General information about the process

The initial one is provided by the manufacturer at the stage of assembling the machine. But gradually, due to temperature changes, any material loses its beneficial properties.

Before you start carrying out the “Shumka” on your own, it is recommended to dismantle the seats, door trims, mats and free the car from the old standard insulation.

Soundproofing panel VAZ 2114

It is especially important to treat doors, as they often become the main installation location for speakers. It is clear that this place should be well protected not only from noise penetration, but also from plastic vibrations and other negative phenomena.

Acoustic speakers in the doors

Along with sound insulation, the interior will also receive high-quality insulation. In Russian conditions this is extremely important. To achieve this effect, you need to combine vibration and sound insulation.

Soundproofing for VAZ 2114

“Shumka” carried out on a VAZ 2114 is often called tuning. This is true, because a real modernization of the car is being carried out. Operational parameters are increased and comfortable conditions are created when the vehicle is moving.

The driver is no longer oppressed by engine noise, his nervous system is not irritated by the strumming and vibration of plastic elements. All this cannot but have a positive impact on overall driving safety.

As mentioned above, the standard “Shumka” will not be of good quality; relying on it is the last thing. The process of carrying out “Shumka” on cars with high mileage is especially relevant. In general, such cars are very difficult to drive, since the noise penetrates everywhere, interferes with the normal operation of the acoustics, creates complete discomfort, and the trip turns into a very tedious task.

On sale today you can find a sufficient amount of high-quality materials for carrying out “Shumka”. There are a lot of them and making the right choice can sometimes be extremely difficult. One of the main indicators of a good material is not only the ability to absorb sounds, but also to be light in weight (details about materials in the table below).

Splen with foil

Among other things, you also need to lay out materials skillfully. The fact is that if you don’t pay attention to this, the materials will simply turn into a time bomb for the metal component of the car.

Poorly laid material creates gaps through which air, moisture, etc. will penetrate. And all this will inevitably lead to the appearance of the most terrible enemy of the body - corrosion.

Correct installation of the material always means following the instructions in a step-by-step sequence, using the right tools, using a hair dryer and much more.

In some cases, especially when carrying out the noise yourself, partial sound insulation is also appropriate. In this case, the target is the most noise-producing parts of the machine. Definitely the doors, then the trunk, the rear parcel shelf, and so on.

It is important, when working on your own, not to damage the upholstery. Unfortunately, this often happens due to the inept actions of the car owner who is carrying out such an operation for the first time. In general, conducting a “Shumka” is a painstaking and lengthy process, but it’s worth it.

Before carrying out soundproofing, it is recommended to carry out a partial or complete inspection of the machine. The causes of all vibrating and knocking sounds produced by suspension elements or other vehicle components must be eliminated. They may be loose or need to be replaced. The body and its parts must also be checked.

The first option for soundproofing the VAZ 2114

First of all, you should dismantle all interior elements that may interfere with sound insulation, including trim, panels, handles, glass, seats, etc. Do everything as in the photo.

Most of the time will be spent on disassembling the interior and preparing the surfaces than directly on the Shumka pasting itself. You need to do all the work very carefully so as not to damage the interior trim. At this stage, use the services of an assistant; you will also need one when soundproofing the ceiling. After dismantling the standard sound insulation, you will see a bare metal surface; after cleaning it and degreasing it, you can begin applying vibration and noise-absorbing materials.

Apply Visomat MP as the first layer. It must be glued to the entire area of the trunk (see photo)

The application of a vibration damper allows you to remove the resonant sounds of metal and various vibrations, and also increases the rigidity of the structure. In addition, the material acts as a heat insulator, maintaining the interior microclimate in the summer heat and retaining heat in the winter. Before application, Vizomat should be heated with a hair dryer so that it becomes soft and elastic, and only then, freeing it from the protective film, quickly stick it on, rolling it with a special roller for a better fit. When applying the material, make sure that there are no gaps, spaces or air bubbles between the joints. If there are such shortcomings, then the vibration isolation will not work at full strength.

It’s good if single sheets of material are used when pasting, but to process the figured parts of the car you need to cut out parts from the vibration damper and noise absorber, so lay the pieces overlapping 15-20mm.

Remember that when applying materials, you cannot seal process holes, fastening elements of parts and hatches, i.e. those parts that need access after sound insulation.

Keep in mind that vibration insulation should be applied to the maximum surface area, covering the entire floor, ceiling, and be sure to go under the dashboard, since this area is in close proximity to the car engine.

The second layer is applied to soundproofing materials, usually Accent 10-15mm. As a third layer, the surface can be treated with Splen; it works as a heat insulator.

Algorithm for carrying out an operation to “shumka” a VAZ 2114 car

To isolate the interior from excess noise, you need to carry out soundproofing by following these step-by-step instructions:

- First, disassemble the car, removing those parts that make noise when driving. These could be mudguards, arches, fenders, etc. It is advisable to cover them from the inside with some kind of vibration-damping material;

- The seats will also need to be removed if the interior is fully soundproofed;

VAZ 2114 sound insulation of the panel and the interior as a whole

- Cover the floor of the car with a vibration damper and roll it in with a special tool.

