In this version, the bendix would not move away after starting the engine and turning off the starter and would “buzz”, but would not break during starting. In addition, more often it is the front, pressure washer that melts - then yes, it is possible that the initial impulse from the fork throws the bendix out and engages, and after picking up the engine it moves back. But melting of the rear, outlet washer is possible only in the case when the retractor's nickels are stuck, but the fork has returned the bendix to its original position. Or when the starter turns off, but the bendix does not come off, for example, stuck due to dried grease and dirt on the shaft.

It often happens, especially on domestic cars, that the starter spins at idle, does not engage the flywheel, and, of course, the car does not start. It’s especially unpleasant when everything was fine with the car just yesterday, but in the morning you have to go somewhere, and such a situation happened with the starter.

There are several reasons why the starter turns but does not engage, so if these reasons are eliminated, the starter will start the car well. But first, let's figure out how the starter works and what can happen in it that it stops grabbing.

Starter-related breakdowns

- There is a short circuit in the relay winding;

- there are breaks in the power supply circuit;

- breakage of the solenoid relay;

- brushes are worn out;

- the nickels at the starter solenoid relay are stuck or burnt;

- The switch has failed.

In general, after you have disassembled the starter, if you haven’t found any damage, then you need to clean all the components there and lubricate them. Then everything can be put back together.

Types of starters and their components

Gearbox

All starters can be divided into two groups:

- Without gearbox.

- With gearbox.

The design and operation of a starter belonging to the first and second groups, as the name implies, differs only in the presence or absence of a gearbox.

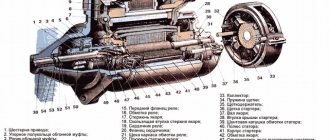

So, what does an electric car starter consist of? Like any DC motor, it consists of a rotor, stator, and commutator-brush assembly. In addition, to transmit the rotation of the armature to the flywheel, it includes an overrunning clutch with a gear (Bendix), and solenoid relays are used to turn on the rotation and engage the Bendix with the flywheel crown. The fork in the starter transmits force from the retractor relay to the bendix.

Gearless

The design of a car starter with a gearbox, as a rule, differs in that permanent magnets are installed on the stator instead of electromagnet coils. A starter with permanent magnets in the stator differs from those equipped with electromagnets in that it consumes less current and develops less power. Such a starter definitely needs a gearbox to increase torque. Such a device has both its advantages and disadvantages. The advantage is the low current required to start the motor. The disadvantage is that the design is more complex than that of a starter without a gearbox.

The electrical circuit of any automobile starter is similar to that of a DC electric motor with the addition of a solenoid relay circuit.

The connection circuit for a starter with permanent magnets in the stator is the same as for a starting unit with electromagnets. Therefore, when manufactured for the same car model, they are interchangeable.

Article on the topic: How to reduce gas mileage in a car

The principle of operation of a car starter: when the ignition switch is turned to the start position, the starter relay supplies control voltage to the solenoid relays, which engages the Bendix gear with the flywheel ring and turns on the starter, supplying power to it. When the ignition key is turned from the start position to any other position, the starter relay cuts off power to the retractor. The core return spring throws it out of the coil housing. And he disengages the bendix from the flywheel crown and turns off the power.

What to do if the starter spins for a long time when starting the engine

Despite the fact that starting the engine falls almost entirely on the starter and battery, we must not forget about other elements that are involved in solving this problem. The following are the most common reasons why the starter spins for a long time when starting the engine:

- Dirty fine fuel filter. If low quality fuel is used or various debris gets into the gas tank - sand, dust, stones, then over time the fine fuel filter will become clogged. This will lead to difficulties in the flow of fuel into the combustion chamber, which will cause difficulties when starting the engine and its operation. In such a situation, you need to change the fine filter to a new one and clean the gas tank from accumulated contaminants;

- Worn starter brushes. The longer the starter is used, the more its brushes wear out. Replacing starter brushes is a simple procedure, but it is not always advisable. If the starter is old, sometimes it is better to install a new one in its place instead of replacing the brushes;

- Air filter dirty. Due to accumulated contaminants in the air filter, difficulties will also arise with the operation of the engine, especially at the time of start-up. It is recommended to replace the air filter and clean the air intake system;

- Low compression in cylinders. This problem is relevant for older cars. Due to low compression in the cylinders, exhaust gases leak into the crankcase, which disrupts the ignition process of the fuel-air mixture when starting the engine. To correct the situation, you can try decoking the piston rings. When it does not help and the problem is related to a change in the shape of the cylinders, only a major overhaul of the engine can correct the situation.

