A broken timing belt (gas distribution mechanism) on many modern engines causes the piston to hit the valves. The result is that the valve bends, and the piston itself can also be damaged. For this reason, some car enthusiasts change the piston group in the engine, installing a so-called plugless piston.

Plugless pistons have a slightly modified design compared to the standard, which avoids contact between the valves and the piston in the event of a timing belt break. However, it should also be taken into account that after installing pistons of this type, the characteristics of the motor also change. Read more in our article.

Plug-in motor: features

Motors of this type differ from analogues in that if the camshaft stops, there is no collision with the valves. The main difference between “stickless” pistons and conventional ones is that they have special grooves in the upper part. Due to this, the pistons do not “stick” into the valves.

Thanks to such grooves on the piston mirror, it is possible to increase the service life of timing parts and the piston itself. However, in practice, such pistons are not installed on modern engines.

The fact is that today in the manufacture of engines the most lightweight parts are used; they try to get maximum output from the engine to the detriment of the resource. It is simply not possible to make grooves on lightweight pistons. In this case, the solution is to install heavier pistons with grooves.

List of car models in which it was installed

For the first time, the VAZ 21126 engine appeared on the Lada Priora sedan 2170 and hatchback 2172 in 2007 - 2008. Later the Priora station wagon and coupe came out. After running in the VAZ 21126 engine on Priora, it was installed on Kalina, Samara and Grants.

Similar article Technical characteristics of the VAZ 2130 engine

| Models of cars with VAZ 21126 engine | Body | Years of manufacture |

| Kalina | Sedan 1118 | 2008 — 2014 |

| Sports 1119 | 2009 — 2013 | |

| Station wagon 1117 | ||

| Hatchback 1119 | ||

| Kalina 2 | Hatchback 2192 | 2013 — 2018 |

| Station wagon 2194 | ||

| Sports 2192 | 2014 — 2018 | |

| NFR 2192 | 2016 — 2017 | |

| Samara 2 | Hatchback 2114 | 2009 — 2013 |

| Coupe 2113 | 2010 — 2013 | |

| Granta | Sedan 2190 | Since 2011 |

| Liftback 2191 | Since 2014 | |

| Station wagon 2194 | Since 2018 | |

| Hatchback 2192 |

The VAZ 21126 engine is mainly used in cars equipped with a Jatco JF414 automatic transmission.

Why install a “stickless” piston on a Priora

In practice, a standard design with proper care, compliance with operating rules and maintenance will work for a long time. The main thing is to timely service the timing belt, change the rollers and belt, troubleshoot problems, and use high-quality parts.

However, high loads, difficult conditions, irregular maintenance and the use of spare parts of questionable quality significantly reduce the reliability of the motor. You can also mention engine tuning.

In this case:

- The service life of the rollers and timing belt is noticeably reduced; replacement is required not every 40 thousand km, but every 15-20 thousand.

- Driving at extremely high speeds, boosting the engine or installing turbocharging will also require frequent replacement of the belt and rollers.

It is quite obvious that if the belt breaks, the engine will suffer seriously and will require expensive repairs. In turn, “stickless” pistons solve this problem. Installing such a piston on the Priora will allow you not to worry about the engine in the event of jammed rollers and a broken belt. However, the disadvantages of such a modification must also be taken into account.

Installation on PRIORU

As promised, I will describe the installation on our VAZ (PRIORA), because it is one of the most purchased cars in our country and it has frequent problems with the timing belt. Many will immediately ask the question - do the valves bend when they break? Read the answer here.

In principle, no difficulties should arise here, but it is practically impossible to do this yourself in your yard! The engine will need to be disassembled.

1) We buy plugless pistons; usually the kit can be selected directly to your piston size. That is, if you have an 86 mm piston, then you can also take a plugless piston of 86 mm. However, you need to either know the exact dimensions, or measure them at a service station during disassembly. The cost can vary from 3,000 to 6,000 rubles per set.

