped through the RTD into the return line. The pressure in the ramp changes (increases) not so much with the speed, but at the moment of accelerating (this is clearly visible in the video), because at this moment, the vacuum (vacuum) in the receiver drops and the RTD adds pressure to the ramp. If you turn off the engine, the pressure in the ramp will slowly begin to decrease exponentially. The rate of decline (from several minutes to several hours) depends on the quality of the check valve, which is located on the back of the fuel pump motor.

When diagnosing, pressure measurements in the system are made in different ways:

- Measuring how much the needle jumps when the ignition is on

- Measured at XX

- Measurement with the tube dropped from the RTD

- Metering with pinched return

What is the permissible pressure in the fuel rail ? The bigger, the better. You can't spoil porridge with oil. An example when there are no problems in the fuel system: when idling the pressure is 2.5 atm, when removing the tube from the regulator it is 3.3 atm, and when the drain pipe is pinched it is 7 atm. When accelerating, it jumps up to 3 atm and is restored back to 2.5 atm.

How to determine the status of the fuel pressure regulator (FPR) ?

There are two ways to determine if an RTD is faulty:

- If the pressure with the engine not running with the fuel pump turned on is below 2.8 atm. To turn on the fuel pump directly without starting the engine, then on the diagnostic block we close the closest contacts to the gear shift lever.

- Turn off the fuel pump. The pressure in the ramp should drop by about 0.7 atm and remain at this level. If the pressure in the fuel system does not hold and immediately drops to zero, then the RTD or the pump check valve is faulty (located on the back side of the fuel pump motor; it is not advisable to change the pump because of it). Do not rule out cracks in the fuel line or poor condition of the injectors (gasoline flows in)

How to determine the condition of the fuel pump ? In order to determine a fuel pump malfunction, you need to check the fuel pump “at the wall” (zero supply pressure or “at the plug”). In simple terms, this is the pressure that the fuel pump develops. It is by this parameter that the service life of the fuel pump can be determined. As the pump wears out, this parameter gradually decreases. When the pressure is “into the wall”:

- about 3 atm - the car stalls

- 4 atm - the pump will still serve

- 5-7 atm - the state of the new pump (the Czech gas pump produces 7 atm)

Checking the fuel pump “for a plug” is quite simple; you need to pinch the return line with pliers (for 2-3 seconds) with the car running and watch the pressure gauge readings.

Another way to check the fuel pump: smoothly raise the engine speed to 3000 rpm. If the pressure gradually drops, then this is a sign of a “dead” pump.

How to determine the condition of the fuel filter or fuel pump filter ? There are two ways to check the condition of the fuel system filters:

- If, when checking the pump “into the wall”, the pressure rises slowly, then this is a sign of a clogged fuel or fuel pump filter.

- We start the engine. The pressure gauge needle should tremble slightly, if it “walks” within 0.3 atm, then this may be a consequence of a clogged fuel pump mesh.

Question.

I recently went for an injector diagnostic.

The following figures were obtained: fuel pressure 2.4 kg/cm^3; injection pulse duration 2.01ms; discharge in the intake manifold 0.6/0.5; pump performance is 1.24 l/min (they removed the return hose and substituted a measuring jar) they said that the last figure is small, b.b. >=1.5 advised to change the fuel filter. I changed it, by the way, a lot of dirt came out. I drove up and measured the pump performance again - nothing had changed. They advised me to think about replacing the fuel pump, citing the fact that this figure will decrease and at some inopportune moment (for example, when overtaking) there may not be enough fuel with the fuel pump - I got this one or they “sit down” over time, the mileage is only nothing = 15 thousand km. At other stations they looked at me with round eyes when I asked about this parameter - Is the fuel pump disassembled and does it have a filter? I don’t notice anything yet (more precisely, there is nothing to compare with), although sometimes the car hesitates when accelerating... Could this be causing the following - after a short period of parking (5-20 minutes, the engine is warmed up to operating temperature), the car starts, but after 1 -2 sec. The engine begins to run unstably and stalls. Very similar to problems with starting a hot carburetor engine (overfilling?? or underfilling??). An immediate restart helps. I can’t say that I deliberately wait a couple of seconds after turning on the ignition for the fuel pump to work. This is from birth, appears randomly and, as I understand it, is practically not diagnosed. I would be grateful to hear the opinion of a specialist. Best wishes, Alexander. Answer.