Article on the topic: How to restore a sunken car

The above are the most common problems for any type of engine, but we can also highlight characteristic malfunctions for injection and carburetor engines.

The starter spins for a long time on an injection engine

A typical problem with an injection engine, due to which it takes a long time to crank the starter to start the engine, is an error in the on-board computer. This problem can be solved in two ways:

- By reflashing the on-board computer at a service center (or resetting errors);

- Resetting the on-board computer memory by disconnecting the battery. It is necessary to remove the wire from the negative terminal of the battery for 15-20 minutes so that errors are automatically deleted from the memory of the on-board computer, if they were recorded in it.

Why is it dangerous to turn the starter for a long time when starting the engine?

Starting an engine is a process in which the starter and battery are directly involved. They are the ones who suffer the most when starting the engine for a long time. Accordingly, the following problems are possible:

- Low battery. Each time you try to start the engine, battery power is consumed. Moreover, if the attempt is not successful, then we can assume that the battery is consuming its charge “idle”. In order for the battery to charge, the engine must start and run for a while. Several unsuccessful attempts to start the engine, and you will get a discharged battery, which will need to be charged from the station, or you can start the engine “by lighting” in other cars;

- Starter failure. When the starter is cranked for a long time, it begins to overheat, which can negatively affect its components and lead to complete failure of the part. Also, do not forget about the bendix, which when trying to start the engine is connected to the crankshaft. If the engine does not start, there is a high risk of damage to the splines on the bendix or the bearing. If you constantly have to turn the starter for a long time when starting the engine, over time this will lead to its failure and the need for replacement.

Article on the topic: Why does the muffler shoot?

Most often, you can solve the problem with the starter cranking for a long time when starting the engine without contacting a service center yourself, thereby preventing early failure of the starter.

Features of operation, typical starter malfunctions

Our technical assistance service technicians hear every day that the Volvo VNL starter does not turn. But after carrying out on-site diagnostics, it becomes clear that malfunctions are a consequence of the influence of negative factors.

It is believed that the Volvo VNL starter does not work and breaks on its own due to low reliability. In fact, it is one of the elements of the circuit that starts the truck's engine. It is subject to accelerated mechanical wear as a result of “avalanche failures.”

In this case, the Volvo VNL starter does not work, since it is negatively affected by malfunctions in the circuit. In other words, failure of one element leads to failure of the starter. For example, at low voltage in the network, an electric arc occurs, which disables the collector (it burns out).

Repeated attempts to start the engine lead to the Volvo VNL starter not turning. This significantly accelerates the wear of the bushings, causing overheating and damage to the winding. The result is the need to repair the unit.

If you ignore minor faults, you will have to replace the starter completely. A common problem is the armature shaft beating against the bushings and destroying the planetary mechanism. This, in turn, destroys the stator. The result of such an avalanche of breakdowns is a major repair or replacement of the starter. Sometimes the flywheel teeth become damaged.

In order for the repair to be truly effective when the Volvo VNL starter does not turn, you need to use original spare parts. The use of proven analogues is allowed. For the correct selection of components: brushes, relays, bendix (catalog numbers are used), special programs are used. This is a guarantee of operation of the units without serious failures.

If the Volvo VNL starter does not work, our technicians conduct a comprehensive check of the ignition system. This saves time on dismantling and disassembling the unit if the problem is not in it, but in the wiring or voltage. We recommend complete replacement only in case of critical damage. We install spare parts correctly and work accurately and accurately.

starter problems vaz 2106 doesn't turn well

Good day! I haven’t been writing often lately because I’ve been busy painting my car and all my free time is being consumed by preparation.

The prehistory of writing this post was a friend’s appeal regarding the fact that the starter of his VAZ 2106 did not turn properly

gas stove 31029

The windows in the car from the garage fog up

Good day! I haven’t been writing often lately because I’ve been busy painting my car and all my free time is being consumed by preparation.

