- a five-door hatchback from the Volzhsky Automobile Plant, a restyled version of the VAZ-2109, a continuation of the family under the code name “Samara-2”. The model differed from its predecessors in the original design of the front part of the body with new headlights, hood, radiator trim, bumpers and the presence of moldings.

Presented to the public in 2001, serial production - from April 2003 to December 2013 [1].

The interior of the VAZ-2114 was equipped with a new instrument panel (the so-called “European panel”), an adjustable steering column, a steering wheel from the “tenth” family, a new heater design, and front power windows. The car was equipped with a 1.5-liter eight-valve engine (VAZ-2111) with distributed fuel injection.

The first copy of the VAZ-2114 was assembled on the factory assembly line in October 2001.

From 2003 to 2005 they were produced with 1.5L Euro-2 engines. From 2005 to 2007 they were produced with 1.6L Euro-2 engines. Also during this period, we smoothly switched from the 21114 engine to the Kalinovsky VAZ-11183.

Since 2008, cars began to be equipped with a new control unit (M73) and environmental friendliness became higher than Euro-3.

Since 2011, the control unit (M74) has been replaced. According to the documents, environmental friendliness has not changed, but in fact, thanks to the transition to a new control unit, the car began to comply with Euro-4 requirements [ source not specified 658 days

] . Because of the new control unit, the gas pedal was replaced by removing the cable, now the engine is completely electronically controlled, which immediately gave rise to a bunch of problems in the first batches of the car. By the end of 2011, the problems were partially resolved with the release of new firmware I414DE06. At the beginning of 2012, the malfunctions were overcome with the new firmware I414DE07, which became final and no more updates were released.

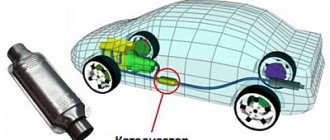

Since 2007, the car has been equipped with a new eight-valve 1.6-liter engine (VAZ-11183) of environmental class up to Euro-3 inclusive, the model receives the VAZ-21144 index. An “electric throttle” and an “electronic gas pedal” (E-gas) were installed. It was produced in standard and luxury versions. Distinctive features from the old engine - the catalyst is located not under the bottom, but near the engine, a plastic decorative cover is put on the engine, instead of an aluminum receiver, a plastic one is installed. In addition to the new engine, the car received a new front panel (there is no glove compartment in the upper part, a more rigid material is used, which increases strength, but also increases the likelihood of extraneous noise), a new instrument cluster with an on-board computer function (shows outside temperature, voltage in the on-board networks, current time and other parameters).

In 2007, there were minor changes in appearance: instead of wide moldings, narrow ones began to be installed on the doors. In 2009, a subsidiary of AvtoVAZ OJSC, Super-Avto CJSC, modernized the VAZ-2114, namely, it installed a 16-valve 1.6-liter engine on the car; The car's power became 89 horsepower. With a 16-valve engine, the car model received an index 211440-24

. The dynamic characteristics of the car have increased. In addition to the engine, the suspension, gearbox, clutch and brakes were changed. This model was equipped with 14-inch wheels on stamped rims.

In 2010, Super-Avto CJSC prepared for production a car with a 1.6-liter 21126 16V engine from [[VAZ 2170|Lada Priora]] with a capacity of 98 hp. With. This model received the index 211440-26

.

Engine 1.6l 16kl

On VAZ 2114, 2113, 2115, in a limited series from the SuperAvto production, 16kl were installed. 1.6 liter engines with indexes 21124 from “Dvenashka” with a power of 89 hp. and from Priora with index 21126 with a power of 98 hp.

Engine 21124 1.6l 16kl:

- Power – 89hp

- Torque – 131 Nm at 3100 rpm. min.

- Acceleration to 100 km/h – 11.5 s.

Engine 21126 1.6l 16kl:

- Power – 98hp

- Torque – 145 Nm at 4000 (rpm).

- Acceleration to 100 km/h – 10.5 s.

Review of VAZ 21114 (2007)

The last review I published described operation up to a mileage of 50 thousand km. At the moment, there are already 72 thousand on the odometer. I’ll tell you my operating experience during this period.

engine (1.6L; 16V) copes well with the tasks assigned to it. The compression in all cylinders is almost the same - 14.0...14.5, despite the fact that a completely new engine, as a rule, shows 15...16 units. No significant oil consumption was observed. Oil: Shell Helix Ultra 10W40, change every 8...10 thousand km. The last time, due to circumstances, I delayed it until 12 thousand. After changing the oil and flushing it with a cold one, a knocking noise began to be heard periodically from the cylinder head. Probably some of the hydraulic compensators are clogged. An autopsy, as they say, will show.