The fuel pressure can be 2.4 at idle without load.

If you remove the hose from the pressure regulator and thereby supposedly create a load on the engine, the pressure should be approximately 3.0, but certainly not less than 2.8. If the service station workers did not do this, then they do not understand the principle of engine operation. If the 2.4 was under load, the fuel pump will indeed have to be replaced due to reduced performance. At low loads and at idle, an engine with such a pump will still work, but it will pull poorly, the car will not reach its maximum speed, and problems may occur when starting. Try to clamp the return line and measure the maximum pressure of the pump. It should be 5.5...6.0. If you get it in the region of 2.5...3.0, this will mean that the pump is on its last legs. If you refuel your car with low-quality gasoline containing dirt and water, the likelihood of the fuel pump failing is very high. pump performance 1.24 l/min

- information is incomplete.

At what speed, with what load, at what battery voltage? the engine is warmed up to operating t.) the machine starts, but after 1-2 seconds.

The engine starts to run erratically and stalls. Hang the pressure gauge on the line and after turning on the ignition, watch its readings: If the arrow rises slowly, it means that the performance is really low and it looks like the pump is clogged with dirt. Just replace.

Alexander Yakovlev Engine Design Department

What kind of fuel pumps are installed on VAZ 2110/2112 cars

The fuel pump is considered the most important element of the fuel system of any car. So, depending on what type of engine the VAZ 2110/2112 model is equipped with, the choice of fuel pump will also depend. An electric pump is installed on injection cars, and a mechanical one on carburetor cars.

The family is equipped with fuel pumps produced by AvtoVAZ. However, these units do not have a high service life and reliability, so often car owners do not wait until the fuel pump fails and replace it.

Installed at the factory on every VAZ 2110/2112 model

Most often, fuel pumps (Russia) and “Bosch” (Germany) are chosen for replacement. Their quality and durability have been known for a long time, although their cost is several times higher than the price of AvtoVAZ gasoline pumps.

The German manufacturer ensures the quality and durability of the products

It’s worth mentioning separately about the location of the fuel pump in the VAZ 2110/2112: the device is not located under the hood. To achieve maximum optimization of the fuel pump, manufacturers install it directly into the fuel tank. That is, to get to the pump, you will need to fold back the cushion in the back seat of the car and open the hatch hidden under the carpet.

The fuel tank and fuel pump are located under the seat cushion.

description, operating principle, malfunctions and repairs

The fuel pump is one of the important elements of the fuel system of any car. Its main task is to supply fuel from the tank to the distribution rail and injectors under the required pressure. Read about the VAZ 2110 mechanical fuel pump here.

Where is the VAZ 2110 fuel pump located?

And it is located in domestically produced cars directly in the tank of the car. Let's take a closer look at the VAZ 2110 injector fuel pump.

What, where and why?

As mentioned above, the pump is located in the car tank, while it is immersed in fuel. It would seem that this is a dangerous proximity (of fuel and an element driven by electric current), but I dare to reassure you, this arrangement of the pump does not pose any danger and was done for the following reasons:

- the pump contains an electric motor that directly drives the pumping element itself;

- a bunch of these units must not only supply fuel, but also do so under significant pressure.

All of the above, in turn, leads to the pump being noisy and requiring cooling. It is for these purposes that it is immersed in the fuel tank: the fuel acts for the fuel pump both as a coolant and as a noise-insulating compound.

By the way, the described scheme is applicable not only to the VAZ 2110, but also to most fuel-injected cars.

As for the “ten” itself, it uses a fuel pump manufactured by Bosch.

This pump is capable of creating a pressure in the fuel system of 3 atm. It is located in the so-called fuel assembly in the car tank, which also includes a fuel level monitoring system in the tank and a pre-cleaning mesh filter. The VAZ 2110 fuel pump is controlled by the engine’s electronic control unit (ECU) through the corresponding relay.

Principle of operation.

Fuel from the fuel pump is supplied through the fuel line to the fuel rail, having previously passed through a fine filter. The fuel rail is connected to the injectors. The latter, at the commands of the ECU, spray fuel into the engine manifold.

The pressure regulator included in the rail allows you to maintain the required pressure in the rail. It releases excess pressure through the fuel line back into the tank.

Malfunctions and repairs.

The main malfunctions of the “tens” fuel pump include cases when it does not create the necessary fuel pressure or does not work at all. Moreover, the reasons for both the first and second cases can be: breakdown of both the pump itself and its control elements; the condition of the fine filter and the tightness of the fuel line.

