I decided to tell everyone about a little-known method of testing the dashboard and identifying errors without an on-board computer. The method is primitive because They developed it at Auto VAZ, but still.

Instructions: Hold down the odometer button, turn the ignition key to the first position, release the button. The arrows start moving, press again, release, and see the firmware version (in the video, ver 1.6). And the third time they pressed, released, saw the error code (if there is one) on the video code: 8. To reset the error code, press and hold the button until the number 0 appears.

1

Microprocessor error

2

gauge

sensor circuit error

4

High voltage

8

Low voltage

12

Indicator lamp diagnostic circuit faulty

No oxygen sensor/LAMDA probe signal

14

Coolant temperature sensor signal high 15 Coolant temperature sensor signal low

16

On-board network voltage too high

17

Low voltage on-board network

19

Incorrect crankshaft position sensor signal

21

High signal level of the throttle position sensor

22

Low level of the throttle position sensor signal

23

High level of the intake air temperature sensor signal

24

No signal from the vehicle speed sensor

25

Low level of the intake air temperature sensor signal

27

High signal level of the CO potentiometer

28

Low signal level of the CO potentiometer

33

High signal level of the mass air flow sensor For GM NIVA: High signal level of the absolute pressure sensor

34

Low signal level of the mass air flow sensor For GM NIVA: Low signal level of the absolute pressure sensor

35

Idle speed deviation

41

Incorrect phase sensor signal

42

Malfunction of the electronic ignition control circuit

43

Incorrect knock sensor signal

44

Lean mixture

45

Rich mixture

49

Vacuum loss diagnostics

51

PROM error

52

RAM error

53

No CO potentiometer sensor signal For GM NIVA: high voltage

54

No signal from the octane corrector sensor

55

Leaning at high engine load For GM NIVA: error in the electronic control unit

61

Degradation of the oxygen sensor/LAMDA probe

Errors persist until they are reset manually! Also mistakes add up! Those. If you have errors 8 and 14, the display will show error 22.

If you have any information on this topic, please add it in the comments!

The on-board computer installed in the VAZ-2114 makes life much easier for the car owner in such a difficult task as diagnosing faults. Agree, there can be quite a lot of breakdowns with the same symptoms, and sometimes you have to check several versions until you get to the bottom of the real cause.

What does error 14 mean on the odometer display of the VAZ-2114 during self-diagnosis

Often, many car enthusiasts strive to solve all problems with their car on their own, going for service only in particularly serious cases. This approach in relation to the VAZ “fourteenth” model is completely justified. The design of the car is quite simple, because it is a restyling of the well-known “nine”, to which the designers made some changes. Well, the undoubted advantage of self-diagnosis and repair is the absence of the need to pay, in addition to spare parts, for the work of car service technicians.

The car has become more modern, it now has the ability to conduct self-diagnosis. Let's look at this procedure in a little more detail. First of all, you should find the odometer button on the instrument panel, which is responsible for mileage (total and daily) - you need to press it and hold it in this position. Next, turn the key in the ignition switch - you need it to be in position 1. After this, release the odometer button. You will see arrows start running on the panel. Then we press the odometer button again, but no longer hold it, but immediately release it. You will see information about the firmware.

After this, you should repeat the steps described above again, in exactly the same sequence. If there is any malfunction in your car, its code should appear on the odometer display.

There is a special table to decipher them. For example, the appearance of code 14 means the signal level coming from the coolant temperature sensor is too high. Accordingly, to eliminate the problem, you should check its performance and, if necessary, replace it with a new one.

You can do this yourself, there is nothing complicated here. At the same time, there is no need to delay solving the problem. The thing is that a problem with the coolant temperature sensor leads to such unpleasant moments in the car’s operation as:

- significant increase in fuel consumption;

- startup problems;

- uneven engine operation;

- change in the composition of exhaust gases.

Diagnostics of wiring and lambda probe chips

Sometimes P0134 appears at the same time as P0171 indicating a lean condition. In this case, you can be sure that there is a wire break or a short circuit. The oxygen sensor controls its supply to the engine. If there is no signal, the mixture supply is limited.

The wiring is inspected. If there is visible damage, it must be repaired or replaced. Oxidized contacts are cleaned.

Car self-diagnosis

- First you need to sit in the driver's seat and hold down the odometer button on the speedometer.

- Then insert the key into the ignition and set it to the first position.

