Each car in its design is equipped with such a device as a clutch master cylinder. The car in question, like most modern cars, is also equipped with a master and slave cylinder in the design of the clutch mechanism. In this material we will pay attention to the clutch master cylinder on the VAZ 2107, its location, diagnostics and replacement features on the seven.

Product location

The master cylinder on a VAZ 2107 is located under the hood, directly on the wall separating the interior from the hood, near the driver’s feet. Directly above it is the expansion tank, and next to it are the vacuum booster and the brake master cylinder. Usually, simply looking at the product is enough to determine the problem. The presence of a leak indicates that the part is faulty and requires repair or replacement.

Purpose of the device

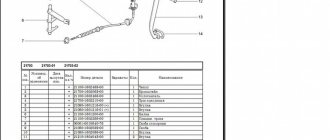

Cars are equipped with clutch master and slave cylinders, without which the operation of the mechanism is impossible. The VAZ 2107 clutch master cylinder is designed to push out brake fluid. Below is a diagram from which you can visually find out the operating features of the unit.

When you press the clutch pedal, the piston moves in the device in question, thereby pushing out the brake fluid. This liquid enters the working cylinder through a tube, where the reverse process is observed (the liquid pushes out the piston). Brake fluid drives a piston, which is connected by a fork to the clutch disc. As a result, the clutch disc and flywheel are separated, allowing you to change gear. The GCS is also called the main one, since it is with its help that force is supplied from the pedal when it is pressed.

The need to replace the device: when required

Like all parts of any car, the GVC tends to wear out, resulting in the need for repair or replacement. The simplest breakdown of a product is wear of the boot, which can be determined by the characteristic signs of a fluid leak.

To identify a cylinder malfunction, an initial visual inspection is required. It is possible to repair a failed main circulation system on a VAZ 2107; for this you can look for repair kits, but this is not always rational due to the quality of modern spare parts, so it is easier and faster to replace it entirely. The malfunction can also be determined by the characteristic loss of pressure in the system, which is determined by pressing the pedal. Let’s take a closer look at how to change a faulty VAZ 2107 mechanism.

We change it ourselves

Replacing the VAZ 2107 clutch master cylinder begins with the need to pump out the brake fluid from the hydraulic reservoir. This can be done using a syringe or a rubber bulb. Together with this socket or a 10mm wrench, unscrew the bracket securing the expansion tank and move it to the side to gain access to the cylinder.

The next step involves removing the clutch expansion tank hose. To do this, you need to loosen the hose clamp, then disconnect the hose and position it so that it does not interfere with further work. If you want to remove the tank completely, this is done very simply.

Further actions are performed in the following sequence:

- Using a “10” wrench, you need to unscrew the pipeline securing nut to the device. Once the nut is unscrewed, the tube can be moved to the side.

- There is a hose nearby near the steel pipeline, which also needs to be disconnected from the main device. This can be done by loosening the fixing clamp.

- The GCS is fixed to the body using two fastening nuts. To unscrew them, you will need to use a wrench with an extension and a “13” socket. After unscrewing the two nuts, you can remove the product and drain the remaining brake fluid from it. If it is not possible to dismantle the unit, you can press the clutch pedal, as a result of which it will move.

- But repairs are usually not rational, so after removing the old one, a new unit is installed in its place. Installation is carried out in the reverse order of removal. After installation, it is necessary to carry out the process of pumping the hydraulic drive, first pouring fuel fluid into the tank. You can find out how the system is pumped from the relevant material on the website.

After the work is completed, you can test the operating features of the new GVC. If necessary, the RCS (working cylinder) should also be replaced, but you can find out more about this in the corresponding material.

Cars of the Volzhsky plant models 01-07 have a hydraulic clutch drive. The main actuator of this mechanism of the VAZ 2107 is replaced in the event of its breakdown or failure. The cylinder is secured to the engine compartment shield on the driver's side with two studs and nuts, and a reservoir with brake fluid is installed in the upper part. A pipeline is laid from it to the working unit.

Dismantling the hydraulic drive

To perform the operation we will need:

- container for operating fluid and a large-volume syringe.

- set of wrenches and sockets;

- screwdriver and pliers.

The order of work is as follows:

- Brake fluid is pumped out from the expansion tank of the master cylinder of a VAZ 2107 car using a syringe. A rubber tube is disconnected from the drive, from which the remains are also poured into the prepared container. If liquid gets on paint surfaces, they must be wiped with a damp cloth.

- Using an open-end wrench set to “10”, unscrew the fitting of the pipeline connecting the main and working hydraulic drives.