By the way, if the VAZ 2110 fuel pump itself breaks down, it cannot be repaired (it is replaced). The following factors in vehicle operation can lead to this:

- the habit of driving with an almost empty tank, due to which the fuel pump housing is almost always in a semi-dry state, causing it to overheat and suddenly fail;

- Failure to comply with the regulations for replacing filter elements in the fuel system leads to increased load on the fuel pump, because it not only has to maintain the required pressure in the fuel system, but at the same time also pushes gasoline through a filter clogged with dirt.

Considering the above, I would like to advise you to take care of your car and follow all the recommendations of its manufacturer. Only with such an attitude can you count on him to respond with loyalty and not let you down at a crucial moment.

Video on removing and disassembling the VAZ 2110 fuel pump

How to check the performance of the fuel pump

Checking the condition of the fuel pump is carried out only in cases where certain signs of its malfunction are observed:

increased noise during pump operation;

the engine power has sharply decreased - the car cannot accelerate quickly;

The car does not start because no fuel is supplied to the engine unit.

You can determine that the cause of the malfunction lies in the fuel pump yourself. In addition, this does not require complex diagnostic equipment or special knowledge.

Initially, you need to check whether the pump itself is working. After the ignition is turned on, a slight buzzing noise should be heard under the rear seat cushion for a few seconds. If there is sound, it means the pump is working.

Pressure check

To check the pressure of the fuel pump, you will need a pressure gauge . It will need to be connected to the fuel system, which is located under the hood of the VAZ 2110/2112. A pressure gauge is connected to the fitting of the fuel pipe that goes to the engine. If at idle the device shows a pressure of more than 3.3 kg/cm3, then the fuel pump is clearly faulty.

When connecting, be careful not to damage nearby hoses and wires.

If the pressure gauge reading is less than 2.3 kgcm, then the problem in the fuel system lies not in the pump, but in another element - the filter.

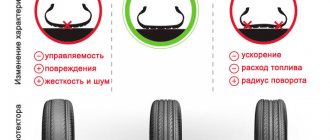

Based on these indicators, you can immediately identify the nature of the problems in the fuel system

What to do if the pump does not pump fuel

In some cases, the problem lies in the fact that the fuel pump does not turn on. Accordingly, it will not provide gasoline to the power unit, and the car simply will not start.

Checking the functionality of the pump is as follows:

recline the rear seat in the cabin;

remove the hatch cover;

turn the starter on to crank, but do not start the car;

Connect a tester to the contacts of the fuel pump - if power is supplied, but the fuel pump does not pump, therefore, the device itself has failed;

if there is no power supply, the problem lies in the relay, fuse or wiring.

The easiest way to check the health of the relay and fuse is to replace them with new ones. If the fuel pump still does not work, there is a short circuit in the wiring.

Based on the diagram, you can identify the location of the malfunction

Replacing the fuel pump VAZ 2114

You can turn to specialists, although replacing the fuel pump on a VAZ 2114 is often done by yourself.

You don't need any special skills or specialized tools. You will need this set:

- Key to 17;

- Ratchet with heads 10 and 7;

- Crosshead screwdriver.

Next follow the instructions:

- Remove the rear seats by removing two plugs and bolts with a 10mm ratchet. Behind them you will see a sound insulation slot made in the shape of a U. Under it is the pump cover.

- Use a screwdriver to unscrew the cover, after which you will see the upper part of the module.

- Disconnect the wiring harness that goes to the module.

- Relieve pressure in the system. To do this, start the engine until all the fuel is used up in the line. In other words, wait for the car to stall.

- Disconnect the battery.

- Using a wrench, unscrew the tubes on the gas line.

- There are 8 nuts around the perimeter of the clamping ring, which also need to be removed. Here you will need a 7 ratchet.

- Remove the pressure ring.

- After the manipulations have been completed, the module can be removed, a new one can be installed in its place, and the system can be reassembled in the reverse order.

Replacing the fuel pump on a VAZ 2110/2112 with your own hands

If the car owner has accurately diagnosed the failure of the pump mechanism in the fuel system, it will need to be replaced. It is worth noting that replacing the fuel pump on VAZ 2110/2112 cars is quite simple; even an inexperienced driver can cope with this task.