All other engine faults were related to the ECM. The most consumable of the entire system is the idle air control. 6 pieces in 6 years. And for all of them, the motor falls out of the housing in the same way. Only recently did a motor mechanic I know suggest the true reason for the frequent breakdown. The throttle assembly is located exactly above the exhaust manifold and takes on all the heat, so the IAC cannot withstand it. The body rivets are purely symbolic. Temporary repairs are ridiculous to the extreme: wrapping the regulator body with electrical tape for a little thermal insulation. Later I plan to install a thermal screen.

Also, once the car suddenly stalled at a traffic light and refused to start. After some tests and manipulations, the culprit was discovered - DPKV - the only sensor without which the car will not start at all, because. In case of failure of others, emergency engine operation modes are provided for almost all cases. The sensor is located on the open crankshaft damper and is not protected from dirt. Metal filings simply fell on its magnet (“caught” somewhere in the industrial zone).

I also noticed that due to the heat of the engine, as well as, probably, abrasive dirt particles, the protective corrugations of the engine compartment wiring began to collapse in places. Repaired by replacing it with the same flexible cable channels. In the hottest place (on the back side of the engine), I pulled the branch going to the IAC and TPS in two layers, just in case.

As for fuel consumption, the figures vary depending on the conditions. For example, if you smoothly “vegetate” without a load in a relatively free city, you can achieve an average consumption of about 8 l/100 km. In traffic jams, even with a moderate load, consumption can easily jump to 14 liters. It may not be indicative, but my average consumption per week is ~12 l/100 km. On the highway with a cruising speed of 90 km/h, “empty” it’s easy to keep within 7 liters. On mountain serpentines with cargo and passengers, not even more than 10 liters. Fuel: only AI-95 recommended by the factory, because the compression ratio is 10.3. It can move at 92m, but the engine control unit adjusts the SPD using the knock sensor, which leads to a decrease in power.

The checkpoint, on the contrary, was disappointing. At 60 thousand km the 2nd gear synchronizer failed again. Yes, maybe I’m sometimes rough with the gearbox and the engine, but it’s worth admitting that the gear ratios in the gearbox are poorly chosen. Moreover, this problem is familiar not only to those who like to “shoot at a traffic light”; driving with a load and towing cars no less shortens the life of the box.

The step when moving from 1st to 2nd gear is large and puts a lot of stress on the synchronizers. The solution to the problem was radical and uncompromising: the 18th row of gears with the main pair of 3.94. It turned out expensive, but effective.

The new transmission is ideal for a utility vehicle: even when driving with an almost full load, the car can easily take any inclines, and can tow other cars weighing up to 1.5 tons without any problems (I just haven’t tried it anymore). At the same time, the engine can always be kept in the optimal speed zone, without strain.

The only thing that let me down about the new box was the clutch fork. An ordinary factory part purchased by assemblers in a store. The quality of spare parts speaks for itself.

As for the suspension , I don’t see the point in writing anything, since it was built from scratch using components that sometimes bear little resemblance to the original parts. Therefore, my experience is atypical and not representative.

currently two sets of wheels For the summer, Slik L184S 15×6.5J ET32 with Yokohama S-drive 195/55 R15 85V tires. In winter, VSMPO Alpha 14x6J ET35 are shod in Goodyear Ultra Grip Ice+ 175/65 R14 90R. I plan to take another set of forged wheels, slightly wider than the current ones, 15x7J and pseudo-semi-slick 195/50.

Let's move on to the steering . The impressions are only positive: sharpness in corners and stability on a straight line with a “short” ZF rack cannot be compared with the EURs on Priors and Kalinas. However, since I sometimes neglect the rules such as jumping over bumps and curbs, for example, I try to follow the system.

Last spring, with a mileage of ~55,000 km, I tightened the rack prophylactically. But at a wheel alignment recently (67,000 km), the technician discovered a slight play in the rack, although there were no knocks. Again he pulled it up slightly. Also, during a recent inspection of the suspension after winter, it was discovered that the pump and high-pressure line were abundantly covered with hydraulic fluid. The level in the expansion tank is periodically checked, but is now taken under regular control. No more than 100 ml left the system, despite the fact that the last refill was made about 3 years ago. But nevertheless, according to the recommendations of Steering Systems LLC (co-developer of the power steering for 2110), I replaced the unreliable hoses with modified ones (double pressing of fittings, relocated damper). At the same time, I also replaced all the other pipes: the pump supply hose was fairly worn out by the drive belt due to unsuccessful fastening, the low-pressure hose “for company” gave way to a modified one (with a larger flow area and with a thermally insulating braid). There is also a new filter tank and a new liquid Pentosin CHF 11S, which cannot be mixed with anything.