- After turning the key, you must release the pressed button. This will cause the needles on the speedometer, tachometer and other gauges to move quickly.

- Then you need to press the odometer key again and release it. An inscription with the firmware version will appear on the device.

- After the third press of the odometer button, the VAZ 2114 error codes will start to light up on the display.

How to reset errors yourself

After self-diagnosis of errors and elimination of their causes on a carburetor or injection engine, a malfunction message may remain on the standard panel. If the problem has been deleted, this means that the code combination remains in memory. We'll look at the description of the faults below, and now we'll tell you how to remove the code from memory. To remove it after testing the device, when VAZ 2114 errors appear, the codes themselves must be written down. After this, the daily mileage reset button is pressed again, this will clear the fault from the control unit’s memory.

Resetting the "Check Engine" error

It often happens that the instrument panel 2114 8 or 16 valves displays a check error - engine malfunction, the orange icon is on. Self-diagnosis does not always allow you to accurately check and determine how to fix such a problem. To fix the problem and find a solution, you should perform more detailed diagnostics of the car using a computer and additional equipment. Perhaps, during diagnostics, an unknown error indicates a malfunction in the microprocessor, on-board network or sensors. After the problem is fixed, the receipt may remain.

The "Check Engine" indicator indicates a problem with the engine.

How to reset the fault code:

- First, turn on the ignition; you do not need to start the car engine.

- Then open the hood. Use a wrench to loosen the bolt on the negative terminal of the battery.

- Wait about one minute, after which the battery terminal must be replaced.

- Close the hood and turn off the ignition.

- After that, turn it on again and start the car engine. If the check remains, it should go out on its own after some time. If the instructions given did not work and the solution did not help, then you need to look for the cause of the problem and fix it.

Deciphering error codes

The explanation of the most common errors in the 1.6-liter Volkswagen Polo V engine is given in the table below.

| VAG code | Code ODB-2 | Malfunction |

| 16489 | P0105 | Damage to the electrical circuit of the air flow meter sensor |

| 16496 | P0112 | Low signal level of air temperature sensor |

| 16497 | P0113 | High level of air temperature sensor signal |

| 16500 | P0116 | Damage to the electrical circuit of the coolant temperature sensor |

| 16501 | P0117 | Coolant temperature sensor signal low |

| 16502 | P0118 | High signal level of the coolant temperature sensor |

| 16505 | P0121 | Damage to the electrical circuit of the throttle position sensor |

| 16506 | P0122 | Low throttle position sensor signal |

| 16507 | P0123 | Throttle position sensor signal high |

| 16514 | P0130 | Damage to the electrical circuit of the oxygen sensor |

| 16515 | P0131 | Low oxygen sensor signal |

| 16516 | P0132 | High signal level of the oxygen sensor |

| 16517 | P0133 | Slow response of oxygen sensor |

| 16518 | P0134 | Poor oxygen sensor performance |

| 16519 | P0135 | Damage to the electrical circuit of the heated oxygen sensor |

| 16520 | P0136 | Damage to the electrical circuit of the downstream oxygen sensor |

| 16521 | P0137 | Low signal level of the lower oxygen sensor |

| 16522 | P0138 | High signal level of the lower oxygen sensor |

| 16525 | P0141 | Damage to the electrical circuit of the heated oxygen sensor |

| 16585 | P0201 | Damage to the electrical circuit of the fuel injector of cylinder 1 |

| 16586 | P0202 | Damage to the electrical circuit of the fuel injector of cylinder 2 |

| 16587 | P0203 | Damage to the electrical circuit of the fuel injector of cylinder 3 |

| 16588 | P0204 | Damage to the electrical circuit of the fuel injector of cylinder 4 |

| 16614 | P0230 | Damage to the electrical circuit of the fuel system |

| 16684 | P0300 | Random misfires |

| 16685 | P0301 | Misfire in cylinder 1 |

| 16686 | P0302 | Misfire in cylinder 2 |

| 16687 | P0303 | Misfire in cylinder 3 |

| 16688 | P0304 | Misfire in cylinder 4 |

| 16710 | P0326 | Damage to the electrical circuit of the knock sensor |

| 16719 | P0335 | Damage to the electrical circuit of the crankshaft angle sensor |

