Cars admin26.02.2020

Regardless of the type of fuel for which the car is designed, it must be supplied to the engine uninterruptedly. Its reliability and stable operation directly depend on this. The quality of domestic gasoline traditionally leaves much to be desired - most engine mechanisms and systems suffer from this, primarily the fuel pump. To prevent it from breaking down at the most unexpected moment, you need to know the signs and causes of the malfunction, and also adhere to preventive measures to maximize the life of the gas pump.

Purpose and principle of operation of the fuel pump

The fuel pump is designed to pump fuel from one point to another. In a car, the role of the first point is played by a fuel reservoir - the tank, and the second - by the engine, where the pumping takes place. This process occurs at a certain pressure, which is maintained by the pump reducer, which is a very important point.

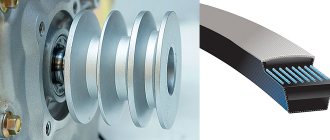

Fuel pumps are divided into 2 types according to the type of drive: electric and mechanical. Inside the first there is an electric motor with a mini-pump, which operates from the mains and uninterruptedly pumps fuel into the engine. The second type is becoming increasingly rare, as it is installed on carburetor cars, and operates due to the reciprocating movement of the lever.

Signs of a fuel pump malfunction

Mechanical fuel pumps

In a mechanical fuel pump, malfunctions most often occur due to wear of the sealing gaskets and the formation of leaks between parts of the housing. As a result, the tightness of the structure is broken, air gets in, fuel stops getting into the carburetor and the engine stalls. A similar consequence is caused by membrane rupture and valve failure. At the same time, the car begins to move jerkily until the fuel supply stops completely.

Electric fuel pumps

On cars with mechanical and electronic injection, the signs of a fuel pump malfunction are slightly different, but they can be classified into certain groups:

- The engine does not start. Rotation of the starter with dry spark plugs does not cause flashes in the cylinders. There is no pressure in the fuel line, or it is extremely low; the buzzing of the pump is not heard when the ignition is turned on or the starter is operating.

- The engine does not start, although occasional flashes occur in the cylinders. There is pressure in the fuel line, but without a pressure gauge its value cannot be determined. The candles are dry.

- The engine starts and idles normally, but pressing the accelerator causes it to stop. If you want, it is possible to raise the speed to medium, but attempts to start lead to the engine stalling. There is a black coating on the spark plugs, the operation of the fuel pump is characterized by a changing sound.

- The engine starts, holds idle speed normally, and picks it up easily at neutral speed. When driving at medium and high speeds, a “twitching” is observed. It happens that after a certain mark on the tachometer the speed does not pick up, and the engine stops producing the required power under load. At the same time, the spark plugs are white, and by their appearance it seems that the car is ignited too early or has a lean mixture.

It is worth noting that the above symptoms of fuel pump malfunctions are also typical for other engine breakdowns, and they cannot be used to unambiguously diagnose a fuel pump malfunction. For example, speed also fluctuates if there is a problem with the air sensor, throttle valve, clogged injectors or poor quality fuel.

Similar symptoms not related to the fuel pump

The symptoms that appear due to a lack of fuel in the supply line are quite typical and are very similar to problems with other systems. How to eliminate possible problems using the elimination method:

- Unscrew and inspect the spark plug skirts. When there is not enough fuel, the electrodes remain clean or become covered with a white coating. This is further evidence of a malfunction in the power system.

- Replace spark plugs. If they wear out, they create a similar effect - failures, difficult starting, and a drop in engine power.

- Check the functionality of the throttle position sensor (TPS) and idle air control.

- Measure the compression in all engine cylinders. Due to excessive wear, the naturally aspirated engine is unable to create the required pressure and vacuum; the mixture burns poorly, which is why identical symptoms occur.

When troubleshooting, take into account one important factor - the service life of the fuel pump, which is at least 100 thousand kilometers. The longer the operating period of the unit, the lower the fuel pressure it creates at the outlet. The reason is wear of the membrane and other internal parts. If the pump has served 150 thousand km or more, you should think about purchasing and installing a new spare part.

What are the symptoms of a dying PETROL fuel pump besides the fact that it is humming...