- Using a “13” socket and an extension adapter, unscrew the nuts holding the assembly to the engine compartment panel.

- To remove the master cylinder from the studs, simply press the clutch pedal, this will move it out of place, after which you can pull it out by hand.

The work on removing the unit is completed, and you can begin installing the spare part.

Article: 21010-1602610-00, additional articles: 21010160261000, 2101-1602610

Order code: 010771

- You may need

- show more

- Buy analogues

- Passenger cars / VAZ / VAZ-21021 drawing

» href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2102-4/privod_scepleniya-118/#part7264″>Main cylinder Clutch / Clutch drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2104-5/privod_scepleniya-93/#part14364″>Main cylinderClutch / Clutch drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2106-7/privod_scepleniya-92/#part20391″>Main cylinderClutch / Clutch drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2121-13/privod_scepleniya-83/#part59253″>Main cylinderClutch / Clutch drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213-731/privod_scepleniya-120/#part2010227″>Main cylinderClutch / Clutch drive

- » href=»/catalog/chevrolet-125/legkovye_avtomobili-30/chevrolet_niva_1_7-1233/privod_scepleniya-139/#part2974047″>Clutch main cylinderClutch / Clutch drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2101-3/privod_scepleniya-118/#part2780″>Main cylinderClutch / Clutch drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2103-106/privod_scepleniya-88/#part10905″>Main cylinderClutch / Clutch drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2105-6/privod_scepleniya-93/#part17470″>Main cylinderClutch / Clutch drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2107-8/privod_scepleniya-132/#part24647″>Main cylinderClutch / Clutch drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2131-73/privod_scepleniya-161/#part63933″>Main cylinderClutch / Clutch drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213_214i-1240/privod_scepleniya-164/#part2989381″>Main cylinderClutch / Clutch drive

- There are no reviews for this product yet.

Today, the next article in the series “Crystal VAZs or typical breakdowns of domestic cars” is dedicated to the “classics”: VAZ-2101, 2103, 2104, 2104, 2105, 2106 and 2107. These cars have been driving along our roads for decades and, despite Despite all the shortcomings that we will talk about, their popularity is still high.

Hydraulic drive installation

Replacing a mechanism involves purchasing it in a retail network or via the Internet. Installation work is performed in the following sequence:

- The clutch master cylinder of the VAZ 2107 is put on the studs and pushed all the way to the base.

- The nuts are screwed onto the fasteners and tightened with a wrench to “13”.

- The union nut of the pipeline laid to the working hydraulic drive is screwed into the main cylinder.

- The rubber tube is connected to a plastic connecting element and secured with a clamp.

- The expansion tank is filled with brake fluid, which enters the main and slave cylinders of the clutch through tubes. Replacing the fluid in the system is mandatory due to wear products.

Upon completion of installation of parts, it is necessary to inspect and check the tightness of the nuts. Replacing the main or working clutch drive of a VAZ 2107 car ends with bleeding the system.

The main purpose of the clutch master cylinder is that it transmits force to the slave cylinder from the clutch pedal using working fluid.

If the master cylinder is faulty, vehicle control will be impaired and it will be impossible to disconnect the transmission from the engine.

How to determine if the clutch master cylinder is faulty:

- Periodically check the level of working fluid in the tank. A sharp decrease in it will indicate a system malfunction;

- check for leaks in the main and working cylinder housings;

- failure of the clutch pedal, which occurs due to the entry and accumulation of air in the clutch system;

- underpressure of the pedal and vibration of the gear shift lever.

Main types of faults:

- there is a leak in the master cylinder;

- cuff wear;

- piston wear;

- the inside of the case is damaged (chips, scratches, etc.);

- For all classics of the Auto VAZ family, the clutch device is the same, including for 2107. The sequence of actions is the same.

There are two ways to eliminate a malfunction of the master cylinder - replacement with a new one and repair. What can be repaired:

- replace rubber cuffs;

- frame.

These actions do not always lead to the desired effect, especially on an old car with decent mileage. It is recommended to replace the master cylinder with a new one. Its cost is not high, approximately from 450 to 500 rubles. It's better to buy the original.

Malfunctions of the clutch slave cylinder VAZ 2107-2101

The most common system malfunctions, which can lead to complete failure of the entire unit, include:

- Presence of excess air in the system. This situation can arise if there are cracks in the rubber pipes or sealing joints, as well as as a result of fatigue of the plastic housing and the presence of microcracks. In this case, a complete replacement of the failed part is carried out, since excess air does not allow creating the necessary pressure to open the bearing and clutch, thereby the owner simply will not be able to engage the gear correctly.