| 16720 | P0336 | Random malfunctions of the crankshaft angle sensor |

| 16726 | P0342 | Low signal level of the camshaft position sensor |

| 16727 | P0343 | Camshaft position sensor signal high |

| 16806 | P0422 | Poor catalytic converter efficiency |

| 16828 | P0444 | Open circuit in the activated carbon canister cleaning valve |

| 16829 | P0445 | Activated carbon canister cleaning valve circuit shorted |

| 16885 | P0501 | Damage to the electrical circuit of the vehicle speed sensor |

| 16890 | P0506 | Reduced idle speed |

| 16891 | P0507 | Increased idle speed |

| 16946 | P0562 | Low voltage in the vehicle's on-board network |

| 16947 | P0563 | Increased voltage in the vehicle's on-board network |

| 16990 | P0606 | Internal damage to the ECM |

| 17531 | P1123 | Rich fuel mixture |

| 17532 | P1124 | Lean mixture |

| 17535 | P1127 | Long-term over-enrichment of the fuel mixture |

| 17536 | P1128 | Long-term leanness of the fuel mixture |

| 17918 | P1510 | The idle air system valve is constantly open due to a short circuit in the valve coil power supply circuit. |

| 17921 | P1513 | The idle air system valve is constantly open due to a break in the electrical supply circuit to the valve coil |

| 17960 | P1552 | The idle air system valve is constantly closed due to a short circuit in the valve coil power supply circuit. |

| 17961 | P1553 | The idle air system valve is constantly closed due to a break in the electrical supply circuit to the valve coil |

| 18013 | P1605 | Damage to the electrical circuit of the acceleration sensor |

| 18014 | P1606 | Inappropriate signal received from acceleration sensor |

| 18018 | P1610 | MIL Input Low |

| 18019 | P1611 | MIL Input High |

Meaning and interpretation of error codes

To read the faults, first consider the list with a table of UEr errors that self-diagnosis produces (the author of the video is Ivan Vasilyevich).

| Number | Description |

| 1 | Problems with the functioning of the microprocessor. |

| 2 | Self-diagnosis of the VAZ 2114 detected problems with the electrical wiring of the fuel level indicator controller. The signal level coming from the sensor may be too high or low. It is necessary to test the controller and check the wiring. |

| 4 | Increased voltage in the on-board network. |

| 8 | Low voltage. What to do: in this and in the previous case, the battery and generator must be checked. |

| 12 | There is a problem with the diagnostic indicator circuit on the instrument panel. |

| 13 | The control unit cannot detect the signal coming from the oxygen controller. |

| 14 | An increased signal is received from the refrigerant temperature controller. |

| 15 | The problem is in the operation of the coolant temperature sensor (coolant temperature sensor) - the on-board computer records a reduced signal level. |

| 16 | There is increased voltage in the car wiring. |

| 17 | Reduced voltage in wiring. |

| 19 | Problems have been reported in the operation of the crankshaft position sensor (CPS). An incorrect signal is sent to the control unit. |

| 21 | Problems with the operation of the TPS controller (throttle position sensor). There may be problems with the throttle valve. Check the connection circuit and sensor. |

| 22 | A reduced signal is sent from the TPS. |

| 23 | The intake air temperature controller gives an increased signal. |

| 24 | There are problems with the speed controller. Its failure can be diagnosed by a non-working speedometer. |

| 25 | Reduced signal from the incoming air temperature controller. |

| 27,28 | Incorrect signal coming from the CO sensor. |

| 33,34 | Malfunctions of the mass air flow sensor (mass air flow sensor). Check the flow meter connection circuit and its functionality. |

| 35 | The ECU has detected a deviation in the idle speed values. The sensor may be faulty. |

| 41 | Incorrect pulse coming from the phase controller. |

| 42 | Problems with the electronic ignition wiring. |

| 43 | An incorrect pulse is supplied from the detonation controller. |

| 44,45 | Problems with the composition of the combustible mixture. It can be depleted or over-enriched. |

| 49 | Check for vacuum loss. |

| 51,52 | Problems in the functioning of the PROM or RAM. |

| 53 | There is no CO controller pulse. Open circuit or sensor failure. |

| 54 | No impulse is received from the octane corrector controller. |

| 55 | When the load on the power unit is reduced, the ECU detects depletion. |

| 61 | Problems with the oxygen controller. |

These codes can add up; if you see the number 6, this may indicate errors 2 and 4, or if the number 9 is displayed, errors 1 and 8.