The fuel pump is usually replaced not only because it has lost its functionality, but also in other cases:

incorrect pressure readings when the pump is working;

insufficient fuel capacity;

after purchasing a new VAZ in order to get rid of the “weak points” of the model.

To work you will need a small set of tools:

10mm socket wrench.

The work procedure can be divided into two stages: dismantling the old device and installing a new one.

Instructions for dismantling the fuel pump

Disconnect the “+” terminal from the battery.

Fold back the seat in the back row and remove it.

Find a small hatch under the carpet.

Unscrew its fastenings and remove the cover.

Remove the connector with wires from the fuel pump.

To make it more convenient to work, the plastic clamps on the fuel pipes are cut, the tubes themselves are separated and removed from the fuel pump.

The pump itself is attached to the tank with 8 bolts. Using a 10mm wrench, you need to unscrew all the bolts and pull the device out of the socket.

The pump is pulled out along with the float and seal.

The procedure for removing a faulty fuel pump will take no more than 10 minutes - everything will depend on how rusty the fastening bolts are.

Installation instructions for fuel pump

A new pump is inserted into the vacated socket. In this case, the arrow on the body should point towards the rear of the car - this is the only way to ensure the correct position of the device.

After which the pump is screwed back to the tank with the same eight bolts.

Next you will need to connect the two fuel pipes to each other.

A connector is connected to the pump contact.

The final stage is installing the hatch cover and returning the rear seat cushion to its original place.

The procedure will take no more than 7–8 minutes.

Video: how to replace the fuel pump on a VAZ 2110/2112 with your own hands

Thus, the owner of cars of the “tenth” VAZ family can independently cope with such work as checking and replacing the fuel pump. It must be said that the fuel pump is indeed considered one of the most vulnerable points on the VAZ 2110/2112, so owners better be prepared in advance to carry out the necessary procedures with this device.

Malfunctions and repairs

The fuel pump fails for various reasons. Often - low quality gasoline. It is important to remember: before removing the pump, check the condition of the filter and the supply voltage at the terminals. Pump malfunctions are varied: failure of the electric motor, breakdown of the impeller, etc. The diagnostic and repair process includes the following steps:

- the rear seat and carpet are removed and the iron hatch comes off (the pump is located under it) - use a 12mm wrench and remove it from its seat with a slotted screwdriver;

- after dismantling, use a screwdriver to unscrew a pair of side screws - they hold the fuel pressure sensor in place (the float must be in good working order);

- two blocks are disconnected (supplying power) - one is connected to the bracket, the second to the motor (before disconnecting, the clamps should be released);

- the coarse filter is removed (looks like a fine mesh) - just pry it off with a screwdriver and move the lock washer;

- the electric motor is pulled out of the plastic housing - just press the plastic down (there are springs inside) and pull out the cotter pin;

- unscrew 2 screws securing the cover - after which it can be removed along with the rubber bushing;

Read also: Do you need a taxi license?

When all of the above operations are completed, you can remove the engine itself from the housing and install another module. It is important to remember: if the rubber bushing installed in the housing is deformed or partially destroyed, it must be replaced.

Fuel pump pressure VAZ 2110 injector

This article will talk about the purposes for which the VAZ 2110 fuel pump is used. As you know, the heart of any car is the internal combustion engine. With its help the car is set in motion. Among the main systems that are the most important in a car, the fuel system stands out. It is with its help that gasoline is supplied from the tank, which is located in the rear of the car, to the internal combustion engine. The fuel pump ensures uninterrupted pumping of gasoline at the required pressure. Moreover, the fuel pump operates in different modes, everything depends on the load on the engine itself, its saturation and performance. And don’t forget about the VAZ 2110 fuel pump fuse; if suddenly there is no fuel supply, check it first.

Mechanical fuel pump VAZ-2110 - characteristics and design

This type of mechanism is used exclusively on cars with carburetor engines. This VAZ-2110 fuel pump has its own mechanical drive from the camshaft, and it is located on the internal combustion engine.

By its design, this element is one of the types of piston and includes the following parts:

- Two-piece body with a lid on top.

- Diaphragm. It is installed between the lower and upper parts of the housing.

- Return spring.

- Stock. It is rigidly connected to the diaphragm.

- Discharge and suction valve. It is located at the top of the pump.

- Mechanical drive.

- Mesh filter.