The prehistory of writing this post was a friend’s request that the starter of his VAZ 2106 did not turn the engine as it should. This prompted me to write a theoretical post about the common causes of this most unpleasant phenomenon.

The starter does not turn

To begin with, we should indicate that a starter is an electric motor that is designed to start a vehicle engine. Looking at the root, we see that since the starter is an electric motor, it is accordingly powered by a battery. This leads to several main reasons why the starter does not turn the engine properly. Let's name them all (maybe not all, but those that come to mind):

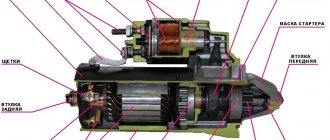

The battery is discharged. Unreliable contact on the battery terminals. Unreliable contact of the wire between the engine and the car body. Burnt coins in the solenoid relay. Sticking or worn brushes.

Burnout of the commutator due to unreliable contact or sticking of the starter brushes Short circuit between the contact plates of the commutator Wear of the armature shaft bushings

Burnout or burning of the stator windings or starter armature

Well, it seems that we have briefly described the main malfunctions of the starter

VAZ 2114 speed fluctuates at idle

I may not give some reasons (the engine is jammed, the starter is unscrewed, etc.), but here I am counting on your common sense, the serviceability of the electrical system, etc.

Now let's go through everything in order. The first and most obvious reason that the starter of your car does not turn is the discharge of the main source of electricity in the car - the battery. The solution to this problem is simple:

Find the reason for the battery discharge Charge the battery If charging is not possible, then replace it with a new one, borrow for a while from friends and acquaintances

It is quite difficult to deal with unreliable contact in the terminals; the main difficulty is the oxidation of the terminals over time due to exposure to electrolyte vapors

voltage regulator vaz 2110

It has been noticed more than once; as soon as a white or green coating appears, the starter rotates the engine much more lazily, especially in winter. Also, the use of dismountable terminals from the market does not contribute to the best current transmission, those that allow you to clamp the wires with two screws and cost about 12 - 15 UAH. Their problem is rapid oxidation, poor quality crimping of the wires (lead is a fairly ductile metal, and even if you press the fastener quite tightly, it does not guarantee anything, since the positive temperature affects and the properties of this metal and the wires begin to wobble anyway), not high quality workmanship.

After checking the battery, you need to thoroughly clean the wires and terminals of deposits, maybe this will help you, if not, then read on.

The following situation is familiar to me personally, I also observed it on about 5 - 6 cars. It consists in the fact that the contact between the engine and the car body is broken. There may be several reasons, the main ones being a break in the wire that connects the body and the engine, as well as oxidation at the point where this wire is attached to the body.

This wire, which connects the body and the engine, is located (in VAZ 2101 - 2107 cars) on the left side near the gearbox. This problem can be cured using an additional wire from the engine to the body, it is important with a suitable cross-section

VAZ 2114 troits engine

For quick diagnostics, it is enough to connect the wire that goes from the battery to ground directly to the engine.

If it helps, just add a wire.

One of the most common reasons that the starter does not turn is the burning of the nickels (contacts) in the solenoid relay. During long-term operation and frequent engine starts, the contact in this place is broken and becomes unable to provide the necessary current to rotate the starter.

szd

This problem can be cured by removing the starter, the retractor relay, and replacing/cleaning/turning over the nickels.

If you decide to clean the nickels, then this must be done first with a coarser abrasive until all traces of burning are removed, then with a fine polishing abrasive. You can also polish the surface using a wooden board; polishing is important for long-term and high-quality operation of the contact elements.

Brushes getting stuck doesn’t happen that often, but the consequences can be tragic.

refilling the air conditioner yourself

Most often, brushes become stuck due to the accumulation of dirt, brush wear, misalignment, etc.

VAZ 21083 carburetor

The main indicator of brush freezing is the appearance of point-like burnouts on the commutator.

If you continue to use the starter with an oversized brush, it is quite possible that the commutator will burn out, which will lead to its replacement. Repair is quite easy - just remove the starter and replace the brushes, clean and wash off dirt and debris inside the starter.

Also, the reason that the starter does not develop the required torque may be a short circuit or burning of the collector plates. It is worth remembering that the collector must be clean, not have significant depressions, or short circuits with floating metal plates. It is recommended to clean the collector only along the plates; cleaning across it with an abrasive can lead to shorting of the plates to each other. A needle file of suitable width will help you eliminate short circuits between the collector plates quickly and efficiently.

