Timing belt. Basic questions about replacement.

What is a timing belt?

In a nutshell, the timing belt is a serrated belt on the inside that connects the crankshaft and camshaft of the engine. The crankshaft rotates due to pistons through connecting belts. This occurs on the same principle as the rotation of a bicycle gear. The camshaft must open the valves at the top of the piston movement, so it is necessary to synchronize the rotation of the camshaft and crankshaft. The timing belt serves this purpose. By means of teeth, it drives the pulleys of both shafts and regulates their rotation.

Do all cars have timing belts?

Strictly speaking - NO. On some cars, the crankshaft and camshaft are driven by a chain; in the design of some engines, the principle of connecting both shafts in an aggregate way is implemented.

When should you replace your timing belt?

Check the instructions or manual. The Japanese usually indicate the timing of replacing the timing belt with amazing accuracy. Usually the threshold is 100,000 km. mileage (this is what they recommend doing on Toyota), but it’s different for each car. Sometimes the timing belt “clings” to several other units in addition to the camshaft and crankshaft, which reduces its service life.

Is it worth replacing the water pump along with the timing belt?

In principle it is worth it, but not necessary. If the timing belt also drives the water pump in your case, then definitely YES. This will help save time and money. If everything is somewhat simpler: your car is quite new, just from Japan, then you need to check the mileage (to be sure, it would not be a mistake to assume that it is not entirely accurate), then assess the condition of the engine by eye, and decide whether or not to change the pump along with timing belt. The design features of some engines do not allow replacing the timing belt without removing the water pump. If this is your case, then it is better to replace the pump at the same time as the timing belt. If the water pump in no way complicates the task of removing the belt and is peacefully attached at a distance, then there is no point in changing it without obvious signs of wear and leaks. In general, the decision is up to you, in the end, each case is unique, you need to be creative here.

Do the seals on the camshaft, crankshaft and water pump need to be replaced?

If they leak, then YES. It’s easier to change everything together, i.e. simultaneously with replacing the timing belt. If they don’t leak, then decide for yourself.

Is it worth replacing the sloth and tension roller?

If they are far from presentable, then it is better to replace them. The role of the “sloth” in the operation of the timing belt, as its name suggests, is simply to be... that is, to serve as an additional support for tensioning the timing belt. The video has a slightly different task. There are at least two types of tension rollers: spring and hydraulic. Spring rollers are located in an expanded groove and, due to the force of the spring, tension the timing belt. Hydraulic rollers are a little more complicated; in them, the spring energy is replaced by a special fluid that maintains the position of the roller. Therefore, whether or not to change the video with the “sloth” is a question of the effectiveness of their work.

Is there a difference in using an original timing belt or an analogue?

There is a difference. It is strongly recommended to use only original timing belts for your vehicle for your engine type. When buying an analogue, there is always a possibility that it is not made according to the technology, and then the timing belt breaks only a matter of time.

Checking and replacing the timing belt Volkswagen Transporter T4 1990 - 2003

Tools:

- Open-end wrench 10 mm

- 13 mm curved box spanner

- Ratchet wrench (or pneumatic wrench)

- Extension

- 10 mm head

- 12 mm head

- 13 mm head

- 19 mm head

- Hex head bit 6 mm

- Torque wrench

- Driver for socket attachment

- 27mm wrench attachment

- Spring clamp pliers

- Medium flat screwdriver

- Medium Phillips screwdriver

- Hammer medium

- Electric screwdriver

- Screwdriver bit

- Special tool Matra 3370 / Hazet 2520-1 (or medium flat screwdriver)

- Hydraulic jack

- Special tool for fixing the crankshaft pulley VW-T10025

- Special key for replacing the accessory belt VW-3299 (or pry bar)

- Ring wrench VW-3355 (or 32 mm box spanner)

- Wheel chock (shoe)

Parts and consumables:

- Timing belt 074109119R

- Tension roller 074109243F

- Bolt N0103771

- Bolt N90498002

- Accessory drive belt 074260849AE (if required)

- Idler roller 074145278E 2 pcs. (if necessary)

- Tension roller 074145278F (if necessary)

- Timing belt pulley 074105263B (if required)

- Cabin dust filter 7D0819989 (if necessary)

- Replacement air filter element 074129620 or 074129620A (operation with high dust saturation, if necessary)

- Air intake hose 074129627K (if necessary)

- Air filter housing (074129607M, or 074129607N - operation in high dust concentrations, or 074129607Р - operation in cold climates, if necessary)

