What is a synchronous motor?

To synchronous

It is customary to refer to electric motors that operate on alternating current and have a rotor with a rotation speed that matches the speed of the magnetic field in the design of the unit.

Key elements of a synchronous electric motor:

- anchor;

- inductor.

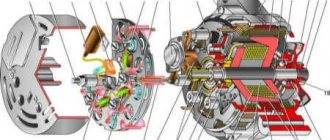

The first element of the unit is located on the stator. The inductor is placed on the rotor, which is separated from the stator by an air gap. The armature structure is represented by a winding (one or more). The currents that are supplied to the corresponding motor element form a magnetic field that rotates at a given frequency and interacts with the field of the inductor. The inductor includes 2 poles - in the form of permanent magnets.

The synchronous unit can operate in two modes:

- like the electric motor itself;

- like a generator.

The first operating mode involves the interaction of the magnetic field formed at the armature and the field that forms at the poles of the inductor. A synchronous motor in generator mode operates due to electromagnetic induction: during the rotation of the rotor, the magnetic field that is formed on the winding interacts in turn with the phases of the winding on the stator, resulting in the formation of an electromotive force.

Difference between asynchronous and synchronous motor

As I understand it, both of them are powered by alternating current, and in fact are Transformers whose primary winding is the stator. Secondary – rotor. The rotor is, or rather, a short-circuited secondary winding.

But in the stator, half of the windings must receive power out of phase by 90 or 180 degrees

In synchronous, this is done by introducing a capacitor; in asynchronous, this is done by a separate control system.

Are there trams with a synchronous motor? ————————————————————————————— Is it really NOT true that the rotor of a Synchromotor is just a Permanent Magnet?

Apparently there are no windings there and the steel is magnetized so that North becomes North, South becomes South, then half a turn and the poles change.

Is this Squirel Cage Moror? (motor shape “Cages for squirrels”)

The stator is exactly the same. The windings must be powered with a phase shift (its value depends on the number of poles), and how it is carried out (by a capacitor, an electronic converter, a multiphase generator) is not fundamental.

The difference is in the rotor. In a classic synchronous motor, this is a permanent magnet (or an electromagnet powered by direct current - in powerful motors), which is carried along by the rotating field of the stator. A synchronous motor can develop torque only if the rotor speed and the stator field exactly match (that’s why it’s called synchronous). In an asynchronous motor, the rotor has a winding, either squirrel-cage (squirrel-cage rotor is the most common type) or loaded with resistors (wound rotor). An electric current is induced in the rotor winding from the stator, like in a transformer, which in turn again induces a magnetic field that interacts with the stator field. An asynchronous motor develops torque only when the rotor speed is less than the stator field speed (otherwise the field is not induced in the rotor). When powered by a current of a stable frequency, a synchronous motor has an absolutely rigid mechanical characteristic (the speed does not depend on the load), while the speed of an asynchronous motor depends on the load and the rigidity of the characteristic can be changed by the resistance of the alloy filling the rotor (in squirrel-cage motors) or the resistance of shunt resistors (in motors with wound rotor). It follows that in its classical form, a synchronous motor is absolutely unsuitable for transport as a traction motor. In transport, the stator windings of a synchronous motor are switched from rotor position sensors; such a motor is analogous to a commutator one, but instead of a brush-commutator mechanism, commutation is carried out electronically and the armature and excitation seem to “swap places” (the rotor is magnetized with direct current, and the stator windings are commutated). A typical example of such a motor is fans in computers.

What is an asynchronous electric motor?

To asynchronous

It is customary to refer to electric motors in which the rotational speed of one of the key elements - the rotor - does not coincide with the rotational frequency of the magnetic field formed by the current that occurs on the stator winding. Asynchronous units are sometimes called induction units. This is due to the fact that current is induced in the rotor winding when exposed to the stator magnetic field.

The design of an asynchronous electric motor contains a stator and a rotor, which are separated by an air gap. Main active elements of the unit:

- winding;

- magnetic circuit

An important role in the functioning of an asynchronous motor is played by additional structural elements that provide strength, cooling and stable operation of the unit.

Comparison

The main difference between a synchronous motor and an asynchronous one is the relationship between the rotor speed and the magnetic field. In the first type of unit, both indicators are the same. In an asynchronous machine - different.

It can be noted that electric motors of the second type are generally more common than the first. At the same time, asynchronous units are most often presented in a variety in which a squirrel-cage rotor is installed. These devices have a number of important advantages over electric motors of other categories. Namely:

- simplicity of design, reliability;

- relatively low cost of production and operation;

- ability to operate using existing network resources without connecting converters.