In order to immediately read and decipher problems when diagnosing, it is advisable to download and always carry with you a printout with a description. When diagnosing using a computer, codes on engine 21124 may differ depending on the car model. To read the codes, you need to know how they are supposed to be deciphered. Errors must be reset after they have been deleted (the video was filmed and published by the KV Avtoservis channel).

| Number | Decoding |

| p0102, p0103 | An incorrect pulse is supplied from the mass air flow sensor controller. This means you need to check the wiring. |

| p0112, p0113 | 112 or 113 - the incoming air temperature sensor needs to be replaced. |

| p0115-p0118 | Errors from 0115 to 0118 - the antifreeze controller sends an incorrect impulse. There may be problems with the wiring or the sensor itself. |

| p0122, p0123 | TPDZ. The controller is sending an incorrect signal. If the wiring is damaged, interference may occur. |

| p0130, p0131 | The lambda probe requires diagnostics and replacement. |

| p0135-p0138 | Error 0135 and higher - the lambda probe heating regulator needs to be replaced. |

| p0030 | The ECU reports problems in the electrical circuit in the area from the lambda probe heater to the converter. If error p0030 occurs, you need to test the electrical circuit and the sensors themselves. |

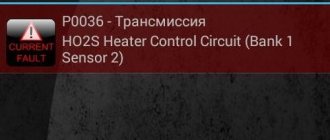

| p0036 | P0036 - a break in the wiring of the heating device DK-2 was detected. |

| p0300, p0302 | When codes 300 and 302 appear, the ECU reports a misfire. |

| p0301 | Gaps were detected in the cylinders of the power unit. Compression needs to be checked. |

| p0325 | The knock sensor is not working correctly. In particular, we are talking about a break in the connection wiring. |

| p0335, p0336 | P0036 error VAZ 2114 or 10335 - the DPKV has failed or its connection circuit is damaged. If the wiring is intact, then the sensor is replaced. |

| p0340 | Phase sensor malfunction. |

| p0341 | Error VAZ 2114 0341 means a problem with the camshaft controller. |

| p0342, p0343 | Problems with the phase controller. With such an error, detonation of the car engine is possible. Most likely, only replacement will solve the problem. |

| p0346 | P0346 VAZ error - also a problem with the phase regulator. |

| p0363 | P0363 - misfire of the combustible mixture was detected. In cylinders that refuse to work, the fuel supply is cut off. |

| p0422 | Failure to operate the neutralizing device. |

| p0443, p0444, p0445 | Malfunctions 0443, p0444 and 0445 - adsorber regulator, purge is not carried out. |

| p0480 | The engine cooling fan device has failed. The power unit may overheat if it is not replaced in a timely manner. Before replacing, you need to check the connection contacts to the wiring. |

| p0501-p0504 | Error 0501 VAZ 2114 and error code 0504 - the speed controller refuses to work. The device needs to be replaced. |

| p0505, p0506, p0507 | The idle speed sensor does not work or does not work correctly. Its failure can lead to floating idle speed. Possible engine tripping. The controller itself is tested and the wiring is checked. |

| p0607 | The knock controller operates intermittently. |

| p1135 | Error 1135 VAZ 2114 - you need to test the oxygen controller. |

| p6060 | Processor failure. If the fault remains after resetting the code, then the controller must be replaced. |

| p2020 | It is necessary to test the intake flap position sensor. |

| p1617 | Error 1617 - Rough road controller, wiring damage. |

| p1513 | There is a short circuit in the wiring of the idle speed sensor. It is necessary to test the electrical circuit and check the contacts. |

| p1602 | Failures in the voltage supply to the vehicle's electrical network are detected. |

| p0560 | Incorrect voltage level in the on-board network. This parameter can be overestimated or underestimated. The car battery, as well as the generator unit, are subject to testing. |

| p1514, p0511 | The appearance of these errors indicates a problem with a break or short circuit in the IAC (idle speed regulator) wiring. First of all, diagnose the sensor contacts, and then test the circuit, if possible. The sensor itself may also be damaged. |

| p1303 | P1303 - A detected misfire of the air-fuel mixture in the third cylinder is reported. The malfunction must be corrected as quickly as possible, since it can be critical for the neutralizer. |

| p1578 | Throttle valve malfunction. Literally, the problem stands for “zero adaptation parameter is outside the permissible value.” There are several options to solve the problem. The first thing you need to do is clean the throttle valve. If this does not help, then the throttle is adapted. To do this, you need to activate the ignition, and then start the engine after 40 seconds. Alternatively, you can test and tighten the contact terminals on the throttle. |

| p1621 | Malfunction of the RAM, memory problems in the control unit. Detailed testing of the computer is required. |

| p0650 | Problems in the control circuit of the on-board computer error code indicator State. |

| p2135 | P2135 - malfunction of the throttle assembly. If replacing the sensor and cleaning the damper did not help, then the problem may have to be solved by flashing the on-board computer. |

| p2187 | Lean mixture in internal combustion engine cylinders. You need to do a detailed diagnosis of the problem. |