2) We disassemble the engine to remove the pistons; it may need to be removed. (Of course, you don’t have to remove it, this is at the discretion of the masters, there are methods both ways)

3) Remove the piston group and replace it with grooved pistons.

4) Next we assemble the engine

Many drivers sacrifice power for the sake of greater practicality - you can understand them, especially if you look at the aftermarket. If there is a break, you can fly into such repairs that it won’t seem like much, but this way you are protected.

Let's watch a short but useful video on the topic.

I will finish, I think you liked the continuation of the article. Read our AUTOBLOG, updates almost every day.

(

26 votes, average: 3,77 out of 5)

Pistons with grooves for valves: pros and cons

As mentioned above, the standard piston is light and smooth at the top. When the timing belt breaks, the valves collide with the piston, which leads to engine failure. On a “stickless” piston, which is “heavier”, there are several grooves in the upper part (2 or 4, depending on the number of valves per cylinder).

Advantages

Among the main advantages are:

- High reliability, since if the timing belt breaks, the valves fall into the grooves and the engine does not suffer damage. It is enough to replace the belt and rollers and you can continue to operate the motor.

- Some experts and car owners note that the pistons themselves on the Priora with grooves are more reliable, are not so afraid of overheating, are less likely to burn out and crack, etc.

We also recommend reading the article about which is better, a timing chain or a timing belt. From this article you will learn about the advantages and disadvantages of these types of timing drives.

Flaws

When it comes to cons, the disadvantages of plugless pistons for automakers outweigh the advantages. Simply put, with such a piston, power decreases, fuel consumption increases, and the environment suffers.

- The piston for the grooves must be “heavy”; the piston body cannot be lightened. The reason is that in order to make grooves, the top of the piston must initially be thick. At the same time, with lightweight pistons without grooves, the engine receives additional power of up to 7%.

- The presence of grooves worsens the compression of the working fuel mixture and at the same time slightly increases the volume of the combustion chamber. This additionally takes away power, since a slight increase in volume is not able to compensate for the losses from a lower compression ratio. On average, an engine with plugless pistons is 10% less powerful and also consumes 10% more fuel.

- Another disadvantage is detonation, which can occur due to uneven distribution of piston pressure when compressing a mixture of gasoline and air, etc.

As a result, automakers abandoned the decision to make grooves on the pistons and relied on engine performance. Lada Priora was also no exception. However, if necessary, you can purchase Priora plugless pistons and modify the engine.

“Priors” piston: features of selection, replacement. Domestic car LADA Priora

Not all consumers like the products of the domestic manufacturer of passenger cars represented by the leading flagship AvtoVAZ. This explains the fact that in almost any metropolis in Russia, mostly foreign-made cars drive on the roads. However, not all domestic cars are so bad.

It is worth highlighting the Lada Priora brand (VAZ 2170), which has one feature. The car's engine is equipped with a lightweight connecting rod and piston group, which reduces the noise level during operation of the power plant. In addition, less fuel is now consumed.

And everything would be fine, but each piston on the Priora has a plug-in design.

What could it be? As noted by many drivers who have already enjoyed the silence and economy of a car, a broken drive belt is a fairly common occurrence. As the manufacturer notes (this is also indicated in the instructions), the timing drive resource is 200 thousand km, but practice proves the opposite. For many drivers, a belt break occurs much earlier - after 40-60 thousand kilometers.

In any car, even with the most modern electronics, there is a gas distribution mechanism (or timing). The general system consists of:

- camshaft;

- valves (intake and exhaust for each cylinder);

- rods (intermediate link between the shaft and valves);

- drive belt (sometimes it is a chain or a group of gears).

All engines operate in four stroke mode. In this case, the operation of all valves (opening and closing) and Priora pistons of each cylinder is performed in strict sequence. To do this, the camshaft needs to rotate. To do this, the crankshaft is used, from which motion is transmitted to the timing shaft, and a belt, chain or group of gears acts as a connecting link.

On many cars, including Priora, a belt is used to reduce noise levels.