At the same time, asynchronous machines with a squirrel-cage rotor also have a number of disadvantages. Namely:

- presence of low starting torque;

- the presence of a large starting current;

- reduced power factor;

- low controllability in terms of speed regulation;

- dependence of the maximum speed on the frequency of the electrical network;

- The electromagnetic torque in asynchronous motors of this type is characterized by strong sensitivity to a decrease in voltage in the network.

In turn, synchronous units also have undeniable advantages. These include:

- relatively low sensitivity to voltage changes in the network;

- stability of rotation regardless of the load on the rotor.

Synchronous motors also have disadvantages:

- relative complexity of the design;

- difficulty starting the rotor.

The noted features of the operation of synchronous and asynchronous units make it optimal to use the former if the required motor power in the system (for example, as part of a factory line infrastructure) should be about 100 kW or more. In other cases, the use of asynchronous machines, as a rule, becomes more preferable.

Having considered the difference between a synchronous and asynchronous motor, we will display the conclusions in the table.

The classification of engines is based on different parameters. According to one of them, a distinction is made between a synchronous and an asynchronous motor. The differences between the devices, general characteristics and operating principles are described in the article.

Operating principle of a synchronous motor

Its operation is based on the interaction of the rotating magnetic field of the armature and the magnetic fields of the inductor poles. Typically the armature is located in the stator, and the inductor is located in the rotor. For powerful motors, electric magnets are used for the poles, and for weak motors, permanent magnets are used.

The operating principle of a synchronous motor includes (short-term) and asynchronous mode, which is usually used to accelerate to the required (that is, rated) rotation speed. At this time, the inductor windings are short-circuited or by means of a rheostat. After reaching the required speed, the inductor begins to be powered

Synchronous and asynchronous motor: differences

The difference between how engines work is in the rotor. In the synchronous type, it consists of a permanent or electric magnet. Due to the attraction of opposite poles, the rotating field of the stator also attracts the magnetic rotor. Their speed is the same. Hence the name - synchronous.

In it, unlike asynchronous, it is possible to achieve even a phase advance of voltage. The device, like capacitor banks, can then be used to increase power.

Asynchronous motors, in turn, are simple and reliable, but their disadvantage is the difficulty of adjusting the rotation speed. To reverse a three-phase asynchronous motor (that is, change the direction of its rotation in the opposite direction), the location of two phases or two linear wires approaching the stator winding is changed.

If we consider the rotation speed, then there are differences between synchronous and asynchronous motors. In the synchronous type, this indicator is constant, unlike in the asynchronous type. Therefore, the first is used where constant speed and complete controllability are required, for example, in pumps, fans and compressors.

It is very easy to detect the presence of the types of devices in question on a particular device. An asynchronous motor will have a non-round number of revolutions (for example, nine hundred and thirty per minute), while a synchronous motor will have a round number (for example, a thousand revolutions per minute).

Both motors are quite difficult to control. The synchronous type has a rigid mechanical characteristic: for any changing load on the motor shaft, the rotation speed will be the same. In this case, the load, of course, must change taking into account that the engine is able to withstand it, otherwise this will lead to breakdown of the mechanism.

This is how a synchronous and asynchronous motor works. The differences between both types determine the scope of their use; when one type copes with a task optimally, for the other it will be problematic. At the same time, you can also find combined mechanisms.

Before you figure out what is their difference, you need to find out what an electric motor is? An electric motor is an electrical machine that is powered by electricity and serves as a drive for other mechanisms.

Asynchronous motor

In its grooves there are conductive rods made of aluminum or copper, connected at their ends to rings of the same material, which short-circuit these rods. Therefore, the rotor is called squirrel-cage. Eddy currents interacting with the field cause the rotor to rotate at a speed less than the rotation speed of the field itself. Thus, the entire engine was called asynchronous. This movement is called relative slip, since the speeds of the rotor and the magnetic field are unequal and the magnetic field does not intersect with the conductive rods of the rotor. Therefore, they do not create torque.

The fundamental difference between both types of engines is the design of the rotor. In synchronous it is a permanent magnet of relatively low power or the same electromagnet. The rotating magnet that creates the stator drives the magnetic rotor. The speed of movement of the stator and rotor, in this case, is the same. Therefore, this motor is called synchronous.