Decoding error codes Lada Kalina

In previous articles, namely Lada Kalina error codes (part 2) and Error codes, their decoding on the Bosch ME 7.9.7 controller, I described the decoding of error codes that may occur when diagnosing a Lada Kalina car .

In this article, I think the final one on error codes for Lada Kalina , we will look at the remaining codes and their decoding. The decoding of the codes applies to the Bosch ME 7.9.7 . So, when the neutralizer efficiency is below the threshold, we observe error No. P0422. If the air flow through the canister purge valve is incorrect , error P0441 is observed . P0480 code indicates that the control circuit in the first fan relay is faulty. P0500 - speed sensor faulty . P0506/P0507 - the error appears at low/high engine speeds, respectively. If the on-board network voltage is below the system operability threshold, error No. P0560 occurs. P0562/P0563 - low/high voltage level in the on-board network, respectively . Error P0601 appears in the event of a checksum error in the read-only memory device (ROM) in the engine control system (EMS). If the control circuit of the additional starter relay is broken - error No. P0615 . P0616 / P0617 - short circuit of the control circuit of the additional starter relay to ground / to the on-board network, respectively. P1135 - the control circuit for the oxygen sensor heater to the converter is faulty. If error P1141 , the cause is a malfunction of the oxygen sensor heater control circuit after the converter. P1386 - error in the detonation detection channel in the engine control system controller (ECS). P1410/P1425 - short circuit of the control circuit of the canister purge valve to the on-board network/to ground, respectively. If the control circuit for the canister purge valve is broken - error No. P1426 . P1501/P1502 - short circuit of the fuel pump relay control circuit to ground/on-board network, respectively. P1513 - an error code occurs when the idle air control control circuit is shorted to ground . P1514 - the idle air control control circuit is faulty. Open circuit of the fuel pump relay control circuit - error code No. P1541 . P1570 - the Lada Kalina immobilizer circuit is faulty. P1602 - voltage lost in the engine control system controller. If the signal in the road roughness sensor circuit (RSD) is out of the permissible range, error code P1606 . P1616/P1617 - low/high signal level in the rough road sensor circuit. P1640 - error reading or writing EEPROM memory in the engine control system controller (ECS) . On this, I think, we’ll finish deciphering the error codes on the Lada Kalina . Next, I will begin to describe methods for eliminating these errors , but that will come a little later.

Diagnostics using special equipment

The diagnostic process using special equipment consists of checking the car using a laptop. To connect to the diagnostic connector you will need a cable with an adapter. Using this cable, we connect the computer to the connector via USB output. For testing you will also need software; the power of the computer used is not important. There are many versions of different testing programs on the Internet.

Diagnostics is performed as follows:

- It is recommended to inspect the vehicle before starting the inspection. Check the volume of consumables - engine oil, brake fluid, coolant.

- Find the diagnostic connector and connect your laptop to it. If you have a special scanner, then that's even better. But since finding a scanner is not so easy, and buying one is not cheap, you can use a laptop. Before testing can begin, the ignition must be activated. There is no need to start the power unit.

- After connection, the testing utility starts. The software interface may vary. When you launch the software, graphs or a list of parameters with numbers may appear. This information will allow you to draw conclusions about the operation of the power unit.

- The scan starts. Fault codes will appear on the laptop screen. To decrypt, use the information provided in this article. We could not describe all the codes, but we deciphered those that occur most often. Usually, when downloading a program to a computer, users are provided with a separate file describing the faults.

- After decryption, the problem is repaired.