The drive of this device, as we said earlier, is carried out from the camshaft eccentric. When this element rotates, the part moves the rod with the diaphragm down, and the spring force is overcome. The volume of space above it increases, and gasoline, due to the resulting vacuum, enters the pump through a separate valve from the gas tank. The discharge valve is closed.

The main operating mechanism of the pump is the diaphragm. It consists of two membranes, between each of which there is its own gasket. The diaphragm is connected to the rod. The latter interacts with the mechanical drive parts. There are different pump drive schemes. For example, domestic “tens” use a design that consists of a pusher and a lever with a balancer. Foreign cars use their own technology with a double-arm “rocker arm”.

Pump operation

Anything can happen while operating a car. In particular, the fuel pump may break down. Or the fuel tank is dirty, and therefore the filter installed at the bottom of the pump. It is worth paying attention to the fact that VAZ cars are very popular in our country. There are a lot of spare parts for them; you can find them in any auto store. True, the quality of products is not always good. Sometimes you come across outright fakes on the market that cannot last even a few months. Of course, you can run into a low-quality spare part even if you purchase it for a foreign-made car. The service life of the VAZ 2110 pump is about 100 thousand km. If we take into account the fact that on average a motorist travels about 30 thousand kilometers per year, then in the time period the pump service life will be about three years. After this, it is necessary to replace the VAZ 2110 fuel pump.

Causes of fuel pump failure on a VAZ-2110

Contamination of the fuel tank leads to premature failure of the fuel pump.

The main reason that can lead to failure of the fuel pump is poor fuel and a constant low amount of fuel in the tank (5 liters or less).

Incorrect operation of the unit can also lead to unit malfunction. Experts advise that when starting the engine, initially turn on only the ignition for 2-3 minutes and do not turn on the starter. During this time, the pump will pump the required amount of fuel into the system and create a certain pressure there.

The pump may also fail due to natural wear and tear . It usually lasts for a mileage of 150,000 kilometers . This is 4-5 years. But the timing may be different. It all depends on the conditions of its operation.

Burnt contacts of the fuel pump terminal block.

Sometimes a pump failure can be caused by a breakdown in the electrical network, failure of a relay or fuse. Such malfunctions can be quickly eliminated on your own. It's not expensive.

Important! The fuel supply pump can be repaired. This procedure will cost less than buying a new pump. But it’s not worth it (editor’s opinion).

Symptoms of a problem

There are several signs of a broken fuel pump. The sound it makes can be heard when the ignition is turned on. At this time, gasoline is pumped into the fuel rail to achieve the required minimum pressure value. If the sound suddenly begins to change, most likely the pump is broken. Also, extraneous noise may indicate a malfunction. If the car moves jerkily, the engine revs poorly. Or it has difficulty moving in first or second speed, most likely the reason lies in the fact that the fuel pump cannot provide a normal level of pressure in the fuel system. In this case, the internal combustion engine may suddenly stop because the VAZ 2110 fuel pump does not work. The injector functions only if a certain pressure is maintained in the ramp. And it is created by a pump.

Where is he located?

This device is located in the fuel line or in the fuel tank. Thanks to this placement, the risk of losses is significantly reduced due to the absence of suction lines.

Read also: Varta blue dynamic battery

The design of the electric pump assumes the presence of the following elements:

- Electric motor.

- Pump housed in a metal casing.

In other words, this device consists of an electric drive and a pump part. All its components are in direct contact with the fuel. In addition to the above elements, the module of this device also includes a fuel flow sensor, a fuel intake and a strainer.

And the part we are considering operates due to the presence of two valves - a check valve and a pressure reducer. The first locks the system when the engine stops operating. The second one performs the function of maintaining pressure in the system, while part of the fuel is transferred back to the inlet.

There are several types of electric pumps based on their design:

System pressure

Now let’s talk about how to determine if the fuel pump is faulty. And also about how to diagnose its breakdowns in the early stages. If suddenly all of the above symptoms begin to appear, it is necessary to clamp the fuel return hose to determine whether there is pressure in the system. In this case, it is necessary to perform this action as sharply as possible. As a rule, the maximum pressure value in the fuel rail is about 7 kgf/cm2. On average, a more or less normal gasoline pump shows an outlet pressure of about 5 kgf/cm 2 . In the car's operating instructions you can read that the minimum permissible pressure value is about 4 kgf/cm2. But this is in theory; practice shows that provided that the pump develops such pressure, it can still last for quite a long time. But replacing the VAZ 2110 fuel pump will still be necessary.