- Fastening clip 701805163 - 4 pcs. (if necessary)

- Pipe (if necessary)

- Rags

Notes:

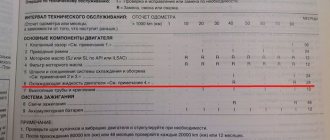

The technical condition of the timing belt of the ACV engine must be checked every 30 thousand km. Check the tension level of the timing belt. If necessary, adjust the tension, since when the belt is weakened, its teeth quickly wear out and, in addition, it is possible for the belt to jump on the toothed pulleys of the crankshaft and camshaft, which will lead to disruption of the valve timing and loss of engine power, and if it jumps significantly, to its emergency damage. There are several types of drive belts used in cars. Use only original timing belts. In this case, no savings can cover the consequences of a broken low-quality, defective or counterfeit timing belt. Change the timing belt strictly in accordance with the manufacturer's recommendations, which is 120 thousand km. Always replace the tension and guide rollers when changing the timing belt. Sometimes car manufacturers indicate in documentation that if you remove the timing belt, regardless of the reason for removal and how long ago the previous replacement was, it must be replaced.

Checking and removing the timing belt

1. Remove the cabin dust filter housing as described here.

2. Then remove the neck of the washer reservoir and the air filter with the air intake hose to improve access to the engine.

3. Move the radiator forward out of the engine compartment. How to do this, see here.

4. Remove the front right wheel and the wheel arch liner as described in this article.

5. In order to remove the crankcase protection, unscrew the bolts and nuts (the location of the fastening elements is shown on the removed casing), unlock the closing lever, slide the plate down and remove it from the holders.

6. Using a special wrench 3299 or a pry bar, turn the tension roller lever against the direction of action of its spring (turn the pry bar clockwise) and remove the serpentine belt from the generator belt pulley (the placement of the lever is shown for clarity on the removed engine).

7. Completely remove the accessory drive belt and remove it from the engine compartment.

Note:

If the accessory drive belt is reinstalled, ensure that it runs in the same direction as before. To do this, before removing it, mark an arrow on the belt with a marker, showing the direction of its movement. The engine crankshaft rotates to the right (clockwise) when looking at the engine from the belt side. When installing the belt, it is necessary to ensure that the arrow also points to the right. Installing the belt in the opposite direction increases wear and may cause it to break.

8. Check the condition of the removed belt for cracks and damage, separation of the cover layer or harnesses, fringe of the harnesses or side surfaces, traces of oil and grease.

Note:

If the above damage is present, the accessory drive belt should be replaced.

9. Remove the bolt securing the power steering return line hose bracket.

10. Using a screwdriver, remove the accessory drive belt idler pulley cover and unscrew the bolt securing it.

11. Remove the accessory drive belt idler pulley and check for wear.

Note:

If there is noticeable play in the bearing, replace the roller.

12. Unscrew the bolt securing the upper idler pulley of the engine auxiliary drive belt and remove it (for clarity, shown with the crankshaft pulley removed).

Note:

If there is noticeable play in the bearing, replace the roller.

13. Release the latches and remove the upper timing belt cover.

14. Check the condition of the timing belt by looking at it. To do this, slowly rotate the crankshaft clockwise by the central bolt securing the auxiliary drive pulley.

Note:

Immediate replacement of the T4 timing belt is necessary if there are cracks on the outer surface of the belt, fringe, side wear or cracks at the base of the teeth.

15. Unscrew the three bolts and remove the upper part of the lower timing belt housing.

16. During maintenance, it is also necessary to check the timing belt tension. To do this, check the coincidence of marks 1 and 2 (see the first photo below) on the tension roller of the timing belt.

17. If the marks do not match, it is necessary to adjust the device, since incorrect tension accelerates the wear of the timing belt. Using a 13 mm socket, loosen the tension roller bolt.

18. Using a VW-3355 ring wrench (or a 32 mm wrench), turn the Volkswagen T4 timing tension roller in a clockwise direction so that the right edge of indicator 1 coincides with the right edge of indicator 2 (see photo p. 17).

Note:

The right edge of indicator 1 must not extend beyond the right edge of indicator 2, otherwise the tension roller will be damaged. If this happens, the tension roller should be completely unloaded and then loaded again, since simply turning the tension roller eccentric in the opposite direction is not enough.

19. Tighten the tension roller mounting bolt to a torque of 20 Nm.

20. If, after checking the timing drive (points 14-17) or based on the mileage of the vehicle, it is decided to replace the timing belt and/or tension roller, it is necessary to remove the auxiliary drive pulley from the crankshaft.