Possible causes of error P0598

Wiring short to ground, relay, thermostat heater

Experience suggests that the problem is usually a loose or corroded electrical connector or that the electrically operated thermostat itself is faulty. Sometimes the Motronic (engine management) computer fails, but this is the least likely cause. A loose or corroded connector on a thermostat coolant leak will cause a code set The thermostat itself has failedA short or open has occurred in the wiring diagram between the computer and the thermostat the Motronic computer has failed

Video “Visual instructions for self-diagnosis”

For a simpler check, you can resort to the self-diagnosis method - detailed instructions for checking are presented in the video below (the video was filmed and published by the channel Your Own Mechanic).

We recommend watching:

- Error codes VAZ 21124 16 valves

Error 0030 VAZ 2114 how to fix- Diagnostics of the VAZ 2110 dashboard

- On-board computer malfunctions

- Error p0685 VAZ 2114

On-board computer VAZ 2114 how to view errors

How to fix PartitionMagic error 1513

Manually editing the Windows registry to remove Error 1513 keys that contain errors is not recommended unless you are a PC service professional. Mistakes made when editing the registry can render your PC inoperable and cause irreparable damage to your operating system. In fact, even one comma placed in the wrong place can prevent your computer from booting!Due to this risk, to simplify the process, it is recommended to use a program to clean the OS registry. A registry cleaner automates the process of finding invalid registry entries, missing file references (like the one causing Partition Magic 8 Error 1513), and broken links in the registry. Before each scan, a backup is automatically created with the ability to undo any changes with one click, protecting against the possibility of damaging your PC.

As a Microsoft Silver Partner, we provide software to help you resolve the following issues:

- WinThruster OS registry cleaner [download]

Warning: Unless you are an experienced PC user, we DO NOT recommend manually editing the Windows Registry. Using Registry Editor incorrectly may cause serious problems that may require you to reinstall Windows. We do not guarantee that problems resulting from incorrect use of Registry Editor can be corrected. You use Registry Editor at your own risk.

Before you manually repair the Windows registry, you need to create a backup by exporting the part of the registry associated with Error 1513 (for example, PartitionMagic):

- Click on the Start .

- Type " command " in the search bar... DON'T PRESS ENTER YET !

- CTRL-Shift keys on your keyboard, press ENTER .

- A dialog box for access will be displayed.

- Click Yes .

- The black box opens with a blinking cursor.

- Type " regedit " and press ENTER .

- In the Registry Editor, select the Error 1513-related key (for example, PartitionMagic) that you want to back up.

- From the File , select Export .

- From the Save in , select the folder where you want to save the PartitionMagic key backup.

- In the File name , enter a name for the backup file, for example, “PartitionMagic backup.”

- Make sure that the Export Range is set Selected Branch .

- Click Save .

- The file will be saved with the extension .reg .

- You now have a backup of your PartitionMagic-related registry entry.

The following steps for manually editing the registry will not be described in this article, as they are likely to damage your system. If you would like more information about editing the registry manually, please check out the links below.

We do not accept any responsibility for the results of the actions performed according to the instructions below - you perform these tasks at your own risk.

Windows XP https://www.theeldergeek.com/windows_xp_registry.htm

Windows 7 https://www.theeldergeek.com/windows_7/registry_edits_for_win7.htm

Windows Vista https://support.microsoft.com/kb/2688326 - LetMeFixItMyselfAlways

Chevrolet Niva error codes

Error codes Niva Chevrolet (VAZ 2123)

List of fault codes recorded by the BOSCH M7.9.7 controller (euro-2, euro-3)

