Publication date: December 01, 2020. Category: Motor vehicles.

Some owners of “iron horses” consider the speedometer to be the main measuring instrument installed on a motorcycle. Of course, the speed at which you are moving is important information (especially for traffic police officers). However, only a tachometer, informing the motorcyclist about the number of engine revolutions, will help “tell” whether the gear is selected correctly for a given speed. Not all bikes are equipped with this useful device. Installing a tachometer on a motorcycle with your own hands is now quite simple.

Purpose and principle of operation of the tachometer

A tachometer is a device that measures the number of revolutions of a motorcycle engine in one minute and displays this information on the dashboard (in an easy-to-read form). The readings of this device are necessary for a motorcyclist (especially a beginner) to:

- timely gearbox speed switching: as soon as the engine speed increases to a certain value, it is necessary to switch to a higher gear and vice versa;

- preventing the operation of the motorcycle power unit at extreme conditions (this is indicated by the red sector of the tachometer);

- fuel economy if the engine operates at optimal speed (the one most appropriate to the gear engaged, the load on the motorcycle and road conditions).

The dashboard of many modern bikes is initially equipped with this useful “informant”. However, in the vast expanses of our Motherland, there are still a huge number of Soviet and Russian-made motorcycles in use (for example, “Ural”, “IZH”, “Voskhod”) that are not equipped with tachometers. By the way, many models of the legendary Harley Davidson and Triumph also do not have standard engine speed indicators. A tachometer for a motorcycle that was not installed during construction can be purchased and installed yourself.

How to connect a car tachometer with your own hands?

The main function of the tachometer in a car is to determine the correct gear, which has a positive effect on the life of the engine. Most cars have an analog tachometer built into them during assembly.

The driver looks at the arrow approaching the red line and knows when to shift into a higher gear.

Not all cars have the type of device that satisfies the owner, so you just need to figure out what they have and how to connect the tachometer.

Types of tachometers How to connect a tachometer via an ECU. Diagram for connecting a tachometer to a gasoline engine. How to connect a tachometer to a diesel engine. How to check the tachometer for operation.

Did you know? The term “tachometer” comes from the Greek τάχος - speed and μέτρον - measure.

Types of tachometers

There are two types of tachometers: digital and analog.

The first looks like a small screen on which the driver can see all the data he needs while driving.

The second one is simpler and looks like a board with arrows and values.

Remote

A remote tachometer is installed on the front panel of the car. For greater ease of placement, this device has a leg for mounting on the panel.

Remote digital tachometers are good for monitoring idle speed. Their readings have fewer errors, so using such a device you can check the operation of a standard tachometer.

In addition, their stylish appearance gives the car elegance.

Staff

The standard tachometer is built into the dashboard of the car. This device is more convenient, since it is easier for the driver to perceive the movement of one arrow, rather than several indicators while driving. A standard tachometer is more often used in cars, and manufacturers of electronic devices produce kits for self-equipping cars.

Important! Measuring instruments are produced according to the car brand. The readings from a non-native mechanism will be incorrect.

How to connect a tachometer through the computer If your car does not have a carburetor engine, and the injector, the tachometer is not connected to the ignition. In this case, you need to connect the engine control unit to the controller.

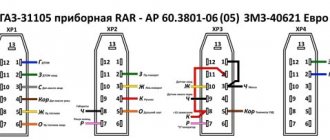

The connection diagram for the tachometer is simple: take the ground to the body (ground), connect the plus from the device to the ignition positive. The tachometer has two inputs: the first goes to the control unit, the second to the crankshaft position sensor.

The device connected to the computer will read pulses directly from the control unit controller.

Connection diagram for a tachometer on a gasoline engine

Before installing a tachometer on a carburetor engine, read the instructions included with the device. If it is not there, install according to the following steps:

Secure the mechanism in its place (the location is determined by the type of device). Connect the black wire to the ground (body) of the car. Connect the red wire to the ignition switch terminal, which supplies 12 W during operation of the ignition system.

The third wire can be any color. Since the ignition system is contact and non-contact, we will consider where to connect the tachometer in both. With a contact system, the device is connected to the distributor breaker. In the second system - to the voltage switch.

If the car has a display backlight, the tachometer is connected to the terminal provided for this in the ignition switch.

How to connect a tachometer to a diesel engine

Before connecting, let’s figure out what makes the tachometer on a diesel engine work. The operating principle of an electronic device is to read pulses sent by a terminal located in the generator.

Since the process is labor-intensive, it must be carried out in an inspection pit. The first point of work is to dismantle the protective casing of the generator, try to avoid getting dirt. The second step is connecting the tachometer to the diesel generator. To do this, find the terminal marked “W” on the generator body and connect the device output to it.