Timing belt diagnostics

Many new Prior owners may be wondering how to diagnose a timing belt. Experienced drivers know very well that such a procedure does not involve anything complicated. As is already known, a broken drive belt can have dangerous consequences for the entire engine.

This can be recognized by a characteristic sound - at the moment when the belt breaks, a loud bang is heard for a short time from under the hood, and the car immediately stalls.

After this, it is no longer possible to start the engine, and the operation of the starter will be accompanied by a characteristic metallic knock - this is how the Priora piston hits the valves.

In order to once and for all prevent the meeting of pistons and valves, it is necessary to periodically check the technical condition of the timing belt. It is also worth checking its tension.

Approaching the mileage mark of 60-70 thousand km, you should listen carefully to the operation of the engine and if you detect any extraneous sounds that should not be there, you must immediately carry out diagnostics.

You can do this yourself or go to a car service center, where the work will be done at a more professional level.

A visual inspection will determine whether the belt needs replacing or not. There should be no defects on its surface. If you can see cracks or find that the integrity of the teeth is compromised, then you can draw disappointing conclusions and go to the nearest auto parts store. You should also be alert for oil leaks and wear.

Causes of belt breakage

Due to a broken belt, the Priora piston begins to bend the valves, but what can bring the belt itself to this state? The main reason is inevitable natural wear and tear.

Here it is important to be realistic and understand that any belt, even from the highest quality material, is unlikely to be able to withstand the load for more than 100,000 km.

In this connection, it is better to replace it after every 60-65 thousand kilometers.

But besides wear and tear, the belt breaks for other reasons. If you install a timing drive with weak or excessive tension, damage cannot be avoided. Operating Russian cars under high load conditions is also not beneficial.

In some cases, the tension pulley may become loose or suffer varying degrees of damage. Also, the water pump pulley can jam at the wrong time. All this can also lead to slippage or breakage of the timing drive.

If the connecting link is worn out, then the economy does not work here, since everyone knows perfectly well what usually happens to stingy people, from the well-known saying.

Why is timing belt break so scary?

The entire timing assembly is an important mechanism in the engine of not only the Priora, but also any other car. And in this node there is one element that bears a very great responsibility.

We are talking about a drive belt that connects all the elements of the system. When in good condition, the timing belt allows valves and pistons to operate in synchronization.

At the same time, they do not interact with each other, which significantly extends their service life.

However, such a minor malfunction on Russian cars as a broken drive belt can lead to a disastrous result - the well-functioning operation of the entire system fails.

The entire mechanism stops and each of the valves freezes in a different position. And it’s good if any of them does not meet the piston that is moving towards.

Unfortunately, in most cases the inevitable happens - the piston hits the valve.

The outcome of this meeting can be very different. And valve curvature is not all. The piston itself and the entire gas distribution unit are destroyed.

It’s rare that you can get away with minor damage, but in practice the consequences can be serious. The possibility of complete engine failure cannot be ruled out, and in this case only a major overhaul will help.

Does anyone know how much the Priora costs? We'll talk about this a little later.

Such consequences can be caused by factory defects, although not everything is so clear. On the original pistons, the counterbores (recesses for the valves) are very small. Someone may immediately object, expressing the opinion that you need to carefully monitor the condition of the drive belt.

This remark is partly true. However, in reality, even a scrupulous diagnosis does not provide a complete guarantee, and sooner or later trouble still strikes. The only question is when and where?!

Features of the pistons

The piston of an automobile engine is a necessary element of the cylindrical shape of the crank mechanism (crank mechanism), which plays a key role. It is he who converts the explosive energy from the combustion of the fuel-air mixture into forward motion, which is transmitted to the crankshaft. In this case, everything happens in a cyclical mode.

It’s interesting, after all, has anyone thought about the question: “How much does Priora cost?” We inform you especially for them: a new car will cost 390-490 thousand rubles (depending on the configuration).