- Wear due to various reasons of the components of the assembly themselves. Thus, as a result of the breakdown of any part of the assembly, the general principle of operation is violated, since, despite the simplicity of the design, each element, performing a specific function, directly affects the performance of the system as a whole. In this case, in addition to simply replacing the entire system, the option of disassembling and eliminating a specific malfunction may be considered by replacing a certain component in the form of a part using a repair kit.

Replacement

The cost of this type of work in a car service starts from 550 rubles. But for most car enthusiasts, this operation is not so difficult to perform on their own.

- new GVC;

- brake fluid;

- set of wrenches with extension;

- syringe or rubber bulb.

- Pump out the fluid from the hydraulic drive reservoir using a syringe or rubber bulb.

- Remove the expansion tank and move it to the side so that it does not interfere with work.

- Unscrew the tube with a 13mm wrench. Move it a little.

- Loosen the clamp and disconnect the rubber hose that goes from the tank to the cylinder.

- Unscrew the two nuts with a 13mm socket wrench and an extension.

- Remove the master cylinder from the studs.

- Replace the GCS with a new one.

- Reassemble everything in reverse order.

Bleeding the clutch

The replacement has been made, but you should not hit the road without bleeding the clutch system. The process is similar to bleeding the brakes and is carried out in the following sequence:

- Brake fluid is poured into the reservoir.

- A hose is put on the master cylinder fitting, the other end is lowered into a bottle filled with liquid. This will show how air leaves the system during the pumping process.

- The operation requires an assistant. One sits in the car and presses the clutch pedal 5-6 times on command, after which he leaves it pressed. The second one opens the fitting until the release of air stops. This is done several times until all air is removed from the clutch system.

- Tighten the fitting and add fluid to the reservoir.

Conclusion

After replacing the clutch master cylinder and bleeding the entire system, you can safely hit the road without fear that the clutch will fail and the car will lose control because of it.

And again we are repairing the VAZ 2107

Clutch problems? Does it not engage completely, is the clutch pedal “soft” or does it fail altogether? All this will tell us that the time has come to repair the clutch - the master and slave cylinders! How this is done will be discussed in this article. Here you will find: instructions for repairing the clutch on a VAZ 2107 car, a useful video, tips and features of this type of work. Here you will find information on how to change cylinders, repair and bleed them.

Selection of GVC for VAZ 2107

The best option for replacement is to purchase a GCS designed specifically for classic VAZ models. Clutch master cylinders from UAZ, GAZ and AZLK vehicles are not suitable. The same applies to foreign analogues - foreign cars with rear-wheel drive are equipped with GVCs, which only highly qualified specialists can adapt to the VAZ 2107 (different sizes, different threads for pipelines, different pipe configurations). However, you can easily replace the original cylinder with a GCS from a VAZ 2121 and from a Niva-Chevrolet.

Manufacturer's choice

When purchasing a new GVC, you should focus on products from trusted Russian manufacturers (AvtoVAZ JSC, Brik LLC, Kedr LLC), the Belarusian company Fenox, which is adapted to our conditions and is affordable. The average cost of GVC is 600–800 rubles.

Table: comparative characteristics of GVCs from different manufacturers

| Manufacturer, country | Trademark | Cost, rub. | Reviews |

| Russia, Tolyatti | AvtoVAZ | 625 | Original GVCs are made with high quality and are more expensive than analogues |

| Belarus | Fenox | 510 | Original GVCs are inexpensive, made with high quality, and are popular among drivers |

| Russia, Miass | Brick Basalt | 490 | Improved design: the absence of a technological plug at the end of the cylinder and the presence of an anti-vacuum cuff increases the reliability of the product |

| Germany | AND THOSE | 1740 | The originals are of the highest quality. The price is tied to the EURO exchange rate |

| Germany | HORT | 1680 | Original GCS are reliable and durable in operation. The price is tied to the EURO exchange rate |

| Russia, Miass | Cedar | 540 | The original GVCs do not cause any particular complaints |

Preparing for clutch repair

What you need to prepare in order to repair the clutch yourself:

- A set of keys

- Screwdriver (preferably thin)

- Special pliers-pullers

- WD-40 or similar rust remover

- Knife

- Brake fluid

- Bleeding hose

- Bleeding container

- Syringe

That's probably all that is needed.

Expanding pliers (circlip pliers)

Clutch replacement

Often, car owners prefer to simply replace clutch parts, since the cost is low and time can be saved significantly. Therefore, you can first consider the process of replacing clutch parts.