Pressure check

But we should not forget that the automaker wrote all its requirements based on the experiments carried out. If the gas pump does not pump fuel into the system at a pressure of 4 kgf/cm2, then the best way out would be to install a new element. Of course, it is quite possible that the filter at the bottom of the fuel pump has simply never been cleaned. If you replace it, it is possible that the level of pressure created by the VAZ 2110 fuel pump will increase significantly. And it will be quite enough for the car to have normal throttle response and dynamics when driving at high speed. Conventionally, you can carry out a small diagnostic of the fuel pump by disconnecting the fuel line from the ramp. When the power is turned on, a one and a half liter bottle should run to the pump in exactly a minute. Such a check is very relative; it can only be performed if there is no pressure gauge at hand or computer diagnostic systems.

Extraneous sounds

If suddenly there is an extraneous sound when the fuel pump operates, you will need to completely remove it. It is worth noting that the VAZ 2110 fuel pump consists of several parts; the base is an electric motor. It drives an impeller, which pumps gasoline from the tank into the fuel line. As a rule, extraneous sounds appear when the engine itself wears out or when the mesh is excessively contaminated, as well as when a non-original one is installed. If you suddenly have such a symptom, it is necessary to either replace or repair this mechanism, since there is a very high risk that in the near future this unit will simply fail.

Relay and fuse

If the engine suddenly stops starting, you should not immediately blame the fuel pump for everything. First of all, make sure that the switching relay is working properly. Also be sure to check the VAZ 2110 fuel pump fuse to see if it is receiving power from the battery. The relay, which turns on the tens fuel pump, is located in an additional compartment, which is located at the passenger's feet. It happens that the contact disappears in the relay connection block itself. Therefore, it is enough to just pull out and install a new one of this relay. If the car is quite old, then it is quite possible that the circuit board has begun to deteriorate. Small cracks form at the soldering site, which prevent current from flowing normally. As a result of this, the VAZ 2110 fuel pump relay does not turn on.

The article will be of interest to those who are looking for information about the technical characteristics and performance of the VAZ 2110 gasoline pump. Gasoline engines can be equipped with electrical or mechanical devices. For the VAZ 2110 car, the electric fuel pump of the Bosch brand is the most popular, as it has universal sizes, is always available in stores and is inexpensive.

Electric type fuel pump

The fuel pump for VAZ 2110 is an electric injector and is installed in cars with an adjustable injection system. The “tens” electric fuel pump is located in the fuel pipeline system in the vehicle’s gas tank. This dislocation of the element greatly reduces the possibility of fuel loss due to the use of a scheme without the participation of pipelines that work to suck in fuel.

This element of the fuel supply system includes:

- EDH;

- a pump, the body of which is made of metal;

- fuel level sensor;

- fuel intake component;

- filter mesh;

- check valves and pressure reducing valves.

The valve of the reverse principle of action stops the fuel distribution complex when the power plant is stopped. A pressure-reducing element controls pressure by acting as a bypass valve.

The designs of electric fuel pumps are:

- roller type;

- gear type;

- centrifugal type.

An electric roller pump sucks in fuel and drives it through the functionality of the rotor element and the movement of special purpose rollers. The gear electric pump sucks in fuel and drives it through and is pumped by moving an internal gear relative to the stator element, which plays the role of an external gear. When a rotational type rotor moves, the side elements of the tooth create a chamber in their segments that changes the degree of rarefaction, with the help of which the effect of suction and supply of fuel is created.

At the same time, a centrifugal type fuel pump is mounted directly in the fuel line. Such elements make it possible to ensure an even supply of fuel and operate almost silently. They have one significant feature - a limit on pressure parameters and functionality.

Main characteristics of the Bosch model

The VAZ 2110 gasoline pump has a performance in the range of 3-3.8 bar.

For each type of fuel system, the manufacturer produces a separate device. Many car enthusiasts replace a broken mechanism with a Bosch model with high pressure. The pressure of the VAZ 2110 fuel pump does not affect consumption, because the cars are equipped with a return line and excess fuel is returned to the tank. There is also a fuel pressure regulator. Fuel consumption may increase if the rail is not at optimal pressure. After which the nozzles do not spray, but pour gasoline, which does not have time to burn.