Comments 42

It drives with dips, sometimes, especially when switching, as if it’s then normal. I drove like this for about a month, then the pump died. I was traveling with my family from the dacha and stopped. I remove the supply to the injector and there is horseradish and not pressure. They pulled me home, took off the pump, went straight to him and it sprayed into me, but he was dying right before my eyes. Stelox did not take bad reviews. I took another one, but it’s also from China, I’ll post it a little later

It buzzes and holds you by the ass, didn’t finish it off, replaced it with Pirburg (it was GP). The mesh was knocked out, when I removed the hose, gasoline poured into the sleeve :)

And it started gushing, I replaced the pump and filter, by the way it didn’t bleed the filter

How is it that it wasn't blown through?

I blow into the new one, I’m sulking, I drained everything from the old one and I can’t blow it))

Have you installed everything? Works?

Yes, the girl went, I’ll go myself in an hour, I’ll see if she went faster)))

What pump did you install?

I got it from China, Stelox, it was very cheap, and I wasn’t sure what the problem was... Before that there was tech ass, also from China

For a while, maybe longer, it’s like a lottery :)

Everything will be fine))) our gasoline is better than yours

Cherkani then lives like a pump.

Remind me in PM like a thread

Measure the pressure at the “wall”

remove the hose that goes from the gas tank to the pump; if the gas flows poorly, pierce the mesh in the tank. If it’s not pierced, then it’s clogged anyway

everything is fine with this

I came across something that stalls when hot and does not start, sits for about 5 minutes and starts with half a push, I changed the pump.

You give it gas and it feels like your ass is being pulled.

It would be good to check the pressure in the ramp)

It took it from me and stopped working))

Check the performance of the pump. Connect directly to the 12V pump and 650 grams of gasoline should flow out in 30 seconds. Remove the outlet hose from the pump.

I won’t write any more, turn off the feed and check the flow. Then conclusions.

Oh well. I wasted my time.

I won’t write any more, turn off the feed and check the flow. Then conclusions.

I have a supply hose from the tank 2 cm in diameter, when I removed the pump and plugged it up a little, gasoline poured out of a tap. This is a convertible

bad morning start - “cold”, “sluggish” gas pedal, poor acceleration...

Great in the morning, the pedal is sluggish

Humming is not a sign. Are we talking about v3? For the first time I howled - I thought about changing it. But - in the pit we remove the supply to the pump - if the trickle is barely there, then there is water in the tank. It does not pass through the mesh and does not supply gasoline.

Convertible, external there, the symptoms are the same

Humming is not a sign. Are we talking about v3? For the first time I howled - I thought about changing it. But - in the pit we remove the supply to the pump - if the trickle is barely there, then there is water in the tank. It does not pass through the mesh and does not supply gasoline.

There is no water in the tank, but clogged with dirt. Water’s density is not very different from gasoline, so it doesn’t pass through the mesh.

Yes. I drained the gasoline three times and the remainder into 5-liter transparent plastic. The water is visible. The tank was removed, dried - no dirt. We fill everything except the last container - voila, the pump is silent. The last time was the day before yesterday. The pump howls, the car stalls - it's in the battery. I bought a “tank dehumidifier”, the composition is isopropyl alcohol. There were 15 liters in the tank, I poured in the entire bubble, drove 3 km, the pump went silent. So I don’t need to talk about water and the pump, I spent half a year on this. I went to Sochi with a buzzing sound and returned, additives in the tank did not help. I arrived, did the procedure above - and that’s it.

Possible causes of fuel pump malfunction

Mechanical fuel pump disassembled

A mechanical fuel pump may fail for the following reasons:

- If the integrity of the diaphragm is damaged.

- After dirt accumulates under the valves.

- When the filter is clogged.

- When the spring loses its elasticity.

- If the seal of the housing is broken.

- Due to natural wear and tear of parts during operation.

The electric fuel pump of a modern car is quite reliable. Malfunctions in it arise only due to the influence of certain factors, among which the most common are the following:

Burnt contacts inside the fuel pump

1. Faulty wiring in the form of dirty, rusty, melted or damaged wires in the fuel complex interferes with the operation of the device and also limits the required current parameters, making it difficult to pump fuel.

2. Debris and foreign impurities in the fuel tank in the form of rust, dirt, water, mechanical particles that penetrate the fuel pump and cause its breakdown.

Clogged fuel pump filter

3. A clogged fuel filter with debris from the tank contributes to a sharp decrease in the pressure created by the pump and a deterioration in its operating parameters.