Note:

If the Volkswagen T4 timing belt is not removed for replacement, then mark the direction of rotation on it with a marker (the crankshaft rotates clockwise when looking at the engine from the belt side). Installing the timing belt in the opposite direction can cause it to break and cause severe engine damage.

21. Before removing the crankshaft pulley, apply the handbrake and securely secure the pulley against rotation using the special tool VW-T10025. Using a 27 mm socket, loosen the central bolt securing the accessory drive pulley to the crankshaft, using a special tool to fix the crankshaft pulley.

Note:

You may have to use an additional arm in the form of a pipe placed on the knob.

22. Remove the plug on the clutch housing (the location of the plug installation is shown on the removed gearbox).

23. Using the crankshaft pulley mounting bolt (in step 22 it was only loosened approximately one turn), turn the crankshaft clockwise until the mark on the camshaft gear coincides with the mark on the rear protective screen of the engine timing belt.

Note:

In this case, the mark on the flywheel should also be located opposite the installation mark. If necessary, turn the engine crankshaft accordingly.

If the marks match in both places, then the crankshaft is in the position corresponding to TDC for cylinder No. 1.

24. Unscrew the crankshaft pulley center bolt completely using the same tools as in step 14 and remove it.

25. Remove two diametrically located M8 bolts securing the crankshaft pulley to the toothed pulley. Loosen the two remaining mounting bolts, lightly tap the heads of the bolts with a hammer to loosen the fit of the crankshaft pulley, then remove the bolts.

26. Remove the accessory drive pulley from the crankshaft.

27. Loosen the tension roller locking bolt and turn the roller to the left to loosen the tension on the timing belt (see photos, paragraphs 18-19) and remove it.

Note:

The toothed belt must not be bent. A belt that is bent at least once must always be replaced, as it may break later during operation, which will lead to severe engine damage.

28. Completely unscrew the tension roller bolt and remove it.

Note:

If play is detected, the roller must be replaced. If the belt is replaced regularly (after 120 thousand km), then replace the tension roller regardless of its condition.

29. Take the opportunity to remove the timing belt pulley and check its condition for wear or damage.

Note:

If necessary, replace the timing belt pulley.

Installing the timing belt

Note:

Install the timing belt in the reverse order.

1. Check that the alignment marks of the piston of the 1st cylinder match at TDC.

2. Install the timing belt tension roller so that its bar sits on the pin of the lower protective screen, which prevents it from turning.

3. Install the timing belt onto the pulleys and tension the belt using a tension roller as described in steps 18-20 above.

4. Install the upper part of the lower timing belt cover as described in step 16 above. Tighten its fastening bolts to a torque of 10 Nm.

5. Screw in the 4 bolts securing the crankshaft pulleys and tighten them to a torque of 20 Nm. Finally, tighten them 1/4 turn (90°).

6. Install a new accessory drive pulley center bolt and tighten it to 160 Nm. After this, tighten it 1/2 turn (180°).

7. Turn the crankshaft 2 turns clockwise and set it again to the TDC position of the piston of the 1st cylinder. Check the tension of the timing belt and, if necessary, adjust it (points 17-19).

8. Install the upper timing belt cover, the rollers and accessory drive belt, as well as the remaining removed parts in the reverse order of removal.

The article is missing:

- Photo of the instrument

- Photos of parts and consumables

Source:

How to put on a timing belt

Good afternoon, colleagues!

From time to time I come across online discussions on the topic in which direction to install timing belts and assemblies, is there any difference if the belt is turned in one direction or another.

The fact is that belts often have arrows indicating the direction of rotation:

However, due to inattention or ignorance, sometimes the belt is installed “against the grain”, with arrows in the opposite direction, and the owner, having discovered this, worries whether the belt will break during this installation.

For an example of this concern, see here

.

At the same time, such arrows are not found on all belts:

So what is the meaning of the arrows on the belt, and how dangerous is it for the engine to turn the belt with the arrows in the opposite direction?

The answer to this question is in an article published in the Gates Techzone

.

The article is called "Replacing the Drive Belt: Does the Direction of Rotation Matter?

"

Link to article: www.gatestechzone.com/ru/…direction-of-belt-rotation

Here are the comments from Gates, one of the world leaders in the production of drive belts:

1. From a purely technical point of view, the NEW timing belt is absolutely symmetrical, i.e. it has no direction of rotation.