Explanation of the operating principle of a synchronous electric motor for dummies

From childhood we remember that two magnets, if brought closer to each other, in one case attract, and in the other they repel. This happens depending on what sides of the magnets we connect them with, opposite poles attract, and like poles repel. These are permanent magnets in which the magnetic field is constantly present. There are also variable magnets.

There is a drawing in a school physics textbook that shows an electromagnet in the shape of a horseshoe and a frame with half rings at the ends, which is located between its poles.

When the frame is positioned horizontally in the space between the poles of the magnets, due to the fact that the magnet attracts opposite poles and repels like ones, a current of the same sign is supplied to the frame. An electromagnetic field appears around the frame (here is an example of an alternating magnet!), the poles of the magnets attract the frame, and it rotates to a vertical position. When the vertical is reached, a current of the opposite sign is applied to the frame, the electromagnetic field of the frame changes polarity, and the poles of the permanent magnet begin to repel the frame, rotating it to a horizontal position, after which the rotation cycle is repeated.

This is the principle of operation of an electric motor. Moreover, a primitive synchronous electric motor!

So, a primitive synchronous electric motor works when current is supplied to the frame. In a real synchronous electric motor, the role of a frame is played by a rotor with coils of wires, called windings, to which current is supplied (they serve as sources of an electromagnetic field). And the role of a horseshoe magnet is played by a stator, made either from a set of permanent magnets, or also from coils of wires (windings), which, when current is supplied, are also sources of an electromagnetic field.

The rotor of a synchronous electric motor will rotate at the same frequency as the current supplied to the winding terminals changes, i.e. synchronously. Hence the name of this electric motor.

Explanation of the operating principle of an asynchronous electric motor for “dummies”

Let us recall the description of the drawing in the previous example. The same frame located between the poles of a horseshoe magnet, only its ends do not have half rings, they are connected to each other.

Now we begin to rotate the horseshoe magnet around the frame. Rotate it slowly and observe the behavior of the frame. For some time, the frame remains motionless, and then, when the magnet is rotated at a certain angle, the frame begins to rotate following the magnet. The rotation of the frame is delayed compared to the rotation speed of the magnet, i.e. it does not rotate synchronously with it - asynchronously. So it turns out that this is a primitive asynchronous electric motor.

In fact, the role of magnets in a real asynchronous motor is played by windings located in the stator slots, to which current is supplied. And the role of the frame is played by a rotor, into the grooves of which metal plates are inserted, connected to each other briefly. Therefore, such a rotor is called squirrel-cage.

Asynchronous electric motor

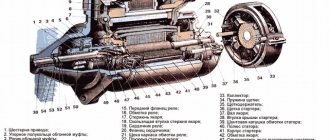

So, we need to start by looking at the design of the asynchronous model. The main difference from the synchronous one is the presence of three windings in the stator, the ends of which are brought out for connection to the terminal box. The second main part of the motor is a solid-type rotor, the ends of which are closed to each other, hence, in principle, the name - short-circuited.

An addition to the design is an impeller, with which the engine is cooled. The impeller is installed on the shaft (rotor) of the electric motor. The rotor itself is supported and rotates in bearings installed in two housing covers. Please note that the bearings are the most vulnerable point of the unit. They are the ones that most often fail. True, replacing them is not very difficult.

Principle of operation

On what principle does an asynchronous motor work? Inside the motor housing, where the stator windings are located, a magnetic field arises that acts on the rotor, causing it to rotate under the influence of the resulting electromotive force. But the rotor can rotate only if the speed of rotation of the magnetic field is faster than the rotation of the motor shaft itself. If the speeds are the same, then the electromotive force will not appear.

But in any case, this cannot happen, because there are several reasons that limit the speed of rotation of the rotor.

- Friction in bearings.

But the most important thing is that the magnetic poles in an asynchronous motor are constantly changing, which affects the change in current directions in the stator of the electric motor. That is, at a certain time the current begins to rotate “towards us”, and at the next interval “away from us”. That is why such motors are called asynchronous; they simply do not have a stable direction of current.

As for the rotor rotation speed, one remark must be made here. This indicator will depend on how many poles are simultaneously connected to the power supply. For example, the maximum shaft rotation speed will be with two poles connected. To reduce this indicator, it is necessary to add two more poles, that is, double them.

And one more drawback. Asynchronous motors have different shaft rotation speeds during operation. For example, at idle this may be one value, but under load it decreases sharply. In essence, it turns out that changing the frequency of the current affects the speed of the shaft. There is no other way to change the rotation speed.