Melted fuel pump turbine

4. Driving a car for a long time with a small amount of fuel, during which the pump is not immersed, experiences significant overheating, quickly consumes internal lubricant and fails.

5. Natural wear of the rubbing parts of the pump.

How to clean the fuel pump yourself

Let's start with the fact that the mesh filter for the fuel pump is a coarse filter and is designed to capture large particles and deposits that are in the fuel and inevitably accumulate in the fuel. It turns out that the fuel pump has its own additional fuel filter mesh, which prevents debris from entering the fuel system from the tank parallel to the usual fuel filter. The process of cleaning or replacing the fuel pump mesh is almost similar to the general scheme for replacing the pump itself:

- The fuel pump is installed directly into the gas tank. You can get to the pump from the passenger compartment, as it is located under the rear seat. To gain access to the fuel pump, you need to remove the rear seat cushion or fold down half of the sofa (if possible).

- The fuel pump is usually located on the right and covered with a special plastic cover. The specified cover must be removed.

- Before removing the fuel pump itself, it is necessary to relieve the fuel pressure in the system. To do this, you will need to disconnect the power connector from the fuel pump, and then turn the engine with the starter.

- The next step is to remove the negative terminal from, after which the tubes from the fuel pump are disconnected.

These tubes are “supply” and “return”, they are secured with clamps that need to be pressed out. You should be prepared for the fact that a certain amount of gasoline may spill after removal. For this reason, safety precautions must be observed! - Next, you need to unscrew the special pressure ring-cover of the fuel pump. It is very difficult to unscrew this cover manually. There is a special fuel pump cover puller for removal. If there is no such puller, then you can try to carefully unscrew the ring using improvised means. We strongly recommend that you first study on specialized auto forums how to remove the fuel pump cap on a specific car model.

- After unscrewing the cap, you can remove the fuel pump. Before complete removal, the remaining gasoline should be drained from its body, and the sealing ring should be removed.

- Now you can begin disassembling the fuel pump housing. To clean, you will need to remove the bottom part. There is often dirt in the indicated lower part of the housing.

- After this, remove the fuel pump screen. To remove the mesh, just pry out the filter at the place of attachment to the pump body using a regular screwdriver. The fuel pump strainer usually becomes completely clogged, especially on cars with high mileage.

- Then the fuel pump mesh can be replaced with a new one or cleaned. It is better to wash the fuel pump mesh first with carburetor cleaner. Mechanical cleaning is done with a soft brush. Then the mesh should be dried and blown. The bottom of the pump housing and the cleaned mesh are finally washed again with gasoline.

- The final step is to reassemble the fuel pump and install the device in the gas tank. To facilitate installation, it is better to invite an assistant, as it may be necessary to ensure high-quality pressure of the pump to the tank. The fact is that many gasoline pumps have a special spring, the force of which must be overcome. At the same time, you need to make sure that the rubber seal is in place and at the same time screw in the pressure ring-cover of the fuel pump. When tightening the clamping ring with a puller or improvised means, do not exceed the tightening torque. If you tighten it too tightly, the fuel pump cap may burst; if you tighten it too weakly, the fuel pump will wobble due to poor fixation.

Please note that when installing a fuel pump on many car models, you must be careful not to bend the fuel level sensor in the gas tank. It is also important to adhere to the position in which the pump was originally located.

In order to determine the correct position of the fuel pump, there are special indicators. Such indicators are made in the form of arrows and are located on the fuel pump, the gas tank body and the pressure ring. The correct installation of the fuel pump can be considered when all the arrows are in the same line. We would like to add that if the gasket is installed incorrectly, gasoline may leak out if you fill the tank full.

Now all that remains is to connect the fuel supply and return pipes to the fuel pump, while simultaneously checking that the clamps are securely fastened. The completion is to connect the electrical power connector to the fuel pump, after which you can start the car for testing.

In the case when the gas tank is heavily contaminated, cleaning or replacing the fuel pump mesh will only be a temporary measure, and the rate of subsequent contamination of the mesh will not greatly depend on the quality of the fuel being filled. In such a situation, it is necessary to remove and wash not only the mesh, but also the gas tank.

Remember, cleaning the fuel pump mesh or replacing the pump itself in the fuel tank is a responsible procedure that involves working with fuel equipment and flammable fuel. Follow safety precautions! If you have not previously removed the fuel pump yourself, do not have sufficient experience and are not confident in your abilities, then it is better to turn to specialists.