If there are timing marks on the new timing belt, then there are also timing marks on the pulleys/engine. The directional arrows only help to set the timing marks correctly and are not necessary at all since the new timing belt can run in any direction.

2. If the timing belt is installed properly and the belt tension is correct, then you should not touch it, even if you suddenly notice that the arrows are pointing in the “wrong” direction.

Once the vehicle is running, removing and reusing the timing belt becomes impossible since the timing belt can only be installed and tensioned once.

3. Likewise, for accessory drive belts, it does not matter whether the NEW belt is installed in the direction of the arrow or vice versa.

However, during operation, the belt gets used to the grooves of the pulley, so when reinstalling a used accessory belt, it is necessary to install the belt in the original direction. So it is very useful to draw an arrow on the belt before removing it.

Despite this “reassuring” information from the respected Gates company, I will express my own, more cautious point of view.

Personally, I believe that: - If there are no arrows, then the belt can be installed in any direction. — The material and manufacturing technology of belts from different manufacturers may differ significantly. If the belt is visually symmetrical, its internal structure may have a certain direction. “Therefore, for a particular belt, the direction of rotation indicated by the arrow may still matter. — If the belt is accidentally installed the other way around, nothing fatal will happen, but, depending on the specific belt and its material, the service life of the belt may be reduced if installed incorrectly. — If there are arrows on the belt, it is better to install it as the arrows indicate. On some belts, the arrows are even duplicated with inscriptions indicating the required direction of rotation:

I hope this information was useful.

Have a nice day everyone, see you soon!

Timing belt rating

Our store specialists recommend timing belts and kits from three leading manufacturers: Dayco, Contitech, Gates. These are companies that produce premium quality spare parts comparable to the original ones. More precisely, these companies produce belts for many automakers for installation on the assembly line. Moreover, the number of belts produced for factory equipment is no less than for the secondary market of auto parts. Well, we have already explained that in the timing system it is not worth saving on the quality of belts. By the way, all manufacturers offer timing kits with pulleys/tensioners and water pumps.

Dayco is an American concern that produces timing belts of the highest quality. In Ukraine they are not as well known as their competitors, but this is purely a matter of marketing and promotion, because their products are in no way inferior to their competitors. Since 2020, they also offer reinforced timing belts with the High Tenacity marking. They have an extra outer layer on the teeth that makes them more durable.

Contitech is one of the world's two largest belt manufacturers. It is part of the Continental concern, which produces various rubber products (for example, the well-known premium tires), as well as a huge amount of automotive electronics. Since 2020, timing belts installed on highly loaded engines have been using Synchroforce Carbon reinforcement technology.

Gates - together with Contitech, constantly competes for 1st place in the world of belts. The American corporation has been producing belts for more than 100 years and their products are used not only in cars, but also in industry. By the way, it was Gates in the early 90s that offered ready-made solutions for replacing all components of the timing system - belt and rollers/tensioners. Today they even offer kits with thermostats - for those cars where the thermostat is part of the water pump system.

When to change the timing belt

There is no clear answer to this question - each automaker makes its own recommendations. For example, the Renault Megane 3 1.5 dci timing belt needs to be changed after 150,000 kilometers. And the timing belt for a Ford Focus 2 with a 1.6-liter gasoline engine is 160,000 km or 8 years. And this is also an important nuance - sometimes for cars with low mileage, the timing belt needs to be changed not according to mileage, but according to age. Because over time, the structure of the belt deteriorates - it simply gets old and may fail. But not all cars have such long replacement intervals. For example, in a 2008 Hyundai Accent 1.4, the timing belt needs to be checked at 60,000 kilometers and replaced exactly at around 90,000. For a Chevrolet Lacetti with a 1.8 F18D3 engine - after 60,000 km.

Here we will give important advice. If you bought a used car, then you need to replace not only all the filters, but also the timing belt, along with all the rollers/tensioners and the water pump. Because it is impossible to determine when they were changed, and the consequences of failure can be very serious. You can refuse this operation only if you have reliable information about the resource of spare parts that you can trust 100%. Because saving can cost a lot more.

Frequency of timing belt replacement when using factory materials

Manufacturers give very vague recommendations regarding the frequency of replacing the timing belt on a car. Many offer two replacement options. The first option is the normal operating mode of the machine. In this case, the manufacturer allows replacing the belt and rollers once every 100 thousand kilometers. Let us repeat that this is individual data that can be found in the operating instructions.