Attention! It is imperative to close the contact coming from the oil pump. If this is not done, the tachometer may “lie”.

It happens that the terminal indicated above cannot be found. In this case, disassemble the generator. Connect one of the wires connecting the winding and the rectifier to the tachometer cable. Insulate the wires and reassemble the generator in reverse order.

Installing a measuring device is not very difficult, but without any knowledge of how a diesel engine works, how a tachometer works on a diesel engine, without the slightest idea about car repair, it is better to turn to professionals.

How to check the tachometer for functionality

We figured out how to connect a tachometer to a diesel and carburetor engine. Now let's look at the reasons for device breakdowns.

You notice problems in the operation of the measuring device, for example, an arrow jumping in different directions. There may be several reasons for the breakdown. If the engine runs for a long time, vibration will occur, which may damage the display.

The next reason may be oxidation of the contact group of the electrical wiring, damage to its insulation or disconnection from the tips. These are all visible causes that need to be eliminated immediately. If the sensor itself is broken, it needs replacement.

If self-diagnosis does not reveal the cause, you should contact a car repair shop.

Interesting! The tachometer was designed by the American Curtis Widder in 1903.

Models, manufacturers and prices

The range of tachometers intended for installation on motorcycles, mopeds and scooters is very diverse both in price, design, execution (with an arrow or digital display), and in the number of manufacturers producing products for this purpose.

A universal electronic tachometer (from Chinese or “Kkmoon”) with LED backlight in a stainless steel case (Ø=56 mm, case height – 60 mm) costs only 540÷650 rubles.

For the same 500÷700 rubles you can purchase products with a digital indication of the number of revolutions per minute from Ironwalls or FCD.

Owners of expensive and prestigious brands of motorcycles (however, those not equipped with a standard tachometer) can purchase and install products from the world-famous and well-established Baron, Koso, J&P Cycles or Sunpro. However, the cost of these products will already range from 3,000 to 12,000 rubles.

Connection diagram for tachometer to motorcycle

The diagram for connecting a tachometer to a motorcycle is not fundamentally different from its installation on a VAZ-2106 car. The input of the device is connected to the output of the primary winding of the coil, after which the positive and negative wires are connected to the battery. Installing the toggle switch on the positive line will significantly save battery power when the motorcycle is idle.

A two-cylinder unit with single-channel ignition must be equipped with a rectifier. The battery that powers the tachometer is connected to its output. When the TX-193 is directly connected to the generator, the device will fail in the shortest possible time.

In the case of dual-channel ignition, to transmit pulses from both cylinders it is necessary to create an identical tachometer input line. After drilling an additional hole in the bottom, connect the wire to the device terminal.

Three-cylinder motorcycles are usually equipped with three-channel ignition systems. In this case, the connection to the tachometer is made from any two coils. In the same way, pulses are supplied in multi-cylinder equipment, but here it is more advisable to use models designed for this type of engine.

Connecting a tachometer to a single-cylinder unit is a little more complicated. Here it is necessary to adjust the resistor R7, which is responsible for the sensitivity of the measuring device. If necessary (lack of power), you should double the power of capacitor C5, and then readjust the resistor.

How to find the tachometer signal

How to find a tachometer signal When connecting an alarm system that starts the engine, it is always advisable to take the engine operation signal from the tachometer

VAZ 2114 starter relay But how to find it, especially if you don’t have a car diagram at hand? There are several proven methods for this

carburetor adjustment VAZ 2107

Before

The simplest k-line adapter

How to make a programmable windshield wiper

How to find the tachometer signal

When connecting an alarm system to start the engine, it is always advisable to take the engine operation signal from the tachometer. But how to find it, especially if you don’t have a car diagram at hand? There are several proven methods for this.

First of all, you need to check the presence of this signal on the diagnostic block, and you can also look in the connection block of the instrument cluster.

The tachometer signal can be looked for with a tester by setting the switch to alternating voltage. The tachometer wire is the one on which the change appears when the engine is running.

carburetor 2107

But personally, I look for it using a simple, self-made probe.

To do this, I solder a resistor with a nominal value of 680 - 1000 Ohms in series to the LED, depending on the type of LED, and a wire about 0.5 m long. I solder a crocodile on one wire and a probe on the other. If such a probe is connected to a battery, it will burn to the floor - incandescent

yeah

Having started the crocodile engine, we connect it to ground and use a probe to look for a signal.

When the diode lights up, you need to wave it with a big flourish; if the diode is constantly on, the signal is not the same, but if it flickers like a dotted line, then most likely this is our signal

ignition module vaz 2114 price

The flicker frequency also changes depending on the engine speed. The result was a simple osciliograph.