To keep the fuel pump screen clean, try not to lower the fuel level in the gas tank below ½ unless necessary. Dirt and deposits that clog the mesh are usually located at the very bottom and are the last to be drawn in by the gas pump.

Repair

Mechanical fuel pump repair

Repairing a mechanical fuel pump consists of installing a new repair kit (diaphragm and valves) and, if necessary, a worn pusher with a spring. A deeper repair of this device is impractical, since the costs of purchasing and repairing worn parts are close to the cost of a new product. If the pump housing is deformed or damaged, it must be completely replaced.

Electric fuel pump repair

The electric fuel pump is equipped with a non-separable housing, and if it breaks down, the product is replaced with a new one. Without special skills, equipment and spare parts, opening and repairing it is impossible. But some workshops undertake similar work, the price of which is lower than buying a new pump. The main failures of the device are as follows:

- Damage to brushes and motor commutator. Repair involves replacing them with new ones.

- Breakage of the plastic coupling connecting the rotor and the motor armature shaft. The clutch is replaced with a new one.

- Anchor failure. The repair involves rewinding this part.

The described actions allow us to eliminate the gas pump malfunction on all models of the VAZ: 2101, 2102, 2103, 2104, 2105, 2106, 2107, 2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, Niva, Priora, Kalina, Grant, Vesta and most foreign cars.

Preventing fuel pump breakdowns

The best prevention for long-term operation of the fuel pump is its careful and proper operation, as well as compliance with the following rules:

- All scheduled vehicle repairs must be accompanied by the replacement of all fuel filters.

- It is necessary to monitor and ensure the cleanliness of the fuel tank and filters, as well as monitor the quality of the fuel being refilled (the absence of water, sand and other impurities in it).

- Eliminate the possibility of water getting into the fuel tank.

- Protect the fuel pump housing from mechanical stress that causes dents and cracks that contribute to the development of corrosion processes.

When and why you need to change/clean the fuel pump screen

Let's start with the fact that general problems with the fuel system (fuel pump in particular) should be divided into the most common groups:

- the fuel pump mesh and fuel filter are clogged;

- the fuel pump itself has failed;

- injector problems;

Currently reading:

Muffler resonator: purpose, design and features

Aug 30, 2020

Replacing the Ford Focus 2 fuel pump: available methods

Aug 30, 2020

Let us add that we should also not exclude the possibility of air leaks, that is, airing of the power system. Another culprit of problems may be the pressure regulator in the fuel rail. In this case, engine malfunctions may be partially similar to some of the symptoms mentioned above. For example, a slight ingress of air into the fuel system results in the engine not starting for a long time after parking.

We also recommend reading the article on how to determine airing of the power system using the example of a diesel engine. From this article you will learn how to check the fuel system for leaks yourself.

Let's go back to the fuel pump. Its malfunction means that the performance of the fuel supply system is reduced. If the fuel pump breaks down, then the car becomes unsuitable for normal use. Signs of a fuel pump malfunction are as follows:

- It is impossible to start the engine, the fuel pump does not pump;

- the engine starts, but runs with serious interruptions;

In this case, the service often recommends diagnosing, repairing or replacing the fuel pump. It should also be taken into account that the fuel pump mesh filter may become clogged inside the device. Let us immediately note that it is impossible to accurately answer the question of when to clean the fuel pump stack. Some car enthusiasts clean/replace the fuel pump mesh as needed or as a preventative measure every 50-70 thousand km. mileage, while others are faced with the need to clean the fuel pump grid for the first time at mileages of 150 thousand km or more. and more. Let us add that the operating manual for some models specifically states that it is recommended to replace the fuel pump stack once every 120 thousand km.

It should be added that the loss of dynamics and the appearance of symptoms of a clogged mesh occurs gradually. For this reason, each driver decides to clean the fuel pump himself. On powerful naturally aspirated engines, the gradual deterioration in acceleration is not felt as strongly as compared to highly accelerated engines with a small displacement. For this reason, many owners of large-volume trucks begin to solve the problem after noticeable complications appear. Also, the condition of the pump grid is greatly influenced by the quality of the fuel being filled and a number of other factors and individual operating conditions, which we will talk about a little later.