Also, most car manufacturers allow the car to be used under heavy duty conditions. In this case, the timing belt should be changed once every 60 thousand kilometers. The problem is that there is no definition for such intense operating conditions, so it is very difficult to determine them. If we take into account the difficult travel conditions in Russia, the belt, according to factory recommendations, is changed as follows:

- when passing each major maintenance after 60 thousand kilometers;

- after four years of vehicle operation, if the mileage of 60 thousand kilometers has not reached;

- if ruptures or cracks are detected on the belt when removing the protective housing of the mechanism;

- when there is a noticeable weakening of the belt tension or other changes in its physical condition;

- after detecting sounds unusual for the engine from the timing belt area;

- due to a direct rupture of the belt - in this case, along with the replacement, a set of other measures to repair the engine is carried out.

- Below we will talk about what unpleasant features a timing belt rupture can cause. Factory recommendations can only be followed if official components are used. If you are not sure of the quality of the purchased spare parts, you will have to rely on other features and characteristics when performing maintenance.

Together with the timing belt, rollers are changed, which serve to rotate the necessary systems and ensure minimal resistance to the timing belt. It is important not to forget about the rollers, since replacing the belt alone can cause serious problems directly with the fastenings of this mechanism. In this case, you will have to carry out more serious repairs after the rollers break.

What needs to be changed along with the timing belt

The Russian Lada Grant has been available for several years. And with good performance and several different trim levels, it has won the trust of many drivers. Now let's talk about replacing the timing belt on a Lada Grant.

In any machine, the gas distribution mechanism allows for the timely introduction and removal of working fluid and exhaust gases. This mechanism includes the camshaft, as well as various valve actuation parts, as well as valves with springs, as well as guide type bushings.

Speaking of timing belts, this is a special element that works as a link. This ensures synchronous operation of the camshaft and crankshaft.

Finding such a belt is very easy. The hood will be quite open for you, then the belt will appear on your eye. However, this “special device” will be protected by a special casing, which should prevent the entry of dirt and protect it from other mechanical influences.

The external timing belt has a toothed inner surface and a rubber base. Unlike other types of belts, it covers several pulleys at the same time.

Camshaft drive diagram

- engine crankshaft toothed pulley;

- Gear for water cooling pump:

- tension roller or automatic tensioner;

- Timing belt cover;

- camshaft pulley;

- Timing belt;

- leakage on the oil pump cover;

AND . mark on the crankshaft pulley; IN . mark on the oil pump outlet cover; FROM . protrusion on the rear timing belt cover; D. _ mark on the camshaft gear pulley

Type

In addition to said two shafts, the belt connects several other components, such as the water pump (pump) and the like.

READ How Much Oil Should There Be On The Engine Dipstick

If the rollers or pump are damaged, this indicates excessive wear of the belt, which significantly reduces its service life.

Cars of the Lada Grant family are equipped, as we have already said, with various engine modifications. Some of them don't have the problem that when the timing belt breaks the valves bend, while others have a similar function.

If the timing belt breaks, only 11183-50 engines do not bend the valve; such an engine is installed on the Lada Grant as standard. Read more about which engines, when the timing belt breaks, it breaks the valve in this material.

To eliminate emergency situations, the manufacturer advises changing the belt every 70 thousand miles . But you will have to monitor his condition more often. during each maintenance, in other words, after 15 thousand km. This statement is true for both 8-valve and 16-valve engines. Despite the fact that the most common Lada Grant 21116 engine consists of an imported cylinder head, it will also have to be repaired due to a broken belt!

Naturally, the manufacturer does not recommend changing the belt without outside help, or checking it. If you try to do all the work yourself, in other words, there is a good chance that you will be denied the following warranty. It is recommended to change only the filter (cabin filter replacement, air filter replacement, fuel filter replacement).

Most Lada Grant owners, especially owners of 16-valve engines (much more expensive to repair than the 8-valve equivalent), recommend not waiting for 75,000 miles. The fact is that due to poor components, wear can begin after 20,000 km.

READ How to Remove Vents Fan Cover

Most owners use proven Gates products when replacing. But they love to counterfeit this brand, so try to take on the tried and tested suppliers time!

K015670XS. Part number for 16 valve engines.

If you decide to change the belt without assistance, then there are some tips worth considering.

For example, after installing the belt, you will also need to tension it correctly. This is done using a special key. Some will see that you can do the right thing, but then no one guarantees the result.

The force characteristic for turning the belt 90 degrees between the crankshaft pulleys and the camshaft should be no more than 20 Nm and no less than 15 Nm. All other characteristics indicate that the belt tension has not been adjusted correctly and you will need to make the following adjustments.