Another very important point: you should always install a 2.2 -4.7 uF capacitor at the break in the tachometer wire to the signaling signal. ceramic, not electrolyte, to remove the permanent component. Without it, under- or over-twisting of the starter is a common occurrence.

If you still couldn’t find the tachometer signal, you can connect using the injector signal, or from the ignition module, again through the condenser

how to connect a tachometer

The most extreme case is to connect using the generator signal, but not via voltage without connecting a wire.

DIY speaker repair

Do-it-yourself stop/gauge voltage stabilizer

Pulse charger 12V 10A - diagram

Similar articles:

Useful tips → Secret letters in your car

Useful tips → How to protect your car and property from theft?

Useful tips → Winter driving rules

Useful tips → How to get out of a skid correctly

Helpful tips → How to properly drive over a speed bump

We recommend reading:

Feasibility of direct flow, installation instructions

Nowadays, it is not at all difficult to acquire a speed meter for further installation on a bike. As a tachometer on the Izh Jupiter 5 and other Izhmoto models, as mentioned above, the speed meter that is equipped with the VAZ 2106 car (simply popularly called the “Zhiguli Six”) can be safely used. This product can fit well into the standard panel of these Russian Soviet motorcycles In this case, connecting the tachometer to the Izh involves cutting its body to half. All connectors that are connected to the light devices (indicators) of the dashboard must be lowered to the lower limit. After installation, the tachometer on the motorcycle must not sit unevenly, resting against wires and other elements standard bike design.

How to install a tachometer on an Izh

Note that the Izh planet tachometer is designed according to a similar scheme of actions.

There is no need to move the control lamps if the latter are replaced with a box with LEDs. You yourself will appreciate the super-bright indicators of the latter above the brightness that the light indicator elements had in the standard form of the iron horse. You can attach the above box (socket) with LEDs to the end of the tidy. And the body of the latter itself is not difficult to create, using, for example, cases from an old audio cassette. Not a bad excursion into the 1990s, isn't it?

The tachometer on the Ural motorcycle can be equipped according to a similar principle, replacing the speedometer or moving the device for measuring revolutions to a separate area at the steering wheel. Connecting tachometers to an Izh motorcycle is carried out independently with the same success and simplicity as the installation of the latter itself. You can make a colored outline around the new location for the design of light bulbs or LEDs. A bright circle, mostly of a light color, is drawn around each light element. After such a simple innovation, your devices (indicators) will look much better.

How to connect a tachometer to an Izh motorcycle?

After securing the tachometers, you can begin connecting their wires to the electrical wiring elements of the bike.

Simply put, our semi-homemade Izh Planet tachometer, or a device that will work on another bike, has only three wires. The mass goes to the frame of the iron horse.

The plus is connected to the ignition switch (to the positive terminal that comes from the battery). The third wire is mounted on a coil. In the case of the tachometer on Izh Jupiter 5 and other two-cylinder Soviet bikes, there is no difference at all which coil to connect to. The easiest way is to separate the wire to connect to both.

Note that the wire going to the coil needs to be equipped with a “d226d” diode. Often a tachometer is installed on a motorcycle by replacing a capacitor of 0.22 μF (microfarad) with a product with a value of 0.47 μF, for example. This innovation allows you to modernize the bike for use on an Izh motorcycle. The connection diagram for the last wire looks like this.

How to connect a tachometer?

Both in principle of operation and in maintenance, gasoline and diesel engines are different from each other. You can immediately see this by looking under the hood of the car or by pressing the accelerator pedal a couple of times. Devices installed in a car have the same functionality and appearance, but the connection in some cases is different.

No less important on the topic under discussion is such a factor as: where to connect the tachometer. The following discussion can be divided into two parts.

Connection to a car to a diesel engine

To connect the tachometer to a diesel engine, you need to get close to the generator coil. In most cases, you need to go to the inspection hole, remove the generator protection and clean it of dirt. On the generator coil itself there are terminals, each responsible for a separate process. We find the terminal labeled “W”. It is to this terminal that you need to connect the contact from the tachometer.

To ensure that its readings are correct, we take and close the contact that comes from the high-pressure oil pump. Otherwise, after reaching 2500 rpm, a light on the dashboard will light up, responsible for the oil pressure in the system.

And I completely forgot, in a number of cases, after opening the generator cover, car owners do not find the terminal marked “W”, blaming the manufacturer, who did not see the need for this. When this is the case, you need to see on the winding the output of the contacts to the built-in rectifier of the generator; there will be three of them. The end of the tachometer cable should be soldered to one of them.

If all actions are correct, the tachometer will work. After all the manipulations have been done, screw on the generator cover and make sure that the wire does not touch moving parts.