Replacing the clutch master cylinder

- First you need to drain the fluid from the clutch reservoir. This can be done using a syringe - select the liquid and pour it into another container.

- You can also remove the hose from the master cylinder fitting and insert it into the same container. Slightly straighten the clamp on the fitting to make it easier to remove the hose. Do whatever is more convenient for you.

- After this, you need to unscrew the pipe fitting that fits the clutch slave cylinder.

- Then spray the two studs that secure the clutch master cylinder to the car body with WD-40 or an equivalent to prevent breaking them when unscrewing the nuts.

- Take a 13mm wrench or a socket with extensions (whichever is more convenient) and unscrew the two fastening nuts one by one.

Removing the nuts securing the main brake cylinder VAZ 2107

- Remove the clutch master cylinder.

Ready! Withdrawal completed. Now let's install the new cylinder:

Advice! Before installing a new master cylinder, pay attention to the condition of the clutch reservoir flexible hose. It often happens that it cracks at the end. There are two options - either replace the hose or cut it (if the length allows).

- First you need to get the drive rod from the clutch pedal into the hole in the new master cylinder. For convenience, ask a friend to press the clutch pedal a little.

- Then install the clutch master cylinder onto the mounting studs.

- Tighten the fastening nuts with a 13 mm wrench or a socket with extensions.

- Using a 10mm wrench, connect the pipeline from the clutch slave cylinder.

- Install the clutch reservoir flexible hose.

- Fill the reservoir with brake fluid to the filler neck.

The master cylinder has been replaced.

Replacing the clutch slave cylinder

Clutch slave cylinder for VAZ 2107

Now we will change the clutch slave cylinder on a VAZ 2107:

Advice! When unscrewing and tightening the slave cylinder mounting bolts, be careful not to strip the threads in the gearbox housing.

- Remove the spring from the slave cylinder.

- Next, you need to unscrew the tube that connects the main and working cylinders using a 10mm wrench. Brake fluid will flow from it - put the cap on the end of the tube, which is located on the bleeder fitting of the working cylinder.

- Unscrew the two bolts securing the working cylinder using a 13mm wrench and remove them together with the plate.

- Remove the slave cylinder.

Removed. Now we will install a new clutch slave cylinder on the VAZ 2107:

- To begin, unscrew the adjusting nuts in approximately the same way as they were set on the old cylinder. This will help you either avoid clutch adjustments altogether or reduce them to a minimum.

Clutch adjustment VAZ 2107

- Then insert the slave cylinder push rod into the transmission fork.

- Screw the two bolts together with the plate. As practice shows, it is most convenient to tighten the upper bolt first, and then the lower one.

- Connect the fluid supply tube. Screw it into the cylinder with a 10mm wrench.

- Put the spring back on.

After replacing the working cylinder, it must be bled. If both the clutch master and slave cylinders were replaced at the same time, then read the bleeding method below:

- Unscrew the bleeder fitting 1 turn.

- Wait until liquid flows out along with air bubbles.

- When the air bubbles come out, tighten the fitting until it stops.

- Put on the cap.

- The pumping is over!

Let's move on to removing the clutch

Let's move on to work “under” the car.

Disconnect the driveshaft from the box.

We unscrew the fastenings of the gearbox safety bracket, as well as the tube from the gearbox. There is no need to disconnect the cardan, since the box does not need to be removed.

Unscrew the nuts that secure the box to the bottom of the car.

Disconnect the wires from the reverse sensor.

Remove the fork spring, which is responsible for disengaging and engaging the clutch, and disconnect the two bolts from the clutch working cylinder.

Remove the clutch pan. Then remove the four clutch housing mounting bolts.

Using a pry bar, push the box as far back as possible. This way she won't get in the way.

Now you will see the flywheel, the basket is secured with six bolts.

Unscrew them and the clutch will be removed along with the release bearing.

Pull out the clutch basket and disc and look at them. If they are in order, then there is no need to change them, or replace them if necessary.

Before starting assembly, it is recommended to lubricate the splines of the gearbox input shaft and polish the clutch disc with a dry cloth.

It is necessary to adjust the location of the clutch disc to the crankshaft bearing. This must be done using a special mandrel. It can be purchased at any auto store. If everything is done correctly, the mandrel will come out freely from the bearing.

Read more: Gas distribution mechanism of an internal combustion engine: device, purpose, principle of operation

That's all, you replaced the clutch yourself, now you can be confident in the reliable operation of your car's clutch.

Clutch repair

Now let's consider another option - using a repair kit for the clutch cylinders - main and working.

Master cylinder

So, we have removed the main cylinder and now we begin to disassemble it.