What are the differences between synchronous and asynchronous electric motors?

If you place two modern electric motors of one type or another next to each other, it will be difficult even for a specialist to distinguish them by external signs.

Essentially, their main difference is discussed in the given examples of the operating principles of these electric motors. They differ in rotor design

. The rotor of a synchronous electric motor consists of windings, while the rotor of an asynchronous electric motor consists of a set of plates.

The stators of one and the other electric motors are almost indistinguishable and represent a set of windings, however, the stator of a synchronous electric motor can be composed of permanent magnets.

The speed of a synchronous motor corresponds to the frequency of the current supplied to it, while the speed of an asynchronous motor lags somewhat behind the frequency of the current.

They also differ in areas of application.

. For example, synchronous electric motors are used to drive equipment that operates at a constant rotation speed (pumps, compressors, etc.) without reducing it with increasing load. But asynchronous electric motors reduce the rotation speed as the load increases.

Synchronous electric motors are structurally more complex, and therefore more expensive, than asynchronous electric motors.

The operation of any electric motor is based on the principle of electromagnetic induction. An electric motor consists of a stationary part - a stator (for asynchronous and synchronous AC motors) or an inductor (for DC motors) and a moving part - a rotor (for asynchronous and synchronous AC motors) or an armature (for DC motors). Permanent magnets are often used as an inductor on low-power DC motors.

All motors, roughly speaking, can be divided into two types: DC motors, AC motors (asynchronous and synchronous)

DC motors

According to some opinions, this motor can also be called a synchronous DC machine with self-synchronization.

A simple motor, which is a direct current machine, consists of a permanent magnet on an inductor (stator), 1 electromagnet with pronounced poles on the armature (a two-prong armature with pronounced poles and one winding), a brush-collector assembly with 2 plates (lamellas) ) and 2 brushes. A simple engine has 2 rotor positions (2 “dead spots”), from which self-starting is impossible, and uneven torque. To a first approximation, the magnetic field of the stator poles is uniform (uniform). These engines with a brush-commutator unit are:

Collector

- an electrical device in which the rotor position sensor and the current switch in the windings are the same device - a brush-collector unit.

Brushless

— a closed electromechanical system consisting of a synchronous device with a sinusoidal distribution of the magnetic field in the gap, a rotor position sensor, a coordinate converter and a power amplifier. A more expensive option compared to brushed motors.

AC motors

Based on the type of operation, these motors are divided into synchronous and asynchronous motors.

The fundamental difference is that in synchronous machines the 1st harmonic of the stator magnetomotive force moves with the speed of rotation of the rotor (this is why the rotor itself rotates at the speed of rotation of the magnetic field in the stator), while in asynchronous machines there is and remains a difference between the speed of rotation of the rotor and the speed of rotation of the magnetic field in the stator (the field rotates faster than the rotor). Synchronous

- an alternating current motor whose rotor rotates synchronously with the magnetic field of the supply voltage. These engines are traditionally used at enormous power (hundreds of kilowatts and above). There are synchronous motors with discrete angular motion of the rotor - stepper motors. In them, this position of the rotor is fixed by supplying power to the corresponding windings. The transition to another position is accomplished by removing the supply voltage from some windings and transferring it to other windings of the motor. Another type of synchronous motor is a switched reluctance motor, the power supply of the windings of which is formed using semiconductor elements.

Asynchronous

- an alternating current motor in which the rotor speed differs from the frequency of the torsional magnetic field created by the supply voltage; the second name for asynchronous machines is induction due to the fact that the current in the rotor winding is induced by the rotating field of the stator. Asynchronous machines now make up a huge part of electric machines. They are mainly used in the form of electric motors and are considered key converters of electrical energy into mechanical energy, and asynchronous motors with a squirrel-cage rotor are mainly used

According to the number of phases, motors are:

- single-phase

- two-phase

- three-phase

The most popular and most in demand engines that are used in production and households:

Single-phase squirrel-cage asynchronous motor

A single-phase asynchronous motor has only 1 working winding on the stator, to which alternating current is supplied during motor operation.

Although to start the motor, there is also an auxiliary winding on its stator, which is briefly connected to the network through a capacitor or inductance, or is short-circuited by the starting contacts of the switch. This is necessary to create an initial phase shift so that the rotor begins to rotate, otherwise the pulsating magnetic field of the stator would not move the rotor from its place. The rotor of such a motor, like any other asynchronous motor with a squirrel-cage rotor, is a cylindrical core with grooves filled with aluminum, with immediately cast ventilation blades. Such a rotor is called a squirrel-cage rotor. Single-phase motors are used in low-power devices, including room fans or small pumps.