During engine operation, the piston is constantly under the influence of mechanical load under conditions of particularly high temperature. Inside the Priora engine, the pressure can reach a colossal value - 6.5-8 MPa, which is equivalent to almost several tons.

Fuel explosions can accelerate the pistons to speeds of 100 km/h or faster. When the working mixture explodes, the temperature reaches 1800-2600°C, and this temperature load greatly affects the strength characteristics. Sudden temperature changes also occur, leading to thermal stress.

Piston design feature

To withstand the enormous loads during engine operation, the piston must have the necessary characteristics. First of all, the part must be as light as possible.

The material from which pistons for internal combustion engines are made must have high wear resistance.

And in order for the part to cool quickly, the alloy used in production must conduct heat well.

In addition, the surface of the piston in a domestic car engine must be manufactured accordingly to eliminate the risk of jamming when exposed to high temperatures. At the same time, fuel combustion products should not leak into the crankcase.

Typically, the top surface of the piston is coated with a special protective coating to withstand maximum loads. The entire working surface of the piston also has a special coating for better sliding in the cylinder cavity. In this case, the material remains throughout the entire service life of the parts.

The piston skirt is designed to compensate for thermal expansion. During the production process, it goes through the stage of processing with cutters, as a result of which a microrelief is created. This measure allows the oil to stay on the part longer and effectively reduce friction.

This all applies to standard products for the Lada Priora. As you can see, the pistons meet many requirements for strength and reliability. The “Priora” plugless piston is completely similar to the standard product, with only one difference – there are deep recesses on the upper part. As a result, the possibility of pistons and valves meeting is eliminated, which protects both from damage.

Options for plugless pistons

This is decided individually in each specific case. On the Russian market you can find various products, including buttless pistons:

- “STI.”

- “Autramat.”

- “STK” (Samara).

“STI” pistons from Tolyatti are produced by hot pressing, which is their main feature. However, they did not receive a response from many Priora owners, and here’s why: the compression ratio is very low, and the combustion chamber is very large.

As a result, the engine efficiency drops significantly. Such products are less heat-resistant due to the low silicon content. And the lack of nickel reduces their resource. In addition, when installing such pistons, timing belt breakage is a fairly common occurrence.

In addition, the price of such pistons is quite high.

Avtramat products are manufactured in Ukraine on the territory of a Kharkov enterprise using the injection molding method. They also have their weaknesses, but the efficiency is not significantly reduced, which is not bad.

Samara “STK” pistons on “Priora” have similar characteristics as Kharkov parts, but have more weight. This is their main drawback, but the advantage will most likely please many, since their price is a third less. In addition, the samples on the surface are deeper.

From the options considered, everyone will choose something to their liking, but it is better, if possible, to avoid products from craftsmen from Tolyatti for obvious reasons. It is better to initially buy expensive pistons than to suffer with cheap parts later.

Replacing pistons

The decision to replace standard pistons with a plug-in version is more than justified, since it will protect the engine from early breakdown. The work requires a good approach and free time, since a considerable amount of detail will have to be removed.

However, if you lack time and have funds, you can use the services of a car service. There, the replacement of pistons (Priora) will be carried out at a professional level, but money will also be required in the region of 7-10 thousand rubles.

It all depends on the complexity of the repair.

It is better to replace pistons on a lift or a well-equipped inspection pit. First you need to drain the antifreeze and oil into containers. The further procedure looks something like this:

- The engine must be thoroughly cleaned of dirt.

- Using a 13mm wrench, unscrew the bolts securing the engine support bracket on the right side.

- The next step requires unscrewing the generator mounts using a 15mm wrench. Remove the freed front engine bracket.

- The pipeline is disconnected, the cylinder head is dismantled along with the flywheel and oil filter.

- The tube connecting the pump to the cylinder block is removed.

- The next step is to remove the oil pan, oil pump and oil receiver.

- Use a 10mm wrench to unscrew the crankshaft rear oil seal holder fasteners. It can be easily removed - just pry it off with a screwdriver.

