Electric power steering (EPS) is a device for reducing the force that the driver must apply to the steering wheel to change the position of the steering wheels. This system is called EPS (from the English Electric Power Steering, electric power steering).

The presence of an amplifier (hydraulic power steering or electric power steering) allows you to:

- increase comfort;

- make driving easier;

- improve overall driving safety.

At the same time, power steering was the only option for a long time, while electric power steering (EPS) appeared on cars relatively recently. Although this solution is a more modern analogue, the EUR has both pros and cons. Read more in our article.

Electric power steering: advantages

This type of amplifier is based on the fact that the force is created by an electric drive. It should be noted that there is a complete absence of hydraulics, which increases the overall reliability and service life of the system. Thanks to the EUR, you can implement the functions of autopilot, automatic parking, etc.

In general, installing electric power steering allows for greater steering precision and sharpness.

Also, the ESD is more economical and is activated only at the moment when the driver applies force to the steering wheel. This means that the engine does not need to constantly drive a pump to pump hydraulic fluid. The result is lower fuel consumption and minimized engine power loss.

Also, modern types of electric power steering make it possible to implement the functions of adaptive electric power steering. Such an amplifier closely interacts with other systems (for example, the exchange rate control system).

This allows:

- significantly improve safety;

- perform wheel rotation angle correction;

- improve the overall stability of the car.

The electric amplifier does not require additional maintenance and operates almost silently. In the event of a breakdown of the amplifier, the ability to drive the car is fully preserved. Also, the steering force can optionally be changed in accordance with the speed and road conditions. As a result, feedback improves.

The main reasons for pump failure:

Untimely replacement of the working fluid in the system. Using a low-quality liquid or one that is not suitable for this car model. Ingress of dirt or foreign bodies (a clot of oily dust that usually accumulates around the oil reservoir cap is a common cause of pump failure). Lack of tightness and, as a result, leakage of working fluid. After which the system becomes airy and fails. Oil starvation due to kinks in oil lines. Significant overheating of the system, or systematic minor overheating. Errors during installation, poor quality assembly. During operation, the power steering pump parts, as they wear out, saturate the working fluid of the system with metal dust or even small metal particles. When the time comes to replace the old power steering pump with a new one, the entire power steering system must be thoroughly flushed, and elements in which wear products have accumulated must also be replaced. If you ignore this instruction, you risk that the new pump will be damaged as soon as possible.

admin 02/04/2015

“If you notice an error in the text, please highlight this place with the mouse and press CTRL+ENTER” “If the article was useful to you, share the link to it on social networks”

EUR device and types of electric amplifiers

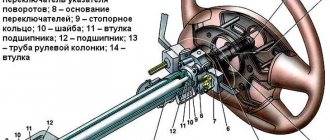

The main element in the design of this type of steering is an electric motor. The amplifier itself actually consists of two main elements:

- electric motor;

- electric power steering control system.

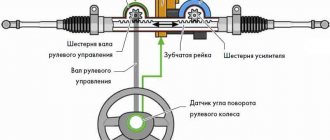

Depending on the type, electric amplifiers are usually divided into EUR and EMUR. In the case of an electric power steering, the engine can be located in the steering column, while the electric power steering requires integration into the steering rack (electric power steering rack).

The first option is the simplest and cheapest; the electric motor in the steering column is often an asynchronous electric motor that transmits the generated force in the form of torque to the steering wheel shaft through a mechanical transmission.

The second option is electromechanical power steering. This amplifier may differ in design:

- with two gears;

- with parallel drive.

The gear design means that the transmission of torque from the steering wheel to the steering rack is carried out by one gear, while the second gear receives the torque from the electric motor.

If the EUR is with a parallel drive, then the electric motor transmits force to the steering rack through a belt drive or transmission through a screw and a ball nut.

Electric power steering control system

The EUR control system includes the following components:

- electronic control unit;

- electric power steering sensors;

- executive device.

Sensors determine the angle of rotation of the steering wheel, as well as the force (torque) on the steering wheel. Additionally, the ESD system receives information from the ABS unit, exchange rate control system, and engine ECU. As a result, the electric booster also receives signals from the speed sensor, crankshaft sensor, etc.

Next, the electric power steering control unit, receiving signals from a group of sensors, sends commands to the actuator (power steering electric motor). This solution makes the steering light, precise and responsive.

Pros and cons of electric power steering.

Pros.

- Economy: the power steering is activated only when the steering wheel is turned, while its opponent, the power steering, works constantly, unnecessarily consuming both engine power and fuel reserves.

- Has several modes of use.

- Compactness: in comparison with the hydraulic booster, the electric booster takes up very little space in the engine compartment.

- Easy to maintain.

- The EUR works equally well in both hot and cold weather.

- A car with an electric booster has a sharper response to driver input at high speeds than the same car with a hydraulic booster.

Minuses.

- Low power, and therefore this type of power steering is installed only on passenger cars.

- Under unfavorable driving conditions (for example, a loose dirt road), the EUR may overheat and fail for a short time (until it cools down).

- Very expensive repair.

How does electric power steering work?

To understand how electric power steering works, it is necessary to separately study the principle of its operation. When turning the steering wheel, the torsion shaft is twisted. The torque sensor sends a signal to the control unit, after which the ECU processes the information.

The control unit then analyzes the field from a number of other sensors, the field of which the unit determines the required force to turn the wheels, taking into account various driving conditions.

Next, a control signal is sent to the amplifier electric motor, after which the electric motor will act on the steering column shaft or steering rack. In this case, the operating modes of the amplifier will differ depending on the conditions.