Two-phase squirrel-cage asynchronous motor

Two-phase asynchronous motors are more efficient when operating from a single-phase AC network.

They contain two working windings on the stator, located perpendicularly, while one of the windings is connected to the AC network directly, and the second through a phase-shifting capacitor, so a rotating magnetic field comes out, but without the capacitor the rotor would not move. These motors, among other things, have a squirrel-cage rotor, and their use is even wider than that of single-phase ones. There are already washing machines and various machines. Two-phase motors for power supply from single-phase networks are called capacitor motors, because a phase-shifting capacitor is often considered an essential part of them.

Three-phase squirrel-cage asynchronous motor

A three-phase asynchronous motor has three working windings on the stator, shifted relative to each other so that when connected to a three-phase network, their magnetic fields are shifted in space relative to each other by 120 degrees.

When a three-phase motor is connected to a three-phase AC network, a rotating magnetic field appears, causing the squirrel-cage rotor to move. The stator windings of a three-phase motor can be connected according to a “star” or “delta” circuit, while to power the motor according to a “star” circuit, a voltage higher than for a “delta” circuit will be required on the motor, therefore 2 voltages are indicated, for example: 127/220 or 220/380. Three-phase motors are indispensable for driving various machines, winches, circular saws, cranes, etc.

Three-phase asynchronous motor with wound rotor

A three-phase asynchronous motor with a phase rotor has a stator similar to the types of motors described above, a laminated magnetic circuit with 3 windings laid in its slots, but the phase rotor is not filled with duralumin rods, but a real three-phase winding is already laid, in a “star” connection.

The ends of the wound rotor winding star are led out onto three contact rings mounted on the rotor shaft and electrically separated from it. By means of brushes, three-phase alternating voltage is supplied to the rings, among other things, and switching can be done either directly or through rheostats. Of course, motors with a wound rotor are more expensive, although their starting torque under load is much higher than that of motors with a squirrel-cage rotor. It is precisely as a result of the increased force and huge starting torque that this type of engine has found use in the drives of elevators and cranes, in other words, where the device starts under load and not at idle, as in engines with a squirrel-cage rotor.

How does a synchronous motor differ from an asynchronous motor? This question is often asked on various forums.

Operating principle and design of different types of electric machines

Asynchronous and synchronous electric motors are similar in design, but there are also differences.

Design and principle of operation of asynchronous electric motors

These are the most common AC machines. Such electric motors consist of three main parts:

- Housing with bearing shields and feet or flange.

- The housing contains a magnetic circuit made of iron plates with windings. This magnetic circuit is called a stator.

- Shaft with bearings and magnetic core. This structure is called a rotor. In electric motors with a squirrel-cage rotor, the magnetic circuit contains aluminum rods interconnected; this design is called a “squirrel cage”. In machines with a wound rotor, instead of rods, windings are wound.

Three windings are wound in the stator slots with a 120° offset. When connected to a three-phase network, a rotating magnetic field is induced in the stator. The speed of rotation is called "synchronous speed".

Reference! In single-phase electric motors, the rotating field is created by an additional winding or design features of the stator.

This field induces an EMF in the rotor, and the resulting current creates its own field, interacting with the stator field and setting it in motion. The rotor speed is less than the synchronous speed. This difference is called slip.

Slip is calculated using the formula S=(n1-n2)/n1*100%, where: · n1 – synchronous speed; · n2 – rotor rotation speed.

the slip rate in conventional electric motors is 1-8%. As the load on the motor shaft increases, slip and torque increase to a critical value, upon reaching which the motor stops.

In electric motors with a wound rotor, instead of a squirrel cage, three windings are wound in the slots of the rotor. They are connected to additional resistances through slip rings and brushes. These resistances limit the current and magnetic field in the rotor. This increases slip and reduces engine speed.

Such devices are used for heavy starting and in devices with speed control, for example, in overhead cranes.

Operating principle of synchronous electric motors

The stator of a synchronous machine is no different from an asynchronous one. The difference is in the rotor. Unlike an asynchronous motor, rotation is carried out due to the interaction of the rotating magnetic field of the stator and the constant field of the rotor. To create it, there are electromagnets in the rotor. Voltage is supplied to the coils using slip rings and graphite brushes.