- Next, all fasteners of the connecting rods are unscrewed, after which they are removed along with the pistons.

- The rings are removed from the pistons; it is worth paying attention to their condition and replacing them if necessary.

- Using a 16-18 mm mandrel, remove the pin, after which the piston can be easily removed from the connecting rod.

- 3 mm;

- 10 mm;

- 60 mm;

- 112 mm.

If a domestic car has traveled a long distance, an additional procedure is required, which requires a bore gauge.

Final process

With this tool you need to measure the inner surface of each cylinder at the following points (starting from the top):

The degree of wear should be judged by the difference in these measurements. If it is approximately 0.05 mm, then this is still an acceptable value. If the difference is 0.15 mm or more, cylinder boring is required.

At the final stage, all that remains is to install new pistons and assemble all the parts in reverse order.

Finally

After the standard pistons are replaced with an improved analogue, new oil should be added. After this, let the engine idle for 10 minutes. At first, you will have to drive a car with great care. This means that for the first time (the first 2000 km) you need to drive at a speed of no more than 90 km/h and maintain the speed around 3500, no more.

If you follow these tips, the price of a piston for a Priora will not seem so high in the end. At least for the near future, you don’t have to worry about the belt breaking. But it is still worth periodically checking its condition.

Design Features

crank mechanism

The cylinder block (BC) is made “traditionally” of cast iron and painted gray. Cast iron has high strength and rigidity characteristics and is easy to process. The internal surfaces of the block are treated with honing, which gives the structure anti-friction properties and wear resistance. The distance between the axes of the cylinders is 89 mm, height is 197 mm. The block is engraved with cylinder class markings A, B, C with a dimensional increment of 0.01 mm.

The BC head has been modified to accommodate the new timing belt installation scheme. Casting technology has also changed. Together with the cylinder head, spark plug well channels and channels for coolant circulation are cast. A reinforced gasket is installed under the head: two-layer metal 0.45 mm thick.

A design feature of the ICE 21126 is the partial use of foreign components. Thus, the lightweight ShPG is supplied by the American company Federal Motors. The weight of the connecting rod-piston group set in the VAZ 21126 engine is reduced by 32% compared to the VAZ 21124.

The connecting rods are forged from steel. 17.2 mm liners are installed in the lower head, and a steel-bronze bushing is pressed into the upper head. When reassembling the connecting rod, new bolts must be used.

The pistons are cast from aluminum alloy. Two compression rings and one oil scraper ring are installed in the head. Until 2020, the pistons of the VAZ 21126 engine were plug-in, despite the presence of small recesses. When the timing belt drive failed, the valve legs were bent, and the engine required expensive repairs.

timing belt

The valves are driven by two cam camshafts located in the cylinder head. Hydraulic compensators are used to automatically adjust the gaps, which simplifies maintenance and does not require manual adjustment.

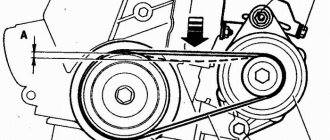

The VAZ 21126 engine is equipped with a 22 mm wide timing belt with 137 teeth from Gates. Rollers are used to automatically tension the belt. The use of a new mechanism led to the need to manufacture other pulleys for the camshafts, pump and crankshaft. The profile of the toothed pulleys corresponds to a timing belt with a semicircular tooth.

Systems

In the VAZ 21126 ignition system, a separate coil is provided for each spark plug. Pulses are controlled through an electronic system. The disadvantage of the scheme is the low quality of consumables and the rapid breakdown of non-factory coils.

To supply fuel to the internal combustion chamber of the VAZ 21126, an electric fuel pump, a throttle, a fine filter, and Bosch or Siemens injectors located on a stainless steel fuel rail are used. The vapor recovery system prevents vapors from escaping into the atmosphere. The fuel supply is controlled by the ECU.

Combined lubrication system. Oil is supplied to the rubbing surfaces under pressure and sprayed onto the cylinder walls and piston heads.