You should not use a knife or similar tools, or grind too deeply with a needle file, because along with the deposited metal you can also remove part of the insulator that is located between the plates.

Wear of copper-graphite bushings is not a very common occurrence and comes to the car user along with a major engine overhaul, although sometimes there are exceptions. The main indicators for replacing bushings is the appearance of a gap between the bushings and the armature shaft. Replacement is carried out by pressing out the old bushings and pressing in new ones.

If you do everything carefully, you may not need to use a reamer to obtain the required diameter.

Burnout of the starter windings is the most difficult breakdown, which, most likely, you will not be able to repair. There is only one conclusion - replacement:(

Happy renovation!

2109 replace the liners without removing the engine

vectra panel vaz 2107

The windows in the car from the garage fog up

Similar articles:

Useful tips → How to protect your car and property from theft?

Helpful tips → How to properly drive over a speed bump

Useful tips → How to get out of a skid correctly

Useful tips → Winter driving rules

Useful tips → Secret letters in your car

Possible reasons

So, let's figure out why a cold starter turns poorly in winter?

Initially, the difficulty in identifying a malfunction is that the car’s starting system includes a lot of additional elements. Therefore, there is no point in immediately sinning on any particular detail. After all, something else could have gone wrong. So, let's look at the elements that are part of or at least somehow affect the ignition system, their role, and the possibility of failure:

- The power source, of course, is the battery. It allows the starter to rotate;

- The network is closed between the ignition switch and the relay and the energy is directed to the solenoid relay and to the winding;

- Having received energy, the solenoid relay starts the Bendix operating gear into engagement with the flywheel. In this way, the contacts are closed and current is supplied;

- Before starting, the starter starts the engine flywheel and the elements of the connecting rod and piston group with the gas distribution mechanism.

Each of these parts has a certain shelf life, and the breakdown itself can quite possibly happen for several reasons: improper operation, extreme wear, use of defective parts, incorrect assembly, use of parts not according to the passport.

I have provided this list so that you can clearly see how many elements are used in the ignition system to start the car. That is why it is not easy to determine the real reason why the starter does not turn when cold.

Starting a car engine, especially in the cold season, at low temperatures, is often a problem for a motorist. To avoid this, it is necessary to inspect two things from time to time: the battery charge and the viscosity of the engine oil.

Due to the low temperature (below zero), the flow of physical and chemical processes in the battery cells slows down significantly, which makes charging it take much longer. And also the oil, which is located in the lubrication system, becomes thick and very viscous, and therefore, in order to successfully start the engine, you have to warm up the block yourself using improvised means. To protect yourself and make winter enjoyable, you need to change the oil to winter oil in the spring.

Only in the case when the starter does not turn when cold or turns weakly, but when warming up it seems to get a second wind, it is necessary to carry out a series of diagnostic work. The first step is to recharge the battery (if it has lost charge). Perhaps it is the lack of charge that is the cause, since the battery cannot provide power. In the case when the power supply is either new or perfectly charged, but the starter still does not work, we continue our search.

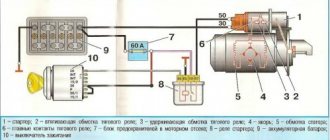

Retractors

Solenoid relays to reduce current consumption usually have two coils. One coil, made of thicker wire and consuming more current, is activated only when the starter is turned on in order to reliably retract the core. The second one, made of thinner wire, consumes less current. It is designed to hold the core while the ignition key is in the start position. The scheme for their inclusion is as follows:

- one terminal of each coil is connected to the control terminal of the relay;

- the second terminal of the holding coil is connected to ground.

Since the second terminal of the holding coil is connected to ground, current always flows through it when the ignition key is in the start position. The second terminal of the solenoid coil is connected to the positive terminal of the starter, that is, at the moment power is supplied to the solenoid relays, it is also connected to ground through the stator and rotor coils. Once the retractor operates, it will supply power to the starter. And at both terminals of the retractor coil there will be a positive potential, which means that the current through the retractor coil will stop. From now on, only the holding coil will work. By using two coils, a significant retraction force of the core is achieved with a small holding current.

Article on the topic: The best forged wheels