VAZ 2107 clutch master cylinder repair

- We start by removing the fitting. Use a screwdriver to remove the retaining ring.

- After which you can easily remove the fitting with the gasket.

- Now remove the rubber boot (protective cap) by simply prying it with a screwdriver or other convenient object.

- Now, using a 22 key on the other side, you need to unscrew the plug of the VAZ 2107 clutch master cylinder.

- You also need to remove the retaining ring from the boot side. This can be done using two screwdrivers, or special pliers. It is more convenient to use expansion pliers.

- Now you can easily remove all the insides of the cylinder.

Now about damaged parts and their replacement:

- All rubber seals should be replaced. 2 rubber rings - on the piston and pusher rod, one on the fitting, and we also replace the protective cap if necessary.

- If necessary, replace the spring. If it is deformed or damaged.

- Also pay attention to the internal mirror of the cylinder. It should not have burrs or chips.

- If the piston is damaged or the pusher is bent, then it is better to replace the cylinder with a new one.

- When assembling, all parts should be washed very thoroughly.

Note! Never wash parts in gasoline or oil and do not allow these liquids to get inside the cylinder. Lubrication is carried out only with brake fluid!

- Put all retaining rings back.

- Tighten the clutch master cylinder plug tightly!

Then install the cylinder back on the car. This is how the clutch master cylinder is repaired on a VAZ 2107 car.

Working cylinder

VAZ 2107 clutch slave cylinder repair

- Clamp the VAZ 2107 clutch slave cylinder in a vice and unscrew the rear plug.

- Remove the protective rubber cap.

- Remove the retaining ring from the plug side and remove all internal parts of the working cylinder.

- Using a 10mm wrench, unscrew the bleeder fitting.

- Check the condition of the spring.

- Replace all rubber seals of the VAZ 2107 working cylinder.

- Check the condition of the working cylinder mirror.

- Wipe the inside with a clean cloth if necessary.

- Clean the bleeder fitting. If the edges on it are “licked”, replace it.

- Wash all parts in brake fluid.

- Lubricate each part with brake fluid during assembly.

- Reassemble all parts in reverse order.

- Install the retaining ring, protective cap and plug.

Install the VAZ 2107 clutch slave cylinder on the car (see above).

Do-it-yourself replacement of the VAZ 2107-2101 clutch slave cylinder

Carrying out independent repairs of this drive will require the owner not only to have a certain set of tools in the form of various keys with different head sizes and repair kits, but also certain repair skills. Self-repair is quite within the capabilities of an experienced owner of a VAZ classic. Also, the owner will definitely need a lift or MA in the garage, since the part is located in the lower part of the engine compartment, in close proximity to the gearbox.

For beginners, in most cases you will need an assistant. In total, there are two main types of work with this part - removing and installing a new device into the system, which will not require additional time, and repairing the original part with complete or partial disassembly, which will require a sufficient amount of time, this directly depends on the experience of the owner.

How to remove the clutch slave cylinder VAZ 2107-2101

The procedure for removing the unit as a whole takes place in several main stages:

- All fluid must be removed from the clutch reservoir. To do this, you will need a regular small volume syringe. This tank is located in the upper part of the engine compartment. This is necessary to prevent the substance from spilling onto the owner or outside the system.

- After this, it is necessary to loosen the fastenings of the tank itself and, if necessary, dismantle it. At the same time, use a 13-mm wrench to loosen the rubber pipe leading from the tank to the master cylinder, thereby freeing up free access to the system.

- After this, also use a 13 key to disconnect the part from the other clamps of the clutch system and unscrew the 2 mounting fasteners using a regular screwdriver, which hold the body in the seat. After this, the part can be completely removed.

Repair of clutch slave cylinder VAZ 2107-2101

Repair work also takes place in several stages and is carried out immediately after dismantling the device itself:

- Using a 22mm socket wrench, unscrew the plug and remove the boot along with the locking ring.

- Then move the VAZ 2106 clutch slave cylinder rod all the way and then remove the fitting from the seat. This opens access to all internal parts of the device.

- These parts are located inside the housing and are arranged in a certain sequence.

Installation of the clutch slave cylinder VAZ 2107-2101

Reinstallation of a repaired part or installation of a new device occurs in the reverse order:

- The tank and cylinder linkage assembly must be secured in the standard mounting points in the engine compartment using keys.

- After this, it is necessary to connect the main part with the branch pipes of the vehicle systems, while choosing the correct tightening torque for the clamps.

- After this, connect the tank to the general hydraulic drive system and fill the liquid in accordance with the level.