P0102—Low signal level of the mass air flow sensor (MAF). P0103—High signal level of the mass air flow sensor (MAF). P0112—low signal level of the intake manifold temperature sensor (ITM). P0113—Intake manifold temperature sensor (ITM) signal level is high. P0116—The signal from the coolant temperature sensor (TTOZH) is out of the permissible range. P0117—Low signal level of the coolant temperature sensor (DTOZH). P0118—High signal level of the coolant temperature sensor (DTOZH). P0122—Low signal level of the throttle position sensor (TPS). P0123—High signal level of the throttle position sensor (TPS). P0130—Incorrect signal from oxygen sensor No. 1 to the converter. P0131—Low level signal from oxygen sensor No. 1 to the converter. P0132—High level signal from oxygen sensor No. 1 to the converter. P0133—Slow response to rich or lean oxygen sensor No. 1 to converter. P0134—No signal (open circuit) of oxygen sensor No. 1 to the converter. P0135—Oxygen sensor No. 1 heater circuit to converter malfunction. P0136—Short to ground in the oxygen sensor circuit No. 2. P0137—Low level signal from the oxygen sensor No. 2 after the converter. P0138—High signal level of oxygen sensor No. 2 after the converter. P0140—No signal (open circuit) of oxygen sensor No. 2 after the converter. P0141—Oxygen sensor No. 2 heater circuit malfunction after converter. P0171—Fuel system (air/fuel mixture) too lean. P0172—Fuel system (air/fuel mixture) too rich. P0201—Open circuit for controlling the injector of the 1st cylinder. P0202—Open circuit for injector control of the 2nd cylinder. P0203—Open circuit of the 3rd cylinder injector control. P0204—Open circuit for the 4th cylinder injector control. P0261—Short to ground in the 1st cylinder injector control circuit. P0262—Short circuit to the on-board power source of the 1st cylinder injector control circuit. P0264—Short to ground in the 2nd cylinder injector control circuit. P0265—Short circuit to the on-board power source of the 2nd cylinder injector control circuit. P0267—Short to ground in the 3rd cylinder injector control circuit. P0268—Short circuit to the on-board power source of the 3rd cylinder injector control circuit. P0270—Short to ground in the 4th cylinder injector control circuit. P0271—Short circuit to the on-board power source of the 4th cylinder injector control circuit. P0300—Random/multiple misfire detected. P0301—Misfire detected in Cylinder No. 1. P0302—Misfire detected in Cylinder No. 2. P0303—Misfire detected in Cylinder No. 3. P0304—Misfire detected in Cylinder No. 4. P0327—Knock Sensor (DS) Signal Low . P0328—High signal level of the knock sensor (DD). P0335—Crankshaft position sensor (CPS) signal missing. P0336—The crankshaft position sensor (CPS) signal is out of acceptable limits. P0337—Crankshaft position sensor (CPS) circuit short to ground. P0338—Open circuit of the crankshaft position sensor (CPS). P0340—Camshaft Position Sensor (CPS) circuit malfunction. P0342—Low signal level of the camshaft position sensor (DPRV). P0343—High signal level of the camshaft position sensor (CPS). P0422—Converter efficiency is below the permissible threshold. P0441—Incorrect air flow through the valve. P0443—Canister purge valve control circuit is faulty. P0480—Cooling Fan No. 1 Relay Control Circuit Malfunction. P0481—Cooling Fan No. 2 Relay Control Circuit Malfunction. P0500—Invalid vehicle speed sensor signal. P0503—Intermittent vehicle speed sensor signal. P0506—Low idle speed (idle speed control blocked). P0507—High idle speed (idle speed control blocked). P0560—On-board network voltage is below the system operability threshold. P0562—On-board network voltage is too low. P0563—On-board network voltage too high. P0601—Controller ROM checksum error. P0603—Error writing/reading external RAM of the controller. P0604—Error writing/reading controller internal RAM. P0615—Starter relay control circuit open. P0616—Short circuit to ground in the starter relay control circuit. P0617—Short circuit to the on-board power source of the starter relay control circuit. P1135—Oxygen sensor No. 1 heater circuit to converter malfunction. P1140—Incorrect signal from the mass air flow sensor (MAF), the measured load parameter differs from the calculated one. P1141—Oxygen sensor No. 2 heater circuit malfunction after converter. P1386—Test pulse or controller knock channel integrator is out of tolerance. P1410—Short circuit to the on-board power source of the canister purge valve control circuit. P1425—Short to ground in the canister purge valve control circuit. P1426—Open circuit for controlling the canister purge valve. P1501—Short circuit to ground in the electric fuel pump relay control circuit. P1502—Short circuit to the on-board power source of the electric fuel pump relay control circuit. P1509—Idle air regulator (IAC) control circuit overload. P1513—Short circuit to ground in the idle air regulator (IAC) control circuit. P1514—Short circuit to the on-board power source (or open circuit) of the idle air regulator (IAC) control circuit. P1541—Open circuit of the electric fuel pump relay control circuit. P1570—No response from the vehicle anti-theft system (ATS) or open circuit. P1602—Loss of on-board power supply voltage in the controller. P1606—Incorrect rough road sensor signal. P1616—Rough road sensor signal low. P1617—Rough road sensor signal level high. P1640—Error writing/reading internal flash RAM (EEPROM) of the controller. P1689—Incorrect code values in the controller fault memory.