The following main modes can be distinguished:

- wheels turn in standard mode;

- the driver turns the steering wheel at high speed;

- the wheels turn at low speed;

- the wheels turn on a car that is standing;

- the wheels return to the “zero” position;

- the steering wheel is maintained in the “zero” position.

Moreover, in each case the force that the amplifier will generate will be different. For example, if a car is stationary, a lot of force must be applied to turn the wheels easily.

However, if you apply similar force while driving at high speed, the steering wheel will be too “light” and the car may simply fly off the road. To prevent this from happening, the amplifier ECU will adjust the force of the electric motor and make the steering wheel heavier, which is necessary for comfortable and confident control at high speeds.

Malfunctions and their symptoms

Undoubtedly, the electric booster is a more reliable unit than a device running on hydraulics, but malfunctions also appear in the power steering. If they are detected, repairs must be carried out immediately, since the safety of the driver, his companions and other road users depends on the operation of the amplifier.

Complete failure of the EUR

As practice shows, this unit does not have many faults; breakdowns occur in the same parts. The first thing worth considering is the complete failure of the ESD. When you turn off the amplifier, you need to check the on-board computer screen; most likely, you will see a code there indicating a malfunction in the unit. But sometimes it is possible to determine when an amplifier is turned off only in practice.

We perform the following actions:

- Turn off the engine and turn the steering wheel in different directions several times;

- We repeat these steps, but with the engine running;

- Has the steering effort changed? This means the node has completely shut down.

Even with the ESD not working, you can continue driving, but this is not recommended. The driver needs time to get used to driving with the help of an amplifier. It is better to immediately begin diagnostics and determine which component requires repair or replacement.

Sometimes the amplifier and speedometer stop working at the same time. The cause of this defect is a speed sensor that has failed. Taking a look at the electrical diagram, you will understand that these three elements are connected. The torque sensor supplies data to the control unit, it compares it with speed and determines the force. If the cause is the speed sensor, then the repair consists of checking the wiring that leads to this element. It is also worth checking the wires connecting the sensor to the speedometer and power steering. If there are no breaks in the switching, then the sensor should be changed.

Low voltage in the car network can also lead to the ESD turning off. Faults should be looked for in the wiring insulation. If it is damaged, short circuits will appear in the network. Also, violations in insulation lead to malfunction of the generator. To troubleshoot the problem, check the wiring and generator. The torque sensor contains many contacts, which, if heavily soiled, help turn off the power steering. In this case, repair means disassembling the unit and cleaning the contacts of the torque sensor.

see also

Unpredictable steering behavior

The driver is driving on a flat road, the position of the steering wheel does not change, and suddenly the car turns to the side. Such unpredictable behavior of the power steering requires urgent diagnosis, since at the most inopportune moment the electric power steering of the Lada Priora can send the car to the side of the road or into the oncoming lane. In such a situation, you should stop driving and turn off the amplifier. To do this, we need to remove the fuse, which is responsible for supplying voltage to the amplifier.

To remove this fuse, you need to do the following:

- The mounting block cover is located at the driver’s left foot;

- We turn the clamps and unclip the fasteners;

- You will find the block where the required fuse is located near the expansion tank;

- Feel free to take out fuse F5 (50 A) - it is responsible for providing the power supply circuit to the power steering unit.

The reason for this behavior is a malfunction in the electric amplifier device. This could be a torque sensor, control unit, clogged contacts or mechanical damage. It is recommended that diagnostics be carried out by professionals, since in a garage you will not be able to check the control unit; replacement can be done with your own hands.

Disadvantages of EUR

Along with its advantages, the electric power steering system also has several significant disadvantages:

- ESD is not used on trucks (the electric motor power is insufficient);

- interaction with a large number of sensors reduces reliability, difficulties arise with diagnostics and repairs;

- the cost of adaptive electric amplifiers is much more expensive than traditional power steering;

- even taking into account the possibility of flexible settings, drivers note poor feedback, the force on the steering wheel is not natural, and connection with the road is lost;

It is noteworthy that an EPS malfunction can occur completely unexpectedly; the problem can be floating (appear only in wet weather or after driving on a bad road). The result is that repairing electric power steering can be difficult, as it is difficult to determine the cause even after in-depth diagnostics.

We also recommend reading the article about what malfunctions are often found on the Lada Priora EUR. From this article you will learn about common problems with the Priora electric booster, as well as how to diagnose and repair the ESD on a Priora.

Taking into account such disadvantages, on more expensive modern cars, electric power steering is often installed instead of traditional power steering or electric power steering. This solution combines the main advantages of hydraulics and electronics, allowing to significantly improve the quality of steering.

What is electric power steering

Electric power steering is a system that combines some of the advantages of hydraulic power steering and electric power steering, while devoid of some of the disadvantages of power steering and power steering.

In fact, the electric power steering is a power steering, but the power steering pump in this case is electric. This means that engine power is not taken away.

Also, installing a separate electric pump allows the amplifier to function autonomously (even when the engine is not running) and flexibly change the steering force depending on the vehicle's driving conditions. As a result, the driver receives the main advantages of power steering and electric steering (adaptive steering, as well as better feedback from the road, etc.).

We also recommend reading the article on how to change power steering fluid yourself. From this article you will learn when and why you need to change the power steering oil, as well as how to change the power steering oil yourself.

The disadvantages include the traditional disadvantages of hydraulics (leaks, the need to change the power steering oil, overheating of the power steering oil), as well as possible problems with the control electronics (failures in the operation of the electric pump, problems with sensors, etc.). Also, a serious disadvantage of EGUR is the cost of such a system and the additional difficulties of its repair.