Parameters of the Bosch model 0580453453

If you are interested in a VAZ 2110 Bosch fuel pump, the characteristics of the models will differ in the length and sometimes in the diameter of the body. The diameter of the body is adjusted using a gasket made of gas-resistant rubber. Also, devices may differ in pressure, placement of chips on the terminals. The device grid does not differ in the number of seats, but may vary in shape. You can remake the chip for a terminal or install it from a VAZ car. The length of the fuel pump determines its performance when the volume of fuel in the tank is low. If it is located in a module, then compliance is required to install it. The length of the Bosch model 0580453453 is 105 mm, 0580453449 is 65 mm, and for Bosch 0580453465 this figure is 90 mm. The pump is located in the car tank, it is immersed in fuel. It contains an electric motor that drives the pumping element. A combination of these components supplies fuel under high pressure. As a result, the fuel pump is noisy and needs cooling. Therefore, the equipment is immersed in a tank of fuel, as it serves as a coolant and noise-insulating compound.

Fuel pump for VAZ-2110 - characteristics

The main characteristics of this device are the pressure level and housing dimensions. The most popular units today are German-made Bosch units. The pressure of the VAZ-2110 fuel pump is about 2.8-3.8 Bar. The characteristics of a fuel pump itself are rarely determined by the diameter of the housing; most often it is the length.

The dimensions of this part can be very diverse. Depending on the model and brand of the manufacturer, this parameter is 65, 90 or 105 millimeters. And these are not all the sizes of VAZ fuel pumps.

In addition to the length, these devices differ in the location of the terminal chips. The mesh itself, in terms of its seats, practically does not differ by brand. By the way, the length of the gasoline pump itself determines its performance when the fuel level in the tank is low. That is, when choosing, you need to pay attention to longer elements. By the way, the diameter of the housing can be varied using a gasket made of gas-resistant rubber.

How to buy a quality device?

The price for a VAZ 2110 fuel pump in market conditions will be 2 times lower than in a specialized store. The equipment is in durable and sealed packaging. Inside the package is purified gasoline. If you smell gasoline, then the seal of the packaging is broken and there is a possibility of corrosion forming inside the gasoline pump. Submerged equipment is lubricated and cooled by fuel. When using low-quality additives and gasoline, internal electrical mechanisms are corroded. If additional substances are not used in the operation of the device (dry), then the brushes wear off and it overheats. The service life of the equipment is longer. Some car owners are planning to replace the VAZ 2110 Bosch fuel pump, the characteristics and pressure of which are not normal only due to long-term use. Its pressure can be 6-7 atmospheres. It was amazing to hear from an experienced driver his method for testing the fuel pump. To do this, he took a jar of water, turned it on on the battery, and by the flow of liquid he realized that the power of the gas pump had decreased.

How to check the pressure in the fuel rail of a VAZ 2110

There are several ways to check pressure. This article will describe the most commonly used of them.

To do this, you will need to purchase a special kit, which includes:

- Special adapter for connection;

- Pressure gauge;

- Drain.

All this will cost you approximately 1,500 rubles. You can also turn to specialists (service stations) for help, who will perform an inspection for 300-500 rubles.

Pressure gauge

But there is a more interesting method that will allow you to do without extra costs. Fuel pressure can be measured with a tire pressure gauge to check tire pressure. To do this, it is better to use pressure gauges with a minimum limit (6-7 atmospheres). This will reduce the error as much as possible.

Now let's take a closer look at how to do this:

- First, you need to prepare a pressure gauge and wind the fum tape directly under the pipe.

- Secondly, you will need an oxygen tube with a diameter of 9 millimeters, put it on top.

Next, we fix the fasteners on both sides with clamps. To avoid fire, the generator should be covered with something.

Now you need to reduce the pressure to a minimum. This is not difficult to do. To do this, remove the fuse that powers the fuel pump (in the case of the VAZ 2110, it is located near the control unit, on the left under the trim).

The next step is to start the engine and wait until it stops.

Unscrew the cap installed on the fuel rail.

Inside the cap you can see a nipple and a standard hole. Then take the wheel cap and unscrew it. Due to the presence of residual pressure, you should be prepared for a small fuel release.

Now you need to put the second edge of the hose on the ramp outlet, and then secure it with a clamp.

And the last stage. Remove the “protection” from the generator and start the engine. But before that, do not forget to replace the fuse.

This method of measuring fuel pressure is one of the simplest and most effective.

Normal pressure is from 2.8 to 3.2 bar (atmospheres).