As we have already noted, it is often necessary to monitor the condition of the timing belt.

This will allow him to see his damage before it completely fails, damaging engine parts.

- The first sign will be significant wear and tear on the material. If so, you risk slipping or breaking down when the vehicle is overloaded or in high humidity.

- It follows that wear usually occurs when the position of the tension roller and pulley deviates, also when the bearing temperature is high or performance is low. You can see this because the material will be frayed and the remaining fabric will be poking out of it.

- The 3rd sign implies cracks or ligaments. The more such damage, the greater the likelihood that the belt will break very soon.

- Difficulties are also typical for situations where the back surface of the belt has low elasticity and significant rigidity. This will also add appropriate brightness to the belt. This will prevent it from making good contact with the pulley.

- The belt can be extended during operation. If this parameter is very large, then it is necessary to replace the belt with a new one, especially since its elastic capabilities will be significantly reduced.

- And, of course, if the belt position deviates from this, then this will give a clue to a situation where the tension pulley components may be failing.

READ Coronavirus epidemic is rapidly changing China's auto industry

I took off the timing belt and it still looks like it, but the owner decided to replace it

In this case, the belt is still in good working order.

4 valves bent after timing belt broke

As we have already said, only the 1st engine should not have serious problems after the timing belt breaks. 11183-50 . But other models may have serious failures that will lead to significant financial investments! On our site, in the middle of the Grand Guides, there was a battle about which engine is better: 8-valve or 16-valve, we are also interested in your worldview.

The fact is that when the belt breaks, the camshaft stops in the position in which it was at that moment. But the crankshaft continues to move. As a result, the pistons hit the valves, which were open, with great force. The valves are bent from this impact, and in rare cases the piston may even break, although this is quite rare. This situation is popularly called the “fist of friendship”!

Source

Helpful information:

You can get professional advice when selecting a product by calling 8 (calls within Russia are free).

Greetings friends! In today's article, we will analyze in detail and answer such an interesting question as: is it necessary to change the rollers and pump when replacing the timing belt?

Therefore, the answer to the question of whether the timing belt needs to be changed is obvious. According to the advice of the experts, it is best to replace it at 100 thousand kilometers , but if defects were discovered on it at an earlier date, then you should not hesitate. In this case, it is appropriate to make a replacement, even if the mileage is small.

Many car enthusiasts are interested in whether it is necessary to change the rollers and pump when replacing the timing belt? This action is optional, but if additional means are available it is best to do so, as this will affect the operation of the new belt. In addition, in order to perform the replacement, you will have to disassemble all the components of this equipment, including the rollers with the pump.

This is what locked camshafts look like when replacing the timing belt and pump

Thus, replacing all consumables will not greatly increase the cost of this procedure. Therefore, the reformatted answer to the question whether it is necessary to change the rollers when replacing the timing belt will sound like “not necessary, but recommended.” This is due to the convenience of complex replacement and increasing the service life of the replaced unit.

Why do you need a timing belt on a car?

The main function of the timing belt (gas distribution mechanism) is to synchronize the operation of the crankshaft and camshaft (or camshafts). It is the timing belt that makes sure that the valves and pistons do not collide with each other. The timing belt is located outside the engine, covered by a protective cover and goes around a varying number of pulleys, depending on the design of the engine. At a minimum, this is a tensioner that guarantees the correct operation of the timing belt. But in modern engines, where more components need to be crammed into a limited space, the timing belt also grips the pulleys of additional equipment. Most often this is a water pump (aka water pump), which is responsible for cooling the engine. But there may be other units.

And a little more theory. In addition to the timing belt, some engines may use a timing chain - for example, Fiat Doblo 1.3 multijet or Opel Astra G, with a 1.4 Z14XEP engine. Its advantages are that it is more durable and lasts several times longer. The disadvantage is that it is several times more expensive and more difficult to install.

The timing belt itself looks like a rubber ring of a certain diameter, with teeth on the inner surface. Despite the fact that the manufacturer may mark the belt with the direction of installation, the timing belt does not have a specified direction of rotation - that is, it cannot be installed “back to front”. The arrows are important for setting the camshaft and crankshaft marks. In order for the timing belt to be installed correctly and ensure correct operation of the engine, it must be installed clearly according to the marks on the belt itself and on the crankshaft/camshaft pulleys. So, in order not to get confused with the marks on the belt, arrows are drawn. So we smoothly approached the issue of replacing the timing belt.