Soundproofing torpedo VAZ 2114

- The next material, as a rule, is Spleen. It has a sticky base, lays on surfaces easily, and perfectly cuts out excess noise penetrating from the outside;

- To install materials in the trunk, the lid is removed in advance, all screws and bolts are unscrewed.

Soundproofing the trunk of a VAZ 2114

VAZ 2114 trunk sound insulation

- Door treatment (see Soundproofing VAZ 2114 doors can be easily done independently) is practically the most important procedure in terms of increasing the so-called “acoustic” properties of the interior. It is recommended to insulate these parts of the car with a good polyurethane-based material. The front doors of the VAZ model, which are entrusted with the role of a stand for acoustic speakers, are recommended to be rolled in two layers.

- The roof of the VAZ 2114 is also treated. In order to fully carry out the “noise” of the car ceiling, you will need to remove everything, from the mirrors to the upholstery;

Soundproofing the roof of a VAZ 2114

Sound insulation of the VAZ 2114 engine compartment and hood

Sound insulation: installed on VAZ 2114

The main task of sound insulation in a car interior is to reduce the audibility of sounds made by the engine, wind, and other extraneous noise.

Sound insulation of the VAZ 2114, like other models of this family, is provided during assembly at the factory. But over time, under the influence of high temperatures and painting, it loses its insulating properties. If it is not possible to undergo service, then you can install the Shumka on the VAZ 2114 with your own hands, in which case it is necessary to empty the interior of seats, rugs, door trim and old factory sound insulation. The car will be quiet and comfortable only with complete and thorough insulation of the doors, arches, fenders, hood, trunk, roof and floor. The doors are insulated to improve the quality of acoustics; the sound of a running engine will not be heard after the hood is insulated. You can not only improve the sound quality of the acoustics, but also insulate the interior if you combine vibration and sound insulation during gluing. The process of preparing for dismantling consists of selecting the necessary tools for removing the casing. Removing upholstery material from the floor and ceiling will not be difficult, since the interior trim and seat mounts have a fairly simple design.

Useful tips

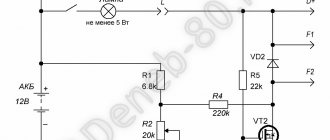

Today, many owners of the VAZ 2114 install new acoustics in the car, more powerful and productive. They buy an expensive subwoofer (see 1000-watt subwoofer and a review of the best models), a powerful amplifier (see The best amplifier for a subwoofer and how to choose it) and a lot of other useful things that significantly increase the level and quality of sound.

It turns out that the whole point is insufficient insulation of the car body panels, through which noise penetrates from the outside. It’s no longer possible to enjoy clear sound: rattles, vibrations, knocks - all this degrades the quality.

As mentioned above, car doors are very important in this regard.

Here's what you need to focus on:

- They must be insulated on both sides, although excessive zeal should not be shown either. Heavy doors mean they may sag over time;

Sound insulation for VAZ 2114

- In addition, we must take into account the fact that the doors of the VAZ 2114 are often covered with cellophane. The latter makes unpleasant sounds and creaks in the cold season in the frost;

- It is advisable to lay materials on the door in large pieces (as much as possible). The materials used should not be visible beyond the edges of the sheathing.

It’s not difficult to learn how to carry out “Shumka” with your own hands. Step-by-step instructions, photos, materials, and videos will help in this matter. The factory standard insulation must be completely stripped off so that new materials can be installed efficiently.

Do-it-yourself noise insulation of VAZ 2114 according to instructions

Do-it-yourself soundproofing of the VAZ 2114 has the most important goal - to reduce the level of audibility of extraneous sounds in the car interior. Noise comes from the power unit, the wind outside when moving quickly, and other sources.

If you know how to make noise insulation for a VAZ 2114 yourself, you can significantly reduce the noise level and save a lot of money at the same time, since services of this kind in service stations are not cheap.

The second option for soundproofing the VAZ 2114

Car sound insulation is an area of tuning that gives the car enthusiast a lot of opportunities to improve his vehicle. The main one is, of course, a lot of means and ways to implement them. We decided to provide you with another option for sound insulation of the VAZ 2114. The treatment scheme is not particularly different from the previous technology, the only difference is in the materials used and the photo report from the sound insulation of another VAZ 2114.

Shumoff M2 material is used as a vibration damper. It is used to glue the doors, roof, floor and trunk. Soundproofing material Shumoff P4 is applied on top of it. The most critical areas - the interior floor and rear wheel arches - were treated with a more effective vibration damper Shumoff M4, the thickest in its characteristics. The plastic panels were additionally covered with anti-squeak material Bitolon 5.

The material should be taken at the following rate: for the ceiling Shumoff M3 - 12 - 14 sheets, Germeton A15 - 2 sheets; trunk: Shumoff M3 - 30 sheets, Comfort 6 - 4 sheets (or better yet, take Comfort 10, the difference in price is not big, but much thicker and close); 1 sheet of Hermeton A15 for 2 arches.