Fuel rail VAZ 2114

The fuel rail is used to install injectors on it. It is a tube or a hollow bar, the ends of which are welded on both sides. It is attached to the intake pipe on the manifold using two bolts.

Fuel rail VAZ 2114

The pressure in the fuel rail of the VAZ 2114 in front of the injectors is maintained by a fuel pressure regulator. In this case, the fuel pressure must be higher than the pressure in the intake manifold, otherwise fuel will not be injected from the injectors and create a mixture. At the fuel rail, the pressure must be maintained within strictly limited limits - from 2.9 to 3.3 kg/cm2.

It is necessary to measure the pressure in the fuel rail if problems arise with the fuel system. Before work, make sure that the vehicle is sealed, there are no microcracks or leaks, otherwise the pressure gauge readings will be unreliable.

- Insert a pressure gauge into the end of the prepared hose and secure it tightly using a clamp.

- On the fuel pressure fitting, which is located at the free end of the ramp, unscrew the plastic cap. He closes the nipple.

- Place an empty bucket to collect gasoline, press the nipple and release any remaining pressure in the rail.

- Do not remove the bucket, unscrew the nipple.

- Place the free end of the hose onto the fitting and tighten the clamp onto the free one.

- Tighten the clamp on the fitting to avoid leakage.

- Pump fuel into the ramp using a fuel pump.

- Start the ignition, check the pressure gauge readings. As a rule, it is 2.9-3.1 kg/cm2, but not less . If the reading drops to zero, then the pressure regulator or pump check valve has failed.

- Now check at idle speed. Start the engine, look at the pressure gauge readings. The norm is an indicator of at least 2.5 . If pulsation occurs and the sensor rises and falls by 0.2, then the coarse filter should be cleaned.

- Before checking the rail pressure to inspect the RTD, remove the vacuum hose that comes from the exhaust manifold. In this case, the pressure should become 3.0-3.3. If no changes occur or they are minimal, then most likely the fuel pump has failed.

- Turn off the return line and check the pressure under such conditions. Pinch the return hose from the RTD to the tank with pliers. Then the pressure increases to 6-7. If the readings are lower, then the pump is worn out. An indicator of 4.0 indicates the need to clean the pipeline and fine filter.

How to check the pressure in a system with no return?

The VAZ-2110 with a volume of 1.6 liters has constant pressure indicators in the ramp, which, as a rule, vary around 3.6-4 bars.

In addition to the most commonly used measurement methods described above, there are several more unusual solutions:

a) Here we return again to the hose with a pressure gauge, the diameter of which should be 7.5-8 millimeters. Measurements should be taken at the outlet of the fuel pump module. Five to seven atmospheres are normal test results.

b) Remember how the return line is closed on motors with a drain frame. It is recommended to turn off the engine directly at the gasoline pump. Next, you will need to remove the double hose and insert a plug (“The nipple” from an old fuel filter may also be suitable for this task). Now you need to pull a single tube onto the pump fitting. The measurements themselves must be made at the fuel rail.

How to clear a blockage if the fuel supply line is clogged.

One of the reasons for low pressure may be a malfunction of the sensor that regulates the fuel pressure before injection. Low pressure may also be a consequence of a clogged fuel line. By taking proper measurements, you can accurately determine the cause of the malfunction. First, you should check the pressure of the pump and line, then measure the pressure in the ramp. All of the above will help determine the exact cause.

How to clear clogged fuel injectors.

There are several signs to tell you that your fuel injectors are dirty. Let's start in order.

- Difficulty starting the engine.

- Unstable engine operation.

- Dips in the timing of sharp pressure on the gas pedal.

- Loss of power and deterioration in acceleration dynamics.

- Increased toxicity of treated gases.

- Increased fuel consumption.

- The occurrence of detonation.

- Popping sounds in the exhaust system.

- Misfires.

To solve this problem you need to clean the fuel injectors.

Clogged valve. How to identify and fix the problem.

When the valve is clogged, fuel is difficult to pass through, and because of this, it begins to leak everywhere. A significantly increased fuel consumption indicates that it is time to change the regulator, since it is the leading component. Fuel stops being supplied to the supply system if the valve becomes completely clogged.

What to do if the valve is stuck.

Uneven pressure in the system is usually the result of a stuck valve. Because of this, the vehicle's movement may be uneven. The car may also jerk or stall.