The body , considering that the car is over 6 years old, is holding up well. The most vulnerable place to stones is the front edge of my hood is intact. Although maybe I don't drive on the highway that often. There are paint chips only on the front bumper, which are promptly covered with a corrector. Otherwise, the condition of the paintwork is satisfactory: the body has multiple scratches (from branches, etc.) and abrasions (careless neighbors in the parking lot), but there is no damage to the metal, mostly within the varnish. I think it would be nice to have the body polished to give the car a fresh look. The only place where signs of corrosion have begun to appear is on the inside of the lower edges of the front doors, under the drainage holes. As for the protection of the engine compartment, the protection that was installed in the car dealership as an additional option has become unusable. The “ears” attaching it to the axles of the levers were repeatedly torn. My version of the reason is this: it is quite heavy (steel) and on bumps it sways in resonance with the body. I replaced it with a 2.5 mm aluminum one, and there are no more problems with tearing off.

Electrics can be tricky. Perhaps the most problematic place is the rear light boards located on the body. Due to poor contact in the lamp bases, the parking lights or brake lights often do not light up. The dashboard backlight mini-bulbs periodically go out due to poor contact.

The salon , after 70 thousand km of running on roads and off-roads, screams over bumps, especially when it comes to noise. The optional rubber mats from the dealership were torn in places and worn out in places, so I bought new ones. In the fall of 2013, I discovered that water was getting into the trunk when it rained—I changed the 5th door seal. The door locks operated by the central locking also began to jam. Most likely, they are simply clogged with dirt entering through the window seals or lower drainage holes. When I find time, I’ll take it apart, clean it, and change the seals at the same time.

I don't plan to change my car in the near future. By selling 11 now, I will lose both the money invested and the priceless fruit of the setup, leaving me with nothing. Starting this journey from scratch again on another Lada is pointless. In the distant future, there are plans to purchase a more comfortable foreign car, but only as a second car. A European or Japanese woman, who is in a completely different price and target category. I don’t see the point in exchanging for a cheap Korean car or an empty European one. I will remain in my possession as long as possible. There are tasks that others simply cannot do.

Which engine is better: 1.5 8kl or 1.6 8kl?

When choosing a car, people often wonder, which engine is better? In our case, everything is not so simple. A similar question may arise if we consider buying a car already in the shaggy year: 2006-2007. It was during this period that both 1.6l and 1.5l engines were installed on the VAZ 2113 2114 2115, the characteristics of which are outlined above.

In essence, the 1.5 and 1.6L 8cl engines are no different, except for volume, exhaust standards, fuel supply systems and a couple of sensors. Therefore, the main distinguishing point is the engine size. A difference of 0.1 liters gives much more torque from the bottom, a little more maximum power and, perhaps, even the same or even lower engine consumption than a 1.5 liter. The only negative is that it is noisier at idle.

Previously, in the years 2008-2012, people were not willing to take 1.6 engines because they were fragile, loud, etc. – in fact, the 1.6 engine is superior to the 1.5 liter engine in all respects, so we recommend it to you. But this applies to 8 cl motors that were installed serially. Next we will consider 16kl. motors.

Removing the additional muffler

To avoid burns, it is recommended to start work after the exhaust system has cooled down.

We carry out the work on an inspection ditch or overpass.

We disconnect the pipes of the additional and main mufflers.

1. To separate the flanges of the pipe of the additional muffler and the catalytic collector, use a chisel to bend the edge of the locking plate of the lower nut and the edges of the heat shield that lock the other two nuts.

2. Using a 13mm socket with an extension, unscrew the three nuts securing the flange of the additional muffler pipe to the flange of the catalytic converter.

3. Remove the locking plate and heat shield.

4. Raise the additional muffler and remove the front muffler bracket from the rubber cushion

5. Similarly, remove the rear muffler bracket from the rubber cushion

6. Remove the flange of the additional muffler pipe from the studs of the catalytic collector

7. Remove the sealing gasket

After each removal of the additional muffler pipe flange from the studs of the catalytic collector, the sealing gasket should be replaced with a new one.

Install the additional muffler in reverse order. After installation, you should lock the nuts securing the pipe flange and catalytic collector by bending the edges of the locking plate and the heat shield.

Which engine is better, 1.6 16kl or 8kl?

16kl engines were installed in a limited series at AvtoVAZ or at the SuperAvto subsidiary. Also, 16 cl engines were installed independently by tuning fans.

In terms of manufacturability, 16kL engines are superior to 8kl engines, therefore, if there is an option to take a 16kl motor, then it would be nice to go with this option, but everything has its own nuances.

Advantages of 16kl. engines over 8kl

- The best cylinder purging is greater power.

- More stable engine operation - less noise.

- More engine efficiency means less fuel consumption.

But! The 1.6 16cl engine from Priora (21126) bends the valve when the belt breaks - for some reason this scares many. You just need to monitor the condition of the car, belts, rollers, pump and everything will be fine! All modern cars have valve bending.